SLS wax printer

Release status: Experimental

| Description | This is a prototype SLS system that prints in a wax and carbon mixture for use in lost-wax casting.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

SLS wax printer is a Selective laser sintering printer which uses wax as the print medium. The Reprap and other FDM printers that fabricate in PLA and ABS are restricted both by the limitations inherent in these materials and by the limitations of the FDM process. Though these printers are entirely capable of self-replication and of producing parts for a variety of light-duty applications, they cannot produce pieces that can replace the cast aluminum parts found in power machinery, CNC equipment, or in numerous other high-strength applications. To address the problem of rapid fabrication in metal, I sidestepped plasma jets, electric arcs, and high-power lasers by opting instead to employ the lost-wax casting technique coupled with a relatively low-power laser sintering system.

A complete report on the project with more technical details can be found here and more information about the development of the print material and hardware can be found here.

An octocat. |

Process Overview

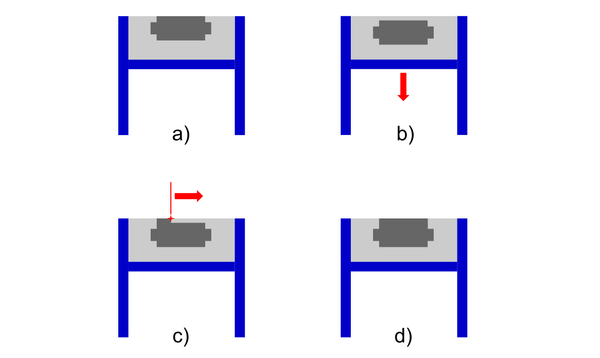

The SLS process can be described with the following graphic:

(a) An object (dark gray) is being printed and is ready for the next layer.

(b) The print piston descends an incremental amount and new powder is deposited in a thin layer over the solid object.

(c) A laser is translated over the freshly spread powder layer and melts the powder to the object beneath.

(d) The layer is finished and the process is ready to repeat until the object is completed.

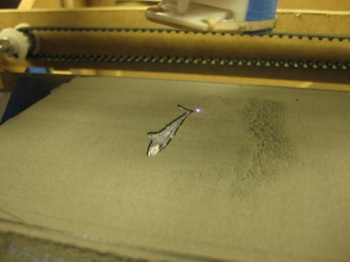

Printing a shark from Thingiverse |

In my system, an infrared laser spot (less than a millimeter in diameter) is translated over a bed of print powder, sintering the each layer into a continuous mass and melting it to the layer below.

Hardware

XY Translator

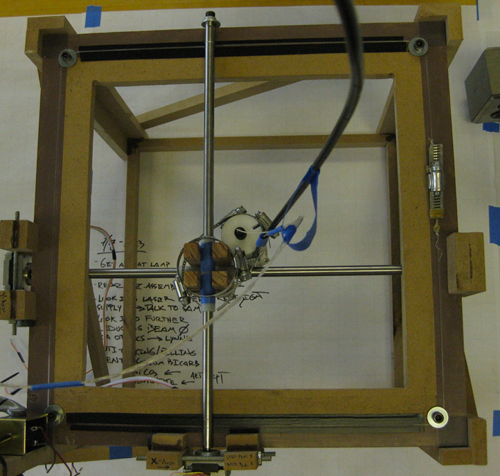

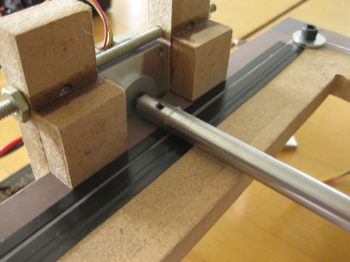

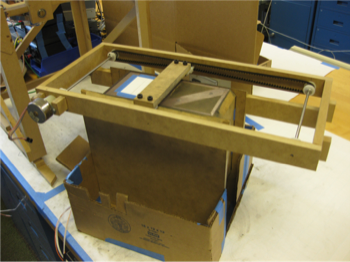

The XY translator is based on the clever cable-based linear translation system implemented by Ilan Moyer in his FoamCore CNC Project. It took just a day and a half of work in the machine shop to create a functional prototype. I employed 1/2" MDF as my primary structural material because of its high tolerances and the ease with which it can be worked with simple tools. I cut the square frame and the motor mounting blocks on a table saw and used a vertical mill to remove material inside the frame. I assembled the motor mounts with super glue and threaded rod and lined the perimeter of the frame with Teflon tape to reduce friction from the riding motor mounts.

I used reamed nylon bushings to create bushings for the simple translation head. The bushings ride on 1/2" drill rod that is driven on one end by a stepper motor. The end of each gantry shaft has been reamed to the diameter of the stepper motor shafts and has a threaded hole to allow the shaft to be secured by a set screw. Because the wrapped, tensioned cables prevent linear translation in the plane of the frame, the torque from the motor results in rotary motion of the shaft, which causes it to roll.

Laser Shutter Mechanism

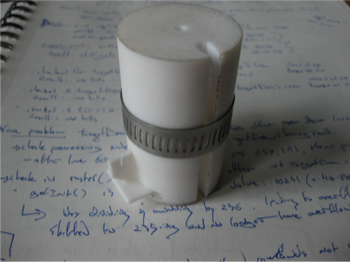

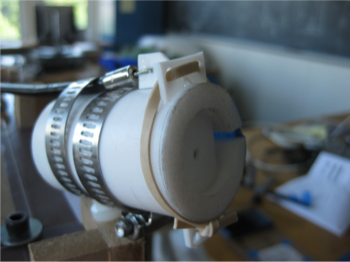

I machined the optics mount from a piece of Teflon round stock. A 40x microscope objective resides within the cylinder, collimating the laser. The cable drives a wedge of Teflon sheet into a slot, pulling a second sheet of Teflon into the path of the collimated laser beam.

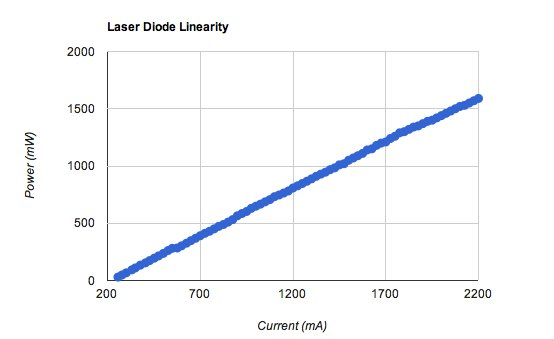

The diode is linear until just over 2.2 Amps where output is roughly 1.5 Watts output, which is primarily the power at which I operated the laser. Because of the high power, I affixed the diode to a large heatsink, though the diode never did get alarmingly warm. I chose the fiber-coupled infrared diode approach after consulting with representatives of several laser sales companies and a local laser technical expert. They all agreed that IR diodes deliver the highest "bang for your buck."

Powder Distribution Mechanism

The power distributor uses a stepper to drive two timing belts to which a Teflon-coated wedge is secured. A feed piston loaded with print powder advances at the beginning of each new layer sequence. The print piston recedes 0.3 mm and then the wiper sweeps across the feed piston and transfers a thin layer of powder onto the print piston. Surplus powder falls off the edges of the piston housing into simple paper hoppers.

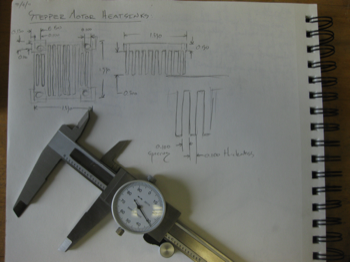

The feed and print pistons are each driven by a stepper motor secured to the underside of each piston platform. The stepper motors are directly coupled to leadscrews that turn in a captive nut to provide very precise Z-positioning (approximately 0.0002" per step). The color difference in the print powder below is due to differences in lighting conditions, not powder composition.

Print Powder

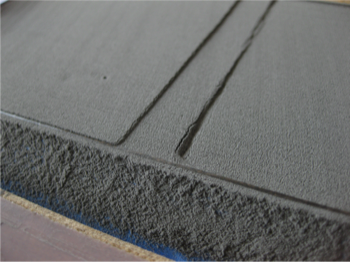

Developing an effective print powder was huge part of this project. The two main challenges were producing powdered wax and getting the wax powder to absorb the laser light (white wax powder reflects most of the energy away). I mixed varying amounts of carbon powder into wax powders to provide an energy-absorbing pigment. I investigated several different methods of producing my own wax powders before exploring commercially produced wax powders.

Early Attempts

My first method of producing wax powder involved filling a household blender with ethanol, dry ice, carbon powder, and fragments of paraffin. The alcohol provided an effective medium for heat transfer between the dry ice and the paraffin and stayed liquid at low temperatures. The alcohol also kept the lightweight fragments of paraffin from travelling too far from the blender blades after being struck. This method was very messy, produced a lot of alcohol fumes while the powder was drying out, and was limited to small batch sizes, but it did produce powder of relatively reliable composition.

Next, I built a simple ball mill using a steel cylinder loaded with ball bearings and dry ice. I locked the cylinder into the chuck of the lathe and rotated it at low speeds to produce my print powder from paraffin pellets and carbon powder. As the cylinder turned, the carbon dioxide from the sublimating dry ice would carry the finest particles from inside the cylinder out a small vent hole in the end cap of the cylinder and into a waiting receptacle. Though elegant in some ways and capable of much larger batches than the blender approach, the ratio of wax powder to carbon powder was very difficult to control.

Successful Print Powder

I abandoned efforts to produce my own wax powder and experimented with several commercially produced powders before finding a suitable wax and wax to carbon powder ratio. Candelilla wax powder mixed with carbon powder in a 100:7 ratio consistently yielded successful print powder. I obtained samples of Candelilla wax powder from Strahl and Pitsch Wax. More information on the development of the print powder can be found here.

Thermal Warping

As was discussed in this thread, sintering processes can have trouble with thermal effects such as warping and curling during cooling. I found warping to be a function both of non-thermal print powder properties and thermal properties inherent to the constituent wax powders I tested. "Sticky" wax powders had marked adhesion between wax particles that led to clumping and reduced warping. This stickiness was higher in print powder formulations that used lower-temperature waxes like paraffin and was also higher when the concentration of carbon powder was lower (and therefore there were fewer carbon particles interfering with wax particle adhesion). Though this "stickiness" property reduced warping, it made the print powder very impractical and difficult to distribute into even, thin layers.

Different waxes also had different thermal warping characteristics. Paraffin didn't warp a lot whereas Carnauba wax and a couple of other wax mixtures from a company called SasolWax did. Candelilla wax demonstrated very little warping or curling when sintered in a single continuous line, but in larger sheets of multiple layers, the printed object often curled around the edges and sometimes separated from the print surface.

Software

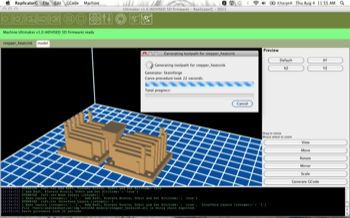

Software was one of the largest challenges I faced in this project. I used a combination of open source software to run my hardware successfully. I used the Ultimaker version of ReplicatorG and I loaded my Arduino with customized Ultimaker firmware. I excised all code that was involved in running the extruder or the heated bed and wrote new code to run my powder management hardware and laser shutter. All code and further documentation of my project can be found at my github repository.

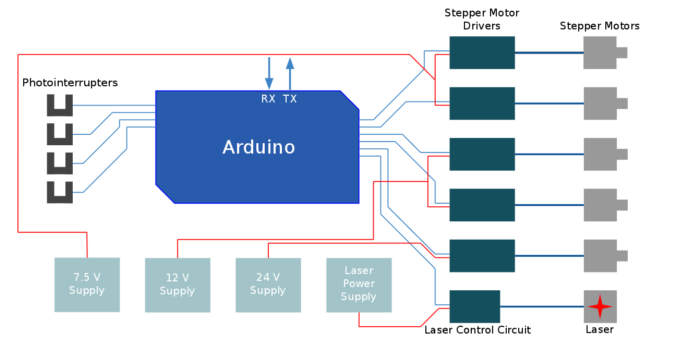

Electronics

An early implementation of the control electronics. The five Pololu A4983 stepper motor drivers (now discontinued) are configured simply to provide speed and direction control here and there are no optical endstops hooked up yet. The shutter control circuit is a simple transistor circuit with a diode to catch back EMF from the solenoid.

The biggest problem with this system is the cost of the laser controller. Used ILX Lightwave diode controllers cost between $1,200 and $2,500, which is prohibitively expensive for the 3D printing community. I was fortunate enough to be able to borrow for the summer during which I worked on this project. I've seen cheap laser diode drivers for sale on eBay that claim to be able to drive 405nm and 808nm diodes at 1 Watt, which is approaching the power at which I was operating.

Lost Wax Casting

The lost wax casting process realizes the printer's potential. In hours, a part can be imagined, designed, and printed in wax. The wax model can then be molded, melted out of the mold, and then cast in the appropriate metal in the same day.

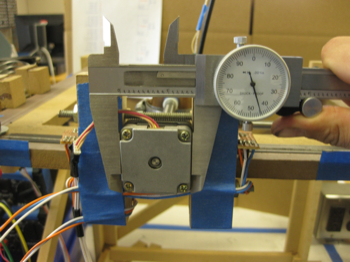

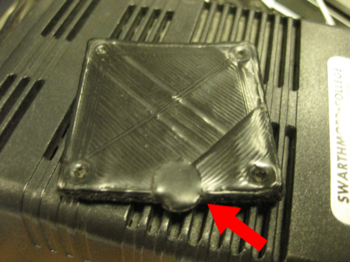

I tested this combination of techniques when I decided to fabricate two heat sinks for the stepper motors that drive my XY translator. To ensure adequate torque for the translation system, I was driving them at a voltage that was likely over their recommended operating voltage. Because this voltage was likely over their recommended level, the motors (unsurprisingly) often got quite hot after extended use. I decided to design, print, and cast heatsinks for these stepper motors.

After roughing out the design on paper, I formalized the design in autoCAD, which can export to .stl. Because I knew that I was going to be casting these parts later, I went ahead and designed the sprues and vents into the model so that they would be printed too.

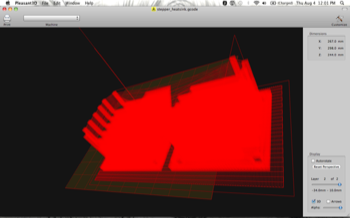

Next I imported the part into ReplicatorG and generated the GCode for the print. After seeing the estimated 10 hour print time for the two heatsinks, sprue, and vents, I decided to proceed with a simpler, single heatsink print without the sprue or vents, which I could attach by hand after the print was finished.

The print proceeded smoothly for half an hour or so and I worked on my computer next to the printer. After half an hour of whirring stepper motors and the clicking of the laser's shutter solenoid, I noticed an ominous stop in the hum of the translation system's steppers. I checked the flow of GCode to the printer and saw that commands were still being sent. I then saw that the laser, no longer making its rounds on the print bed, was steadily melting a growing puddle in the powder. I turned off the laser and aborted the print. The stepper motors had (ironically) overheated during the print of the part that was to save them.

Though the print was a failure, I was still left with a good-sized solid wax object with several features that could be used to evaluate the casting process. Given that my translation system was likely fried, I proceeded with my test of the lost-wax casting process with this sample of my print material.

I used plaster as my mold material because jewelers often use it for lost-wax casting. It has a fine particle size, cures quickly, and is easily found at the hardware store. I used two Zinc ingots left over from a metallurgy project in high school because of their low melting temperature.

After the mold cured, I removed the cardboard, inverted the mold over Aluminum foil, and baked it for several hours at 200 degrees Fahrenheit and then increased the temperature to 400 to preheat the mold before casting. Much of the wax melted out easily, but some leached into the plaster, leaving behind thicker layers of carbon powder than I had been hoping for (I expected some residue to be left and that it would aid in parting the cast piece from the mold).

The mold captured much of the surface detail of the piece, but the thick build-up of carbon powder obscured much of this detail in the casting. On the whole, it was a successful first proof-of-concept exercise, but there is plenty of room for improvement.

Videos

<videoflash type="vimeo">29566951</videoflash> <videoflash type="vimeo">29564093</videoflash> <videoflash type="vimeo">29560030</videoflash> <videoflash type="vimeo">34234394</videoflash>

Future Work

- The current laser power supply is prohibitively expensive.

- I would love to try this with a cheap driver module and a 1-2 Watt 405nm diode from eBay.

- The MDF XY translator frame began to bend under the tension of the cables, which could affect laser spot size during translation (as the laser drops and rises slightly over the course o the print).

- Smaller spot size via better optics.

- More robust frame.

- Higher torque stepper motors for the translation system.