SLS wax printer

This page is a under construction. I will be transplanting content from www.andreasbastian.com/3dp/3dp.html to this wiki over the next week or so. I built a SLS 3D printer that prints objects in a wax and carbon mixture that can be used as positive models for the lost wax casting process.

Release status: Experimental

| Description | This is a prototype SLS system that prints in a wax and carbon mixture for use in lost-wax casting.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | Toolheads, Powder Printers, Wax printing, Laser Printing

|

| CAD Models | |

| External Link |

Contents

Introduction

The Reprap and other FDM printers that fabricate in PLA and ABS are restricted both by the limitations inherent in these materials and by the limitations of the FDM process. Though these printers are entirely capable of self-replication and of producing parts for a variety of light-duty applications, they cannot produce pieces that can replace the cast aluminum parts found in power machinery, CNC equipment, or in numerous other high-strength applications. To address the problem of rapid fabrication in metal, I sidestepped plasma jets, electric arcs, and high-power lasers by opting instead to employ the lost-wax casting technique coupled with a relatively low-power laser sintering system.

A complete report on the project with more technical details can be found here.

Process Overview

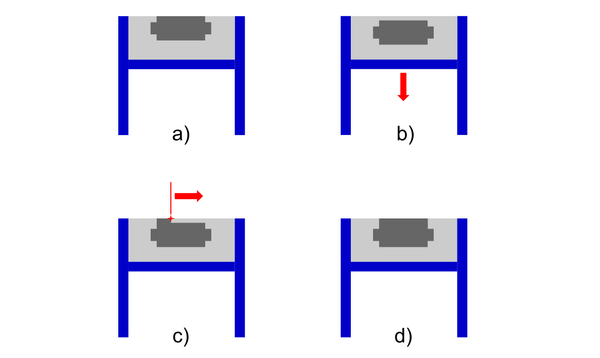

The SLS process can be described with the following graphic:

(a) An object (dark gray) is being printed and is ready for the next layer.

(b) The print piston descends an incremental amount and new powder is deposited in a thin layer over the solid object.

(c) A laser is translated over the freshly spread powder layer and melts the powder to the object beneath.

(d) The layer is finished and the process is ready to repeat until the object is completed.

Hardware

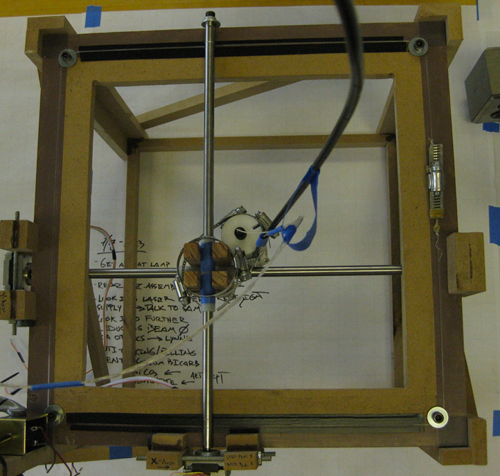

XY Translator

The XY translator is based on the clever cable-based linear translation system implemented by Ilan Moyer in his FoamCore CNC Project. It took just a day and a half of work in the machine shop to create a functional prototype. I employed 1/2" MDF as my primary structural material because of its high tolerances and the ease with which it can be worked with simple tools. I cut the square frame and the motor mounting blocks on a table saw and used a vertical mill to remove material inside the frame. I assembled the motor mounts with super glue and threaded rod and lined the perimeter of the frame with Teflon tape to reduce friction from the riding motor mounts.

Laser Shutter Mechanism

Powder Distribution Mechanism

Software

Electronics

Lost Wax Casting

Videos

<videoflash type="vimeo">29566951</videoflash> <videoflash type="vimeo">29564093</videoflash> <videoflash type="vimeo">29560030</videoflash> <videoflash type="vimeo">34234394</videoflash>