Whats your calibration deviation?

Posted by Sash

|

Whats your calibration deviation? August 10, 2015 04:54AM |

Registered: 8 years ago Posts: 30 |

I have been using the auto bed compensation feature as my biuld platform is not level. I run it several times to increase the accuracy. But I never achieve a 0.000 convergence between the two figures. I am wondering if that is fairly typical?

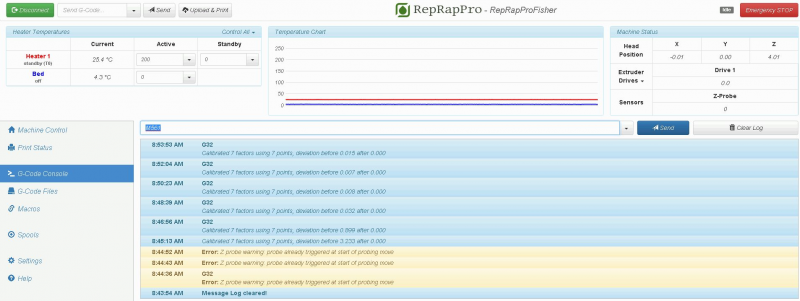

Here is my log showing each run, the smallest (best?) deviation was 0.007 but that last run jumped to 0.015. After this log I printed something that I am happy with so presumably a 0.000 deviation is not critical?

Here is my log showing each run, the smallest (best?) deviation was 0.007 but that last run jumped to 0.015. After this log I printed something that I am happy with so presumably a 0.000 deviation is not critical?

|

Re: Whats your calibration deviation? August 10, 2015 06:00AM |

Registered: 10 years ago Posts: 14,672 |

What you are seeing after the first two times you run G32 is the variation in trigger position of the homing microswitches and the bed probe switches. To see the contribution of each, take a copy of your bed.g file and change the S4 parameter on the final G30 command to S-1. When you run this, it will report the probe height errors, but not calibrate. Run it several times and see how reproducible they are. Then comment out the G28 command at the top of the file (so that it does not do homing), and run it several times again.

To get a good first layer when printing, I aim for a deviation no more than one quarter of my first layer height. I usually print at 0.2mm (not on a Fisher), so I aims for 0.05mm bed height precision.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

To get a good first layer when printing, I aim for a deviation no more than one quarter of my first layer height. I usually print at 0.2mm (not on a Fisher), so I aims for 0.05mm bed height precision.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Whats your calibration deviation? August 13, 2015 02:26AM |

Registered: 8 years ago Posts: 30 |

Quote

dc42

What you are seeing after the first two times you run G32 is the variation in trigger position of the homing microswitches and the bed probe switches. To see the contribution of each, take a copy of your bed.g file and change the S4 parameter on the final G30 command to S-1. When you run this, it will report the probe height errors, but not calibrate. Run it several times and see how reproducible they are. Then comment out the G28 command at the top of the file (so that it does not do homing), and run it several times again.

To get a good first layer when printing, I aim for a deviation no more than one quarter of my first layer height. I usually print at 0.2mm (not on a Fisher), so I aims for 0.05mm bed height precision.

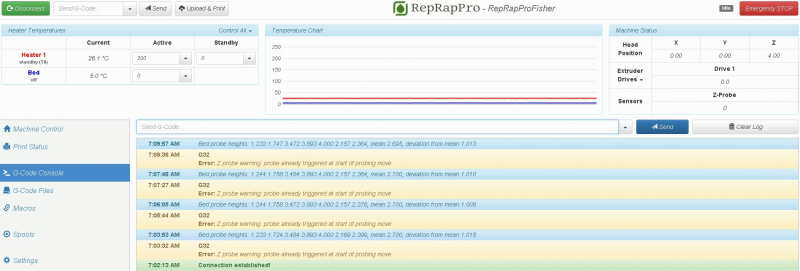

I had a go at using S-1. Because my printer doesn't home itself entirely on its own for some reason I have to move all three towers to the top and trigger the micro switches. From that point I can hit 'Home All' and it will complete the homing and drop down to the build platform. I then ran G32 several times and this is what I got?

At the moment when I want to use the printer I set the three towers to the top in a trigger position then complete 'Home All', run G32 several time until I have an okay bed height precision and try my luck at printing something. I have slowed down the motors in bed.g to prevent my build platform getting trashed the first couple of times I tun G32. Is there a way of adding this 7 point deviation data to the config.g? That way I might be able to speed up the process without risking my build platform.

|

Re: Whats your calibration deviation? August 13, 2015 03:53AM |

Registered: 8 years ago Posts: 68 |

You're homing problem is odd. With the carriages NOT at their home position, what response do you get from M119?

Edit: actually, having just seen your screenshot, it thinks that the bed sensor is already being probed?! What value does the Z sensor read when this message is shown? What is the trigger level set to in your config file?

Edited 1 time(s). Last edit at 08/13/2015 03:58AM by bluesign2k.

Edit: actually, having just seen your screenshot, it thinks that the bed sensor is already being probed?! What value does the Z sensor read when this message is shown? What is the trigger level set to in your config file?

Edited 1 time(s). Last edit at 08/13/2015 03:58AM by bluesign2k.

|

Re: Whats your calibration deviation? August 13, 2015 04:44AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Sash

I had a go at using S-1. Because my printer doesn't home itself entirely on its own for some reason I have to move all three towers to the top and trigger the micro switches. From that point I can hit 'Home All' and it will complete the homing and drop down to the build platform. I then ran G32 several times and this is what I got?

If the printer is not homing, check that your have the XYZ homing switches connected to the same channels on the Duet as the corresponding motors. You can test each tower independently. For example, if you send G91 followed by G1 S1 X10 then it should send the X carriage up 10mm, stopping if the X endstop is triggered. You can use M119 to check the endstop status.

I have my doubts about how the endstop switches are mounted on the Fisher. Most delta printers mount the switches horizontally and upside down, so that the carriages run into them. I find this gives highly reproducible results. On the Fischer, the sideways mounting arrangement looks to me that it needs a larger amount of carriage travel to cause the same amount of switch depression, which I suspect will make the trigger position more variable. If there isn't room to mount the switches horizontally without sacrificing too much build height, then US1881 Hall sensors along with magnets on the carriages would be an alternative.

Edited 1 time(s). Last edit at 08/13/2015 04:44AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Whats your calibration deviation? August 13, 2015 01:30PM |

Registered: 8 years ago Posts: 30 |

Quote

bluesign2k

You're homing problem is odd. With the carriages NOT at their home position, what response do you get from M119?

Edit: actually, having just seen your screenshot, it thinks that the bed sensor is already being probed?! What value does the Z sensor read when this message is shown? What is the trigger level set to in your config file?

Yeah, I have to manual activate the end stops using the carriages so that the homing cycle can complete.

Well 1000 is displayed briefly when triggered. I am using the config.g that came with the firmware download. It has a line that I think defines the trigger value:

G31 X0 Y0 Z-0.1 P200 ; Set the zprobe height and threshold (put your own values here)

|

Re: Whats your calibration deviation? August 18, 2015 12:01PM |

Registered: 9 years ago Posts: 58 |

Quote

I have my doubts about how the endstop switches are mounted on the Fisher. Most delta printers mount the switches horizontally and upside down, so that the carriages run into them. I find this gives highly reproducible results. On the Fischer, the sideways mounting arrangement looks to me that it needs a larger amount of carriage travel to cause the same amount of switch depression, which I suspect will make the trigger position more variable.

It all depends, indeed if you mount them perpendicular you have the smallest travel to activate the switch. But if you mount it directly in the way of the carriage, the carriage might dislocate the switch in case of a firmware error where it ignores the switch, or other unforseen events. It is debatable if/when that is a problem with the fisher. On large machines you certainly want to avoid the possibility of crashing into the endswitches.

Mechanical switches do not have such a great reproducibility anyway: the metal reed inside will expand/contract with different temperatures, so it will trigger at different points at different temperatures. Such is life if you buy one of the cheapest printers available. I quite like the idea of converting to hall endstops, but that adds ~2-5$ to the BOM.

|

Re: Whats your calibration deviation? August 21, 2015 03:44AM |

Registered: 8 years ago Posts: 30 |

|

Re: Whats your calibration deviation? August 21, 2015 04:21AM |

Registered: 8 years ago Posts: 443 |

The problem with closed loop is there are many flavours, and it depends heavilly on exactly what problem you are trying to solve or what improvements you are trying to effect.

The simplest form of closed loop is a rotary encoder that produces pulses as the motor turns and tends to be part of the motor, typically this is not used with low load stepper motor systems as it actually provides little benefit, other than it will catch when the stepper misses steps due to an obstruction or there are wiring problems, that cause the motor to not move or move in reverse, if your belt breaks this kind of system may not detect it

The next level is a scale that measures the displacement along the driven axis, these are typically scales that produce pulses as the carriage moves up/down, again this system could pick up skipped pulses, but it would also pick up a lose grub screw or broken belt.

The problem with a scale on a delta machine however is it doesn't really solve the calibration problem, which is probably due more to geometrical errors than due to axis displacement

To actually solve the calibration problem with a closed loop on a delta you would need something that could measure the actual position of the head..... and to do this your talking about the latest video or tracking laser type systems, these are definitely not practical for a cheap delta.

Edited 1 time(s). Last edit at 08/21/2015 04:23AM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

The simplest form of closed loop is a rotary encoder that produces pulses as the motor turns and tends to be part of the motor, typically this is not used with low load stepper motor systems as it actually provides little benefit, other than it will catch when the stepper misses steps due to an obstruction or there are wiring problems, that cause the motor to not move or move in reverse, if your belt breaks this kind of system may not detect it

The next level is a scale that measures the displacement along the driven axis, these are typically scales that produce pulses as the carriage moves up/down, again this system could pick up skipped pulses, but it would also pick up a lose grub screw or broken belt.

The problem with a scale on a delta machine however is it doesn't really solve the calibration problem, which is probably due more to geometrical errors than due to axis displacement

To actually solve the calibration problem with a closed loop on a delta you would need something that could measure the actual position of the head..... and to do this your talking about the latest video or tracking laser type systems, these are definitely not practical for a cheap delta.

Edited 1 time(s). Last edit at 08/21/2015 04:23AM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Sorry, only registered users may post in this forum.