Home

>

Reprappers

>

Topic

Bed height adjustment when homing to the top

Posted by fr

|

Bed height adjustment when homing to the top January 11, 2014 05:04PM |

Registered: 10 years ago Posts: 15 |

Hi everyone,

I'm currently building my own printer (due to not having a 3d printer and wanting slightly larger rails, it consists entirely of non-printed parts), but after finally being able to give it an initial test run, I'm a bit puzzled about endstops and their setup. I'm using the Marlin firmware and set the printer to home to the top. This, I thought, would be much more convenient since the endstop could then be installed at the top of the printer permanently and never be moved. However, I clearly overlooked the implications this has on setting the bed height. If I understand correctly, on normal RepRaps, the endstop is at the bottom and can be placed so the extruder nozzle achieves just the right height above the printing surface when the endstop is triggered. How do I go about this when I have my endstop at the top? Of course the position of the top endstop can also be adjusted, but this will be incredibly annoying as there will be no immediate feedback about the extruder height. I could measure the exact height and input the exact setting into the firmware, but this will be an enormous hassle with slightly different bed heights. Do you have any suggestions on how to deal with this problem in an elegant fashion? If all else fails, I can of course always build and add a lower endstop.

I'm currently building my own printer (due to not having a 3d printer and wanting slightly larger rails, it consists entirely of non-printed parts), but after finally being able to give it an initial test run, I'm a bit puzzled about endstops and their setup. I'm using the Marlin firmware and set the printer to home to the top. This, I thought, would be much more convenient since the endstop could then be installed at the top of the printer permanently and never be moved. However, I clearly overlooked the implications this has on setting the bed height. If I understand correctly, on normal RepRaps, the endstop is at the bottom and can be placed so the extruder nozzle achieves just the right height above the printing surface when the endstop is triggered. How do I go about this when I have my endstop at the top? Of course the position of the top endstop can also be adjusted, but this will be incredibly annoying as there will be no immediate feedback about the extruder height. I could measure the exact height and input the exact setting into the firmware, but this will be an enormous hassle with slightly different bed heights. Do you have any suggestions on how to deal with this problem in an elegant fashion? If all else fails, I can of course always build and add a lower endstop.

|

Re: Bed height adjustment when homing to the top January 12, 2014 04:13AM |

Registered: 11 years ago Posts: 349 |

Nophead explained homing to the top. Its been a while since i read his article but give it a read, it might help. [hydraraptor.blogspot.co.uk]

|

Re: Bed height adjustment when homing to the top January 12, 2014 10:56AM |

Registered: 10 years ago Posts: 541 |

Nophead's Mendel90 design uses top Z homing and it works well.

The calibration procedure is as follows:

1) Establish an initial known Z Home position in the firmware (for the Mendel90 kit this is 203.0mm).

2) Home the printer.

3) Place a known-height object onto the bed and lower the nozzle until it just touches the object.

4) Use M114 to report the printer position and note the Z height.

5) Modify the firmware Z Home position from step (1) to compensate for real and reported Z height from step (4).

This procedure only needs to be repeated after levelling the bed or changing the heated bed glass plate.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

The calibration procedure is as follows:

1) Establish an initial known Z Home position in the firmware (for the Mendel90 kit this is 203.0mm).

2) Home the printer.

3) Place a known-height object onto the bed and lower the nozzle until it just touches the object.

4) Use M114 to report the printer position and note the Z height.

5) Modify the firmware Z Home position from step (1) to compensate for real and reported Z height from step (4).

This procedure only needs to be repeated after levelling the bed or changing the heated bed glass plate.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Bed height adjustment when homing to the top January 12, 2014 11:55AM |

Registered: 10 years ago Posts: 15 |

Thanks for the explanations! My bed is not installed yet, so unfortunately I can't try it out. Am I correct in undestanding that the firmware needs to be changed each time the bed is levelled? From what I've read so far, at least the Prusa 2 needs to be levelled quite often. I chose a sturdier design based on aluminium extrusions. Is frequently having to level the bed (and thus upload a new firmware configuration) an actual problem during operation or will the need to level the bed arise relatively infrequently? Further enlightenment on this will be greatly appreciated!

|

Re: Bed height adjustment when homing to the top January 12, 2014 04:22PM |

Registered: 10 years ago Posts: 541 |

It is likely that levelling the bed will move the Z=0 value. This should not need to be done often for a rigid-design machine which is not moved.

Another option that some people have used is to set the Z=0 value a little above the bed surface and then set a negative Z offset in either the slicer or firmware by using a specific GCode.

I just recalibrate Z height and reload my Mendel90 firmware after bed levelling or replacing the glass. It is infrequent and not too difficult a procedure.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 01/12/2014 04:23PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Another option that some people have used is to set the Z=0 value a little above the bed surface and then set a negative Z offset in either the slicer or firmware by using a specific GCode.

I just recalibrate Z height and reload my Mendel90 firmware after bed levelling or replacing the glass. It is infrequent and not too difficult a procedure.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 01/12/2014 04:23PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Bed height adjustment when homing to the top January 13, 2014 02:21AM |

Registered: 11 years ago Posts: 349 |

You don't need to reload firmware to adjust the z travel. It can be done using gcode

M208: set axis max travel

Example: M208 X250 Y210 Z180

The values specified set the software limits for axis travel in the positive direction.

With Marlin firmware, this value can be saved to EEPROM using the M500 command.

M208: set axis max travel

Example: M208 X250 Y210 Z180

The values specified set the software limits for axis travel in the positive direction.

With Marlin firmware, this value can be saved to EEPROM using the M500 command.

|

Re: Bed height adjustment when homing to the top January 13, 2014 07:28PM |

Registered: 10 years ago Posts: 474 |

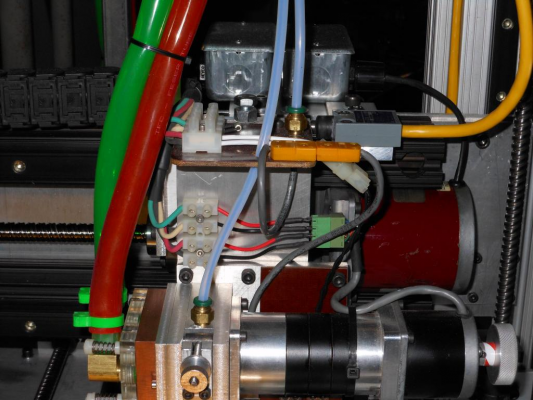

The way I got around this was to mount my extruder on a vertical slide independent of the Z axis so I could get it close leave it alone in software and firmware any adjustments for different nozzles or more squish on first layer is adjusted with a fine thread bolt and nut that moves extruder up-and-down after I send Z to zero

Edited 1 time(s). Last edit at 01/13/2014 08:20PM by cnc dick.

Edited 1 time(s). Last edit at 01/13/2014 08:20PM by cnc dick.

Sorry, only registered users may post in this forum.