ItemsMade

Items Made

This page shows some example objects made by prototype and production RepRap machines. They are in reverse chronological order - most recent first. A lot of these are steps on the road to having the machine copy itself rather than more instantly-appealing utility items like coat hooks, iPod cases, car headlamp housings and so on. We make no apology for this - as any biologist will appreciate, having the machine copy itself is the most useful possible thing we can make it do, and is the primary goal of the whole project.

Almost all these were done by Vik Olliver, who clearly takes advantage of the 48-hour days they have south of the equator...

A page on part development to achieve replication can be found here.

| <div class="thumb tright"></div> |

14 January 2008 |

| <div class="thumb tright"></div> |

13 January 2008 |

| <div class="thumb tright"></div> |

21 October 2007 |

|

12 October 2007 | |

| <div class="thumb tright"></div> |

28 May 2007 |

|

15 May 2007 |

|

|

|

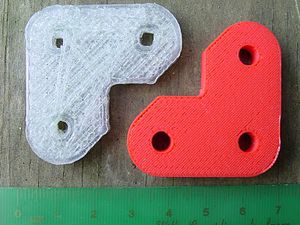

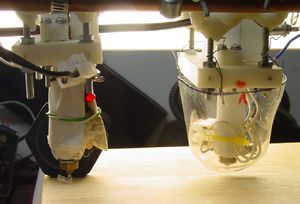

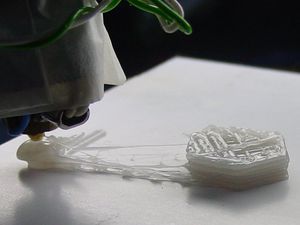

The first image shows the parts for a RepRap extruder made by RepRap itself in polycaprolactone. The second image shows the two complete RepRap polymer extruders. The one on the right was made in a commercial RP machine. The one on the left was made by the one on the right - the first complete self-replicated functioning RepRap part. The new extruder is shown starting to extrude for itself. 6 March 2007 |

|

13 January 2007 | |

|

2 January 2007 | |

|

17 November 2006 | |

|

|

23 September 2006 |

|

13 September 2006 | |

|

17 July 2006 | |

|

This is the first complete object out of a RepRap machine. It is a test hexagon made in polycaprolactone.

|

-- Main.AdrianBowyer - 27 Aug 2007