ShowCase

Contents

RepRap Showcase

This page summarises the progress of the RepRap team so far. It is a very general summary of the blog and should save you time in finding out where we are with the project. However, if you're after the very latest information and news then the blog is where it's at.

[Rappers - lets keep this as brief, history is irrelevant, and untechnical as poss]

The three major areas we're working on are:

And when they're all brought together we'll have a replicating rapid-protyper.

Has RepRap made anything yet?

Yes - we're just getting to the stage of making simple objects. Here, for example, is a test piece out of Vik's RepRap machine described below.

- MachinesHead

Machines

What's the machine going to look like? Well, we're working on three different concepts at the same time. When they're all done we can take the best bits from each concept and come out with an all-singing, all-dancing hybrid architecture.

Vik's Da Witch

Da Witch (named after a recycled DAta sWITCH panel) is a 3-axis RepRap prototype with a single static head. Apart from the frame, rods and fastenings, all parts are FDM'd on a Stratasys. All the axes are screw-driven using salvaged unipolar stepper motors, and have a single limit switch each. The extruder is currently a slightly modified Mk2 extruder with an 0.8mm nozzle, all driven off a unidirectional gearmotor that bears a startling resemblance to a low-end Black & Decker electric screwdriver. It is notable because it is actually fully-functional - if completely uncallibrated - allowing concepts and software to be tested.

Recently, a cooling fan has been added, and a second head is in the works. The stage has been surfaced with sanded wood, which has proved to be an excellent deposition surface.

Forrest's Godzilla

The device name Godzilla is an obvious reference to the size of the system which has a working volume of 300x400x900mm. The system uses a combination of threaded drive rods and cabling to create a stable positioning system. The structural repstrap of the system is made of milled poplar lumber, a inexpensive, light, easy-to-work material.

Godzilla is a test platform for higher speed, viz, 20-40 mm/sec extrusion.

Y-axis cabling

The X, Y and Z positioning stages are powered up. Work is currently underway to develop control boards that incorporate PWM speed control of the brushed DC motors that drive the positioning stages with shaft encoders to precisely determine the speed and position of each stage. PWM speed control of the smaller G4 motor has been demonstrated as well as encoders and limits detectors. Control boards centred around the PIC16F629A microcontroller have been laid out. Completion and testing await the arrival of L298N h-bridge chips.

Control of the Mk II is being built around the PIC16F877A chip which has two PWM channels that will control both the polymer filament feed and the extruder barrel heater circuit.

Firmware is being developed using the Oshon Simulator IDE, an inexpensive proprietary system, and Oshonsoft's BASIC compiler for PIC12-16 and PIC18 microcontrollers. Chips are being programmed with a MELabs USB PIC programmer.

PC-based sestem control routines are presently being written in VB.NET in a Wintel operating environment.

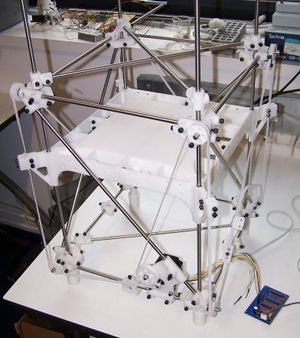

Ed's A.R.N.I.E.

A concept inspired by traditional 2D printing technology. The injection head will be mounted on the top of the frame to be moved in the x and y planes to print each layer of the part. The first layer will be printed directly onto the z-bed which will then be incremented downwards in the z direction for each subsequent layer.

Progress: The z-bed transmission is complete (see below) and now work has started on the x and y to install the injection head.

Brett's King Ghidorah

- ElectronicsHead

Electronics

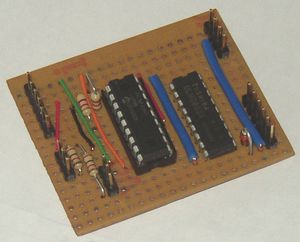

RepRap doesn't have a single internal controlling computer. Each of its components has a microcontroller, the only job of which is to control its particular component. Thus each drive motor and each material write head has a microcontroller to itself that keeps its temperature constant, decides what speed to deposit material, and so on.

Here is a typical controller board (in this case for one of the axes):

<A HREF="Building A Stripboard Stepper Controller">

</A>

As you can see, they are quite simple and easy to make.

All the microcontrollers (Microchip PICs) are connected in a token ring, along with the PC that is controlling the whole RepRap machine. Each microcontroller has a unique number - its address - and messages are passed round the ring until they arrive at the PIC that has been addressed. Anything can talk to anything else, including the controlling PC, of course.

- SoftwareHead

Software

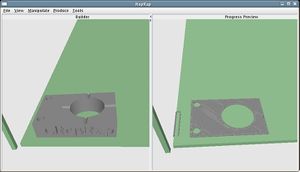

From the user's perspective the system consists of a graphical user interface (above). Users load objects for RepRap to make into the left-hand window, and arrange them in the positions in which they will be made using the mouse. They then select "build" from a menu, and the host computer automatically sends all the instructions needed to the RepRap machine to make the objects. The right-hand window is a simulation of the machine as it works, which is synchronised with the actual machine's movements. (The little inverted U shape is to warm-up the write head.)

The software that runs on the host computer for the RepRap is being written in Java for platform independence. Parts of the Godzilla system are being written in Microsoft Visual Studio.NET's Visual Basic development system.

Creating Object Designs

Objects being designed for prototyping in RepRap machines are created using the open source Art of Illusion 3D modeling package (AoI) and saved as STL files. Several special purpose scripts have been written for AoI for such things as gear design.

Firmware

Firmware is being mostly written in C using the open-source SDCC compiler for PIC microprocessors. The Godzilla project utilizes the Oshonsoft Simulator IDE and Oshonsoft's BASIC compilers for PIC microprocessors.

-- Main.EdSells - 03 Jul 2006