Folger Tech Acrylic Prusa i3 slic3r extrusion width

Posted by igel

|

Folger Tech Acrylic Prusa i3 slic3r extrusion width February 08, 2016 07:33PM |

Registered: 8 years ago Posts: 19 |

I had a FolgerTech Prusa i3 Acrylic Frame for about 5 months. Overall it's running great.

I just noticed a setting that has made a HUGE difference in my prints. They suggest setting the first layer extrusion width in Slic3r to 150%. But that means with a 0.2mm layer height its only going to be 0.3mm thick. But that is way lower than suggested on the RepRap calibration guide which says extrusion width should be > the nozzle diameter. So it should be set to at least 0.4mm thick. I changed the first layer extrusion width to 0.6mm thick and a 0.25mm layer height and the prints stick really well to the blue painters tape. I'm using Atomic Filament PLA.

Why do they suggest setting it at 150%??

I just noticed a setting that has made a HUGE difference in my prints. They suggest setting the first layer extrusion width in Slic3r to 150%. But that means with a 0.2mm layer height its only going to be 0.3mm thick. But that is way lower than suggested on the RepRap calibration guide which says extrusion width should be > the nozzle diameter. So it should be set to at least 0.4mm thick. I changed the first layer extrusion width to 0.6mm thick and a 0.25mm layer height and the prints stick really well to the blue painters tape. I'm using Atomic Filament PLA.

Why do they suggest setting it at 150%??

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 09, 2016 02:12PM |

Registered: 8 years ago Posts: 541 |

Quote

igel

I had a FolgerTech Prusa i3 Acrylic Frame for about 5 months. Overall it's running great.

I just noticed a setting that has made a HUGE difference in my prints. They suggest setting the first layer extrusion width in Slic3r to 150%. But that means with a 0.2mm layer height its only going to be 0.3mm thick. But that is way lower than suggested on the RepRap calibration guide which says extrusion width should be > the nozzle diameter. So it should be set to at least 0.4mm thick. I changed the first layer extrusion width to 0.6mm thick and a 0.25mm layer height and the prints stick really well to the blue painters tape. I'm using Atomic Filament PLA.

Why do they suggest setting it at 150%??

That is not 150% extrusion width. It is 150% of normal extrusion rate. Remember that your ZERO point should be about 0.1mm off of the bed, so if your layer height is 0.3 mm then you are extruding that first layer at 0.4 mm off of the bed, so you need some extra plastic to make sure you have good contact. Don't know about your 0.6 mm width????

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 09, 2016 04:50PM |

Registered: 8 years ago Posts: 19 |

This is from slic3r when I hover over layer width.

It says it is computed over layer height. That means it is a percentage of layer height!!

If the layer height is .2mm then 150% will be .2*1.5= 0.3mm!

Here is from the slic3r website

I see you have folgertech, have your prints been sticking to the bed?

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 09, 2016 11:02PM |

Registered: 8 years ago Posts: 541 |

Quote

igel

[attachment 72199 ScreenShot2016-02-09at4.44.56PM.png]

This is from slic3r when I hover over layer width.

It says it is computed over layer height. That means it is a percentage of layer height!!

If the layer height is .2mm then 150% will be .2*1.5= 0.3mm!

Here is from the slic3r website

[attachment 72200 ScreenShot2016-02-09at4.48.15PM.png]

I see you have folgertech, have your prints been sticking to the bed?

Hmmmm. I fail to see how the slicer could know how far away from the bed your nozzle is, which it must know in order to compute the amount of plastic to extrude. Yes, with my nozzle 0.1 mm away at Z home, and using PLA, I always get good adhesion with a 70 C bed and a little hair spray.

That's interesting as I always thought it was 150% of extrusion volume, which is the only thing that makes sense to me.

Set your slicer to Cura in Retetier and select Speed and Quality, look down at the bottom and click on First Layer Extrusion Width. It will say it increases the extrudate thereby making the line wider. If you want a line 150% wider, you need 50% more extrudate. With a 0.4 mm nozzle, ignoring swell, you're going to lay down a 0.4 mm wide bead unless you push out more plastic. If you push too much out, then you're going to have ripples that your nozzle might drag on when you lay down the next layer, if your layer height is small.

Edited 1 time(s). Last edit at 02/09/2016 11:13PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 10, 2016 10:37AM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 10, 2016 02:10PM |

Registered: 8 years ago Posts: 19 |

Quote

tjnamtiw

Quote

igel

[attachment 72199 ScreenShot2016-02-09at4.44.56PM.png]

This is from slic3r when I hover over layer width.

It says it is computed over layer height. That means it is a percentage of layer height!!

If the layer height is .2mm then 150% will be .2*1.5= 0.3mm!

Here is from the slic3r website

[attachment 72200 ScreenShot2016-02-09at4.48.15PM.png]

I see you have folgertech, have your prints been sticking to the bed?

Hmmmm. I fail to see how the slicer could know how far away from the bed your nozzle is, which it must know in order to compute the amount of plastic to extrude. Yes, with my nozzle 0.1 mm away at Z home, and using PLA, I always get good adhesion with a 70 C bed and a little hair spray.

That's interesting as I always thought it was 150% of extrusion volume, which is the only thing that makes sense to me.

Set your slicer to Cura in Retetier and select Speed and Quality, look down at the bottom and click on First Layer Extrusion Width. It will say it increases the extrudate thereby making the line wider. If you want a line 150% wider, you need 50% more extrudate. With a 0.4 mm nozzle, ignoring swell, you're going to lay down a 0.4 mm wide bead unless you push out more plastic. If you push too much out, then you're going to have ripples that your nozzle might drag on when you lay down the next layer, if your layer height is small.

Oh, I was using Slic3r I'm not sure about the Cura engine. Do you use Slic3r at all?

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 10, 2016 02:22PM |

Registered: 8 years ago Posts: 19 |

Do you use Slic3r.Quote

widespreaddeadhead

I have the acrylic FT i3 and I have no issues with bed adhesion on glass with hairspray. Printing for 1+ years now!

I had problems with adhesion and I had to use a brim to keep it down.

So you have the same printer I wanted to know if you have some of the same problems:

When the y axis moves all the way back it hits the zip ties on the y rod

also the y axis idler doesn't stay straight and wobbles any ideas?

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 11, 2016 10:23AM |

Registered: 9 years ago Posts: 251 |

Quote

igel

Do you use Slic3r.

I had problems with adhesion and I had to use a brim to keep it down.

So you have the same printer I wanted to know if you have some of the same problems:

When the y axis moves all the way back it hits the zip ties on the y rod

also the y axis idler doesn't stay straight and wobbles any ideas?

I do use Slic3r, it's the one I'm most familiar with. Let me comment on your first post after I read it again.

"They suggest setting the first layer extrusion width in Slic3r to 150%. But that means with a 0.2mm layer height its only going to be 0.3mm thick."

I think you might have your extrusion widths wrong. The Extrusion Width table should be set according to your nozzle size not your layer height. The relationship between nozzle size and extrusion width is 120%, so a nozzle of 0.40 x 120% = 0.48 extrusion width, this accounts for die-swell.

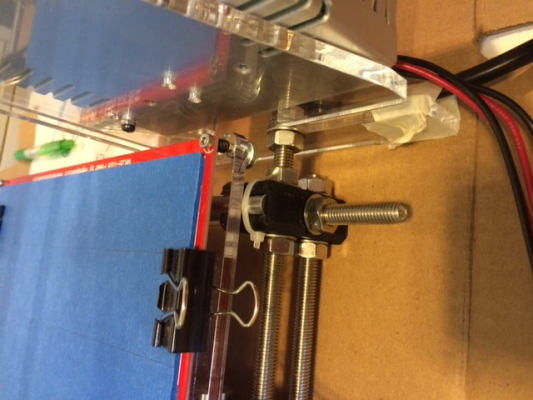

"When the y axis moves all the way back it hits the zip ties on the y rod"

If your y rods snapped into the 3d printed parts well with no play, you don't need the zip ties. Otherwise you could just cut off the excess after the locking part.

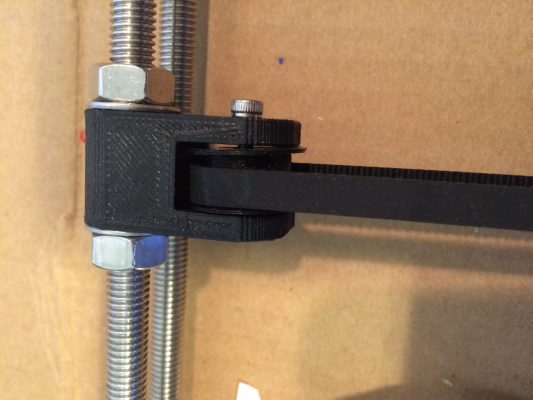

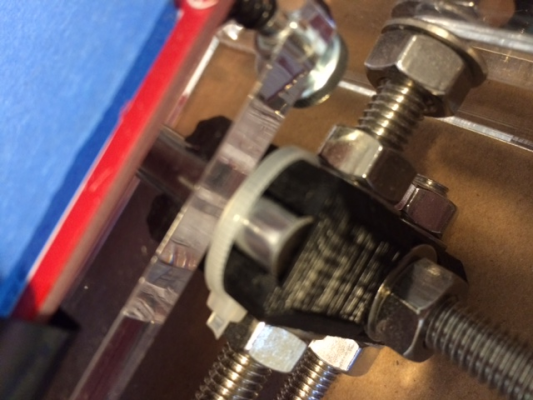

"also the y axis idler doesn't stay straight and wobbles any ideas?"

Just the pulley, or the whole idler? Make sure the belt is straight from the idler to the motor, and make sure it has the right amount of tension. You might want to search thingiverse for adjustable tension idlers, lots of models out there.

Edited 3 time(s). Last edit at 02/11/2016 01:56PM by widespreaddeadhead.

|

Re: Folger Tech Acrylic Prusa i3 slic3r extrusion width February 12, 2016 11:29AM |

Registered: 8 years ago Posts: 19 |

Here is a picture of the y idler

If you can see it is crooked and i tried adjusting the y motor and the belt looks like it will almost come off. Not sure what to do abot it

About the bed hitting the zip ties here is the pic

i have tried flipping over the plexiglass but it didnt help

the rods snapped in so maybe ill just remove the zip ties

about The extrusion width: in slic3r is over extrusion height:

To illustrate- if you are using Repetier and Slic3r in slicer settings->print settings-> advanced, change external perimeter to 150%. slice it and you will see in the beginning of the gcode that the external perimeter width is 0.3mm when . I am using a .2mm nozzle

If you can see it is crooked and i tried adjusting the y motor and the belt looks like it will almost come off. Not sure what to do abot it

About the bed hitting the zip ties here is the pic

i have tried flipping over the plexiglass but it didnt help

the rods snapped in so maybe ill just remove the zip ties

about The extrusion width: in slic3r is over extrusion height:

To illustrate- if you are using Repetier and Slic3r in slicer settings->print settings-> advanced, change external perimeter to 150%. slice it and you will see in the beginning of the gcode that the external perimeter width is 0.3mm when . I am using a .2mm nozzle

Sorry, only registered users may post in this forum.