Hypercube xy distortion

Posted by mjoyce

|

Hypercube xy distortion May 27, 2017 01:05AM |

Registered: 7 years ago Posts: 19 |

Hello,

I have notice a weird distortion, and I'm struggling to understand why it iexists.

The attached image show a 100mm x 100mm square.

What you will notice is a slight curving towards the bottom right.

It's about 102 on the bottom and right hand side.

Can anyone suggest what might be causing that?

Regards

Matt

I have notice a weird distortion, and I'm struggling to understand why it iexists.

The attached image show a 100mm x 100mm square.

What you will notice is a slight curving towards the bottom right.

It's about 102 on the bottom and right hand side.

Can anyone suggest what might be causing that?

Regards

Matt

|

Re: Hypercube xy distortion May 27, 2017 02:18AM |

Registered: 8 years ago Posts: 5,232 |

Is your belt path asymetric?

E.g. on the top left corner the belts are parallel/perpendicular, but on the bottom right they run off.

You could move the square away from the bed center to see, if the sidelength-difference is the same or gets worse the more you print in bottom/right direction.

E.g. on the top left corner the belts are parallel/perpendicular, but on the bottom right they run off.

You could move the square away from the bed center to see, if the sidelength-difference is the same or gets worse the more you print in bottom/right direction.

|

Re: Hypercube xy distortion May 27, 2017 07:31AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Hypercube xy distortion May 27, 2017 07:47PM |

Registered: 7 years ago Posts: 19 |

There's a upper belt (left motor), and lower belt (right motor).

Printer pretty much this : [www.thingiverse.com]

I moved the print closer to the front of the bed, and I see distortion on both front corner (motors are at front).

Items printer towards the back of the are fine.

The curvature of the distortion, make think it's to do with belts, iderlers, motors and gears.

The distortion is front corners which is the closest to the motors.

I'm using GT2 20T gear on the motors, I may switch them out for 16T to see if that has any impact.

Regards

Matt

Printer pretty much this : [www.thingiverse.com]

I moved the print closer to the front of the bed, and I see distortion on both front corner (motors are at front).

Items printer towards the back of the are fine.

The curvature of the distortion, make think it's to do with belts, iderlers, motors and gears.

The distortion is front corners which is the closest to the motors.

I'm using GT2 20T gear on the motors, I may switch them out for 16T to see if that has any impact.

Regards

Matt

|

Re: Hypercube xy distortion May 27, 2017 07:48PM |

Registered: 7 years ago Posts: 19 |

|

Re: Hypercube xy distortion May 27, 2017 09:33PM |

Registered: 7 years ago Posts: 19 |

|

Re: Hypercube xy distortion May 27, 2017 11:07PM |

Registered: 9 years ago Posts: 31 |

|

Re: Hypercube xy distortion May 28, 2017 12:44AM |

Registered: 11 years ago Posts: 5,780 |

I'll hazard a guess without a photo of the printer. Many corexy builders make a specific mistake when they set up the belt paths. The variable length belt segments, such as the segments between the extruder carriage and the pulleys at the ends of the X axis, must be parallel to the printer's guide rails (the same is true for the Y axis segments). If they aren't parallel, the belt tension will vary with the extruder XY coordinates and prints will be distorted. You may not notice it for small prints near the center of the bed, but prints that sit near the corners of the bed will be visibly distorted, much like your prints.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube xy distortion June 07, 2017 12:05PM |

Registered: 8 years ago Posts: 776 |

dd is correct but the terminology (use of the word "parallel") is not entirely clear (sorry, dd, had to point that out).

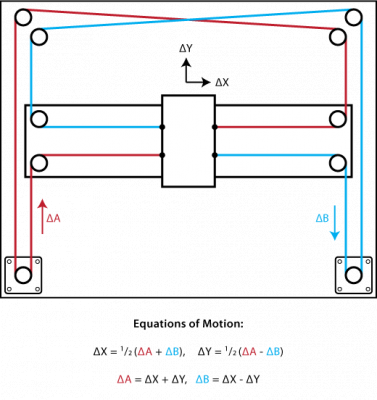

basically the belts as they come off the idlers on the main part of the "H" ABSOLUTELY MUST be at right-angles. also, as they go on they ALSO MUST BE AT RIGHT-ANGLES. you can see a CORRECT implementation at the corexy.com website:

sadly the design called the hypercube clearly does not do this.... or you have mounted the motors in the wrong place.

even the slightest offset will result in a "multiplier" effect as the X-gantry gets closer to the motors. you will see as that happens that the belt leading between the motor and the idlers on the gantry CHANGE ANGLE. that also means that they CHANGE LENGTH (according to a ratio 1/cos(angle) or something like that). so the closer they get the larger the distortion.... and that's what you're seeing in the picture.

you MIGHT be able to rescue the design by moving the corner idlers and motors so that the belts are definitely, definitely at right-angles coming both on and off the idlers on the moving X-gantry.

as people have said here: send photos. in particular take a photo DIRECTLY from above - that is the critical one that's needed.

Edited 2 time(s). Last edit at 06/07/2017 12:07PM by lkcl.

basically the belts as they come off the idlers on the main part of the "H" ABSOLUTELY MUST be at right-angles. also, as they go on they ALSO MUST BE AT RIGHT-ANGLES. you can see a CORRECT implementation at the corexy.com website:

sadly the design called the hypercube clearly does not do this.... or you have mounted the motors in the wrong place.

even the slightest offset will result in a "multiplier" effect as the X-gantry gets closer to the motors. you will see as that happens that the belt leading between the motor and the idlers on the gantry CHANGE ANGLE. that also means that they CHANGE LENGTH (according to a ratio 1/cos(angle) or something like that). so the closer they get the larger the distortion.... and that's what you're seeing in the picture.

you MIGHT be able to rescue the design by moving the corner idlers and motors so that the belts are definitely, definitely at right-angles coming both on and off the idlers on the moving X-gantry.

as people have said here: send photos. in particular take a photo DIRECTLY from above - that is the critical one that's needed.

Edited 2 time(s). Last edit at 06/07/2017 12:07PM by lkcl.

|

Re: Hypercube xy distortion June 07, 2017 03:20PM |

Registered: 7 years ago Posts: 45 |

Definitely need to see pictures as I'm pretty sure that the Hypercube as designed is good as far as the belt path goes. There are a lot of remixed parts out there that "improve" on the design but I'm not certain they all maintain the same geometry so if any of those parts were used in the build that could possibly be a source of the problem.

|

Re: Hypercube xy distortion June 07, 2017 05:00PM |

Registered: 8 years ago Posts: 88 |

Quote

lkcl

dd is correct but the terminology (use of the word "parallel") is not entirely clear (sorry, dd, had to point that out).

basically the belts as they come off the idlers on the main part of the "H" ABSOLUTELY MUST be at right-angles. also, as they go on they ALSO MUST BE AT RIGHT-ANGLES. you can see a CORRECT implementation at the corexy.com website:

No. They must be parallel to the moving axis. I can rotate my X axis at 45 degrees relative to Y axis and keeping the belts parallel to their respective moving axis will still work. And they are not at "RIGHT" angles, they are 45 degrees.

So, dd's "parallel" is good. Think of it as a leadscrew because it is easier to picture. You need to mount it PARALLEL to the guide.

Edited 1 time(s). Last edit at 06/07/2017 05:04PM by sigxcpu.

|

Re: Hypercube xy distortion June 07, 2017 08:07PM |

Registered: 8 years ago Posts: 776 |

Quote

sigxcpu

No. They must be parallel to the moving axis. I can rotate my X axis at 45 degrees relative to Y axis and keeping the belts parallel to their respective moving axis will still work. And they are not at "RIGHT" angles, they are 45 degrees.

So, dd's "parallel" is good. Think of it as a leadscrew because it is easier to picture. You need to mount it PARALLEL to the guide.

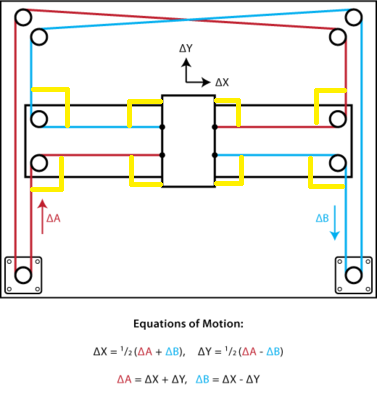

i'm really sorry sigxcpu, perhaps it is me: i can't understand the words and translate them into images. would you mind doing a quick sketch? example: i've marked up where i mean that right-angles are required. they *happen* to result in the left and right belt lines *being* parallel, and they *happen* to result in the 3 top idlers left and right being directly inline (and the belt coming off the lower idler outer edge being *required* to line up with the motor inner side) such that the vertical lengths of the belts that change must be inline and parallel...

... but the *specific* sole and exclusive use of the word "parallel" is itself ambiguous as its use alone is insufficient to pin down every single degree of freedom in the potential relevant (critical) arrangements of belt, idlers, motor gears and X-gantry.

so i've marked in yellow where the right-angles are REQUIRED to be in order to guarantee a correct CoreXY implementation. thus you can see that the use of the word "right-angle" as applied to the eight critical positions is sufficient to unambiguously pin down and specify the degrees of freedom that result in a correct CoreXY implementation. hmmm... *thinks*.... that's not actually true: the additional requirement is that all the idlers for each axis, with the exception of the top-left-most and top-right-most must be in the same Z plane.

note that the actual lengths of those belt sections which are touching yellow right-angle markers do not *actually* need to match (left, right, top or bottom), but if you do not match them then obviously the horizontal X-gantry will hit one of the idlers (and not the other), making it pointless *not* to have the lengths the same.... but it is *not* strictly necessary that they be so.

also the exact positions of the top-left-most and top-right-most bearings also need not be critical: they could if you wanted them to be a million miles away (as long as you had 2 million mile long belts). but, again, this is not totally relevant, but serves to highlight which are the critical aspects of the CoreXY design and which are not.

now, do you mean that the horizontal part (the X-gantry) could be at an angle of 45 degrees (and the left and right belt lines still be "parallel")? because whilst that would work it would require a change to the CoreXY firmware to take into account the angle of the X-gantry. why? because any attempt to move left-right would result in *Y* travel as well

do you mean that the positions of the motor gears may be shuffled left or right as long as they are the same distance apart in the X direction, such that all belt sections connected to the two gears remain "parallel"? because that is *exactly* the mistake that is most commonly made on CoreXY designs that results in exactly the type of distortion shown by the OP.

|

Re: Hypercube xy distortion June 07, 2017 08:12PM |

Registered: 8 years ago Posts: 776 |

sorry, mjoyce, i also forgot to emphasise (but it is mentioned in my reply just now), the motor gears and idlers which must be in the same Z-plane. if the motor gears are not in the same Z-plane (higher or lower) you will _also_ get the distortion that you're seeing... but also you will likely have the belt ride completely off the motor gear. pictures! send pictures! then we can be sure.

|

Re: Hypercube xy distortion June 08, 2017 11:33AM |

Registered: 8 years ago Posts: 88 |

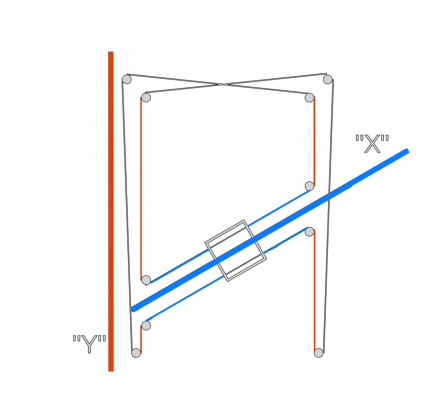

This is a perfectly valid configuration. All the red stuff needs to be parallel. All the blue stuff needs to be parallel. No straight angle anywhere.

You are confusing XY squareness, which is a valid requirement for a standard firmware configuration, but can be corrected in firmware with the actual motion mechanisms. They are not related, as you can see in the above picture.

The only biggest requirement that cannot be corrected in firmware is parallelism between moving mechanism (leadscrew, belt, rack) and the guide mechanism (linear guide, rod and bearing, v-slot and rollers).

Edited 2 time(s). Last edit at 06/08/2017 11:48AM by sigxcpu.

You are confusing XY squareness, which is a valid requirement for a standard firmware configuration, but can be corrected in firmware with the actual motion mechanisms. They are not related, as you can see in the above picture.

The only biggest requirement that cannot be corrected in firmware is parallelism between moving mechanism (leadscrew, belt, rack) and the guide mechanism (linear guide, rod and bearing, v-slot and rollers).

Edited 2 time(s). Last edit at 06/08/2017 11:48AM by sigxcpu.

|

Re: Hypercube xy distortion June 08, 2017 12:06PM |

Registered: 11 years ago Posts: 5,780 |

That's a valid configuration only if the firmware knows that the axes are not square and maps the object coordinates which were created under the assumption of square axes, to the unsquare axes of the printer. I can't think of any reason why anyone would want to configure a printer this way, unless they are trying to fit it into a triangular space.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube xy distortion June 08, 2017 12:18PM |

Registered: 8 years ago Posts: 776 |

Quote

sigxcpu

This is a perfectly valid configuration. All the red stuff needs to be parallel. All the blue stuff needs to be parallel. No straight angle anywhere.

a straight angle would be 180 degrees. a right angle is defined as 90 degrees. you mean no right-angles, not "no straight angles".

Quote

You are confusing XY squareness, which is a valid requirement for a standard firmware configuration, but can be corrected in firmware with the actual motion mechanisms. They are not related, as you can see in the above picture.

although technically you are correct, i cannot imagine that anyone would want to (a) design a CoreXY printer where the angle of the X (blue thick) line was not orthogonal (at right angles to) the Y (red thick) line.such that (b) they had to enter that angle as a parameter into firmware that (c) they had to modify and maintain.

not least, such a design would have one major significant disadvantage over a CoreXY which *did* have that angle be exactly 90 degrees: it would be wasteful of both materials and space, and would be technically extremely challenging. not least: specialist parts would have to be designed or sourced which held the (moving) cross-gantry on rails, you would have to perform complex calculations on the length of the cross-member, source special-length rails or rods...

not only that, but whatever that angle is, the printer would need to be width * cos ( angle ) * 2 larger in its depth than an equivalent-sized printer where angle = 90 degrees.

thus, whilst *technically* you are correct, to even consider such configurations, i have to conclude, is a waste of time, effort, resources and materials to consider as well as being a hugely unnecessary technical complication both in terms of design and firmware for *NO* good reason... except inasmuch as it helps to understand why *not* to design printers in such a non-standard configuration.

so whilst the idea is entirely new to me and i had never considered it before until now (angle != 90) if there was a genuine actual improvement in the quality or resources in considering such a non-standard arrangement, i would say it was worthwhile pursuing (and would actually strongly recommend the configuration in future, to anyone considering making a CoreXY design).

least of all, i have to point out: we have a newbie asking questions here about how to solve a problem with his newly-constructed CoreXY printer, and we're discussing hypothetical, unnecessarily-complex, resource-wasteful and impractical design configurations. hum.

so, can we agree that, whilst such hypothetical configurations are "technically feasible" that they are far from practical, should not be recommended, and that, to ensure that other designers do not make the mistake of considering them, agree to *recommend* that their printer has right-angles (90 degrees) at all the eight points marked in yellow in the (modified) diagram above, because that combines *both* the two aspects "red and blue belt portions must be parallel" *and* it combines the best optimal and least design-complex space-saving design for which end-users will NOT have to write and maintain their own non-standard firmware for what would ultimately be a sub-optimal CoreXY 3D printer.

would you agree with that?

|

Re: Hypercube xy distortion June 08, 2017 12:23PM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

That's a valid configuration only if the firmware knows that the axes are not square and maps the object coordinates which were created under the assumption of square axes, to the unsquare axes of the printer. I can't think of any reason why anyone would want to configure a printer this way, unless they are trying to fit it into a triangular space.

yeah i thought about mentioning that, but what i was writing was long enough. a parallelogram space would be the constraint is that right? i forget my geometry... trapezoid is the one with 2 parallel sides but arbitrary on the other two: parallelogram is the one where both opposing sides are parallel, am i right? anyway it's moot: the configuration is... obscure and hypothetical.

|

Re: Hypercube xy distortion June 08, 2017 01:07PM |

Registered: 8 years ago Posts: 88 |

Quote

the_digital_dentist

That's a valid configuration only if the firmware knows that the axes are not square and maps the object coordinates which were created under the assumption of square axes, to the unsquare axes of the printer. I can't think of any reason why anyone would want to configure a printer this way, unless they are trying to fit it into a triangular space.

The point was to prove that the keyword is "parallel" not "right angle".

|

Re: Hypercube xy distortion June 08, 2017 01:15PM |

Registered: 8 years ago Posts: 88 |

Quote

lkcl

Quote

sigxcpu

This is a perfectly valid configuration. All the red stuff needs to be parallel. All the blue stuff needs to be parallel. No straight angle anywhere.

a straight angle would be 180 degrees. a right angle is defined as 90 degrees. you mean no right-angles, not "no straight angles". English is not my primary language, so take that as "right", not "straight".

although technically you are correct, i cannot imagine that anyone would want to (a) design a CoreXY printer where the angle of the X (blue thick) line was not orthogonal (at right angles to) the Y (red thick) line.such that (b) they had to enter that angle as a parameter into firmware that (c) they had to modify and maintain.

not least, such a design would have one major significant disadvantage over a CoreXY which *did* have that angle be exactly 90 degrees: it would be wasteful of both materials and space, and would be technically extremely challenging. not least: specialist parts would have to be designed or sourced which held the (moving) cross-gantry on rails, you would have to perform complex calculations on the length of the cross-member, source special-length rails or rods...

not only that, but whatever that angle is, the printer would need to be width * cos ( angle ) * 2 larger in its depth than an equivalent-sized printer where angle = 90 degrees.

thus, whilst *technically* you are correct, to even consider such configurations, i have to conclude, is a waste of time, effort, resources and materials to consider as well as being a hugely unnecessary technical complication both in terms of design and firmware for *NO* good reason... except inasmuch as it helps to understand why *not* to design printers in such a non-standard configuration.

so whilst the idea is entirely new to me and i had never considered it before until now (angle != 90) if there was a genuine actual improvement in the quality or resources in considering such a non-standard arrangement, i would say it was worthwhile pursuing (and would actually strongly recommend the configuration in future, to anyone considering making a CoreXY design).

least of all, i have to point out: we have a newbie asking questions here about how to solve a problem with his newly-constructed CoreXY printer, and we're discussing hypothetical, unnecessarily-complex, resource-wasteful and impractical design configurations. hum.

so, can we agree that, whilst such hypothetical configurations are "technically feasible" that they are far from practical, should not be recommended, and that, to ensure that other designers do not make the mistake of considering them, agree to *recommend* that their printer has right-angles (90 degrees) at all the eight points marked in yellow in the (modified) diagram above, because that combines *both* the two aspects "red and blue belt portions must be parallel" *and* it combines the best optimal and least design-complex space-saving design for which end-users will NOT have to write and maintain their own non-standard firmware for what would ultimately be a sub-optimal CoreXY 3D printer.

would you agree with that?

The unsquare XY was a forced hypotetical drawing (although perfectly working) to prove that the constraint is parallelism, not squareness. Squareness is the most used, but optional. A delta printer is not "square" in any plane in terms of XYZ axes. Firmware translates each point in 3D space, so it is much more "non-sense" than my hypotetical arrangement.

The short version is this:

- right angles - optional, can be adjusted by firmware

- parallel - mandatory, cannot be fixed

I really don't understand why the topic moved from "right angle" vs "parallel" to "this mechanism is correct, but unused in practice".

The starting point was that dd saying "parallel" is correct and you saying "right angle" are wrong.

Edited 1 time(s). Last edit at 06/08/2017 01:16PM by sigxcpu.

|

Re: Hypercube xy distortion June 09, 2017 08:08AM |

Registered: 8 years ago Posts: 776 |

Quote

sigxcpu

Quote

the_digital_dentist

That's a valid configuration only if the firmware knows that the axes are not square and maps the object coordinates which were created under the assumption of square axes, to the unsquare axes of the printer. I can't think of any reason why anyone would want to configure a printer this way, unless they are trying to fit it into a triangular space.

The point was to prove that the keyword is "parallel" not "right angle".

ok - you've not done that. what we've identified is that there is a theoretical configuration where the keyword is "parallel", but you neglected to mention at the time (and i had to do quite a comprehensive analysis to work out) that the hypothetical case requires non-standard firmware (which doesn't exist), has significant material wastage for no practical reason. thus what you wrote is severely misleading... whilst at the same time being technically correct.

whilst i apologise for not having spelled it out (because i was not specifically aware of the hypothetical configuration that you made me aware of, for which i am quite grateful), would you agree that it would be reasonable to include the constraint that people creating CoreXY designs should use *standard* off-the-shelf firmware (that absolutely everyone else in the world, without exception both in the proprietary *and* open 3D printing communities is using)?

|

Re: Hypercube xy distortion June 09, 2017 08:17AM |

Registered: 8 years ago Posts: 776 |

Quote

sigxcpu

The unsquare XY was a forced hypotetical drawing (although perfectly working) to prove that the constraint is parallelism, not squareness. Squareness is the most used, but optional.

can you please point me to any existing off-the-shelf firmware for a CoreXY 3D printer which supports the hypothetical arrangement that you've described?

Quote

A delta printer is not "square" in any plane in terms of XYZ axes. Firmware translates each point in 3D space, so it is much more "non-sense" than my hypotetical arrangement.

i don't see the relevance of delta printers, and i believe you may be drastically underestimating the complexity of the job of firmware.

Quote

sigxcpu

- right angles - optional, can be adjusted by firmware

- parallel - mandatory, cannot be fixed

this makes no sense at all. what configuration option - in *any* standard existing firmware available today that supports CoreXY - is related to "right angles"? how is "parallel" related to mandatory "fixing"? what is "fixed"? sorry but there is far too much left unexplained.

xigxcpu i have to apologise but the discussion is getting so far off-topic without providing any perceivable benefit to the 3D printing community that i'm concerned about continuing this discussion "for its own sake". if you can answer the above questions i'll continue it but if you can't then i will, with apologies, drop the conversation. sorry.

|

Re: Hypercube xy distortion June 09, 2017 10:22AM |

Registered: 8 years ago Posts: 338 |

In the context we are talking about, a core xy printer must have it's belts parallel AND at 90 degrees since it seems unreasonable to expect the OP to write his own firmware. I mean, it's possible, sure, but I think the probability range lies somewhere between me winning the powerball jackpot and becoming president tomorrow.

Although, if everything is at right angles it will be constrained and therefore everything that needs to be parallel will be.

Edited 1 time(s). Last edit at 06/09/2017 10:26AM by Qdeathstar.

Although, if everything is at right angles it will be constrained and therefore everything that needs to be parallel will be.

Edited 1 time(s). Last edit at 06/09/2017 10:26AM by Qdeathstar.

|

Re: Hypercube xy distortion June 09, 2017 11:36AM |

Registered: 10 years ago Posts: 14,672 |

Quote

lkcl

Quote

sigxcpu

The unsquare XY was a forced hypotetical drawing (although perfectly working) to prove that the constraint is parallelism, not squareness. Squareness is the most used, but optional.

can you please point me to any existing off-the-shelf firmware for a CoreXY 3D printer which supports the hypothetical arrangement that you've described?

RepRapFirmware should be able to, if you configure it for a normal CoreXY printer and then enable orthogonal axis compensation.

Edited 1 time(s). Last edit at 06/09/2017 11:37AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hypercube xy distortion June 09, 2017 11:36AM |

Registered: 8 years ago Posts: 5,232 |

I have only one comment for this discussion

SteveWozniak_nerds.mp4

Edited 1 time(s). Last edit at 06/09/2017 11:37AM by o_lampe.

SteveWozniak_nerds.mp4

Edited 1 time(s). Last edit at 06/09/2017 11:37AM by o_lampe.

|

Re: Hypercube xy distortion June 09, 2017 11:44AM |

Registered: 8 years ago Posts: 776 |

|

Re: Hypercube xy distortion June 09, 2017 11:54AM |

Registered: 8 years ago Posts: 776 |

Quote

dc42

Quote

lkcl

Quote

sigxcpu

The unsquare XY was a forced hypotetical drawing (although perfectly working) to prove that the constraint is parallelism, not squareness. Squareness is the most used, but optional.

can you please point me to any existing off-the-shelf firmware for a CoreXY 3D printer which supports the hypothetical arrangement that you've described?

RepRapFirmware should be able to, if you configure it for a normal CoreXY printer and then enable orthogonal axis compensation.

allo dc42, nice to hear from you.

[reprappro.com]

jaezuss, i am kinda surprised that such adjustments actually exist - i wasn't actually expecting anyone to say "sure, you can"

but in reading what they're for, it makes sense: basically the documentation there says, not in so many words, "you really should have assembled your printer correctly but if you haven't and for whatever reason you really can't face properly aligning and calibrating it, here's the extraordinarily-complex and convoluted process for calculating the necessary adjustments you'll need to correct the mis-assembly".

but in reading what they're for, it makes sense: basically the documentation there says, not in so many words, "you really should have assembled your printer correctly but if you haven't and for whatever reason you really can't face properly aligning and calibrating it, here's the extraordinarily-complex and convoluted process for calculating the necessary adjustments you'll need to correct the mis-assembly".so if anyone *really wanted* to make a CoreXY printer where huge amounts of materials and space were wasted because the printer's frame was a parallelogram not a cube, and they *really wanted* to waste significant amounts of time on calibration which would otherwise be completely unnecessary if they simply followed everyone else's designs kept everything orthogonal.... they could.

dang.

|

Re: Hypercube xy distortion June 09, 2017 12:36PM |

Registered: 8 years ago Posts: 338 |

|

Re: Hypercube xy distortion June 09, 2017 02:58PM |

Registered: 8 years ago Posts: 88 |

I really don't understand what you don't understand.

A delta printer has no "right angle" requirements, but it has "parallel" axis belt to axis guid requirements. OP issue is elongation at the edge of the printed model, caused by belt not being parallel to the guide.

"Right angle" is a specific case for a squared AB axes (XY, XZ or YZ) in some specific printer configurations (cartesian, H-Bot, CoreXY), it is not the generic requirement.

In a linear motion system the "force" direction vector needs to be parallel to the "guide" direction vector (sorry for my English, I don't know the exact words). In a H-bot or CoreXY configuration the "right angle" is a side-effect of XY being at "right angle".

Is it more clear now?

Edited 2 time(s). Last edit at 06/09/2017 03:02PM by sigxcpu.

A delta printer has no "right angle" requirements, but it has "parallel" axis belt to axis guid requirements. OP issue is elongation at the edge of the printed model, caused by belt not being parallel to the guide.

"Right angle" is a specific case for a squared AB axes (XY, XZ or YZ) in some specific printer configurations (cartesian, H-Bot, CoreXY), it is not the generic requirement.

In a linear motion system the "force" direction vector needs to be parallel to the "guide" direction vector (sorry for my English, I don't know the exact words). In a H-bot or CoreXY configuration the "right angle" is a side-effect of XY being at "right angle".

Is it more clear now?

Edited 2 time(s). Last edit at 06/09/2017 03:02PM by sigxcpu.

|

Re: Hypercube xy distortion June 09, 2017 03:13PM |

Registered: 8 years ago Posts: 776 |

Quote

sigxcpu

I really don't understand what you don't understand.

the relevance to the discussion, which is rapidly veering away from the OP's question. i'm noticing a pattern emerging, which is that you don't answer questions which contradict what appears to be a desire to be "right", even at the expense of people's time and effort. i've encountered this behaviour before, and have learned that by engaging in any way with such behaviour simply increases the noise-to-signal ratio. so, very regrettably, for the sake of the forum and to improve the quality of discussions here it is with much asdness that i have to tell you that i'll not engage with you further, sigxcpu, on this topic.

|

Re: Hypercube xy distortion June 09, 2017 08:10PM |

Registered: 7 years ago Posts: 19 |

Hello,

Sorry for the delay in responding, it's been a hectic week.

I really appreciate the comments and responses.

I have attached a top down picture of my printer, I hope it's useful.

The bottom of the photo, is the front of the printer, where the xy motors are.

That's where the distortion is.

Regards

Matt

Sorry for the delay in responding, it's been a hectic week.

I really appreciate the comments and responses.

I have attached a top down picture of my printer, I hope it's useful.

The bottom of the photo, is the front of the printer, where the xy motors are.

That's where the distortion is.

Regards

Matt

Sorry, only registered users may post in this forum.