Home

>

Reprappers

>

Topic

Sudden printing problem

Posted by syncra

|

Sudden printing problem November 08, 2011 12:24PM |

Registered: 13 years ago Posts: 63 |

I've been printing for ages with my reprap and suddenly the deposition is not as good as before! Instead of being a linear nice filament, it kind of bloops along the deposition line with the results of small balls connected by a micro filament. I tried the classic single wall test and it is a disaster!!! This is a common problem in settings when you set up the machine for the first time, is it? Why is it happening now?

* I tried modify the filament size input in skeinforge thinking that the diameter of this part of the reel was thinner - no effect.

* I tried playing with the temperature, raising up to 210C for PLA, with no effect.

* I feel like not enough material is deposited, but I cannot intervene properly...

I really cannot understand what happened, and especially because I did not modify anything! Same filament, same components, same software and firmware.

Anybody has got an idea of why it happened and how to restore it?

Many thanks,

Sy

* I tried modify the filament size input in skeinforge thinking that the diameter of this part of the reel was thinner - no effect.

* I tried playing with the temperature, raising up to 210C for PLA, with no effect.

* I feel like not enough material is deposited, but I cannot intervene properly...

I really cannot understand what happened, and especially because I did not modify anything! Same filament, same components, same software and firmware.

Anybody has got an idea of why it happened and how to restore it?

Many thanks,

Sy

|

Re: Sudden printing problem November 08, 2011 01:41PM |

Admin Registered: 17 years ago Posts: 7,879 |

You get that effect when the flow rate is way too low. If you haven't changed any settings then perhaps the filament is slipping in your extruder. Look for plastic stuck in the teeth of the hobbed bolt

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Sudden printing problem November 08, 2011 02:09PM |

Registered: 13 years ago Posts: 818 |

Your hot-end may be about to Jam, I have observed this happening to me twice now and both times it eventually jammed with a PLA and ABS plug. It didn't make any difference with extra heat, and although you may see the hobbed bolt jamming, this may be due to hard material build-up in the thermal break and the extra pressure you need to overcome it.

Disassemble your hot-end, clear out the block, and the thermal break (cool-end PTFE/tube) (may need drilling out) and it should be back working again for many more months.

Do you have a PTFE thermal break? supported with a PEEK block?

I made the following comment about it on my blog last month -

Hot-end Jamming -

My only other odd failure was the jamming of hardened filament at the hot-end, this seems happen after many months of printing due to build-up of solid materials, probably because I tend to run PLA hotter and faster than 'normal' which leads me to my top-tip I'm still investigating -

Top Tip - I would be interested if anyone else has spotted this - If you start to see very, very fine 'hairs' of plastic on your printed parts for no real reason you can think of, this may be a sign that your hot-end is about fail, from build-up of hard material. I have spotted this on the last two times my hot-end needed cleaning, it will need disassembling and maybe drilling and cleaning out, after that it will be back to normal and work for many more months. as long as the PTFE sleeve or barrier has not degraded, then it will fail again quite quickly - keep an eye out for the 'hairs'

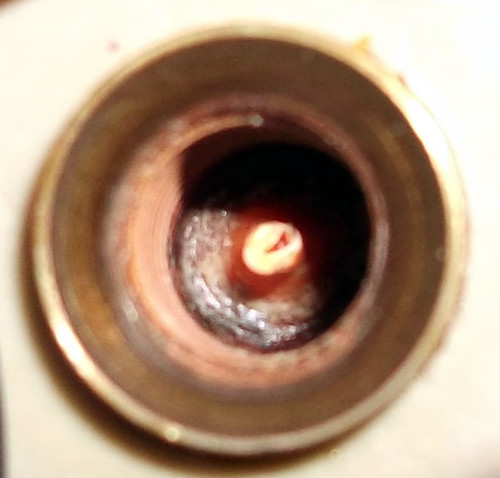

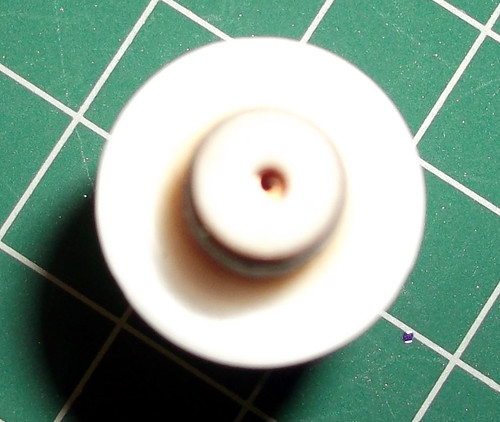

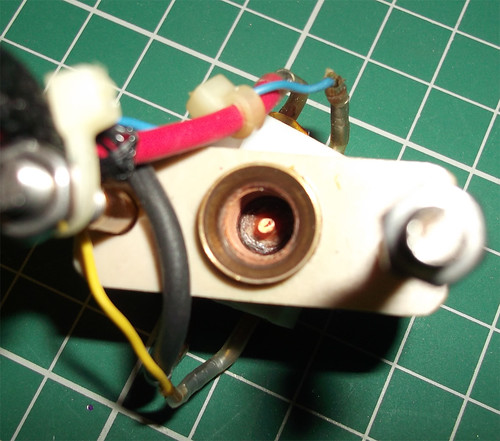

And if this is the problem, then when you disassemble you may see this -

and this

I would be really interested if this was also the same issue for you?

If you need help cleaning out the hot-end take a look at the Art of failure group

Rich.

[richrap.blogspot.com]

Disassemble your hot-end, clear out the block, and the thermal break (cool-end PTFE/tube) (may need drilling out) and it should be back working again for many more months.

Do you have a PTFE thermal break? supported with a PEEK block?

I made the following comment about it on my blog last month -

Hot-end Jamming -

My only other odd failure was the jamming of hardened filament at the hot-end, this seems happen after many months of printing due to build-up of solid materials, probably because I tend to run PLA hotter and faster than 'normal' which leads me to my top-tip I'm still investigating -

Top Tip - I would be interested if anyone else has spotted this - If you start to see very, very fine 'hairs' of plastic on your printed parts for no real reason you can think of, this may be a sign that your hot-end is about fail, from build-up of hard material. I have spotted this on the last two times my hot-end needed cleaning, it will need disassembling and maybe drilling and cleaning out, after that it will be back to normal and work for many more months. as long as the PTFE sleeve or barrier has not degraded, then it will fail again quite quickly - keep an eye out for the 'hairs'

And if this is the problem, then when you disassemble you may see this -

and this

I would be really interested if this was also the same issue for you?

If you need help cleaning out the hot-end take a look at the Art of failure group

Rich.

[richrap.blogspot.com]

|

Re: Sudden printing problem November 08, 2011 05:15PM |

Registered: 13 years ago Posts: 63 |

Thanks guys for the answer.

@ Nophead - the filament drive looks fine. I sensed the lack of material going into the extruder, and I tightened the pressure on the filament against the hobbed drive; then increased the power on the stepper driver; then decreased the filament diameter in the software, but without seeing a solution.

@ Richrap - This sounds an interesting theory and I did not think about it. However, I do not understand the physics behind it... If I raise the temperature 10C or more, any plastic residual that solidified should melt away and get out thanks to the pressure of the fresh filament pushing. And also, as long as the hole is present and the extruder motor pushes the right amount of filament in the hot end, this should come out on the other side!!!

I was leaning on the possibility of the thermistor not working properly (can they break partially or only yes/no functioning?) or maybe it moved out of its position. In this case the wrong temperature reading would mess up the extrusion... right?

In any case, tomorrow I will try disassembling the nozzle and look inside!

I'll keep you posted. Meanwhile, please comment if you have any new clue.

Syncra

@ Nophead - the filament drive looks fine. I sensed the lack of material going into the extruder, and I tightened the pressure on the filament against the hobbed drive; then increased the power on the stepper driver; then decreased the filament diameter in the software, but without seeing a solution.

@ Richrap - This sounds an interesting theory and I did not think about it. However, I do not understand the physics behind it... If I raise the temperature 10C or more, any plastic residual that solidified should melt away and get out thanks to the pressure of the fresh filament pushing. And also, as long as the hole is present and the extruder motor pushes the right amount of filament in the hot end, this should come out on the other side!!!

I was leaning on the possibility of the thermistor not working properly (can they break partially or only yes/no functioning?) or maybe it moved out of its position. In this case the wrong temperature reading would mess up the extrusion... right?

In any case, tomorrow I will try disassembling the nozzle and look inside!

I'll keep you posted. Meanwhile, please comment if you have any new clue.

Syncra

|

Re: Sudden printing problem November 08, 2011 06:38PM |

Registered: 13 years ago Posts: 818 |

Some times hardened residue just builds up and will not melt away at any temp. And when you get a jam no ammount of heat or force seems to free it.

[richrap.blogspot.com]

[richrap.blogspot.com]

|

Re: Sudden printing problem November 08, 2011 08:47PM |

Registered: 13 years ago Posts: 1,780 |

Quote

richrap

Some times hardened residue just builds up and will not melt away at any temp. And when you get a jam no ammount of heat or force seems to free it.

If the nozzle is brass, you can burn the residue away with a blow torch. Look for Repraplogphase youtube video on how to do this.

|

Re: Sudden printing problem November 09, 2011 04:35AM |

Registered: 13 years ago Posts: 818 |

brnrd Wrote:

-------------------------------------------------------

> If the nozzle is brass, you can burn the residue

> away with a blow torch. Look for Repraplogphase

> youtube video on how to do this.

That is a great video.

I have not found the brass nozzle to be the problem, that block can usually be heated, removed and cleaned with a tiny wire brush, the bit that seems to get jammed with hardened material for me is the thermal break. I know I should not really be using just PTFE as it can leak, but I believe the process of jamming for me is a slow build up of residue material (Maybe it's fluff/dust?) on the PTFE inner walls at the hottest part with the PTFE in the barrel, this causes more pressure on the hot-end, and some separation and eventually a plug is formed at the end of the PTFE break, jamming it up solid.

Once it's all cleared the same parts work for many months of printing again until you start seeing hobbed bolt grinding or low extrusion then it's going to fail again, soon.

If anyone has another theory on this - or Ideally a 'perfect' hot-end please share

[richrap.blogspot.com]

-------------------------------------------------------

> If the nozzle is brass, you can burn the residue

> away with a blow torch. Look for Repraplogphase

> youtube video on how to do this.

That is a great video.

I have not found the brass nozzle to be the problem, that block can usually be heated, removed and cleaned with a tiny wire brush, the bit that seems to get jammed with hardened material for me is the thermal break. I know I should not really be using just PTFE as it can leak, but I believe the process of jamming for me is a slow build up of residue material (Maybe it's fluff/dust?) on the PTFE inner walls at the hottest part with the PTFE in the barrel, this causes more pressure on the hot-end, and some separation and eventually a plug is formed at the end of the PTFE break, jamming it up solid.

Once it's all cleared the same parts work for many months of printing again until you start seeing hobbed bolt grinding or low extrusion then it's going to fail again, soon.

If anyone has another theory on this - or Ideally a 'perfect' hot-end please share

[richrap.blogspot.com]

|

Re: Sudden printing problem November 09, 2011 05:08AM |

Registered: 13 years ago Posts: 63 |

@ brnrd - Wow, that looks interesting, but stimulates further questions:

1- is this problem typical of any machine? Is this part of regular maintenance? I never heard of this "fire game" for the UP! or the BfB machine. If this is the case, why we don't all copy their nozzles?

2- If fire solves the problem and melts the residual plastic, cannot we achieve the same by heating the nozzle to higher temp with electricity (yes, still mounted on the machine) and push something inside to clean it?

1- is this problem typical of any machine? Is this part of regular maintenance? I never heard of this "fire game" for the UP! or the BfB machine. If this is the case, why we don't all copy their nozzles?

2- If fire solves the problem and melts the residual plastic, cannot we achieve the same by heating the nozzle to higher temp with electricity (yes, still mounted on the machine) and push something inside to clean it?

|

Re: Sudden printing problem November 09, 2011 05:10AM |

Registered: 13 years ago Posts: 63 |

|

Re: Sudden printing problem November 09, 2011 05:43AM |

Admin Registered: 17 years ago Posts: 7,879 |

I never get build up inside my nozzles, just the hole in the end needs occasional reaming as the plastic burns where it meets the air and slowly reduces the nozzle bore.

The only time I have had hard stuff form inside the barrel was when a thermistor came loose and the temperature got close to 300C.

I don't often print coloured plastic though, whereas Richrap specialises on printing lots of colours. Maybe some of the pigments burn and cause residue.

[www.hydraraptor.blogspot.com]

The only time I have had hard stuff form inside the barrel was when a thermistor came loose and the temperature got close to 300C.

I don't often print coloured plastic though, whereas Richrap specialises on printing lots of colours. Maybe some of the pigments burn and cause residue.

[www.hydraraptor.blogspot.com]

|

Re: Sudden printing problem November 09, 2011 06:10AM |

Registered: 13 years ago Posts: 63 |

|

Re: Sudden printing problem November 09, 2011 07:56AM |

Admin Registered: 17 years ago Posts: 7,879 |

One I made myself with a stainless steel insulator and a combined aluminium heater block / nozzle. [hydraraptor.blogspot.com] with this drive: [hydraraptor.blogspot.com]

Two of Brian's early hybrid PEEK / PTFE insulators with my own brass nozzles plus aluminium / brass heater blocks. Both attached to big heatsinks via aluminium clamps. One driven by a Wade's and the other by a geared stepper from Makergear. I find I need a heatsink at the cold end when running in a heated chamber.

One of Wolfgang's PEEK with external thread into a brass nozzle with a PTFE liner, driven by a Wade's on my Prusa. I haven't extruded much with that setup yet though.

[www.hydraraptor.blogspot.com]

Two of Brian's early hybrid PEEK / PTFE insulators with my own brass nozzles plus aluminium / brass heater blocks. Both attached to big heatsinks via aluminium clamps. One driven by a Wade's and the other by a geared stepper from Makergear. I find I need a heatsink at the cold end when running in a heated chamber.

One of Wolfgang's PEEK with external thread into a brass nozzle with a PTFE liner, driven by a Wade's on my Prusa. I haven't extruded much with that setup yet though.

[www.hydraraptor.blogspot.com]

|

Re: Sudden printing problem November 09, 2011 08:11AM |

Registered: 13 years ago Posts: 1,780 |

I used the blowtorch method on two nozzles that I clogged up when I was having trouble controlling my nozzle temperature. I think, just as nophead experienced, the temperature got above 300C for a long enough time for the plastic feed to decompose. I made sure that the insulator was clear but it still took too much force to extrude plastic. I didn't have a 0.5 mm drill bit and I thought it would be safer to burn the residue off so that I don't enlarge or damage the nozzle.

|

Re: Sudden printing problem November 10, 2011 11:38AM |

Registered: 13 years ago Posts: 63 |

I start being desperate...

As the nozzle cleaning process was delaying me, I decided to mount a mendel-parts nozzle (v6 I think) that I bought few month ago and never tried - in any case, BRAND NEW nozzle! (PS: I don't like it much, it's longer than my previous one, and the heating is not very close to the end of the nozzle, making longer the hot part and making difficult to avoid dropping material, but this is another story).

I test the single wall test and BAM!, again blobs and cheese thin lines. I try a couple of times but nothing improves. So I switched the transparent PLA, that was slightly thinner than normal, for a grey PLA slightly thicker, thinking now material will flow... Slight improvement, but far from good printing the single wall. Still blobs. Only managed 3 decent layers in the middle, but cannot understand if problem is temperature or filament drive (I use a direct drive on NEMA23 with bowden cable).

I was so desperate that I even went in the firmware increasing the step per mm in order to squeeze layers and make them stick - no way.

It's terrible, whatever I do, I cannot get rid of that "simple" issue that usually begineers struggle with. And all this happen suddenly. I am truly puzzled!!!

Any hint on what to try before I randomly change parameters here and there?

Many thanks in any case.

As the nozzle cleaning process was delaying me, I decided to mount a mendel-parts nozzle (v6 I think) that I bought few month ago and never tried - in any case, BRAND NEW nozzle! (PS: I don't like it much, it's longer than my previous one, and the heating is not very close to the end of the nozzle, making longer the hot part and making difficult to avoid dropping material, but this is another story).

I test the single wall test and BAM!, again blobs and cheese thin lines. I try a couple of times but nothing improves. So I switched the transparent PLA, that was slightly thinner than normal, for a grey PLA slightly thicker, thinking now material will flow... Slight improvement, but far from good printing the single wall. Still blobs. Only managed 3 decent layers in the middle, but cannot understand if problem is temperature or filament drive (I use a direct drive on NEMA23 with bowden cable).

I was so desperate that I even went in the firmware increasing the step per mm in order to squeeze layers and make them stick - no way.

It's terrible, whatever I do, I cannot get rid of that "simple" issue that usually begineers struggle with. And all this happen suddenly. I am truly puzzled!!!

Any hint on what to try before I randomly change parameters here and there?

Many thanks in any case.

|

Re: Sudden printing problem November 18, 2011 02:14AM |

Registered: 12 years ago Posts: 57 |

Since it is a BRAND NEW nozzle still blob and string, try looking at the feeder.

I had a similar problem a while ago and it turns out the locking set screw on the extruder drive gear drive gear was slipping off the motor shaft. I just remill the the motor shaft and the set screw locks the drive gear. Now it extrudes on 0.3mm nozzle with 3mm filament.

I had a similar problem a while ago and it turns out the locking set screw on the extruder drive gear drive gear was slipping off the motor shaft. I just remill the the motor shaft and the set screw locks the drive gear. Now it extrudes on 0.3mm nozzle with 3mm filament.

Sorry, only registered users may post in this forum.