RUG/Pennsylvania/State College/Soldering

Never Soldered Before?

Check these out:

Good walk though with pictures

Be Careful

How to Avoid Cold Solder Joints

When soldering, it is very easy to create joints that are "cold." A cold joint is one where the solder has only mechanically joined to one of the two pieces that you are trying to connect. The most common cause of cold solder joints is improper soldering technique. Many people simply add solder to the iron, then transfer that blog of solder from the iron to the lead sticking out of the board. This is not correct. To correctly solder, place the iron at the the intersection of the lead and the pad. Wait 1-3 seconds for the joint to heat up THEN add a small amount of solder ensuring that it flows evenly around the entire joint. A correct joint will look like a volcano:

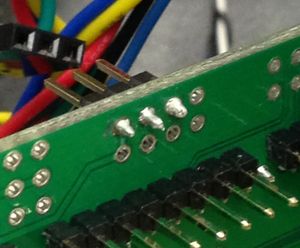

And a bad solder joint looks like this (leftmost header pin)