Home

>

Reprappers

>

Topic

Hot tip jamming issue (3rd design, so frustrated...)

Posted by sxt173

|

Hot tip jamming issue (3rd design, so frustrated...) January 14, 2012 03:45PM |

Registered: 13 years ago Posts: 55 |

I need help... I am on my 3rd hot end design and whatever I do, I cannot get it to work. I will get just a bit of oozing from the tip, but it always ends up jamming. I have tried 3 different designs on the Wade's Accessible Geared Extruder. The main extruder is made of Alumide to stop warping to the tip support. I added a fan to the hot end base with no avail.

I am printing with 1.75mm PLA and have tried 170 degrees, with +20 degree increments all the way up to 250 degrees. I am also checking the temp independently to confirm the tip is hitting the target temp.

Here are pics of my design, any help is appreciated!

- View from fan side: http://goo.gl/8T7M1

- Closeup of heater block and brass tip: http://goo.gl/ssomn

- PEEK bolt attachment & heatsink: http://goo.gl/9G3GO

- Closeup of hobbled bolt: http://goo.gl/L78q6

- Inlet top view: http://goo.gl/ezNvs

*** This is what the PLA looks like when I pull it out (it does melt, but jams): http://goo.gl/yKVz8

Thanks

I am printing with 1.75mm PLA and have tried 170 degrees, with +20 degree increments all the way up to 250 degrees. I am also checking the temp independently to confirm the tip is hitting the target temp.

Here are pics of my design, any help is appreciated!

- View from fan side: http://goo.gl/8T7M1

- Closeup of heater block and brass tip: http://goo.gl/ssomn

- PEEK bolt attachment & heatsink: http://goo.gl/9G3GO

- Closeup of hobbled bolt: http://goo.gl/L78q6

- Inlet top view: http://goo.gl/ezNvs

*** This is what the PLA looks like when I pull it out (it does melt, but jams): http://goo.gl/yKVz8

Thanks

|

Re: Hot tip jamming issue (3rd design, so frustrated...) January 15, 2012 07:31AM |

Registered: 12 years ago Posts: 78 |

|

Re: Hot tip jamming issue (3rd design, so frustrated...) January 15, 2012 11:25AM |

Registered: 13 years ago Posts: 55 |

|

Re: Hot tip jamming issue (3rd design, so frustrated...) January 15, 2012 08:02PM |

Registered: 12 years ago Posts: 20 |

Do you need more spring tension on the wheel?

Ive noticed that I need to adjust that from batch to batch. My most recent batch needed so much more tension that I needed to readjust my trimpot on that motor.

Also, make sure that the path of the fillament is lined up well. Sometimes, mine can wander out of alignment and can cause problems.

Just some ideas

Ive noticed that I need to adjust that from batch to batch. My most recent batch needed so much more tension that I needed to readjust my trimpot on that motor.

Also, make sure that the path of the fillament is lined up well. Sometimes, mine can wander out of alignment and can cause problems.

Just some ideas

|

Re: Hot tip jamming issue (3rd design, so frustrated...) January 15, 2012 09:15PM |

Registered: 13 years ago Posts: 55 |

|

Re: Hot tip jamming issue (3rd design, so frustrated...) February 02, 2012 02:12AM |

Registered: 12 years ago Posts: 229 |

|

Re: Hot tip jamming issue (3rd design, so frustrated...) February 02, 2012 09:50AM |

Registered: 13 years ago Posts: 55 |

|

Re: Hot tip jamming issue (3rd design, so frustrated...) February 02, 2012 01:23PM |

Registered: 13 years ago Posts: 102 |

maybe worth trying a fan on the heat sink or do as i do add a steel clamp (like on those soldering mates) around the barrel with a small magnet so you can keep adding washers, most of my jams are due to heat traveling up the barrel. But if you are pushing 1.75 through a 3mm hole then fix that first, it will bend under pressure.

|

Re: Hot tip jamming issue (3rd design, so frustrated...) February 02, 2012 03:16PM |

Registered: 13 years ago Posts: 55 |

I'll definitely try that after I swicth my nozzle back to 3mm tonight. Do you by any chance have pics of the magnet/washer setup?

hexitex Wrote:

-------------------------------------------------------

> add a steel clamp (like on those soldering

> mates) around the barrel with a small magnet so

> you can keep adding washers

hexitex Wrote:

-------------------------------------------------------

> add a steel clamp (like on those soldering

> mates) around the barrel with a small magnet so

> you can keep adding washers

|

Re: Hot tip jamming issue (3rd design, so frustrated...) February 02, 2012 08:21PM |

Registered: 13 years ago Posts: 102 |

mate, i can't take it apart now, done some bed calibration but.. i took some pics in situ. see attached

sorry about quality,. using a camera phone with no flash!

first pic (under) is showing the clamp and washers

second pic, much of the same but moving you about to get your bearings, so shows the nozzle

third pic (top) is the added heat exchangers (more washers) the magnet is in there somewhere, it is a very small (10mm *3mm *2mm) neodymium i got from an old toothbrush head (Phillips sonicare) to keep them from roaming.

sorry about quality,. using a camera phone with no flash!

first pic (under) is showing the clamp and washers

second pic, much of the same but moving you about to get your bearings, so shows the nozzle

third pic (top) is the added heat exchangers (more washers) the magnet is in there somewhere, it is a very small (10mm *3mm *2mm) neodymium i got from an old toothbrush head (Phillips sonicare) to keep them from roaming.

|

Re: Hot tip jamming issue (3rd design, so frustrated...) February 08, 2012 07:44PM |

Registered: 12 years ago Posts: 229 |

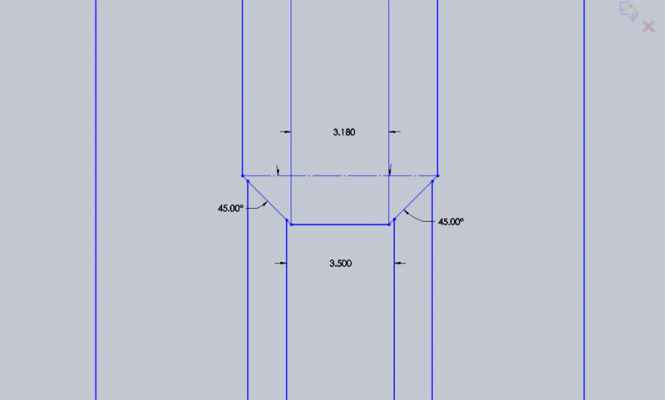

Use a countersink bit or a tapered reamer to make a "V" shape in the topmost part of the hot end where it meets the extruder body. This will make it easier to feed filament.

If the extruder is made of 2 or more pieces there may be gaps that the PLA expands into and jams. symptoms are being able to extrude well at first with fresh (room temperature) filament, but it jams soon after.

I got around this problem by making the bore of the PTFE 3.18mm (1/8") and the bore of the barrel 3.5mm. It looks like this:

The outer is PEEK

The top inner is PTFE

The bottom inner is the brass rod

Making interlocking 45º angles with a bit of an overhang prevents the gaps. The PTFE is pressed in after the barrel is screwed in.

If the extruder is made of 2 or more pieces there may be gaps that the PLA expands into and jams. symptoms are being able to extrude well at first with fresh (room temperature) filament, but it jams soon after.

I got around this problem by making the bore of the PTFE 3.18mm (1/8") and the bore of the barrel 3.5mm. It looks like this:

The outer is PEEK

The top inner is PTFE

The bottom inner is the brass rod

Making interlocking 45º angles with a bit of an overhang prevents the gaps. The PTFE is pressed in after the barrel is screwed in.

|

Re: Hot tip jamming issue (3rd design, so frustrated...) February 09, 2012 09:50AM |

Registered: 13 years ago Posts: 55 |

I mostly resolved my issue: I think the main culprit was that the "feed hole" in the extruder body was for 3mm vs. a 1.75mm hot end.

It seems that as the tip was heating up and transferring some heat up the filament, it basically used the path of least resistance and started buckling right under the hobbled bolt before it got into the extruder feed hole.

In some cases, it just buckled a bit and the hobbled bold started stripping the plastic, or a few times it started pushing the filament out the sides.

I went back to my old (badly crazy glued together and patched up) extruder and it seems to work ok. The extruded PLA is coming out as a pretty swirly for some very odd reason, but I think that is a low temp and speed issue.

It seems that as the tip was heating up and transferring some heat up the filament, it basically used the path of least resistance and started buckling right under the hobbled bolt before it got into the extruder feed hole.

In some cases, it just buckled a bit and the hobbled bold started stripping the plastic, or a few times it started pushing the filament out the sides.

I went back to my old (badly crazy glued together and patched up) extruder and it seems to work ok. The extruded PLA is coming out as a pretty swirly for some very odd reason, but I think that is a low temp and speed issue.

Sorry, only registered users may post in this forum.