A new, smaller sand table mechanism: Arrakis

Posted by the_digital_dentist

|

A new, smaller sand table mechanism: Arrakis November 18, 2020 01:53PM |

Registered: 11 years ago Posts: 5,780 |

I've been building a smaller sand table that will be coffee table sized (600 x 990 drawing area). Like the original, it uses a stacked belt corexy mechanism driven by iHSV-42 servomotors at up to 1600 mm/sec and acceleration up to about 15k mm/sec^2. Linear bearings are all sliding type, made of PTFE. The frame is made from 45 mm square t-slot aluminum and the X axis guide is a 16 mm square aluminum tube. The motor mounts, corner pulley blocks, Y axis bearing blocks, and magnet carriage are all 3D printed in ABS. Pulleys are made from stacked F625 bearings for long life and quiet operation. It uses a Duet WiFi controller and has separate power supplies for each motor.

Here's a video of the mechanism running almost silently at 200 mm/sec, with some explanation of the various parts of the mechanism.

Here's a video of the mechanism running at 1500 mm/sec.

Edited 1 time(s). Last edit at 11/20/2020 07:30AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's a video of the mechanism running almost silently at 200 mm/sec, with some explanation of the various parts of the mechanism.

Here's a video of the mechanism running at 1500 mm/sec.

Edited 1 time(s). Last edit at 11/20/2020 07:30AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis November 24, 2020 09:50AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: A new, smaller sand table mechanism: Arrakis November 24, 2020 10:43AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: A new, smaller sand table mechanism: Arrakis February 22, 2021 01:09PM |

Registered: 12 years ago Posts: 138 |

Greetings!

I've wanted a sand table for a long time. I'm in the processes of building a 500x500mm CoreXY plotter. I could repurpose it as a sand table.

So I don't reinvent the wheel:-)

Your videos look great! My cat would love this:-)

What magnet size are you using?

Ball bearing?

Where are you getting your sand? I saw another youtube video and the kid had issues and had to try different sand. I'm guess finer is better?

How much offset, if any do you have between magnet and ball?

What is the base you use to hold the sand? Plastic, Aluminum?

Any advice would be appreciated:-)

Max

I've wanted a sand table for a long time. I'm in the processes of building a 500x500mm CoreXY plotter. I could repurpose it as a sand table.

So I don't reinvent the wheel:-)

Your videos look great! My cat would love this:-)

What magnet size are you using?

Ball bearing?

Where are you getting your sand? I saw another youtube video and the kid had issues and had to try different sand. I'm guess finer is better?

How much offset, if any do you have between magnet and ball?

What is the base you use to hold the sand? Plastic, Aluminum?

Any advice would be appreciated:-)

Max

|

Re: A new, smaller sand table mechanism: Arrakis February 22, 2021 08:18PM |

Registered: 11 years ago Posts: 5,780 |

I use a 1" cube N52 magnet.

The bearings used for the pulleys are F625 type, stacked with printed flanges.

Sand is baking soda- I used sand blasting medium, but I suspect food grade is finer and should allow finer pattern details. The advantages of using baking soda are many- it doesn't get sticky, it doesn't attract insects, it's uniform grain size, and it's pure white. It's also available everywhere and very cheap.

In the Arrakis table, the bottom of the table is 1/4" thick baltic birch plywood, and there's an air gap of about 3 mm between the magnet and the bottom side of the plywood. It will work fine- The Spice Must Flow had a 1/2" piece of plywood for the bottom of the table and it ran fine without problems.

Don't use metal for the bottom of the sandbox. If you try to move it fast, the magnet will induce current is the metal that will create a magnetic field that opposes the motion and increases the load on the motors.

Make sure you position the magnet with the N-S poles oriented vertically. If not, the ball will be attracted to the edges of the magnet, not the center. You can identify the correct orientation by sticking the ball to the magnet- on two opposite sides (the N-S poles) it will stick to the center of the magnet, and on all the other sides it will stick at the edges.

Edited 1 time(s). Last edit at 02/22/2021 08:21PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The bearings used for the pulleys are F625 type, stacked with printed flanges.

Sand is baking soda- I used sand blasting medium, but I suspect food grade is finer and should allow finer pattern details. The advantages of using baking soda are many- it doesn't get sticky, it doesn't attract insects, it's uniform grain size, and it's pure white. It's also available everywhere and very cheap.

In the Arrakis table, the bottom of the table is 1/4" thick baltic birch plywood, and there's an air gap of about 3 mm between the magnet and the bottom side of the plywood. It will work fine- The Spice Must Flow had a 1/2" piece of plywood for the bottom of the table and it ran fine without problems.

Don't use metal for the bottom of the sandbox. If you try to move it fast, the magnet will induce current is the metal that will create a magnetic field that opposes the motion and increases the load on the motors.

Make sure you position the magnet with the N-S poles oriented vertically. If not, the ball will be attracted to the edges of the magnet, not the center. You can identify the correct orientation by sticking the ball to the magnet- on two opposite sides (the N-S poles) it will stick to the center of the magnet, and on all the other sides it will stick at the edges.

Edited 1 time(s). Last edit at 02/22/2021 08:21PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis February 22, 2021 08:26PM |

Registered: 12 years ago Posts: 138 |

Great info my friend!!!

I ordered the magnet! Do you have a pic of how you mounted your magnet. It seems very strong and I'm assuming you need to trap it well.

About how deep layer of sand?

What size ball bearing do you use?

I'm going to start ordering the parts!

Thanks

Max

Edited 3 time(s). Last edit at 02/22/2021 10:37PM by disneytoy.

I ordered the magnet! Do you have a pic of how you mounted your magnet. It seems very strong and I'm assuming you need to trap it well.

About how deep layer of sand?

What size ball bearing do you use?

I'm going to start ordering the parts!

Thanks

Max

Edited 3 time(s). Last edit at 02/22/2021 10:37PM by disneytoy.

|

Re: A new, smaller sand table mechanism: Arrakis February 23, 2021 06:19AM |

Registered: 11 years ago Posts: 5,780 |

I used silicone caulk to hold the magnet on the carriage in Arrakis.

Sand that's 1/4-1/3 the ball diameter seems to work best. I'm using a 15mm diameter ball and usually set the sand at about 4 mm deep. You can use larger or smaller balls, and with a small table it might be better to use a small ball.

You must design in the ability to access the sand easily- after running patterns for a few days you will have to redistribute the sand as it starts getting pushed to the perimeter of the sandbox.

I recently saw this: [www.edjulius.com]

Edited 1 time(s). Last edit at 02/23/2021 06:19AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sand that's 1/4-1/3 the ball diameter seems to work best. I'm using a 15mm diameter ball and usually set the sand at about 4 mm deep. You can use larger or smaller balls, and with a small table it might be better to use a small ball.

You must design in the ability to access the sand easily- after running patterns for a few days you will have to redistribute the sand as it starts getting pushed to the perimeter of the sandbox.

I recently saw this: [www.edjulius.com]

Edited 1 time(s). Last edit at 02/23/2021 06:19AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis February 23, 2021 12:23PM |

Registered: 12 years ago Posts: 138 |

|

Re: A new, smaller sand table mechanism: Arrakis August 28, 2021 08:53PM |

Registered: 11 years ago Posts: 5,780 |

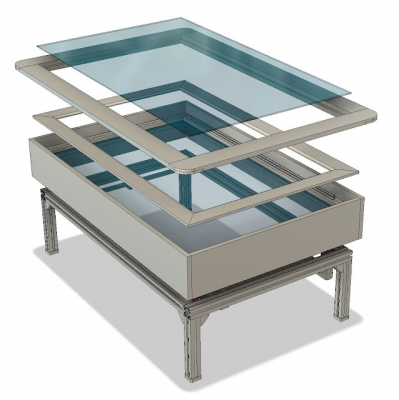

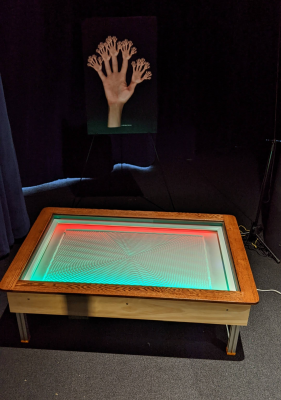

I have finally got it just about complete and fully operational:

The mechanism is built using 45 mm square t-slot, the sandbox is 1/2" baltic birch plywood on the sides and 1/4" baltic birch plywood on the bottom, covered with a sheet of EPDM roofing membrane. The sides of the sandbox have 1/2" high density foam and red and blue striped fur cloth. The top is an oak frame, stained and finished with oil based polyurethane, supporting the 4.7 mm thick glass. I may trim the fur that peeks out under the top cover on the inside of the box.

At 500mm/sec it is completely silent. At 1000 mm/sec it is quiet enough that it wouldn't disturb anyone.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The mechanism is built using 45 mm square t-slot, the sandbox is 1/2" baltic birch plywood on the sides and 1/4" baltic birch plywood on the bottom, covered with a sheet of EPDM roofing membrane. The sides of the sandbox have 1/2" high density foam and red and blue striped fur cloth. The top is an oak frame, stained and finished with oil based polyurethane, supporting the 4.7 mm thick glass. I may trim the fur that peeks out under the top cover on the inside of the box.

At 500mm/sec it is completely silent. At 1000 mm/sec it is quiet enough that it wouldn't disturb anyone.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis August 29, 2021 05:10AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: A new, smaller sand table mechanism: Arrakis August 29, 2021 11:16AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: A new, smaller sand table mechanism: Arrakis August 29, 2021 12:44PM |

Admin Registered: 16 years ago Posts: 13,891 |

... nice!

How often have you to relocate the sand for uniform/even fill?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

How often have you to relocate the sand for uniform/even fill?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: A new, smaller sand table mechanism: Arrakis August 29, 2021 12:53PM |

Registered: 11 years ago Posts: 5,780 |

After several hours of drawing. The sand tends to get pushed out toward the perimeter of the drawing area.

I've got too much sand on the table right now- I'll be pushing some off the drawing area.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I've got too much sand on the table right now- I'll be pushing some off the drawing area.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis August 29, 2021 01:50PM |

Admin Registered: 16 years ago Posts: 13,891 |

... hmmm ... maybe a sort of "concave dish" in combination with a "redistributing" pattern could be usefull ... but then the manufacturing and slider mechanics would be a bit more complicated

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: A new, smaller sand table mechanism: Arrakis September 08, 2021 10:55AM |

Registered: 11 years ago Posts: 5,780 |

I think something like the mechanism used in a powder bed 3D printer would be best. Push all the sand into a box, then push up from the bottom and squeegee it out in a uniform layer over the drawing area.

Maybe the next table...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Maybe the next table...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis September 19, 2021 01:07AM |

Registered: 11 years ago Posts: 5,780 |

I have written a post processor for the pattern files that allows me to specify two speeds, one for the drawing and one for the motion along the edges of the pattern/table. That means I can draw the pattern slowly to preserve detail and I can run the edges very fast to reduce time to pattern completion (especially for patterns with a lot of edge motion).

I posted a sample video of output from the post processor running on the table, here.

In this example, the drawing runs at 100 mm/sec and the edge speed is run at 1000 mm/sec, acceleration is set to 10k mm/sec^2.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I posted a sample video of output from the post processor running on the table, here.

In this example, the drawing runs at 100 mm/sec and the edge speed is run at 1000 mm/sec, acceleration is set to 10k mm/sec^2.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis October 31, 2021 08:32AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: A new, smaller sand table mechanism: Arrakis November 02, 2021 09:33AM |

Registered: 7 years ago Posts: 162 |

Hi,

thanks for posting all this. Would you recommend the PTFE block bearing on the Y axle for a real 3D printer (with a big heavy printer head on it) as well, or is it not accurate enough? I can imagine 3D printing requires more accuracy than this sand table, but it is a very elegant and quiet system.

Thanks,

Hugo

thanks for posting all this. Would you recommend the PTFE block bearing on the Y axle for a real 3D printer (with a big heavy printer head on it) as well, or is it not accurate enough? I can imagine 3D printing requires more accuracy than this sand table, but it is a very elegant and quiet system.

Thanks,

Hugo

|

Re: A new, smaller sand table mechanism: Arrakis November 02, 2021 10:28AM |

Registered: 11 years ago Posts: 5,780 |

No, I would not recommend using the type of bearings I used in the sand table for most 3D printing applications. There is too much slop. Sand tables are very forgiving of slop (except for the noise it produces). Most 3D printers need everything to fit tightly so they can produce accurate shapes and precise positioning of the lines of plastic on each layer.

OTOH, if you're building a printer that's going to use a 3mm nozzle and extrude cake frosting, or a 30 mm nozzle to extrude concrete, the PTFE bearings like I used should be fine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

OTOH, if you're building a printer that's going to use a 3mm nozzle and extrude cake frosting, or a 30 mm nozzle to extrude concrete, the PTFE bearings like I used should be fine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis October 19, 2022 12:37PM |

Registered: 11 years ago Posts: 5,780 |

Arrakis 2.0 will make its public debut at the Milwaukee MakerFaire this weekend.

I have redesigned the sandbox, switched to RGB LEDs, and will soon be simplifying the electronics a bit.

The old sandbox had a 1/4" plywood bottom covered with a sheet of EPDM rubber. There was an air gap between the magnet and the bottom of the sandbox to help keep noise down. I found that the bottom of the box would warp enough with changes in humidity that the magnet would start to drag on the bottom of the sandbox and make noise when the magnet was near the center of the table. The black rubber on the bottom of the box kept noise down, but would show through the sand in patterns that had the ball going over the same spot over and over.

After trying a sheet of polycarbonate and finding it too saggy, I installed a sheet of 4.7 mm thick tempered glass set in a 45mm t-slot frame (same as the corexy mechanism that drives the magnet). I covered the glass with a sheet of cloth backed white vinyl that quiets noise and doesn't obviously show through if the ball goes over the same spot over and over. The glass frame is a little larger than the corexy frame that it sits on, and the side panels of the box attach with M6 screws and t-nuts. Very simple! Like the old sandbox, the new one just drops (gently!) on top of the corexy mechanism.

RGB LED strips are mounted in C-channel aluminum which is in turn screwed to plastic fillers that fit in the t-slots of the sandbox bottom frame. I made a decorative white frame that drops into the sandbox and sits on top of those C-channel pieces, and blocks direct view of the LEDs. The LED strips have a controller with an IR remote control to select color and sequence patterns. It has connections for two LED strips (convenient!), so I just rewired one of the connectors, scrambling the R, G, and B wires so that unless you select white light, which turns on all the LEDs, the two strips always light up in different colors.

I added longer legs to the corexy frame to move the bottom of the sandbox up closer to the top to improve the viewing angle.

Additional changes that are being planned: simplified electronics- one 24V 350W power supply, one buck converter to power LEDs, ReDump protection circuit, LED controller. I'll be mounting the electronics on a hinged panel that will swing down for maintenance and lock up under the table to keep them out of sight.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have redesigned the sandbox, switched to RGB LEDs, and will soon be simplifying the electronics a bit.

The old sandbox had a 1/4" plywood bottom covered with a sheet of EPDM rubber. There was an air gap between the magnet and the bottom of the sandbox to help keep noise down. I found that the bottom of the box would warp enough with changes in humidity that the magnet would start to drag on the bottom of the sandbox and make noise when the magnet was near the center of the table. The black rubber on the bottom of the box kept noise down, but would show through the sand in patterns that had the ball going over the same spot over and over.

After trying a sheet of polycarbonate and finding it too saggy, I installed a sheet of 4.7 mm thick tempered glass set in a 45mm t-slot frame (same as the corexy mechanism that drives the magnet). I covered the glass with a sheet of cloth backed white vinyl that quiets noise and doesn't obviously show through if the ball goes over the same spot over and over. The glass frame is a little larger than the corexy frame that it sits on, and the side panels of the box attach with M6 screws and t-nuts. Very simple! Like the old sandbox, the new one just drops (gently!) on top of the corexy mechanism.

RGB LED strips are mounted in C-channel aluminum which is in turn screwed to plastic fillers that fit in the t-slots of the sandbox bottom frame. I made a decorative white frame that drops into the sandbox and sits on top of those C-channel pieces, and blocks direct view of the LEDs. The LED strips have a controller with an IR remote control to select color and sequence patterns. It has connections for two LED strips (convenient!), so I just rewired one of the connectors, scrambling the R, G, and B wires so that unless you select white light, which turns on all the LEDs, the two strips always light up in different colors.

I added longer legs to the corexy frame to move the bottom of the sandbox up closer to the top to improve the viewing angle.

Additional changes that are being planned: simplified electronics- one 24V 350W power supply, one buck converter to power LEDs, ReDump protection circuit, LED controller. I'll be mounting the electronics on a hinged panel that will swing down for maintenance and lock up under the table to keep them out of sight.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis October 19, 2022 05:41PM |

Admin Registered: 16 years ago Posts: 13,891 |

... maybe another idea -- instead of sand you could use glass micro-spheres (as used for pearl-blasting) and illuminating them from inside the table

*** EDIT *** -- maybe an LCD-screen for illuminating/freeform-imaging under the glass?

Edited 1 time(s). Last edit at 10/19/2022 05:43PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

*** EDIT *** -- maybe an LCD-screen for illuminating/freeform-imaging under the glass?

Edited 1 time(s). Last edit at 10/19/2022 05:43PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: A new, smaller sand table mechanism: Arrakis October 19, 2022 05:54PM |

Registered: 11 years ago Posts: 5,780 |

I tried glass spheres- some of the type to make reflective striping on roadways. Not so good. They were very coarse, and though you might expect them to be very reflective, they are retroreflective- they return light back to its source, not to your eyes which are at a much higher angle than the lights that illuminate the table. Lighting from under the table isn't great either- the patterns are enhanced by shadows cast by low angle lighting. If you light from under the table, the shadows are gone and contrast drops. The ridges look darker and the grooves lighter, but it isn't the same as the low angle lighting.

I have noticed that the status LEDs on power supplies and the controller board are actually visible through the white covering on the glass sandbox bottom. I may add a carboard shield to block that light.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have noticed that the status LEDs on power supplies and the controller board are actually visible through the white covering on the glass sandbox bottom. I may add a carboard shield to block that light.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis October 20, 2022 01:13AM |

Admin Registered: 16 years ago Posts: 13,891 |

... OK, then you have already tested with.

By the way - was there much different behaviour between different powders/sizes?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

By the way - was there much different behaviour between different powders/sizes?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: A new, smaller sand table mechanism: Arrakis October 20, 2022 09:09AM |

Registered: 11 years ago Posts: 5,780 |

I only tested the glass beads and baking soda, so don't know about others, but the motion through the glass beads is very rough and it makes quite a bit of grinding noise, and the baking soda is much smoother and quieter. I see a lot of people using different kinds of actual sand for their tables and wonder if they've tried baking soda, because it is probably much smoother due to the finer particle size.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis October 20, 2022 10:13AM |

Admin Registered: 16 years ago Posts: 13,891 |

... you can find all sorts and sizes of nearly spherical microparticles with distributions around 50, 10 or 5 microns, normally used for SLS 3D-printing.

From my old experiments with MRF (Magneto-Rheological-Fluids) I have some 100 gramms of carbonyl iron spheres, which are perfect round and with 50/10/1 microns distribution ... and some samples of different metals or ceramics with similar sizes ... and plastic powder from PA in white and black, used for SLS too ...

What could be easier to source, are mineral pigments (around/below 1 micron), alumina or clay (have some "african clay" samples).

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

From my old experiments with MRF (Magneto-Rheological-Fluids) I have some 100 gramms of carbonyl iron spheres, which are perfect round and with 50/10/1 microns distribution ... and some samples of different metals or ceramics with similar sizes ... and plastic powder from PA in white and black, used for SLS too ...

What could be easier to source, are mineral pigments (around/below 1 micron), alumina or clay (have some "african clay" samples).

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: A new, smaller sand table mechanism: Arrakis October 24, 2022 08:58PM |

Registered: 11 years ago Posts: 5,780 |

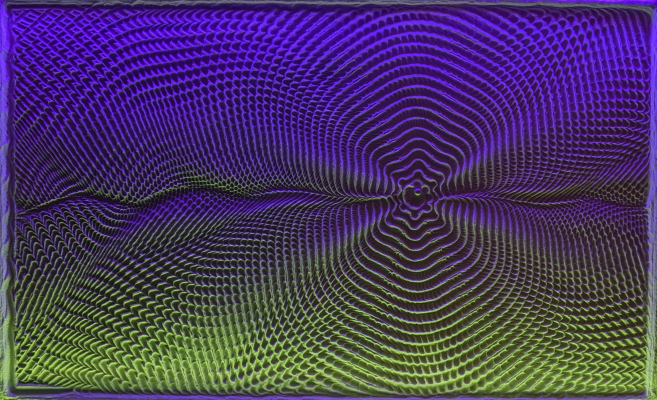

At Milwaukee MakerFaire 2022:

Unfortunately, there was an overhead light shining directly down on the table which wasn't optimal for the effectiveness of the two color lighting.

The machine worked flawlessly on both days except that on Sunday, for some reason, 3 people found the foot switch and killed power to the table. I should have put a box over the switch...

Edited 1 time(s). Last edit at 10/26/2022 05:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Unfortunately, there was an overhead light shining directly down on the table which wasn't optimal for the effectiveness of the two color lighting.

The machine worked flawlessly on both days except that on Sunday, for some reason, 3 people found the foot switch and killed power to the table. I should have put a box over the switch...

Edited 1 time(s). Last edit at 10/26/2022 05:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A new, smaller sand table mechanism: Arrakis October 26, 2022 01:59PM |

Registered: 12 years ago Posts: 1,450 |

|

Re: A new, smaller sand table mechanism: Arrakis October 26, 2022 05:23PM |

Registered: 11 years ago Posts: 5,780 |

I haven't shot any new videos since redesigning the sandbox, but the mechanism hasn't changed, so all the videos in this playlist will give you an idea what it is like, including the noise level when it runs.

Arrakis playlist

I'll shoot more video in different colors soon and add them to the playlist.

I've noticed that after about a year of relatively heavy use, some of the pulley bearings are starting to squeak. I'll be going through the whole mechanism soon and may update some of the designs. I find that the anodized t-slot surface is rough enough that it creates PTFE dust, so I may be replacing some of those bearings, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Arrakis playlist

I'll shoot more video in different colors soon and add them to the playlist.

I've noticed that after about a year of relatively heavy use, some of the pulley bearings are starting to squeak. I'll be going through the whole mechanism soon and may update some of the designs. I find that the anodized t-slot surface is rough enough that it creates PTFE dust, so I may be replacing some of those bearings, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.