Links Into Hangprinter v3 Build Video

On Dec 13-15, 2017, tobben and Tom made a live stream in 4 parts on Youtube, where they built and debugged a Hangprinter v3. The videos are very long, so this wiki page is created as a "table of contents". Help out and fill in if you watch the videos: Part 1, Part 2, Part 3, Part 4.

Part 1

| 1m38s | Start |

| 2m52s | Start of mover build |

| 5m24s | Snap mover into place |

| 14m22s | Cracking sounds in printed mover parts. New versions of those parts do not rely on flex anymore. |

| 17m18s | Orientation of extruder motor. |

| 19m10s | "I want to use a naked mover to make markings on the ceiling plate." |

| 24m44s | D-linerollers use bowden tube" |

| 25m42s | The designer who drew D-linerollers made them too narrow. Called him. Now fixed. |

| 48m30s | Don't trust spools to be 5 cm radius. Measure them and input into firmware the real radius. |

| 51m5s | Noted down radius onto spool. |

| 51m50s | Pro tip about spool/gear mounting. |

| 54m35s | Starting to place out spools. |

| 57m10s | Important note regarding D-lineroller placement. Rotate them appropriately. |

| 58m50s | Close-up of wood screw. |

| 1h23s | Pro tip: Furniture pods on back of ceiling plate. |

| 1h9m45s | Close-up of mounted D-lineroller. |

| 1h17m1s | You can tie lines from heat break to corner clamps to support/stiffen up hot end. |

| 1h18m1s | Pushing 608 bearings into place. |

| 1h18m42s | Pro tip: route thermistor wire inside heat cartridge wire's heat resistant sleeve. |

| 1h19m50s | Let's attach some line. 3x5 m on the D-spool. |

| 1h25m22s | Using one D-line as a reference for the others. |

| 1h26m20s | The Hangprinter Hitch. |

| 1h33m55s | Close-up of D-lines tied into D-spool. |

| 1h35m45s | Tom explains braided/fused line. |

| 1h37m35s | Keep the three D-lines separate while reeling onto spool. |

| 1h39m21s | Pro tip: Mark your spools with "A", "B", "C", and "D". |

| 1h45m38s | Counter sinking hole for M8 bolt the quick and dirty way. |

| 1h47m30s | Inserting 608 bearings again. |

| 1h49m15s | Pro tip: Sandwich spacer tightly between 608 bearings. |

| 1h53m15s | Starting on the ribbon cable. |

| 1h54m40s | Pro tip: Thread a loop in from the top of D-linerollers first to catch the single line from below. |

| 1h58m13s | D-linerollers, D-spool, and D-lines limit where we can place everything else on the ceiling plate. |

| 2h16s | Trying to plan layout of ceiling unit. Stepper cables are short. |

| 2h3m51s | More on the ribbon cable. |

| 2h7m21s | Giving the ceiling plate directions their names. |

| 2h8m3s | Naming convention: B/C are the symmetric/mirrored sides of the mover. A is the third side. |

| 2h8m43s | What to keep in mind for ceiling plate layout. |

| 2h17m3s | Soldering ribbon cable's mover end. |

| 2h37m25s | Assembling ABC spools of ceiling unit. |

| 2h42m7s | Secure spool with nyloc nut or by tightening two M8 nuts against each other. |

| 2h45m25s | Pro tip: Align with bolt while inserting bearing-spacer-bearing in gear sandwiches. |

| 2h54m11s | Making lines for the A, B, and C spools. |

| 2h56m10s | Mounting the ribbon cable on the extruder holder. |

| 2h57m40s | Note down on the spool how long the lines are, so you can feed that into firmware later. |

| 3h6m15s | The ABC spools get two 7.5 m lines each. |

| 3h7m13s | Assembling ABC linerollers. |

| 3h12m46s | ABC lines entangle into spaghetti monster on the floor. |

| 3h21m12s | It's much faster to tie in lines before you attach the spool to the gear and the gear to the plate. |

| 3h25m28s | Attaching motor gears. |

| 3h29m16s | Mounting ABC linerollers. |

| 3h35m20s | Attaching steppers to motor brackets. |

| 3h40m12s | Starting to attach motors to ceiling plate. |

| 3h43m16s | Gettings started on the ABC anchors. |

| 4h4s | The mapping {A, B, C, D, E} -> {X, Y, Z, E1, E0}. |

| 4h4m42s | Mounting the Arduino Mega onto the ceiling plate. |

| 4h11m24s | Suggestion: Screw right through felt pads on backside of ceiling unit. |

| 4h13m3s | Wiring in and mounting power supply. |

| 4h27m49s | Showing off the backside of the ceiling plate. |

| 4h34m32s | Need to add PTFE tube, bearings and one more screw to each ABC anchor lineroller. |

| 4h39m56s | Adding Bluetooth module. |

| 4h47m8s | Powering the RAMPS for the first time. |

| 4h53m25s | Install TMC2130 lib by teemuatlut. Thank you teemuatlut! |

Part 2

3h28m12s: "Tell the printer to feed out line"

3h44m: "Start leveling the mover"

3h52m1s: "We have six of these Beam Sliders. One on each side gets used for D-line."

3h54m43s: "Let's bring the print bed in place"

3h56m20s: "Home position will be vertically below our ceiling unit"

3h57m24s: Torbjørn uses spirit level on mover

4h2m30s: Using mover as aiming plumb

4h4m27s: Drawing marks below mover pivot points

Now going into an hour of measuring this

4h10m7s: First mover levitation.

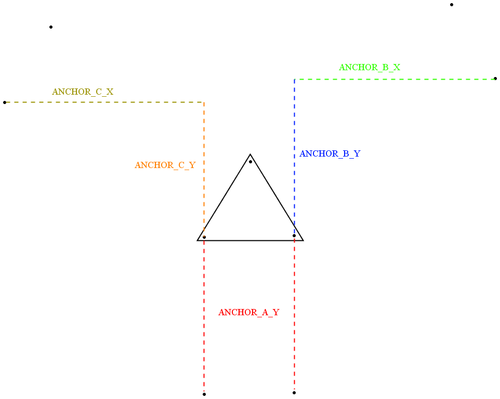

4h12m10s: Measure ANCHOR_A_Y and parallelize A anchor.

4h13m27s: "As long as the lines between mover's pivot points and anchor's pivot points are parallel, then we're good."

4h14m1s: "Let's use the number 230" (cm from anchor to mover). Measuring/deciding ANCHOR_A_Y to be 2300.0 mm.

4h17m47s: Marking out line that is parallel with y-axis.

4h20m53s: To mark out y-parallel lines, start with going through lineroller.

4h25m32s: Placing out C anchor.

4h30m1s: Placing out B anchor.

4h37m25s: Measuring ANCHOR_C_X.

4h39m28s: "This thing is cut square." Getting the 90 degree angle between ANCHOR_C_X and ANCHOR_C_Y.

4h40m25s: Measuring ANCHOR_C_Y.

4h41m45s: "C anchor will have a negative x-position." ANCHOR_C_X is a negative number.

4h42m20s: Measuring ANCHOR_B_X.

4h43m41s: Measuring ANCHOR_B_Y.

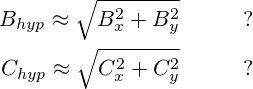

4h44m23s: "Let's do some sanity checking."

Sanity checker's formula:

4h47m53s: "We are going to make two more measurements." ANCHOR_ABC_Z and ANCHOR_D_Z explanation.