How to minimize warping with ABS?

Posted by Wade

|

How to minimize warping with ABS? November 05, 2008 09:50PM |

Registered: 16 years ago Posts: 536 |

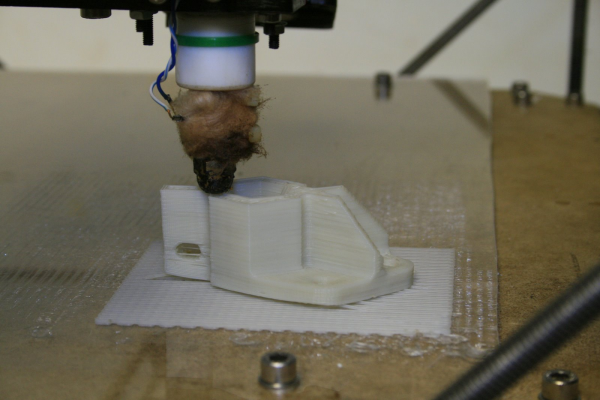

Apologies to those of you with small screens; I wanted to make sure you guys got the whole picture here.

As you can hopefully see, I'm having a small issue with warping on my larger ABS parts. It's not killer; I think these parts will work fine with a bit of sanding, but I think it could be better...

Strangely enough, the warping seems to sort itself out 5 or 10 layers into the build, but the first layers are usually the worst. At first the part was separating from the raft, so I increased the temp of the first part layer; now the raft itself is getting pulled apart.

Right now I'm putting down 3 mostly solid layers on the base; this may be the cause of the extra warping at the base. Has anyone come up with a better way to reduce the warping on the larger parts in ABS? Nophead? Your parts seemed a bit better than this, any tips?

Wade

|

Re: How to minimize warping with ABS? November 06, 2008 04:16AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes my version of that part is a lot better. If the part separates from the raft, or the raft separates from the base than I count it as a failure. It must be held flat during the build. It then warps a bit during the first few hours after it is removed.

I also use three solid layers and then 25% fill. Three is exactly right on the outer surfaces, any less and you see the infill pattern showing through.

I think you need to increase the temperature that the second and third layers of the raft are laid down. It should not pull apart like that. Either that or drop the layer height slightly to get more contact area between the filaments.

Also I think you have the version of the part that is intended to be built with support material. The version on this page has teardropped holes: [reprap.org].

[www.hydraraptor.blogspot.com]

I also use three solid layers and then 25% fill. Three is exactly right on the outer surfaces, any less and you see the infill pattern showing through.

I think you need to increase the temperature that the second and third layers of the raft are laid down. It should not pull apart like that. Either that or drop the layer height slightly to get more contact area between the filaments.

Also I think you have the version of the part that is intended to be built with support material. The version on this page has teardropped holes: [reprap.org].

[www.hydraraptor.blogspot.com]

|

Re: How to minimize warping with ABS? November 07, 2008 02:01PM |

Registered: 16 years ago Posts: 536 |

Thanks Nophead! I'm already at 230 C, so I dropped the layer height a bit, from 0.4 mm to 0.35 - that did the trick. The parts are harder to remove, but not impossible, and lots less warping, although still a small amount.

I had a look at that STL, but I prefer the old one. With Enrique's bridge code, I don't need the teardrop holes at all on simple holes. I get a few stringers on the internal lip below the 8mm nut, but they're easy to remove. The funnel shape worries me - it looks like it could guide a loosely fitting spring right into the threads and cause a jam. If you have properly sized springs, it'd be OK, but I have to cut all my springs downs a bit... Besides, those teardrop shapes look like great stress risers to me... Horses for courses. I meant to remove the teardrops on the corner blocks too, but I don't have a good design package up and running at the moment; I've been spoiled by years of ProE.

Cranking along!

Wade

I had a look at that STL, but I prefer the old one. With Enrique's bridge code, I don't need the teardrop holes at all on simple holes. I get a few stringers on the internal lip below the 8mm nut, but they're easy to remove. The funnel shape worries me - it looks like it could guide a loosely fitting spring right into the threads and cause a jam. If you have properly sized springs, it'd be OK, but I have to cut all my springs downs a bit... Besides, those teardrop shapes look like great stress risers to me... Horses for courses. I meant to remove the teardrops on the corner blocks too, but I don't have a good design package up and running at the moment; I've been spoiled by years of ProE.

Cranking along!

Wade

|

Re: How to minimize warping with ABS? November 13, 2008 01:16PM |

Registered: 15 years ago Posts: 45 |

|

Re: How to minimize warping with ABS? November 13, 2008 01:58PM |

Registered: 16 years ago Posts: 536 |

Well, some rafts may be re-usable, but the other purpose of the raft is to smooth out any discrepancies between the bed height and the nozzle height. A few layers spreads that out more, giving you more leeway. On some of my prints, especially just before the PTFE gave out, the PTFE was elongating more a few hour into the build (maybe due to my thermocouple problems), causing the rafts on the later parts to look quite a bit different, more mashed down, but by the time you get up to the third layer, you're at a pretty even height.

Also, the raft is smoother after several layers. A single layer raft gives you a pretty lumpy base on your object.

Wade

Also, the raft is smoother after several layers. A single layer raft gives you a pretty lumpy base on your object.

Wade

|

Re: How to minimize warping with ABS? November 13, 2008 02:01PM |

Admin Registered: 17 years ago Posts: 7,879 |

My first layer is thick and widely spaced so that it is able to absorb irregularities in the bed material and slight variations in z-calibration. The bed gets quite messy as it gets reused over and over again. You need a thick filament, squashed a lot, to fill any pits or low points. It has to be widely spaced so that the plastic still has somewhere to go if the bed has a high point, or z is a bit low, otherwise blobs build up on the surface.

If I extruded on top of that then the bottom of the object would be undulating.

I then put two finer zigzag layers on top, which have the filaments almost touching. Because the top of first layer has consistent height the next layer has consistent depth so its width is consistent. That allows it to be very close but not touching. I don't want it to touch because it is easier to remove in individual strands.

I used two layers on top because with only one layer there was still some undulation showing through from the base layer. They also give the raft strength in the opposite direction to the base layer.

Edited 1 time(s). Last edit at 11/13/2008 02:05PM by nophead.

[www.hydraraptor.blogspot.com]

If I extruded on top of that then the bottom of the object would be undulating.

I then put two finer zigzag layers on top, which have the filaments almost touching. Because the top of first layer has consistent height the next layer has consistent depth so its width is consistent. That allows it to be very close but not touching. I don't want it to touch because it is easier to remove in individual strands.

I used two layers on top because with only one layer there was still some undulation showing through from the base layer. They also give the raft strength in the opposite direction to the base layer.

Edited 1 time(s). Last edit at 11/13/2008 02:05PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: How to minimize warping with ABS? November 13, 2008 02:10PM |

Registered: 16 years ago Posts: 536 |

Nophead, before I even read this post I was browsing your blog, re-reading your "Catalog of Disasters" post, and commiserating, when I noticed that your rafts are much more dense than mine on the top layer! A-ha! That would almost double the raft strength, and maybe get rid of my last bit of warping.

Could you post your exact raft parameters for Skeinforge, or just describe them if you do it some other way? That might be the one thing I'm missing.

Other than a working extruder, that is... Still mucking about with thermocouples and heater barrels.

Wade

Could you post your exact raft parameters for Skeinforge, or just describe them if you do it some other way? That might be the one thing I'm missing.

Other than a working extruder, that is... Still mucking about with thermocouples and heater barrels.

Wade

|

Re: How to minimize warping with ABS? November 13, 2008 03:15PM |

Admin Registered: 17 years ago Posts: 7,879 |

I am not using skienforge for my rafts. The parameters are a bit hard to describe so here is the code :-

The zigzag routines adjust the gaps to get an integral number of lanes but still start and finish where specified. If pscale is 1, i.e. no gap then the amount of plastic is adjusted instead. I used these routines for making test blocks with perfect infill.

Oddly the temperature control on my machine has been playing up recently. No idea why. I removed a raft today only to find charcoal underneath it. The extruder had been extruding charcoal!

I can't see anything wrong and it is happily building while I type.

[www.hydraraptor.blogspot.com]

def zigzag_x(Do,Vo,x,y,w,h,pscale):

fw = Do * 1.2

lanes = int(round(h / fw))

threads = int((lanes - 1) / pscale) + 1

if pscale == 1:

fw = h / threads

Do = Do * sqrt(fw / (Do * 1.2))

w = w - fw

h = h - fw

pitch = h / (threads - 1)

y = y - h / 2.0

end1 = x - w / 2.0

end2 = x + w / 2.0

hydra.moveto_xy((end1, y))

extruder.extrude(Do, Vo)

hydra.feedto_xy((end2, y))

for i in range(threads - 1):

y = y + pitch

hydra.feedto_xy((end2, y))

end1, end2 = end2, end1

hydra.feedto_xy((end2, y))

extruder.stop()

def zigzag_y(Do,Vo,x,y,w,h,pscale):

fw = Do * 1.2

lanes = int(round(w / fw))

threads = int((lanes - 1) / pscale) + 1

if pscale == 1:

fw = w / threads

Do = Do * sqrt(fw / (Do * 1.2))

w = w - fw

h = h - fw

pitch = w / (threads - 1)

x = x - w / 2.0

end1 = y - h / 2.0

end2 = y + h / 2.0

hydra.moveto_xy((x, end1))

extruder.extrude(Do, Vo)

hydra.feedto_xy((x, end2))

for i in range(threads - 1):

x = x + pitch

hydra.feedto_xy((x, end2))

end1, end2 = end2, end1

hydra.feedto_xy((x, end2))

extruder.stop()

leadin = 4

def raft(x,y,w,h,z):

z += 0.7

hydra.moveto_xy((x - w / 2.0 - leadin, y - h / 2.0 + 0.6))

hydra.moveto_z(z)

extruder.extrude(1.0, 4.0)

sleep(2)

hydra.feedto_xy((x - w / 2.0 + 0.6, y - h / 2.0 + 0.6))

zigzag_x(1.0, 4.0, x, y, w, h, 2.0)

hydra.set_temperature(material.layer_temp)

z += 0.4

hydra.moveto_z(z)

zigzag_y(0.5, 16.0, x, y, w, h, 1.3)

z += 0.4

hydra.moveto_z(z)

zigzag_y(0.5, 16.0, x, y, w, h, 1.3)

extruder.relax()

return z

The zigzag routines adjust the gaps to get an integral number of lanes but still start and finish where specified. If pscale is 1, i.e. no gap then the amount of plastic is adjusted instead. I used these routines for making test blocks with perfect infill.

Oddly the temperature control on my machine has been playing up recently. No idea why. I removed a raft today only to find charcoal underneath it. The extruder had been extruding charcoal!

I can't see anything wrong and it is happily building while I type.

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.