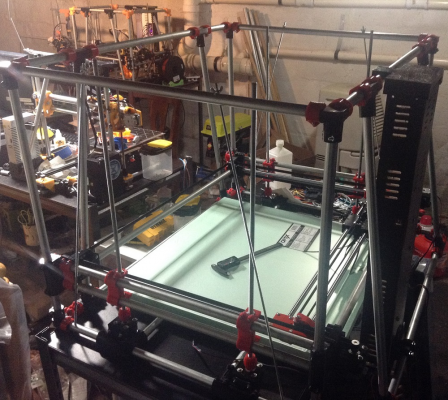

Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry

Posted by piper3d

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 09:26AM |

Registered: 5 years ago Posts: 155 |

I think the reason why so many printer constructions use ABS, PLA etc. is

- the historical RepRap idea to replicate parts with the printer, so a lot of commercial ones use it

- a lot of thingiverse things want to improve the printers (rail/guide connections, extruder holder etc.). What do you print first if you have a printer? A new part for your printer...

- users are afraid and not used to construct in aluminium or steel and don't have routers, mills etc.

So only when one understands mechanical rules, one will use metal based printers.

An alternative to aluminium/steel could be CFK, it is light and stable (hight e-module, low temperature expansion).

I checked a lot of Makes on Thingiverse and with which printer they are printed. The good ones are those with stable frames and good print bed constructions.

Your point that you don't need to calibrate if it's stable enough is a good point. It's like CNC, they don't calibrate often.

BTW about your costs: if you buy a cheap printer and have to invest a lot of time into calibrating and waste a lot of filament, then your printer is not so expensive any more!

- the historical RepRap idea to replicate parts with the printer, so a lot of commercial ones use it

- a lot of thingiverse things want to improve the printers (rail/guide connections, extruder holder etc.). What do you print first if you have a printer? A new part for your printer...

- users are afraid and not used to construct in aluminium or steel and don't have routers, mills etc.

So only when one understands mechanical rules, one will use metal based printers.

An alternative to aluminium/steel could be CFK, it is light and stable (hight e-module, low temperature expansion).

I checked a lot of Makes on Thingiverse and with which printer they are printed. The good ones are those with stable frames and good print bed constructions.

Your point that you don't need to calibrate if it's stable enough is a good point. It's like CNC, they don't calibrate often.

BTW about your costs: if you buy a cheap printer and have to invest a lot of time into calibrating and waste a lot of filament, then your printer is not so expensive any more!

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 09:34AM |

Registered: 6 years ago Posts: 1,007 |

Quote

JoergS5

Quote

MKSA

The advantage of having only one motor is that you don't need to "de-rack" and provided your machine is of a good design, rigid, properly constrained, accounts for thermal expansion, built with the proper components, you don't even need z-probing/auto bed leveling.

... By calibrate I mean small steppers who change two Z parameters and fix it (fixing by using worm drives e.g.).

Seriously ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 09:49AM |

Registered: 5 years ago Posts: 155 |

Quote

MKSA

Quote

JoergS5

Quote

MKSA

The advantage of having only one motor is that you don't need to "de-rack" and provided your machine is of a good design, rigid, properly constrained, accounts for thermal expansion, built with the proper components, you don't even need z-probing/auto bed leveling.

... By calibrate I mean small steppers who change two Z parameters and fix it (fixing by using worm drives e.g.).

Seriously ?

Yes, seriously. This was the idea: a separate process outside of the 3d printer controller (an Arduino with a CNC board):

Measure deviation and then calibrate: one point of Z is fixed, the second is the horizontal level to the other end of the bed (pitch adjuster), the other to the pivot point (roll adjuster), so you need two corrections. Align horizontally. After aligning the XY horizontally, you have the same distance of the nozzle to print bed.

Edited 3 time(s). Last edit at 08/12/2018 09:54AM by JoergS5.

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 10:36AM |

Registered: 6 years ago Posts: 1,007 |

Quote

JoergS5

Quote

MKSA

Quote

JoergS5

Quote

MKSA

The advantage of having only one motor is that you don't need to "de-rack" and provided your machine is of a good design, rigid, properly constrained, accounts for thermal expansion, built with the proper components, you don't even need z-probing/auto bed leveling.

... By calibrate I mean small steppers who change two Z parameters and fix it (fixing by using worm drives e.g.).

Seriously ?

Yes, seriously. This was the idea: a separate process outside of the 3d printer controller (an Arduino with a CNC board):

Measure deviation and then calibrate: one point of Z is fixed, the second is the horizontal level to the other end of the bed (pitch adjuster), the other to the pivot point (roll adjuster), so you need two corrections. Align horizontally. After aligning the XY horizontally, you have the same distance of the nozzle to print bed.

So please do a prototype

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 10:45AM |

Registered: 5 years ago Posts: 155 |

Quote

MKSA

Quote

JoergS5

Quote

MKSA

Quote

JoergS5

Quote

MKSA

The advantage of having only one motor is that you don't need to "de-rack" and provided your machine is of a good design, rigid, properly constrained, accounts for thermal expansion, built with the proper components, you don't even need z-probing/auto bed leveling.

... By calibrate I mean small steppers who change two Z parameters and fix it (fixing by using worm drives e.g.).

Seriously ?

Yes, seriously. This was the idea: a separate process outside of the 3d printer controller (an Arduino with a CNC board):

Measure deviation and then calibrate: one point of Z is fixed, the second is the horizontal level to the other end of the bed (pitch adjuster), the other to the pivot point (roll adjuster), so you need two corrections. Align horizontally. After aligning the XY horizontally, you have the same distance of the nozzle to print bed.

So please do a prototype

I have to wait until the far east delivers ;-) Stepper was a simplification: I will use a DC motor with gear for 1 RPM. Together with a M3 fine for 0.4 mm per round this is 7 um per second. I will make a prototype and show you. I will not use it for 3d print (digital dentist's argument: not necessary if the printer is stable), but for woodworking matters it will be very valuable.

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 12:29PM |

Registered: 6 years ago Posts: 134 |

It does not require frequent adjustments, one of them (the one which is not moving around) had not required bed leveling in months, does not require calibration of any kind with the exclusion of print parameters. It had lost 2 screws in its lifespan of 6 months because I did not use thread locker. And Z works well, and Yes not all 20 bearings bearing and Yes they suppose to give some play and not get jammed. You are not paying attention, look at vertical walls of calibration cubes above one more time. The funniest thing is - it works. I had seen a lot of amazed people who checked print quality coming out of this printer at ERRF.Quote

MKSA

If your machine requires frequent adjustments, it is normal due to the way it is built. Looking at just the Z axis; 4 lead screws, 4 guides and many bearings ... the assembly must be flexible as there is NO WAY to align all this perfectly thus a rigid set up would irremediably bind. Even, I wonder how many bearings are really bearing !

Anyway.

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 01:13PM |

Registered: 5 years ago Posts: 155 |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 01:20PM |

Registered: 6 years ago Posts: 134 |

I may argue that Airwolf or Ultimaker have printed or plastic parts in them. Prusa is printed and considered to be one of the best printers.Quote

the_digital_dentist

Eliminating adjustments is an achievable goal, just not the way you're building the printers.

TLDR: it isn't impossible to eliminate adjustments, but I don't think you can do it if you use printed plastic joints in the frame structure, motor mounts, linear bearings, etc.

My goal was simple - to create coreXY printer design based on EMT conduits and printed parts, which can print at 120 mm/s. That goal has been accomplished as it may print at 200 mm/s and up to 300 mm/s (will require extruder modification). But my next design which I had in mind 5 months ago to improve speed by adding moving bed on coreXY moving opposite direction to the head is out of the question as I reached the limits of the extruder.

I am not trying to avoid calibration I know that eventually it will be required even for your printer. I am working on a solution which will auto calibrate the bed (gantry in my case).

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 01:21PM |

Registered: 6 years ago Posts: 134 |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 01:42PM |

Registered: 5 years ago Posts: 155 |

Have you found the idea of diagonal struts by chance or by mathematical calculation?

I am still searching for a good freeware simulation program to optimize struts construction, especially in respect of vibration effects (how to minimize stepper vibrations e.g.). The program Z88 is a good program in this direction, but has still some limitations at multipart and dynamic calculations.

Edited 2 time(s). Last edit at 08/12/2018 01:45PM by JoergS5.

I am still searching for a good freeware simulation program to optimize struts construction, especially in respect of vibration effects (how to minimize stepper vibrations e.g.). The program Z88 is a good program in this direction, but has still some limitations at multipart and dynamic calculations.

Edited 2 time(s). Last edit at 08/12/2018 01:45PM by JoergS5.

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 02:14PM |

Registered: 6 years ago Posts: 134 |

It was more by intuition.Quote

JoergS5

Have you found the idea of diagonal struts by chance or by mathematical calculation?

Quote

JoergS5

I am still searching for a good freeware simulation program to optimize struts construction, especially in respect of vibration effects (how to minimize stepper vibrations e.g.). The program Z88 is a good program in this direction, but has still some limitations at multipart and dynamic calculations.

Try Fusion 360 and get free startup or individual license. It has a stress test simulations.

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 12, 2018 03:58PM |

Registered: 5 years ago Posts: 155 |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 13, 2018 02:36AM |

Registered: 6 years ago Posts: 1,007 |

Quote

piper3d

It does not require frequent adjustments, one of them (the one which is not moving around) had not required bed leveling in months, does not require calibration of any kind with the exclusion of print parameters. It had lost 2 screws in its lifespan of 6 months because I did not use thread locker. And Z works well, and Yes not all 20 bearings bearing and Yes they suppose to give some play and not get jammed. You are not paying attention, look at vertical walls of calibration cubes above one more time. The funniest thing is - it works. I had seen a lot of amazed people who checked print quality coming out of this printer at ERRF.Quote

MKSA

If your machine requires frequent adjustments, it is normal due to the way it is built. Looking at just the Z axis; 4 lead screws, 4 guides and many bearings ... the assembly must be flexible as there is NO WAY to align all this perfectly thus a rigid set up would irremediably bind. Even, I wonder how many bearings are really bearing !

Anyway.

I was referring to all the adjustments you mentioned you have to do after moving your printer a few fractions of a furlong.

If there are bearings that don't touch the tube, then they are of no use. In fact half of the Z bearing assemblies (which are not very rigid and luckily as the system would bind), half of the lead screws, 3 motors are not required.

Besides, for the X Y, you departed from this kind of assembly. You used it for your Prusa inspired machine. Why ?

o_lampe and DD also mentioned some shortcomings, I agree with.

If I intervened it is because of NathanaelXYZ intervention regarding this great idea of using FOUR Z motors. This is one "non sense" too much.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 13, 2018 02:43AM |

Registered: 6 years ago Posts: 1,007 |

Quote

JoergS5

Have you found the idea of diagonal struts by chance or by mathematical calculation?

I am still searching for a good freeware simulation program to optimize struts construction, especially in respect of vibration effects (how to minimize stepper vibrations e.g.). The program Z88 is a good program in this direction, but has still some limitations at multipart and dynamic calculations.

This has nothing to do with a geode that like lattice beam is based on the properties of the triangle and I don't see any in this frame (some looks like). [techblog.ctgclean.com]

PS: This is my last post on this subject.

Edited 1 time(s). Last edit at 08/13/2018 02:51AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry August 13, 2018 09:13PM |

Registered: 6 years ago Posts: 134 |

I was referring to 8 cubic meter 3d printers built by my friendQuote

MKSA

I was referring to all the adjustments you mentioned you have to do after moving your printer a few fractions of a furlong.

Sorry, I do not understand your statement.Quote

MKSA

If there are bearings that don't touch the tube, then they are of no use. In fact half of the Z bearing assemblies (which are not very rigid and luckily as the system would bind), half of the lead screws, 3 motors are not required.

Several reasons: to get higher speed, compactness, weight.Quote

MKSA

Besides, for the X Y, you departed from this kind of assembly. You used it for your Prusa inspired machine. Why ?

Sometimes it is easier, less time consuming, and cheaper to add motors than build custom motion transfer mechanism for a single motor 3 lead screws. Plus it opens a possibility to achieve auto squaring/cubing which is currently is used in some Prusa like machines with 2 independent Z motors.Quote

MKSA

If I intervened it is because of NathanaelXYZ intervention regarding this great idea of using FOUR Z motors. This is one "non sense" too much.

Thank you for your critical reviews.Quote

MKSA

PS: This is my last post on this subject.

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry September 06, 2018 09:07PM |

Registered: 6 years ago Posts: 134 |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry September 07, 2018 12:37AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry September 07, 2018 01:29AM |

Registered: 6 years ago Posts: 134 |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry September 24, 2018 06:30PM |

Registered: 6 years ago Posts: 134 |

Large format 600x450x400 (24''x18''x16'') or 4 CF version of Piper 2 is up and running.

It was presented at World Maker Fair last weekend.

I was asking people to shake the printer and most of them had been confused seeing that the table was shaking, but the printer was keeping its integrity.

One of the visitors guessed that printer was bolted to the table - it was not

Another has shaken is so hard that 24x20 bed mirror has jumped causing a layer shift on a print, but the printer had continued to print - need to fix mirror on the bed .

.

It has 0.8mm nozzle and prints 0.4 mm layer height. No heated bed yet, so printing PLA on a mirror with blue painters tape.

This is an example of the print - bath tab boat from Thingiverse scaled up 300%, green boat is for comaparison to original size:

It was presented at World Maker Fair last weekend.

I was asking people to shake the printer and most of them had been confused seeing that the table was shaking, but the printer was keeping its integrity.

One of the visitors guessed that printer was bolted to the table - it was not

Another has shaken is so hard that 24x20 bed mirror has jumped causing a layer shift on a print, but the printer had continued to print - need to fix mirror on the bed

.

. It has 0.8mm nozzle and prints 0.4 mm layer height. No heated bed yet, so printing PLA on a mirror with blue painters tape.

This is an example of the print - bath tab boat from Thingiverse scaled up 300%, green boat is for comaparison to original size:

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry September 26, 2018 11:53PM |

Registered: 6 years ago Posts: 134 |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry December 13, 2018 01:16PM |

Admin Registered: 15 years ago Posts: 1,470 |

Looks great! I built a h-bot design using conduit (which looks really nice when powder-coated!), but the h-bot gantry racking was too much of a problem. It printed OK, but skewing in the prints was a big problem. I have enough conduit to build a design like this, and I've been itching to make a new printer, this might be what I'm looking for!

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry December 15, 2018 09:26PM |

Registered: 6 years ago Posts: 134 |

Skewing is regulated by belts tension in coreXY. To square my gantry I am moving X carriage to the front and tension belts so distance from Y crriages on the left and right sides to mounts holding pooleys is the same (my system is simmetrical and Y carriages are touching rod holders in this position)Quote

NewPerfection

but skewing in the prints was a big problem

This is great!Quote

NewPerfection

I have enough conduit to build a design like this, and I've been itching to make a new printer, this might be what I'm looking for!

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry April 05, 2019 12:11AM |

Registered: 6 years ago Posts: 134 |

Enclosed version 2 - was released some time ago and was at MRRF 2019: https://youtu.be/g6x3LBGErbc

Files are at https://www.thingiverse.com/thing:3294998

Also at the same show was 600x450x400 version of the original Piper 2: https://youtu.be/ugT5Qs-Ho4Y

https://piper3dprinters.com

Files are at https://www.thingiverse.com/thing:3294998

Also at the same show was 600x450x400 version of the original Piper 2: https://youtu.be/ugT5Qs-Ho4Y

https://piper3dprinters.com

|

Re: Presenting Piper 2 - CoreXY on EMT conduit frame Single Dual extruder moving gantry May 06, 2019 09:16AM |

Registered: 5 years ago Posts: 148 |

You've certainly stepped on a few toes around here piper3D lol. Well done !

Anyone who enjoys letting their imagination and design ideas out into the open is fine by not just me, we like what you've done piper3D, it prints, which means yes ! and at a price that makes a lot more sense to the home user.

There are things in life that matter (such as making it past the next 5 mins in one piece, the list goes on - assuming you make it past the next 5 mins), 3D printers isn't one of them. Why not play nice and enjoy each others creations and be respectful of those that share ? you know you want too, really

Edited 1 time(s). Last edit at 05/06/2019 09:17AM by Pippy.

Anyone who enjoys letting their imagination and design ideas out into the open is fine by not just me, we like what you've done piper3D, it prints, which means yes ! and at a price that makes a lot more sense to the home user.

There are things in life that matter (such as making it past the next 5 mins in one piece, the list goes on - assuming you make it past the next 5 mins), 3D printers isn't one of them. Why not play nice and enjoy each others creations and be respectful of those that share ? you know you want too, really

Edited 1 time(s). Last edit at 05/06/2019 09:17AM by Pippy.

Sorry, only registered users may post in this forum.