Home

>

Reprappers

>

Topic

What is wrong. See pic

Posted by Gibbedy

|

What is wrong. See pic June 27, 2013 06:13AM |

Registered: 12 years ago Posts: 86 |

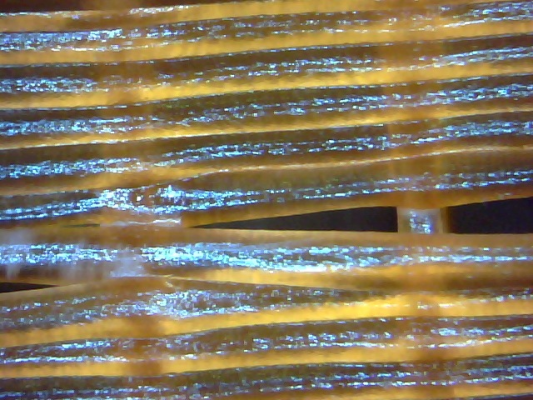

After changing filament I've been having a problem with top layers causing hotend crashes. It looks like some long runs curl up instead of sticking to infill below.

[users.tpg.com.au]

I've been told i can change print speed on the fly. Is it possible to also change extrusion rate, acceleration rate, change layer height?If I could do all this on the fly I think I could solve this and any future trouble I have.

I'm sure someone will know exactly the problem I'm having here.

[users.tpg.com.au]

I've been told i can change print speed on the fly. Is it possible to also change extrusion rate, acceleration rate, change layer height?If I could do all this on the fly I think I could solve this and any future trouble I have.

I'm sure someone will know exactly the problem I'm having here.

|

Re: What is wrong. See pic June 27, 2013 06:01PM |

Registered: 11 years ago Posts: 342 |

I would start by repeating E step calibration. When I switch from PLA to ABS I had to change mine. Thus far switching rolls of PLA seems to have been taken care of by the filament diameter setting in my slicer. As I understand it you should do prints to check E steps with every new roll of filament.

To change firmware settings on the fly you will need to learn gcode. You type them into the terminal of your printer host software.

To change firmware settings on the fly you will need to learn gcode. You type them into the terminal of your printer host software.

|

Re: What is wrong. See pic June 28, 2013 09:11AM |

Registered: 11 years ago Posts: 265 |

Quote

Is it possible to also change extrusion rate, acceleration rate, change layer height?

Extrusion Rate can be adjust by changing ESteps/mm "M92 Ennn"

Acceleration Rate could probably be changed as well.

Layer Height can't be changed on the fly. That's something that's generated when the GCode is created.

Changing ESteps/mm on the Z in attempt to fake it, would be a mess.

|

Re: What is wrong. See pic July 04, 2013 04:27AM |

Registered: 12 years ago Posts: 86 |

This one is driving me crazy.

Temperature makes no difference.

Extrusion rate makes no difference.

Layer height makes no difference.

Fillament makes no difference ( 3 different colors from bilbyCNC)

I have found that areas with less than about 50mm straight runs of the hotend have no issue.

It's when the run is long that I have the issue. You can see the last strip of fillament curl up before the next strip is put down beside it.

I have put a big hole in the center of my print that has let me print fine.

At this point I am going to try another fillament from another supplier. I figure Natural PLA should be the best for this test. This is the first print I have tried with large layer surface area.

As a backup.. Can anyone reccomend what way to go for hotend/extruder setup

On my prusa. I'm currently running a Greg's accessible with mkIv jhead. Although it has been a success it has always required a lot of force to push filament through. I'm thinking ill put together a complete extruder/thermistor/heater ready to snap on.

Temperature makes no difference.

Extrusion rate makes no difference.

Layer height makes no difference.

Fillament makes no difference ( 3 different colors from bilbyCNC)

I have found that areas with less than about 50mm straight runs of the hotend have no issue.

It's when the run is long that I have the issue. You can see the last strip of fillament curl up before the next strip is put down beside it.

I have put a big hole in the center of my print that has let me print fine.

At this point I am going to try another fillament from another supplier. I figure Natural PLA should be the best for this test. This is the first print I have tried with large layer surface area.

As a backup.. Can anyone reccomend what way to go for hotend/extruder setup

On my prusa. I'm currently running a Greg's accessible with mkIv jhead. Although it has been a success it has always required a lot of force to push filament through. I'm thinking ill put together a complete extruder/thermistor/heater ready to snap on.

|

Re: What is wrong. See pic July 04, 2013 09:26AM |

Registered: 11 years ago Posts: 265 |

Need more pictures,

What you picture is showing and what you are describing doesn't really make any sense.

If you are talking about curling up of layers and the hotend running into it, then you have a cooling problem.

The layer below isn't cool enough before you attempt to print the next layer. Place a fan on the part being printed.

If the first layer is curling up, then you have a sticking to the bed problem.

What you picture is showing and what you are describing doesn't really make any sense.

If you are talking about curling up of layers and the hotend running into it, then you have a cooling problem.

The layer below isn't cool enough before you attempt to print the next layer. Place a fan on the part being printed.

If the first layer is curling up, then you have a sticking to the bed problem.

|

Re: What is wrong. See pic July 04, 2013 04:03PM |

Registered: 12 years ago Posts: 86 |

Waiting on a USB microscope cam from china.

I need to describe it better for sure.

I had tried adding a second cooling fan, printing at the hottest temps (pla smoking) , coldest temps (as low as possible before extruder slipping), lowering bed temp to min temp possible before it doesn't hold to bed.

I am able to print well as long as area of solid infill is not large.

If I watch solid infill being layed down one 'stroke' at a time, I can see that short (<50mm) strokes have no problem.

If the stroke is long, by the time the the hotend moves to lay another stroke next to it the already layed stroke is curling up slightly at the edge.

When I get some macro images it will be clear what I'm describing. The only thing I can think is maybe my hotend is damaged/fouled slightly, or something is up with all my supplied pla (I think unlikely).

In between pmy failed large prints I can print pretty fine prints at .1 with no over extrusion or quality issues.

I don't believe it's a ramping speed/extrusion issue because hotend speed is pretty much ramped up after 10mm as far as I see it.

Running marlin at 50mm/s for infill. Reduced from 60mm/s for testing.

I need to describe it better for sure.

I had tried adding a second cooling fan, printing at the hottest temps (pla smoking) , coldest temps (as low as possible before extruder slipping), lowering bed temp to min temp possible before it doesn't hold to bed.

I am able to print well as long as area of solid infill is not large.

If I watch solid infill being layed down one 'stroke' at a time, I can see that short (<50mm) strokes have no problem.

If the stroke is long, by the time the the hotend moves to lay another stroke next to it the already layed stroke is curling up slightly at the edge.

When I get some macro images it will be clear what I'm describing. The only thing I can think is maybe my hotend is damaged/fouled slightly, or something is up with all my supplied pla (I think unlikely).

In between pmy failed large prints I can print pretty fine prints at .1 with no over extrusion or quality issues.

I don't believe it's a ramping speed/extrusion issue because hotend speed is pretty much ramped up after 10mm as far as I see it.

Running marlin at 50mm/s for infill. Reduced from 60mm/s for testing.

|

Re: What is wrong. See pic July 04, 2013 09:21PM |

Registered: 11 years ago Posts: 1,592 |

Are your prints curling up from the glass bed? If so, check your layer height is between .05 and .1mm. A piece of copy paper slid underneath the nozzle should be gripped a little whereas a supermarket receipt should slide under comfortably with only the slightest resistance. Also, rub your glass vigorously with a dry tissue prior to printing.

_______________________________________

Waitaki 3D Printer

_______________________________________

Waitaki 3D Printer

|

Re: What is wrong. See pic July 18, 2013 12:12PM |

Registered: 12 years ago Posts: 86 |

Sorry, only registered users may post in this forum.