Home

>

Reprappers

>

Topic

Rough 1st print job

Posted by mivison

|

Rough 1st print job March 01, 2015 08:50PM |

Registered: 9 years ago Posts: 8 |

|

Re: Rough 1st print job March 02, 2015 01:12PM |

Registered: 10 years ago Posts: 1,401 |

Stepper motors been either underpowered or overpower, belts not tight enough, or Z wobbling.

Most likely is that you haven't adjust the trim pots on the stepper drivers.

Maybe is the picture, but it looks like you are having also some temperature fluctuations, be sure your thermistor is secure in place.

One last thing since you mentioned ABS, what temperature are you printing at and are you protecting the printer from cold air drafts? .

Edited 1 time(s). Last edit at 03/02/2015 01:17PM by ggherbaz.

Most likely is that you haven't adjust the trim pots on the stepper drivers.

Maybe is the picture, but it looks like you are having also some temperature fluctuations, be sure your thermistor is secure in place.

One last thing since you mentioned ABS, what temperature are you printing at and are you protecting the printer from cold air drafts? .

Edited 1 time(s). Last edit at 03/02/2015 01:17PM by ggherbaz.

|

Re: Rough 1st print job March 04, 2015 06:35PM |

Registered: 9 years ago Posts: 8 |

|

Re: Rough 1st print job March 04, 2015 07:02PM |

Registered: 9 years ago Posts: 33 |

|

Re: Rough 1st print job March 05, 2015 05:28PM |

Registered: 9 years ago Posts: 8 |

My folger i3 prints exactly the same patterns. I'm suspecting my extruder motor as I can physically feel and see it pulse slightly. I'm working on changing the hot end and direct drive setup at the moment, if that doesn't help I might try a high torque motor. I honestly don't know if there's anything in the firmware that would help but adjusting current didn't do anything for me.

|

Re: Rough 1st print job March 05, 2015 09:08PM |

Registered: 9 years ago Posts: 8 |

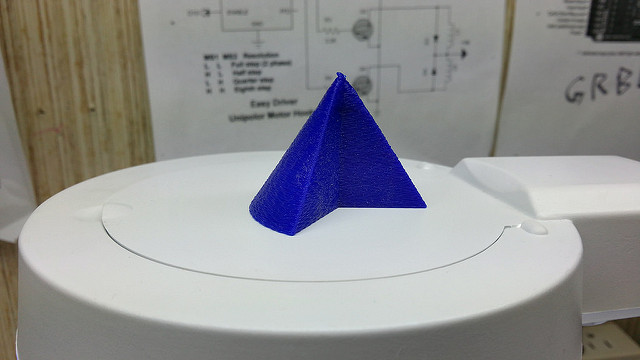

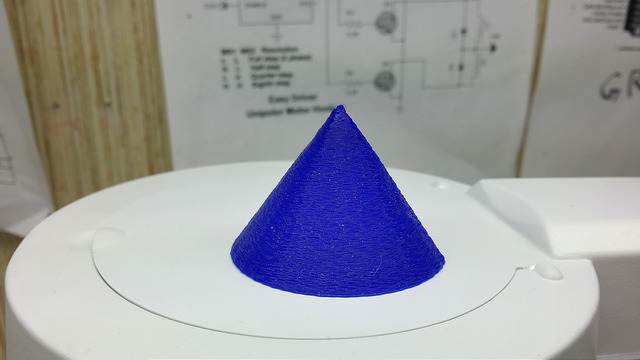

i changed from printing ABS to PLA. i also tweeked slis3r a little and the printing improved some. click on the pictures to zoom in. @nitrhog, what extruder head are you looking at? i too would love to upgrade.

Folger prints by mivison1, on Flickr

Folger prints by mivison1, on Flickr

Edited 1 time(s). Last edit at 03/05/2015 09:10PM by mivison.

Folger prints by mivison1, on Flickr

Folger prints by mivison1, on Flickr

Edited 1 time(s). Last edit at 03/05/2015 09:10PM by mivison.

|

Re: Rough 1st print job March 06, 2015 12:04AM |

Registered: 9 years ago Posts: 8 |

I'm gonna give the knockoff eBay e3d hot ends a go. The plan is to keep the direct drive setup, specifically this one [www.thingiverse.com] .

|

Re: Rough 1st print job March 06, 2015 11:21AM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Rough 1st print job March 08, 2015 08:35PM |

Registered: 9 years ago Posts: 8 |

I have the hot end sitting on my kitchen table and my untrained eye says it looks pretty good for $25. Nice machine work, ptfe liner in the heat brake, etc. The next thing that I learned is that you can get 1/32 stepping out of a drv8825 stepper driver. I just ordered one to play around with, it couldn't hurt for the $6 that I spent on it.

|

Re: Rough 1st print job March 09, 2015 12:44AM |

Registered: 10 years ago Posts: 1,401 |

Quote

nitrohog

ptfe liner in the heat brake

that's not a good idea for an "All" metal hotend, it will limit your max temp to under 250. it will definitely smooth PLA printing but neglect you from printing with high temp materials. The PTFE liner should go only "if needed" in the Aluminum heat-sink part and only connect with the top of the heat brake barrel for a smooth transition, and not going all the way down to the heater block.

Yes it is cheap and "if" properly set will be as good as the original e3d.

There is a very good video in youtube about it and how to set them right.

|

Re: Rough 1st print job March 09, 2015 09:56AM |

Registered: 9 years ago Posts: 8 |

|

Re: Rough 1st print job March 10, 2015 10:48AM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Rough 1st print job March 10, 2015 01:35PM |

Registered: 9 years ago Posts: 8 |

A small update on my experimenting. I installed the hot end, mk8 extruder drive gear, and new brackets. I still have to fine tune everything but the prints seem to be much smoother. I have a feeling that the mk8 gears smaller diameter may have more to do with the improved prints then the extruder itself but I will say the hot end is a definite improvement with reduced stringing.

Sorry, only registered users may post in this forum.