CoreXY design: request for comment and collaboration

Posted by EgonVLC

|

CoreXY design: request for comment and collaboration June 24, 2020 11:11AM |

Registered: 5 years ago Posts: 23 |

Hi everyone!

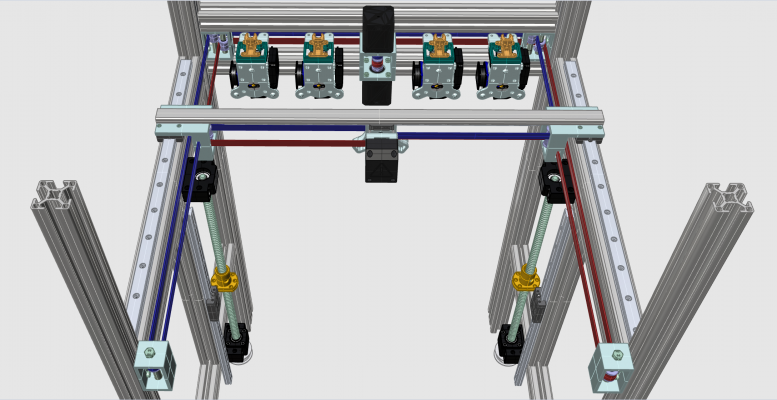

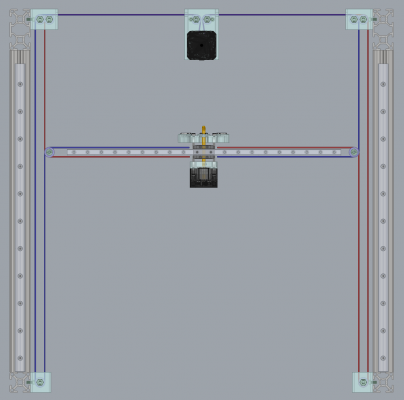

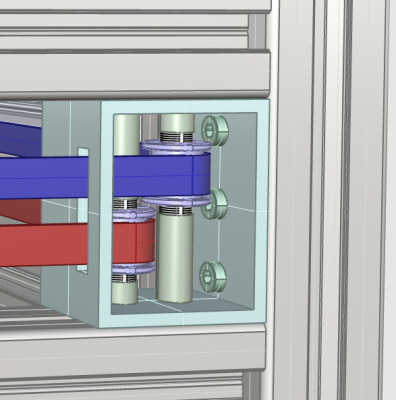

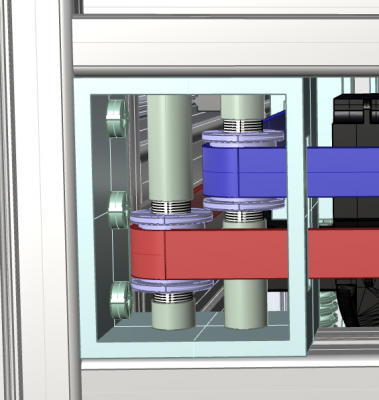

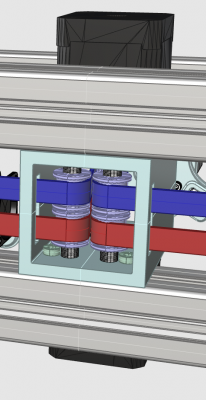

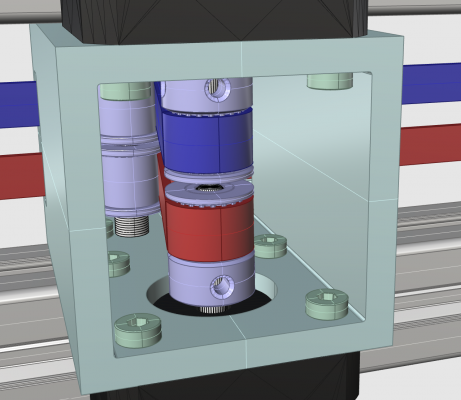

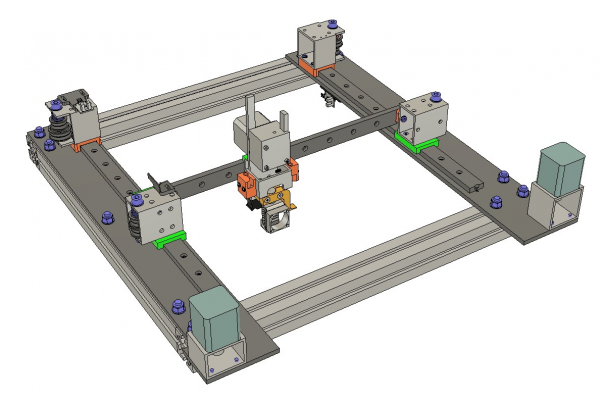

After a long design phase, with several restart-again moments, I got my CoreXY motion stage design finished. I draw a lot of inspiration everywhere, but my main sources where UMMD by our Doctor Mark Rehost, and the E3D Toolchanger.

Main design goals where:

- Simple, but sturdy, metal mounts whereever possible

- Linear rail motion. I've tested wheels on V-Slot, linear rods and linear guides, and I swear for guides

- Built from aluminium profiles. I finally used a mix of 3030, 6030 and 2010, depending the use case

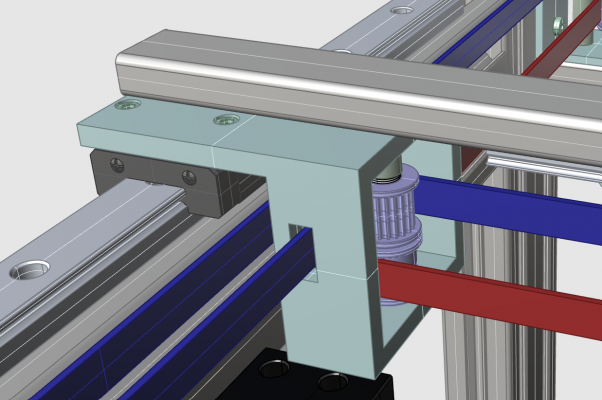

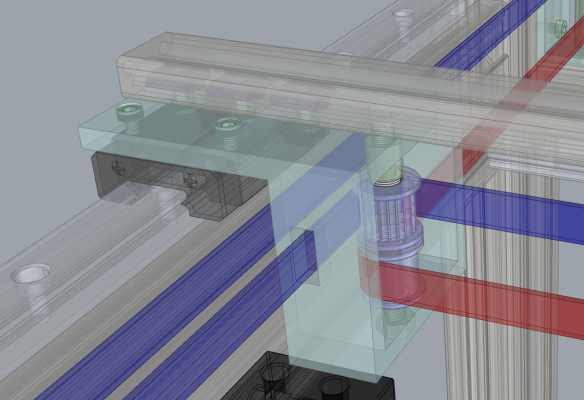

- 9mm Gates belt and pulleys, smooth for back side and toothed for teeth side, but minimizing toothed ones (I got it just with one toothed by belt!)

- 300x300 bed size

- E3D toolchanger compatibility (for all 4 tools)

- Minimum posible printer size, given the bed size and toolchanger movement margins. I got it a 560x560mm, wich fits my aim of having it inside of a wardrobe

- Autoenclosed to be able to print ABS

- I know is not the best option, but wanted the linear rails directly on the aluminium extrusions. I've already done some cartesians printers this way and the result has been superb.

- After all of this, price was not the main driver (mind you, I want to use E3D Toolchanger), so keeping it reasonable is enough

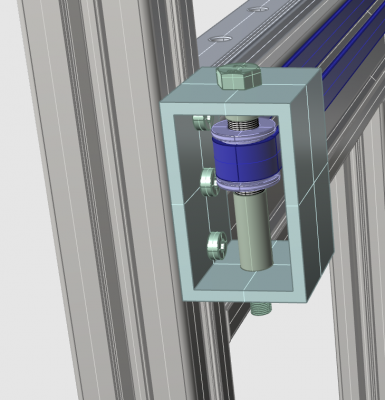

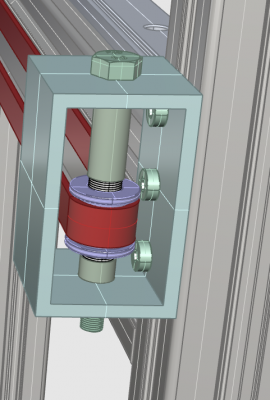

Being an all-metal construction was a must for me, and I wandered back and forth with how to do it. I tried a complete "CNC from chunck of aluminium design", but the parts got terribly expensive. Then I tried a "metal lego" of several smaller pieces, but I was not that fond of the huge number of screws. Then I returned to my original inspiration from Mark Rehorst's UMMD, and designed it around aluminium square tubes.

So, now I'm about to order the metal pieces (need to finish the bed's pieces too), but I wanted to show you the design just in case there's an obvious fail I haven't seen, or even if someone also wants the metal pieces for his own design, to share CNC costs.

Thanks everybody!

- Edit: added in-post image links

Edited 2 time(s). Last edit at 06/25/2020 04:53AM by EgonVLC.

After a long design phase, with several restart-again moments, I got my CoreXY motion stage design finished. I draw a lot of inspiration everywhere, but my main sources where UMMD by our Doctor Mark Rehost, and the E3D Toolchanger.

Main design goals where:

- Simple, but sturdy, metal mounts whereever possible

- Linear rail motion. I've tested wheels on V-Slot, linear rods and linear guides, and I swear for guides

- Built from aluminium profiles. I finally used a mix of 3030, 6030 and 2010, depending the use case

- 9mm Gates belt and pulleys, smooth for back side and toothed for teeth side, but minimizing toothed ones (I got it just with one toothed by belt!)

- 300x300 bed size

- E3D toolchanger compatibility (for all 4 tools)

- Minimum posible printer size, given the bed size and toolchanger movement margins. I got it a 560x560mm, wich fits my aim of having it inside of a wardrobe

- Autoenclosed to be able to print ABS

- I know is not the best option, but wanted the linear rails directly on the aluminium extrusions. I've already done some cartesians printers this way and the result has been superb.

- After all of this, price was not the main driver (mind you, I want to use E3D Toolchanger), so keeping it reasonable is enough

Being an all-metal construction was a must for me, and I wandered back and forth with how to do it. I tried a complete "CNC from chunck of aluminium design", but the parts got terribly expensive. Then I tried a "metal lego" of several smaller pieces, but I was not that fond of the huge number of screws. Then I returned to my original inspiration from Mark Rehorst's UMMD, and designed it around aluminium square tubes.

So, now I'm about to order the metal pieces (need to finish the bed's pieces too), but I wanted to show you the design just in case there's an obvious fail I haven't seen, or even if someone also wants the metal pieces for his own design, to share CNC costs.

Thanks everybody!

- Edit: added in-post image links

Edited 2 time(s). Last edit at 06/25/2020 04:53AM by EgonVLC.

|

Re: CoreXY design: request for comment and collaboration June 27, 2020 06:56PM |

Registered: 7 years ago Posts: 168 |

Regarding the smooth vs toothed pulleys.

From what I have researched, it is not so much whether it is toothed or not as it is that the size of the pulley and number of teeth touching the smooth surface. I have seen mention that a minimum of 9 teeth must touch the surface, and another comment where they said that the smooth pulley must be twice the diameter of the driving/toothed pulley to avoid print artifacts.

I personally strongly dislike the tiny little 5mm shaft bearings on toothed aluminium idler pulleys. As well as often being notchy from new, they are a light duty approach at best for a hard working application. If they made toothed idler pulleys with a decent size bearing in them I would use them.

I've noticed that DD uses flanged bearings with an 8mm shaft for 9mm belt idlers, and reports no issues. I'm inclined to go that way myself.

From what I have researched, it is not so much whether it is toothed or not as it is that the size of the pulley and number of teeth touching the smooth surface. I have seen mention that a minimum of 9 teeth must touch the surface, and another comment where they said that the smooth pulley must be twice the diameter of the driving/toothed pulley to avoid print artifacts.

I personally strongly dislike the tiny little 5mm shaft bearings on toothed aluminium idler pulleys. As well as often being notchy from new, they are a light duty approach at best for a hard working application. If they made toothed idler pulleys with a decent size bearing in them I would use them.

I've noticed that DD uses flanged bearings with an 8mm shaft for 9mm belt idlers, and reports no issues. I'm inclined to go that way myself.

|

Re: CoreXY design: request for comment and collaboration June 27, 2020 08:13PM |

Registered: 11 years ago Posts: 5,780 |

I used some 3D printer pulleys with 3mm bore in my corexy sand table. They wore out in less than a year of occasional use. I replaced them with stacked F625 bearings with 5 mm bore. The belts are twisted so the smooth back sides ride on the pulleys, not the teeth.

In UMMD I used F608 bearings to ensure there would be 9 teeth in contact- they are 22 mm dia, so circumference is 69 mm. Belt wrap on the pulleys is 90 degrees, so covers 17.3 mm of that circumference. 17.3/2 = 8.6 but when you bend the belt, the teeth get closer, so at least 9 teeth will contact each pulley. I get no print artifacts from the belt teeth hitting the smooth pulleys. The large diameter of the bearings means that they can have relatively large balls and that means they will last a long time.

Edited 1 time(s). Last edit at 06/27/2020 08:14PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In UMMD I used F608 bearings to ensure there would be 9 teeth in contact- they are 22 mm dia, so circumference is 69 mm. Belt wrap on the pulleys is 90 degrees, so covers 17.3 mm of that circumference. 17.3/2 = 8.6 but when you bend the belt, the teeth get closer, so at least 9 teeth will contact each pulley. I get no print artifacts from the belt teeth hitting the smooth pulleys. The large diameter of the bearings means that they can have relatively large balls and that means they will last a long time.

Edited 1 time(s). Last edit at 06/27/2020 08:14PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY design: request for comment and collaboration June 27, 2020 09:08PM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

I used some 3D printer pulleys with 3mm bore in my corexy sand table. They wore out in less than a year of occasional use. I replaced them with stacked F625 bearings with 5 mm bore. The belts are twisted so the smooth back sides ride on the pulleys, not the teeth.

In UMMD I used F608 bearings to ensure there would be 9 teeth in contact- they are 22 mm dia, so circumference is 69 mm. Belt wrap on the pulleys is 90 degrees, so covers 17.3 mm of that circumference. 17.3/2 = 8.6 but when you bend the belt, the teeth get closer, so at least 9 teeth will contact each pulley. I get no print artifacts from the belt teeth hitting the smooth pulleys. The large diameter of the bearings means that they can have relatively large balls and that means they will last a long time.

This was the information I was referring to, and I have those same F608 flanged bearings here. They look like the super heavy duty solution for 9mm belt.

Edited 1 time(s). Last edit at 06/28/2020 03:33AM by hobbymods.

|

Re: CoreXY design: request for comment and collaboration June 27, 2020 09:17PM |

Registered: 11 years ago Posts: 5,780 |

Those bearings are normally used in skate wheels, so they're good for pretty heavy loads and long life.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY design: request for comment and collaboration June 27, 2020 09:38PM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

Those bearings are normally used in skate wheels, so they're good for pretty heavy loads and long life.

Also would they be best mounted on a bit of 8mm shaft or shoulder/stripper bolt supported at both ends? Might help with alignment and prevent belt creep?

I do like the look of the OP's box tube idler mount brackets, which might work well compared to a piece of printed plastic holding the idlers. Looks rugged and utilitarian...might try that myself.

Edited 1 time(s). Last edit at 06/27/2020 09:41PM by hobbymods.

|

Re: CoreXY design: request for comment and collaboration June 27, 2020 10:06PM |

Registered: 11 years ago Posts: 5,780 |

Yes, definitely best to support pulley shafts on both ends. Shoulder screws would also be ideal, or other ground 8mm steel shaft. I used cap screws that were partially threaded so there's 8mm unthreaded steel going through the bearings, but one of these days I should probably replace them with shoulder screws.

I used a lot of rectangular tubing in my printer because it made it very easy to make the pulley and motor mounts, and to provide support for the pulley shafts at the top and bottom. You can cut aluminum tubing with almost any saw, and drill it with almost any drill, but drilling on a mill or drill press will get best angulation and location of the holes.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I used a lot of rectangular tubing in my printer because it made it very easy to make the pulley and motor mounts, and to provide support for the pulley shafts at the top and bottom. You can cut aluminum tubing with almost any saw, and drill it with almost any drill, but drilling on a mill or drill press will get best angulation and location of the holes.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.