Hypercube xy distortion

Posted by mjoyce

|

Re: Hypercube xy distortion June 09, 2017 08:54PM |

Registered: 11 years ago Posts: 5,780 |

The belt segments that run from the motors to the pulleys on the ends of the X axis don't look like they are parallel to the Y axis guide rails to me. I can't tell what's happening at the X axis. When you move the extruder carriage around does the belt tension change? It shouldn't.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube xy distortion June 10, 2017 01:37AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Hypercube xy distortion June 10, 2017 03:08AM |

Registered: 8 years ago Posts: 776 |

Quote

mjoyce

Hello,

Sorry for the delay in responding, it's been a hectic week.

I really appreciate the comments and responses.

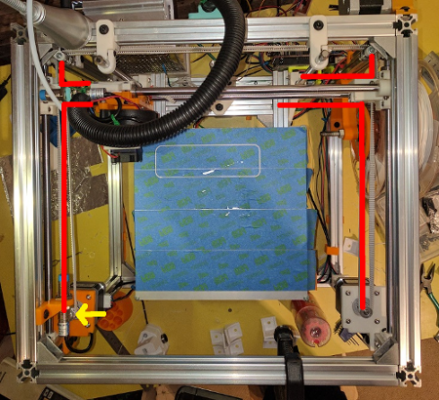

I have attached a top down picture of my printer, I hope it's useful.

The bottom of the photo, is the front of the printer, where the xy motors are.

That's where the distortion is.

Regards

Matt

yes. okay, this is a classic mistake. here's highlighted in red where you'll need to ensure that the belts come off the idlers exactly at right-angles (at all four locations). the right-hand motor looks to be just about ok (but might not be - you'll have to check it carefully, it could be out by as little as 1mm), but the left one is out by a whopping 10mm at least (yellow arrow).

the way to check (and to emphasise the problem really *really* clearly) is: move the horizontal x-gantry down as far as it will go. the angle of those two lower belt parts coming off the motor gears will change MASSIVELY. in the case of the left one it should change to something like almost 30 degrees. don't leave it there very long because it will stretch (and damage) the belt. as a result you should be looking to order a replacement, ready for when you've fixed the design flaws. (edit: dd is correct: the tension should not change. "pungg" the outer part of the belt with your finger - or any part that does not change length. if the note changes when you move the horizontal part of the "H" then you have this classic and very common design flaw).

now, the only major problem that i can see is that moving the left motor over means that it's going to hit the left y-rod. do NOT be tempted to put the motor lower down in order to "fix" this problem because you will simply be exchanging left-right incorrect alignment for up-down incorrect alignment...

if that's the case, what you'd need to do instead is redesign the white parts for the x-y gantry, moving the idlers on it slightly inwards, thus allowing you to move the y-rods OUTWARDS a sufficient amount to accommodate the amount by which the motor(s) need to be shifted over. or... don't move them: you will just have to tolerate a reduction in print area.

you _should_ be able to print things along the top (back) edge of the printer in order to minimise distortion.

now, the other thing: i notice you've copied a cantilevered bed design. those look like 8mm rods, which you should be aware are hopelessly inadequate for the job of supporting a 250mm span. you can check this easily by grabbing the front of the printbed and pushing it up and down. it should be possible to apply a tiny amount of pressure to achieve an alarming amount of "travel". also, you only have a single z lead screw, and you're using plastic pieces to hold the linear bearings. the combination of these two things means that the entire printbed will wobble about. for more details about this see [reprap.org]

one other important thing to check: the belt parts that i've marked in red MUST be all at the exact same height. the other parts (not marked) are not so critical but you really should do an "offset" design (like the Fusebox - the belt arrangement in the Fusebox is its one really really good design aspect). on the right-hand belt i can see that the inner part of the belt is not straight: it "coils" so that about half-way along it faces UPWARDS. this tells me that there is the strong possibility that the right-hand motor's height is not properly alighned: either it is at an angle (not properly vertical) or the belt is not properly horizontal. a photo from the right side would confirm this suspicion.

also: the 20x20 corner-pieces are hopelessly inadequate. you should source at least some 50x50 metal triangles (don't laugh: i use sheet steel 1.5mm corners that were designed for wood-working: they're cheap and amazingly strong). you'll also need to stiffen up all the other five faces: do not be tempted to miss one of them out. think of a cardboard box with its lid open: it's hopelessly structurally unsound. close the lid and it becomes amazingly strong. for more on this (including some video demonstrations) see [reprap.org]

so... sorry to be the bearer of bad news! you have a lot of redesign work ahead of you. but... it's not all bad: sometimes you have to try things without consulting people first, in order to value their input and to know what they're talking about. if you hadn't started at all you would not have the experience to know what corrections needed to be made. you'll do ok

Edited 3 time(s). Last edit at 06/10/2017 03:14AM by lkcl.

|

Re: Hypercube xy distortion June 11, 2017 10:14AM |

Registered: 7 years ago Posts: 19 |

|

Re: Hypercube xy distortion June 11, 2017 10:19AM |

Registered: 7 years ago Posts: 19 |

|

Re: Hypercube xy distortion June 11, 2017 02:00PM |

Registered: 8 years ago Posts: 776 |

|

Re: Hypercube xy distortion June 11, 2017 02:04PM |

Registered: 8 years ago Posts: 776 |

Quote

mjoyce

Could you attached the image you marked-up, I can't see it.

that's odd. it's stored on the server, the link is here [forums.reprap.org] - if you examine the source of the forum page it can also be obtained that way.

Quote

Thanks for the detailed reply, I'll, respond more fully tomorrow.

no problem. remember: move the horizontal x-gantry further down the printer (towards the front), take another photo. also take a photo from the right-hand side, make sure to put the camera *absolutely* dead-level with the belts. we need to check that the required belt-sections are absolutely dead horizontal.

|

Re: Hypercube xy distortion June 11, 2017 09:11PM |

Registered: 7 years ago Posts: 19 |

|

Re: Hypercube xy distortion June 11, 2017 11:43PM |

Registered: 7 years ago Posts: 19 |

Quote

lkcl

yes. okay, this is a classic mistake. here's highlighted in red where you'll need to ensure that the belts come off the idlers exactly at right-angles (at all four locations). the right-hand motor looks to be just about ok (but might not be - you'll have to check it carefully, it could be out by as little as 1mm), but the left one is out by a whopping 10mm at least (yellow arrow).

I think the angle of the photo, has altered the perspective, the left side is not 10mm out.

Looking at the STL files, and taking some measurements.

The idler centre is 11.25mm from the square post.

The bearing used in the ilder are 10mm, so the belt would be 11.25-5= 6.25mm from the post.

The centre of the motor spindle is 12.5mm from the post, the gear diameter is 12mm.

So the belt at the front is 7.5mm from the post

Seems all I need to do is change the idler bracket to shift in 1.25mm.

Quote

lkcl

now, the other thing: i notice you've copied a cantilevered bed design. those look like 8mm rods, which you should be aware are hopelessly inadequate for the job of supporting a 250mm span. you can check this easily by grabbing the front of the printbed and pushing it up and down. it should be possible to apply a tiny amount of pressure to achieve an alarming amount of "travel". also, you only have a single z lead screw, and you're using plastic pieces to hold the linear bearings. the combination of these two things means that the entire printbed will wobble about. for more details about this see [reprap.org]

Well, to be fair, I'm just using the design from here : [www.thingiverse.com]

Some of your points have been raised in that community and the consensus is, it's fine.

Quote

lkcl

one other important thing to check: the belt parts that i've marked in red MUST be all at the exact same height. the other parts (not marked) are not so critical but you really should do an "offset" design (like the Fusebox - the belt arrangement in the Fusebox is its one really really good design aspect). on the right-hand belt i can see that the inner part of the belt is not straight: it "coils" so that about half-way along it faces UPWARDS. this tells me that there is the strong possibility that the right-hand motor's height is not properly alighned: either it is at an angle (not properly vertical) or the belt is not properly horizontal. a photo from the right side would confirm this suspicion.

Thank you for sharing FuseBox, the xyjoiner on that design looks really elegant.

Quote

lkcl

also: the 20x20 corner-pieces are hopelessly inadequate. you should source at least some 50x50 metal triangles (don't laugh: i use sheet steel 1.5mm corners that were designed for wood-working: they're cheap and amazingly strong). you'll also need to stiffen up all the other five faces: do not be tempted to miss one of them out. think of a cardboard box with its lid open: it's hopelessly structurally unsound. close the lid and it becomes amazingly strong. for more on this (including some video demonstrations) see [reprap.org]

All faces have 4 corner brackets. They are metal, and as you correctly identified, 20mm. It seem pretty solid to me, but I can see how bigger brackets would be better, but perhaps not noticeably in this situation.

Quote

lkcl

so... sorry to be the bearer of bad news! you have a lot of redesign work ahead of you. but... it's not all bad: sometimes you have to try things without consulting people first, in order to value their input and to know what they're talking about. if you hadn't started at all you would not have the experience to know what corrections needed to be made. you'll do ok

Not at all, you're clearly knowledgeable about these things, and you've taken the time to share information and concepts.

I did not have a proper understanding about the mechanics, and frankly it seems a bit obvious not that you point out the relationship between the belts and the y axis.

thank you

|

Re: Hypercube xy distortion June 12, 2017 06:43AM |

Registered: 8 years ago Posts: 776 |

Quote

mjoyce

Quote

lkcl

yes. okay, this is a classic mistake. here's highlighted in red where you'll need to ensure that the belts come off the idlers exactly at right-angles (at all four locations). the right-hand motor looks to be just about ok (but might not be - you'll have to check it carefully, it could be out by as little as 1mm), but the left one is out by a whopping 10mm at least (yellow arrow).

I think the angle of the photo, has altered the perspective, the left side is not 10mm out.

Looking at the STL files, and taking some measurements.

The idler centre is 11.25mm from the square post.

The bearing used in the ilder are 10mm, so the belt would be 11.25-5= 6.25mm from the post.

The centre of the motor spindle is 12.5mm from the post, the gear diameter is 12mm.

So the belt at the front is 7.5mm from the post

Seems all I need to do is change the idler bracket to shift in 1.25mm.

ok can you confirm: for that left motor you're measuring the *inner* part of the belt (right-most) *NOT* the outer part that is currently covered by the red line? it's the *inner* part, as it comes off the left idler, that needs to be at right-angles and down to the *inside* (right side) of the motor gear.

the reason i ask is that according to the photo the left motor is so far out that you may be misunderstanding and believing that because the red line covers the OUTER part of the belt, that you must align that part only by adjusting it 1.25mm to the... *thinks*.... right.

whereas in fact you may need to adjust the motor something like 12-1.25mm to the LEFT.

this is why i said that it's important to take another photo, moving the x-gantry down to the front part of the printbed.

to confirm that perspective is not interfering, take the photo directly above the left motor's spindle, stand much further back (above), and use the "zoom" function on the camera.

Quote

Quote

lkcl

now, the other thing: i notice you've copied a cantilevered bed design. those look like 8mm rods, which you should be aware are hopelessly inadequate for the job of supporting a 250mm span. you can check this easily by grabbing the front of the printbed and pushing it up and down. it should be possible to apply a tiny amount of pressure to achieve an alarming amount of "travel". also, you only have a single z lead screw, and you're using plastic pieces to hold the linear bearings. the combination of these two things means that the entire printbed will wobble about. for more details about this see [reprap.org]

Well, to be fair, I'm just using the design from here : [www.thingiverse.com]

Some of your points have been raised in that community and the consensus is, it's fine.

then.. please assume that i am speaking diplomatically: that community has unfortunately arrived at a consensus of collective engineering ignorance. it is quite frustrating to see people continually copying and propagating basic engineering design flaws, and, worse, being reluctant to perform the necessary tests to confirm that their faith in their lack of knowledge is flawed. this is in direct violation of basic scientific enquiry / methodology.

*sigh*.

anyway take a look at the ultimaker-2: you will see that it uses 10mm rods. this is the absolute bare minimum that's needed for a cantilevered 200mm printbed. 12mm is better, and 12mm is essental for a 300mm cantilevered design. again: review those printbed examples at the mechanical rigidity page i wrote.

Quote

Quote

lkcl

one other important thing to check: the belt parts that i've marked in red MUST be all at the exact same height. the other parts (not marked) are not so critical but you really should do an "offset" design (like the Fusebox - the belt arrangement in the Fusebox is its one really really good design aspect). on the right-hand belt i can see that the inner part of the belt is not straight: it "coils" so that about half-way along it faces UPWARDS. this tells me that there is the strong possibility that the right-hand motor's height is not properly alighned: either it is at an angle (not properly vertical) or the belt is not properly horizontal. a photo from the right side would confirm this suspicion.

Thank you for sharing FuseBox, the xyjoiner on that design looks really elegant.

yeah it is... but please do bear in mind that the belt layout really is the only part of that design which is good. everything else, it is a classic example of what not to do. i outline a full list of the fusebox design flaws on its own page here [reprap.org]

there's a _lot_

Quote

Quote

lkcl

also: the 20x20 corner-pieces are hopelessly inadequate. you should source at least some 50x50 metal triangles (don't laugh: i use sheet steel 1.5mm corners that were designed for wood-working: they're cheap and amazingly strong). you'll also need to stiffen up all the other five faces: do not be tempted to miss one of them out. think of a cardboard box with its lid open: it's hopelessly structurally unsound. close the lid and it becomes amazingly strong. for more on this (including some video demonstrations) see [reprap.org]

All faces have 4 corner brackets. They are metal, and as you correctly identified, 20mm. It seem pretty solid to me, but I can see how bigger brackets would be better, but perhaps not noticeably in this situation.

ok i made that mistake as well, by buying a taobao $150 clone which had those 20mm corner brackets. i too genuinely believed that they would be adequate, and was dismayed to find that, on proper testing, they were utterly, utterly useless. you can easily test this for yourself by "twisting" (or unscrewing, like a bottle-top) the frame. tape a piece of paper to the printbed, and securely fasten a pen or pencil to the carriage. then, putting the printer on the floor (even just moving it from the table to the floor is itself a good test), hold the base between your feet and hold the top with your hands. put a SMALL amount of pressure on the top, moving it sideways and back and forth. then, do a "twist" test as well - make sure that at all times the base is firmly held between your feet.

once you've done that, check what the pen has drawn. if it's a "dot" then you have a great design, and there is absolutely nothing to fix.

if on the other hand you have a series of squiggles, you'll know that you're copying and propagating "collective ignorance". i know that you'll be absolutely shocked at how much the pen tells you that the carriage is moving about. with those 20mm corner pieces you should easily have around 2mm of "squiggle" - much more than that if you were confident to try pressing quite hard.

now, if you believe that it doesn't matter, i can tell you that it definitely does. as the printhead goes into corners, the weight of the assembly causes the *entire frame* to judder, and on the "exit" from the corner you get a "wave" pattern for several mm. to stop that from happening you not only need to limit the max speed to under 50mm/sec but also the acceleration to well under 500mm/sec^2. which, if you're using marlin, runs you smack into several design flaws in the marlin firmware itself (i've tried).

Quote

Quote

lkcl

so... sorry to be the bearer of bad news! you have a lot of redesign work ahead of you. but... it's not all bad: sometimes you have to try things without consulting people first, in order to value their input and to know what they're talking about. if you hadn't started at all you would not have the experience to know what corrections needed to be made. you'll do ok

Not at all, you're clearly knowledgeable about these things, and you've taken the time to share information and concepts.

I did not have a proper understanding about the mechanics, and frankly it seems a bit obvious not that you point out the relationship between the belts and the y axis.

thank you

no problem - we'll get you sorted

but do those photos ok! they're important to double-check before you go ahead, make sure we're absolutely talking about the same thing(s).

but do those photos ok! they're important to double-check before you go ahead, make sure we're absolutely talking about the same thing(s).btw i'm on to i think it's my 6th printer, now. from my experience with software libre project management i know to listen to the people who can clearly demonstrate an ability to logically explain their particular area of expertise: dc42, digital_dentist, and several others on here. but i then *write it down* on a wiki page (because otherwise i forget). one of the mistakes that's made by most people who use forums is that they forget that forums are near-impossible to find anything. there was a guy 18 months ago who made a fantastic cantilevered printbed design. can i remember his username? of course not. can i use the search function to narrow down where to find his design? of course not, because there have been tens of thousands of posts on here, since. that's just *one* example of some valuable engineering knowledge that's been totally swamped.

my point is: what you call expertise is just total frustration at wasting my own time and money in the past

if i document things, that stops *me* from forgetting. it also means that other people benefit, and that in turn helps me.

if i document things, that stops *me* from forgetting. it also means that other people benefit, and that in turn helps me.

|

Re: Hypercube xy distortion June 12, 2017 07:37AM |

Registered: 11 years ago Posts: 5,780 |

"Well, to be fair, I'm just using the design from here : [www.thingiverse.com]

Some of your points have been raised in that community and the consensus is, it's fine."

Well, you wouldn't want to go against something that "the community" has decided is OK, would you?

When you start digging into machine design and performance you'll find that what "the community" considers acceptable is often terrible, and even dead wrong. Look at the four screw bed leveling error that has been around for years and shows no signs of ever going away. Any idiot who didn't sleep through the first week of highschool geometry can tell you that 3 points define a plane, not 4. So why are there 4 screws? "Duh, I dunno... the bed has 4 corners?"

If "the community" says the belts don't need to be parallel to the guides rails, "the community" is wrong. It isn't difficult to find HUGE examples of how wrong communities can be. Turn on the news- at any given moment the top story is liable to be an example of how wrong "the community" (a different one) has been. Unfortunately for those of us who are able to learn from our own and others' mistakes, "the community" that can't seems to get larger every day.

Edited 3 time(s). Last edit at 06/12/2017 11:07AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Some of your points have been raised in that community and the consensus is, it's fine."

Well, you wouldn't want to go against something that "the community" has decided is OK, would you?

When you start digging into machine design and performance you'll find that what "the community" considers acceptable is often terrible, and even dead wrong. Look at the four screw bed leveling error that has been around for years and shows no signs of ever going away. Any idiot who didn't sleep through the first week of highschool geometry can tell you that 3 points define a plane, not 4. So why are there 4 screws? "Duh, I dunno... the bed has 4 corners?"

If "the community" says the belts don't need to be parallel to the guides rails, "the community" is wrong. It isn't difficult to find HUGE examples of how wrong communities can be. Turn on the news- at any given moment the top story is liable to be an example of how wrong "the community" (a different one) has been. Unfortunately for those of us who are able to learn from our own and others' mistakes, "the community" that can't seems to get larger every day.

Edited 3 time(s). Last edit at 06/12/2017 11:07AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube xy distortion June 12, 2017 10:17AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

If "the community" says the belts don't need to be parallel to the guides rails, "the community" is wrong. It isn't difficult to find HUGE examples of how wrong communities can be. Turn on the news- at any given moment the top story is liable to be an example of how wrong "the community" has been. Unfortunately for those of us who are able to learn from our own and others' mistakes, "the community" that can't seems to get larger every day.

baaaaa

|

Re: Hypercube xy distortion June 12, 2017 10:40AM |

Registered: 8 years ago Posts: 5,232 |

@DD

"the community" reminds me a bit of my favourite game in the '80: The lemmings...

"the community" reminds me a bit of my favourite game in the '80: The lemmings...

|

Re: Hypercube xy distortion June 12, 2017 10:59AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Hypercube xy distortion June 12, 2017 01:03PM |

Registered: 7 years ago Posts: 45 |

As an exercise I lined up the various parts (motor mount, idler, XY Joiner, belt, pulleys) for the left motor in 123D and the belt path at the XY joiner *should* be well under 1mm tolerance. Assuming I lined everything up correctly the belt path from the motor pulley to the idler pulley looks to be out by 1mm or so.

The drive pulley assumes a 12.7mm belt pitch and the belt segments as drawn are 1.38mm. The idler pulleys are 10mm in diameter.

Edited 2 time(s). Last edit at 06/12/2017 02:10PM by tgmorris99.

The drive pulley assumes a 12.7mm belt pitch and the belt segments as drawn are 1.38mm. The idler pulleys are 10mm in diameter.

Edited 2 time(s). Last edit at 06/12/2017 02:10PM by tgmorris99.

|

Re: Hypercube xy distortion June 12, 2017 10:39PM |

Registered: 8 years ago Posts: 776 |

Quote

tgmorris99

As an exercise I lined up the various parts (motor mount, idler, XY Joiner, belt, pulleys) for the left motor in 123D and the belt path at the XY joiner *should* be well under 1mm tolerance. Assuming I lined everything up correctly the belt path from the motor pulley to the idler pulley looks to be out by 1mm or so.

.... which would be about the right amount given that the belts comprise a part which holds the fibres and another part which has the teeth.

hmmm, so the OP appears to have either modified the design or mis-assembled it. hmm...

|

Re: Hypercube xy distortion June 12, 2017 11:03PM |

Registered: 8 years ago Posts: 776 |

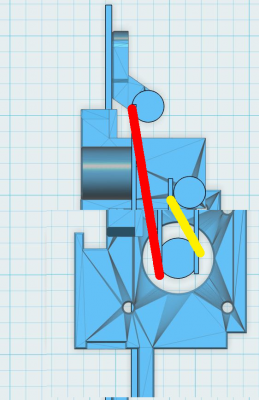

ok mjoyce so i modified the diagram that was just posted: in the image below the red part isn't what you need to be concerned about: the yellow part definitely is. can you see how, when the x-gantry is close to the motor, that the angle of the belt marked in yellow is at such an insane angle? can you see how 1 single tooth movement (2mm) of a belt at 45 degrees would result in 1/sin(angle) of ACTUAL travel?

|

Re: Hypercube xy distortion June 13, 2017 06:52AM |

Registered: 7 years ago Posts: 45 |

The modified diagram doesn't reflect reality as the parts are no longer being constrained by the positions of the 2020 extrusions, which is what the thin reference part is that is to the left of the motor mount and the idler bracket. The position of the XY Joiner also no longer aligns with the position of the guide rod. Now if the OP really built it that way then there would definitely be a problem. But that would be crazy.

Edited 2 time(s). Last edit at 06/13/2017 06:55AM by tgmorris99.

Edited 2 time(s). Last edit at 06/13/2017 06:55AM by tgmorris99.

|

Re: Hypercube xy distortion June 13, 2017 07:54AM |

Registered: 7 years ago Posts: 19 |

Quote

the_digital_dentist

"Well, to be fair, I'm just using the design from here : [www.thingiverse.com]

Some of your points have been raised in that community and the consensus is, it's fine."

Well, you wouldn't want to go against something that "the community" has decided is OK, would you?

When you start digging into machine design and performance you'll find that what "the community" considers acceptable is often terrible, and even dead wrong. Look at the four screw bed leveling error that has been around for years and shows no signs of ever going away. Any idiot who didn't sleep through the first week of highschool geometry can tell you that 3 points define a plane, not 4. So why are there 4 screws? "Duh, I dunno... the bed has 4 corners?"

If "the community" says the belts don't need to be parallel to the guides rails, "the community" is wrong. It isn't difficult to find HUGE examples of how wrong communities can be. Turn on the news- at any given moment the top story is liable to be an example of how wrong "the community" (a different one) has been. Unfortunately for those of us who are able to learn from our own and others' mistakes, "the community" that can't seems to get larger every day.

OK, you make some valid points. Thank you.

I guess my point was that I felt that if the design was so fundamentally flawed, that someone would have noticed and pointed it out before me.

Seems more likely that I have constructed it wrong.

|

Re: Hypercube xy distortion June 13, 2017 08:57AM |

Registered: 7 years ago Posts: 19 |

The modified diagram, must surely be an exaggeration to show the affects of misalignment.

Anyway, I had misunderstood, and did calculate the alignment from the motors to the rear idler.

Looking down at the motor, with the x gantry at it's most forward position, I can see the XY joiner idler is misaligned.

Picture attached.

So now I need to have a think to understand why....

Anyway, I had misunderstood, and did calculate the alignment from the motors to the rear idler.

Looking down at the motor, with the x gantry at it's most forward position, I can see the XY joiner idler is misaligned.

Picture attached.

So now I need to have a think to understand why....

|

Re: Hypercube xy distortion June 13, 2017 09:22AM |

Registered: 11 years ago Posts: 5,780 |

Yes, that's definitely malposed.

Belt misalignment seems to be a very common problem among coreXY printer builders.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Belt misalignment seems to be a very common problem among coreXY printer builders.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube xy distortion June 13, 2017 09:40AM |

Registered: 7 years ago Posts: 19 |

Actually, thinking about it, the original design called for 10mm anodised tubes, but I couldnot source them.

All I had was 8mm smooth rods, I had use use someone else's 8mm xy joiner.

....nope, looking at the two STL files, the distance from the base of the xy joiner to the centre of the xy idler is the same.

So it's not that.

Both sides have the same problem.

All I had was 8mm smooth rods, I had use use someone else's 8mm xy joiner.

....nope, looking at the two STL files, the distance from the base of the xy joiner to the centre of the xy idler is the same.

So it's not that.

Both sides have the same problem.

|

Re: Hypercube xy distortion June 13, 2017 10:44AM |

Registered: 7 years ago Posts: 45 |

Looking at your latest picture it appears that the Y guide rod and the cutout for the endstop on the motor mount are not parallel. Is the motor mount twisted or is the guide rod installed incorrectly? The guide rod also seems angled compared to the blurry 2020 extrusion so I'm guessing the guide rod has an issue but it may just be the slight angle of the photo. Pictures of all 4 corners would definitely help.

|

Re: Hypercube xy distortion December 15, 2023 08:42AM |

Registered: 4 months ago Posts: 1 |

Sorry, only registered users may post in this forum.