P3Steel

Release status: working

| Description | Remix of Twelvepro redesign of Josef Prusa's i3

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Presentation

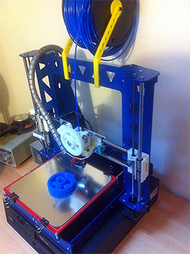

The P3Steel is a remix of Twelvepro redesign of Josef Prusa's i3.

Leonardo, The original P3Steel printer, was built in April 2013, decided by it's designer Irobri after attending a local Maker show in Zaragoza, Spain.

It's chassis, built from lasercutted 3mm Steel, gives her great strength, simplifies the build process and eliminates the need of several printed parts due to the use of steel plates instead of threaded rods for the "y" subframe.

- Steel advantages

- Steel is 10 times cheaper than aluminium

- Laser cutting steel is easier and cheaper than cutting aluminium

- Steel is stronger than aluminium

- Disadvantages

- Steel is 3 times heavier than aluminium.

- Needs to be painted to protect it against corrosion.

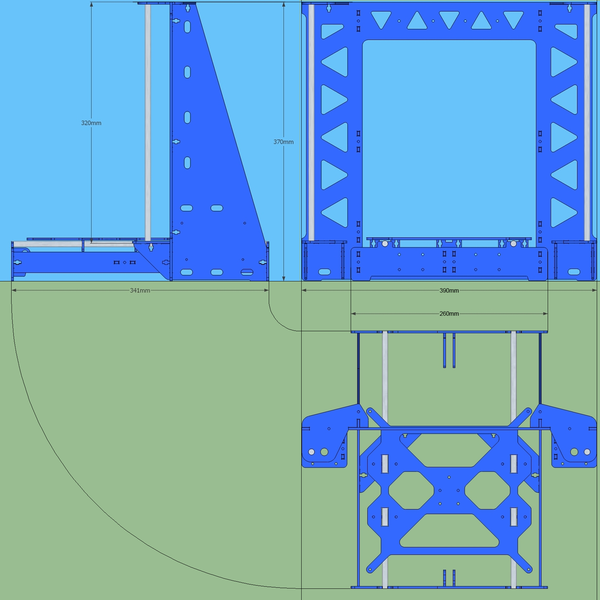

The design is for 3mm thickness steel and with lots of carvings to reduce weight. All square holes and tabs have special rounded corners for accommodating corresponding parts and give a very good fit between plates.

The design has slots for M3 nuts in the places where the screws fit so no threading required.

Improvements over the standard Prusa i3

- Stronger frame due to it's construction on structural steel.

- Solves the frame oscillation thanks to its reinforcement squares.

- Simplifies the construction, eliminating the complex subframe of threaded rods in the Y-axis.

- Once assembled, everything is its place, no adjustments needed.

- Eliminates the need of several printed parts.

- The steel mounts for motors and rods, are infinitely stronger than their plastic counterparts.

- The only two threaded rods needed are the ones for the Z-axis.

- Uses shorter smooth rods lowering the build costs.

- Once assembled, it forms a solid structural unit that can be transported as a block.

Principal dimensions

Instructions

To be completed.

Version 1.2: Leonardo original printer, the one I made.

Version 2.0: After some requests of a spanish group buiding around 30 printers I have modified the bed, now it holds with 4 LM8UU instead of 3 and it has also a system to level with 3 points intead of the original 4, it should be easier with this new design. I kept the original 4 points also just in case someone still wants to use them. I included in the gallery some 3Ds of the new bed. The rest of the printer is exactly the same as version 1.2

Everything snaps together and hold with a lot of M3x12 screws (mainly), I also used nylon self locking nuts to prevent future problems due to vibration.

The printer uses 8mm chromed smooth rods (Z axis: 2 x 320mm, Y axis: 2 x 341mm and X axis: 2 x 375mm) and only two M5 threaded rods (295mm aprox each since depends on motor coupling and if you want some stick out through the top) for the Z-.axis, printed parts required came from a standard Prusa i3, you only need the parts for the x-axis assembly and the extruder.

The printer structure is assembled quite fast and needs no adjustments. The electronics are installed in either side of the frame, horizontally, holes provided are for an arduino mega and ramps 1.4. Motors are NEMA 17, GT2 pulleys, LM8UU and 608zz bearings Hotend is budas type. MK2b hotbed.

Assembly animation

<videoflash>In_Q6NkX3fs</videoflash>

Modification to use Spindles

To use 10mm diameter spindles we need to separate the smooth rod and the spindle, leaving room for the nut and bearing parts in the X axis. Therefore some adaptation is required. We have designed a few pieces for use them in the original structure, so the changes were minimal.

This file File:Adaptacion Husillos.zip contains the OpenSCAD design files along with some other files to support for visualizing the set.

Where to buy

- RepRap Forum https://groups.google.com/forum/#!msg/asrob-uc3m-impresoras-3d/waJV15JftZ4/TTAb1bQ4mPQJ (Stainsless Steel, S235, Rods...) We ship to EU.

- iFusionShop

- KITPRINTER3D (required vitamins to make a P3Steel from a Prusa i3)

- CREATEC 3D

| Proyecto Clone Wars |