Home

>

Reprappers

>

Topic

Over extrusion with RepRapFirmware + Slic3r

Posted by biocomp

|

Over extrusion with RepRapFirmware + Slic3r September 07, 2016 03:37PM |

Registered: 8 years ago Posts: 9 |

Hello.

Sorry for this likely silly question, but I can't seem to be able to figure this out.

I have an over-extrusion problem:

Not only I have bulges all over the place, but the item dimensions are larger (like 2.5mm instead of 2.2 for height, or 5.3mm instead of 5.0 for width), and holes are much smaller than needed (say, 2.4mm instead of 3.0).

I followed this guide to calibrate my e-steps: [reprap.org]. After I follow the first part of e-steps calibration (where I measure how much is extruded and adjust e-steps accordingly), I get exactly 100mm extruded with or w/o hot end. I get something like 720 steps/mm.

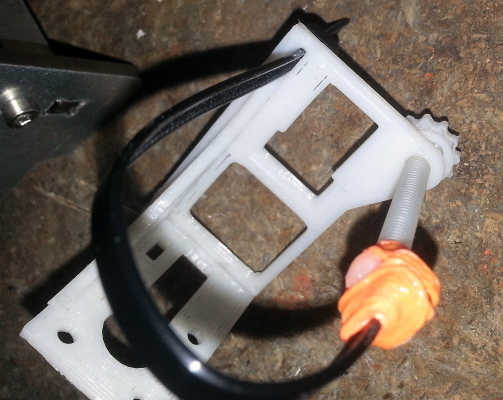

But when I try printing, I get over-extrusion. Then if I try toning down the steps as the "polishing" part of the guide says, I lower it to ~620 steps/mm, then prints are looking better, but I get under-extrusion like this (see the gaps between some walls):

.

And still, part height is a bit higher, and holes are still a bit smaller than I need them to be.

My question is - am I missing something obvious? Some setting (in slic3r or RepRapFirmware) maybe? The "fine-tuning" should not bring 720 steps to 620 as far as I understand.

I think I set up my nozzle size, filament sizes correctly, and x,y,z movements are likely OK.

I have wade-style extruder, Duet with dc42's fork of RepRapFirmware, e3d v6 all metal hotend, and printer assembled from Prusa i3 Steel kit, and slicing with slic3r.

Thanks for the help!

Sorry for this likely silly question, but I can't seem to be able to figure this out.

I have an over-extrusion problem:

Not only I have bulges all over the place, but the item dimensions are larger (like 2.5mm instead of 2.2 for height, or 5.3mm instead of 5.0 for width), and holes are much smaller than needed (say, 2.4mm instead of 3.0).

I followed this guide to calibrate my e-steps: [reprap.org]. After I follow the first part of e-steps calibration (where I measure how much is extruded and adjust e-steps accordingly), I get exactly 100mm extruded with or w/o hot end. I get something like 720 steps/mm.

But when I try printing, I get over-extrusion. Then if I try toning down the steps as the "polishing" part of the guide says, I lower it to ~620 steps/mm, then prints are looking better, but I get under-extrusion like this (see the gaps between some walls):

.

And still, part height is a bit higher, and holes are still a bit smaller than I need them to be.

My question is - am I missing something obvious? Some setting (in slic3r or RepRapFirmware) maybe? The "fine-tuning" should not bring 720 steps to 620 as far as I understand.

I think I set up my nozzle size, filament sizes correctly, and x,y,z movements are likely OK.

I have wade-style extruder, Duet with dc42's fork of RepRapFirmware, e3d v6 all metal hotend, and printer assembled from Prusa i3 Steel kit, and slicing with slic3r.

Thanks for the help!

|

Re: Over extrusion with RepRapFirmware + Slic3r September 07, 2016 03:45PM |

Registered: 10 years ago Posts: 14,672 |

In my experience, every filament that I print with needs a different extrusion factor. I leave the steps/mm alone and adjust the extrusion factor slider in the web interface to suit the filament that I am printing with. It may be partly to do with the filament diameter not being exactly 1.75mm every time, but I think a lot of it is just differences in the chemical composition of the filament, which affects the viscosity and hence the extrusion profile.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Over extrusion with RepRapFirmware + Slic3r September 07, 2016 04:32PM |

Registered: 8 years ago Posts: 9 |

|

Re: Over extrusion with RepRapFirmware + Slic3r September 07, 2016 05:34PM |

Registered: 10 years ago Posts: 14,672 |

An extrusion factor of 0.88 seems rather low to me, I think the lowest I have had to use is 0.92.

Have you measured the filament with calipers, to check that it is close to 1.75mm (or 3mm), and round?

Small holes in the XY plane always come out smaller than you ask for. There are posts that go into this effect in great length. Selecting "External perimeters first" in the slicer reduces this effect, but doesn't eliminate it.

Edited 1 time(s). Last edit at 09/07/2016 05:36PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Have you measured the filament with calipers, to check that it is close to 1.75mm (or 3mm), and round?

Small holes in the XY plane always come out smaller than you ask for. There are posts that go into this effect in great length. Selecting "External perimeters first" in the slicer reduces this effect, but doesn't eliminate it.

Edited 1 time(s). Last edit at 09/07/2016 05:36PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Over extrusion with RepRapFirmware + Slic3r September 08, 2016 02:41AM |

Registered: 8 years ago Posts: 9 |

|

Re: Over extrusion with RepRapFirmware + Slic3r September 08, 2016 05:47AM |

Registered: 8 years ago Posts: 9 |

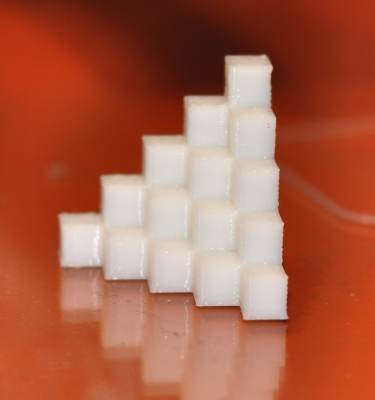

Hmm... so I set filament size to 1.77, reduced number min of perimeters (was set to 5 in slic3r, which caused small parts to consist of mostly perimeters). Then I only needed to set extrusion factor to 0.96, and got my best ever 5mm calibration steps!

Note that I did not print that many of them.

Thanks for the hint!

Note that I did not print that many of them.

Thanks for the hint!

|

Re: Over extrusion with RepRapFirmware + Slic3r September 08, 2016 07:40AM |

Registered: 10 years ago Posts: 14,672 |

I'm glad you solved the problem. An extrusion factor of 0.96 is about right for typical PLA filaments in my experience. I've only needed to use a figure greater than 1.0 on one filament - maybe that one was under-size.

I normally use 2 perimeters.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I normally use 2 perimeters.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.