Home

>

Reprappers

>

Topic

First build - e3d v6 hotend with wade extruder

Posted by riko47

|

First build - e3d v6 hotend with wade extruder February 27, 2015 08:31PM |

Registered: 9 years ago Posts: 9 |

Hi, first time building a 3d printer and got some questions about hotends and extruders.

I'm choosing between J-Head Mk V-BV and e3d v6, I want to try to print flexible materials, pla and abs and maybe try nylon. But from what i've heard you need to have a full metal hotend that can reach higher temperatures to print different materials besides abs and pla.

Is there any difficulty getting a full metal hotend instead of a J-head. I don't see any reason why not to get the e3d or is there something i've missed?

The 3d printer model is going to be a wilson. I'm going to have a wade extruder so is it possible to fit e3d v6 (direct) or bowden version on it? If you can, do you need to make any changes to the hotend or the extruder?

If there are any other factors, or Pros/Cons that I have missed, please let me know!

I'll go for the 5 nema 17 1.8a (17HS8401) but their weight are 400g. Would it be better to go for 1 1.7a (17HS4401) on the wade extruder, because the weight difference between them are 120g, and 4 nema 1.8 for the x,y,z.

Thanks

Edited 2 time(s). Last edit at 02/27/2015 09:40PM by riko47.

I'm choosing between J-Head Mk V-BV and e3d v6, I want to try to print flexible materials, pla and abs and maybe try nylon. But from what i've heard you need to have a full metal hotend that can reach higher temperatures to print different materials besides abs and pla.

Is there any difficulty getting a full metal hotend instead of a J-head. I don't see any reason why not to get the e3d or is there something i've missed?

The 3d printer model is going to be a wilson. I'm going to have a wade extruder so is it possible to fit e3d v6 (direct) or bowden version on it? If you can, do you need to make any changes to the hotend or the extruder?

If there are any other factors, or Pros/Cons that I have missed, please let me know!

I'll go for the 5 nema 17 1.8a (17HS8401) but their weight are 400g. Would it be better to go for 1 1.7a (17HS4401) on the wade extruder, because the weight difference between them are 120g, and 4 nema 1.8 for the x,y,z.

Thanks

Edited 2 time(s). Last edit at 02/27/2015 09:40PM by riko47.

|

Re: First build - e3d v6 hotend with wade extruder February 27, 2015 09:58PM |

Registered: 11 years ago Posts: 805 |

if you have the money go e3d its worth it, although a original j head isnt cheap either. the less ptfe you have in the mix the better. as a beginner take the direct extruder. there are some errors and imprecision that are easier to spot with direct extruders, but you printer mainly dictates what extruder you have to use.

for motors get a strong one for the extruder and dont forget to adjust the driver for it.

for motors get a strong one for the extruder and dont forget to adjust the driver for it.

|

Re: First build - e3d v6 hotend with wade extruder February 27, 2015 10:08PM |

Registered: 9 years ago Posts: 9 |

What's ptfe?

I'm going to have a Wade extruder. But will the e3d (direct) support The Wade extruder mount?

You think i should go for a stronger nema motor on the printhead even if it adds 120g? Do you need that much power on the extruder?

Is it better to go for even stronger motors?

Edited 2 time(s). Last edit at 02/28/2015 04:06AM by riko47.

I'm going to have a Wade extruder. But will the e3d (direct) support The Wade extruder mount?

You think i should go for a stronger nema motor on the printhead even if it adds 120g? Do you need that much power on the extruder?

Is it better to go for even stronger motors?

Edited 2 time(s). Last edit at 02/28/2015 04:06AM by riko47.

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 05:27AM |

Registered: 9 years ago Posts: 1,011 |

With a Wade extruder, you'll get enough torque even with a 30mm motor. It's a good choice. Don't choose a bowden, you won't be able to print flexible filaments and you could even have issues with nylon. What you realy need is an extruder with a gap free filament driving. Like so :

And not like so :

Actualy I use the skarab extruder, compatible with E3D Hotends : Skarab geared extruder.

The E3D V6 is a great hotend that needs to be perfectly cooled. Don't save on the fan, the bigger flow, the better. Some heatbreak uses a PTFE tubing in the barrel, that reduces friction. Actualy, I changed the E3D original for a PTFE intubing one. It works better for ABS too. BUT it could make problems if temperature raise over 250°C. I never print over that temperature so I keep my PTFE intubing heatbreak. If I had to print over 250°C, I'll go back to the full metal heatbreak.

Some heatbreaks with PTFE tubing :

Edited 1 time(s). Last edit at 02/28/2015 05:31AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

And not like so :

Actualy I use the skarab extruder, compatible with E3D Hotends : Skarab geared extruder.

The E3D V6 is a great hotend that needs to be perfectly cooled. Don't save on the fan, the bigger flow, the better. Some heatbreak uses a PTFE tubing in the barrel, that reduces friction. Actualy, I changed the E3D original for a PTFE intubing one. It works better for ABS too. BUT it could make problems if temperature raise over 250°C. I never print over that temperature so I keep my PTFE intubing heatbreak. If I had to print over 250°C, I'll go back to the full metal heatbreak.

Some heatbreaks with PTFE tubing :

Edited 1 time(s). Last edit at 02/28/2015 05:31AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 09:14AM |

Registered: 9 years ago Posts: 9 |

I've taken a look at the Skarab geared extruder and thought it looked amazing. The thing is that i'm going to buy a 3d prined parts set (Aliexpress) for my printer and it will come a wade extruder with it. So would it be possible to just attach the e3d to wade extruder and later 3d print the Skarab parts?

Also you talked about the importance of cooling, what exactly are you cooling? The hotend cool part, hotend heated part or the 3d printed object? The e3d comes with a standard fan mount and fan + i'll add a turbine that will be pointing down at the parts it's printing.

Also you talked about the importance of cooling, what exactly are you cooling? The hotend cool part, hotend heated part or the 3d printed object? The e3d comes with a standard fan mount and fan + i'll add a turbine that will be pointing down at the parts it's printing.

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 01:36PM |

Registered: 9 years ago Posts: 1,011 |

Hi again  So I looked at your parts, and I not able to confirm you can mount a E3D v6 even temporary. I mean It looks like you could, but I cannot be sure at 100%. Maybe you could ask the seller ?

So I looked at your parts, and I not able to confirm you can mount a E3D v6 even temporary. I mean It looks like you could, but I cannot be sure at 100%. Maybe you could ask the seller ?

When I was talking about cooling, it was to cool the coldend part, the heatsink if you like. With the provided small fan provided by E3D (30x30x10mm), some people noticed the 2 first wings near the hotend are sometimes too hot. The heatsink must stay cold. On my machine I mounted a 40x40x20mm fan. And working or not, the heatsink stays at ambient temperature. That's what you want.

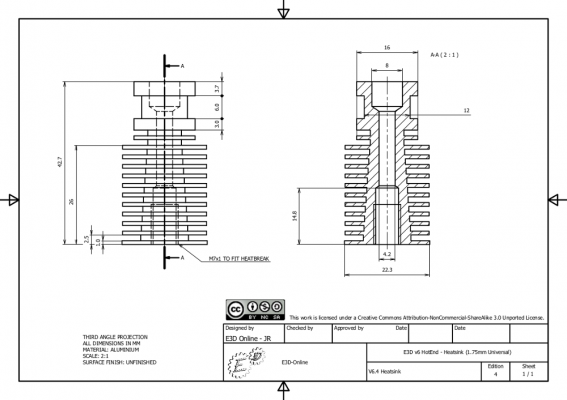

The E3D V6 heatsink :

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

So I looked at your parts, and I not able to confirm you can mount a E3D v6 even temporary. I mean It looks like you could, but I cannot be sure at 100%. Maybe you could ask the seller ?

So I looked at your parts, and I not able to confirm you can mount a E3D v6 even temporary. I mean It looks like you could, but I cannot be sure at 100%. Maybe you could ask the seller ?When I was talking about cooling, it was to cool the coldend part, the heatsink if you like. With the provided small fan provided by E3D (30x30x10mm), some people noticed the 2 first wings near the hotend are sometimes too hot. The heatsink must stay cold. On my machine I mounted a 40x40x20mm fan. And working or not, the heatsink stays at ambient temperature. That's what you want.

The E3D V6 heatsink :

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 01:47PM |

Registered: 9 years ago Posts: 1,159 |

You can mount a E3D V6 to a Wades but I would suggest you drill the filament guide in the wades body to 4mm and pass the PTFE tube all the way from the Hobbed Bolt to the Heatbreak you will also need a washer to tighten the space above the E3d and between the wades recess (about .7mm thick IIRC if you need I can strip mine out and measure it) you will also want to remove the plastic Bowden clip.

Mine works well in this very same setup

However you may want to make sure the Wades is printed in ABS.

HTH Doug

Mine works well in this very same setup

However you may want to make sure the Wades is printed in ABS.

HTH Doug

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 02:51PM |

Registered: 9 years ago Posts: 9 |

In the part kit it says ABS parts? Yes it looks so. I've also read alittle about hos to attach the e3d with a Wade extruder and came to the same conclusion, you can never be to sure.

Should I run the e3d with the stock fan or buy another?

Any ideas about best nema motors? I've already said which nema motor model I'm choosing, but is this model the best to run a printer with? And should I really add 120g to the extruder for a stronger motor?

Should I run the e3d with the stock fan or buy another?

Any ideas about best nema motors? I've already said which nema motor model I'm choosing, but is this model the best to run a printer with? And should I really add 120g to the extruder for a stronger motor?

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 03:54PM |

Registered: 9 years ago Posts: 1,159 |

Quote

riko47

In the part kit it says ABS parts? Yes it looks so. I've also read alittle about hos to attach the e3d with a Wade extruder and came to the same conclusion, you can never be to sure.

Should I run the e3d with the stock fan or buy another?

Any ideas about best nema motors? I've already said which nema motor model I'm choosing, but is this model the best to run a printer with? And should I really add 120g to the extruder for a stronger motor?

I will check my motor for you tomorrow but it isn't a big one the stock fan is absolutely fine even with the largest nozzle they do (0.8mm).

Will put my otor on it in the morning for you?

Doug

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 04:02PM |

Registered: 9 years ago Posts: 9 |

|

Re: First build - e3d v6 hotend with wade extruder February 28, 2015 05:04PM |

Registered: 9 years ago Posts: 1,011 |

You can use a 40mm nema 17 (17HS4401) for the extruder. The way it's geared multiply the torque of the motor output.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: First build - e3d v6 hotend with wade extruder March 01, 2015 03:07AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: First build - e3d v6 hotend with wade extruder March 01, 2015 06:20AM |

Registered: 9 years ago Posts: 9 |

|

Re: First build - e3d v6 hotend with wade extruder March 01, 2015 06:28AM |

Registered: 9 years ago Posts: 1,159 |

Riko

Where are you try looking at Stepper motors These are what I am using on my current Build Low Current High Torque motors.

Doug

Where are you try looking at Stepper motors These are what I am using on my current Build Low Current High Torque motors.

Doug

|

Re: First build - e3d v6 hotend with wade extruder March 01, 2015 07:49AM |

Registered: 9 years ago Posts: 9 |

|

Re: First build - e3d v6 hotend with wade extruder March 01, 2015 08:08AM |

Registered: 9 years ago Posts: 1,011 |

Quote

Zavashier

For lazy people : the lenght of the motor is linked with available torque, your required torque depends of the efforts the motor will hold. Then look at the inductance, the lower, the better.

The choice of the motor is the result of a calculation for a specific situation. I won't explain the calculation procedure here. A lot of manufacturers give stepper motors selection guides. (It's easy if you try). So all depends of the machine itself and of what is expected. My advice, don't ask for someone to do your shopping, ask for knowledge (or where to get it). Get some skills.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: First build - e3d v6 hotend with wade extruder March 01, 2015 09:04AM |

Registered: 9 years ago Posts: 9 |

|

Re: First build - e3d v6 hotend with wade extruder March 01, 2015 12:00PM |

Registered: 9 years ago Posts: 1,011 |

DRV 8825 max power is 2.2A as standard. With heatsink and ventilation it's 2.5A.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Sorry, only registered users may post in this forum.