SLS wax printer

This page is a under construction. I will be transplanting content from www.andreasbastian.com/3dp/3dp.html to this wiki over the next week or so. I built a SLS 3D printer that prints objects in a wax and carbon mixture that can be used as positive models for the lost wax casting process.

Release status: Experimental

| Description | This is a prototype SLS system that prints in a wax and carbon mixture for use in lost-wax casting.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | Toolheads, Powder Printers, Wax printing, Laser Printing

|

| CAD Models | |

| External Link |

Contents

Introduction

The Reprap and other FDM printers that fabricate in PLA and ABS are restricted both by the limitations inherent in these materials and by the limitations of the FDM process. Though these printers are entirely capable of self-replication and of producing parts for a variety of light-duty applications, they cannot produce pieces that can replace the cast aluminum parts found in power machinery, CNC equipment, or in numerous other high-strength applications. To address the problem of rapid fabrication in metal, I sidestepped plasma jets, electric arcs, and high-power lasers by opting instead to employ the lost-wax casting technique coupled with a relatively low-power laser sintering system.

A complete report on the project with more technical details can be found here.

Process Overview

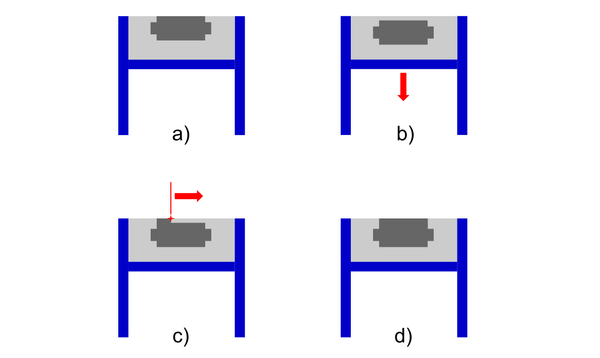

The SLS process can be described with the following graphic:

(a) An object (dark gray) is being printed and is ready for the next layer.

(b) The print piston descends an incremental amount and new powder is deposited in a thin layer over the solid object.

(c) A laser is translated over the freshly spread powder layer and melts the powder to the object beneath.

(d) The layer is finished and the process is ready to repeat until the object is completed.

Hardware

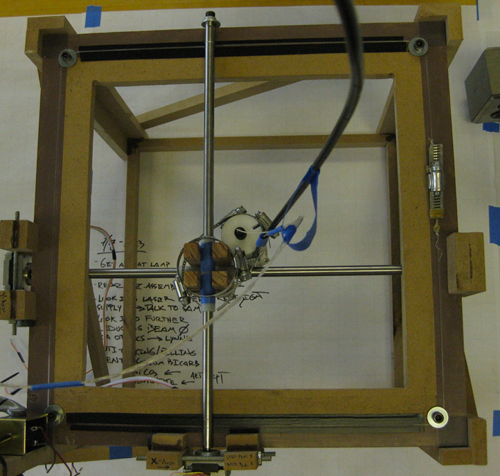

XY Translator

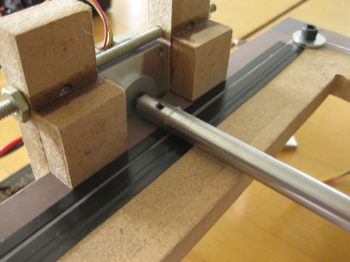

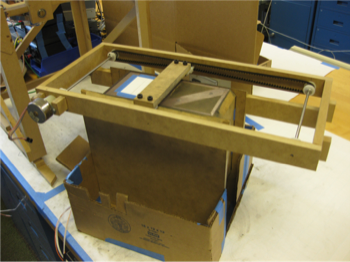

The XY translator is based on the clever cable-based linear translation system implemented by Ilan Moyer in his FoamCore CNC Project. It took just a day and a half of work in the machine shop to create a functional prototype. I employed 1/2" MDF as my primary structural material because of its high tolerances and the ease with which it can be worked with simple tools. I cut the square frame and the motor mounting blocks on a table saw and used a vertical mill to remove material inside the frame. I assembled the motor mounts with super glue and threaded rod and lined the perimeter of the frame with Teflon tape to reduce friction from the riding motor mounts.

I used reamed nylon bushings to create primitive, but very effective roto-linear "bearings" for the simple translation head. The bushings ride on 1/2" drill rod that is driven on one end by a stepper motor. The end of each gantry shaft has been reamed to the diameter of the stepper motor shafts and has a threaded hole to allow the shaft to be secured by a set screw. Because the wrapped, tensioned cables prevent linear translation in the plane of the frame, the torque from the motor results in rotary motion of the shaft, which causes it to roll.

Laser Shutter Mechanism

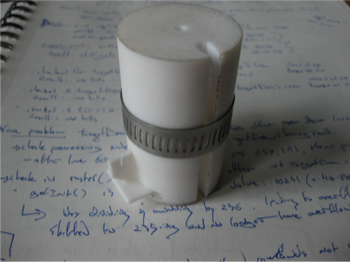

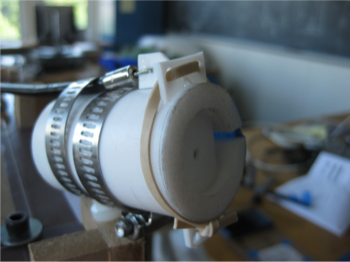

I machined the optics mount from a piece of Teflon round stock. A 40x microscope objective resides within the cylinder, collimating the laser. The cable drives a wedge of Teflon sheet into a slot, pulling a second sheet of Teflon into the path of the collimated laser beam.

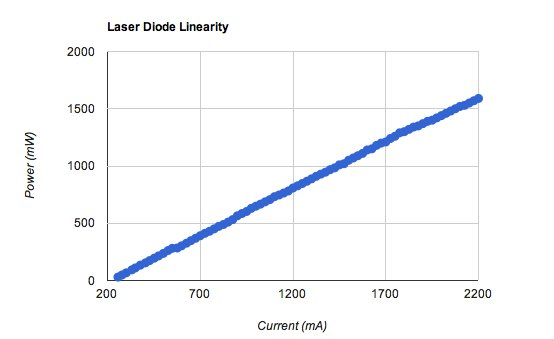

The diode is linear until just over 2.2 Amps where output is roughly 1.5 Watts output, which is primarily the power at which I operated the laser. Because of the high power, I affixed the diode to a large heatsink, though the diode never did get alarmingly warm. I chose the fiber-coupled infrared diode approach after consulting with representatives of several laser sales companies and a local laser technical expert. They all agreed that IR diodes deliver the highest "bang for your buck."

Powder Distribution Mechanism

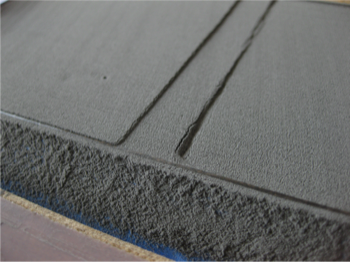

The power distributor uses a stepper to drive two timing belts to which a Teflon-coated wedge is secured. A feed piston loaded with print powder advances at the beginning of each new layer sequence. The print piston recedes 0.3 mm and then the wiper sweeps across the feed piston and transfers a thin layer of powder onto the print piston. Surplus powder falls off the edges of the piston housing into simple paper hoppers.

The feed and print pistons are each driven by a stepper motor secured to the underside of each piston platform. The stepper motors are directly coupled to leadscrews that turn in a captive nut to provide very precise Z-positioning (approximately 0.0002" per step). The color difference in the print powder below is due to differences in lighting conditions, not powder composition.

Software

Software was on of the largest challenges I faced in this project. I used a combination of open soure software to run my hardware successfully. I used the Ultimaker version of ReplicatorG and I loaded my Arduino with customized Ultimaker firmware. I excised all code that was involved in running the extruder or the heated bed and wrote new code to run my powder management hardware and laser shutter. All code and further documentation of my project can be found at my github repository (currently a little messy, sorry).

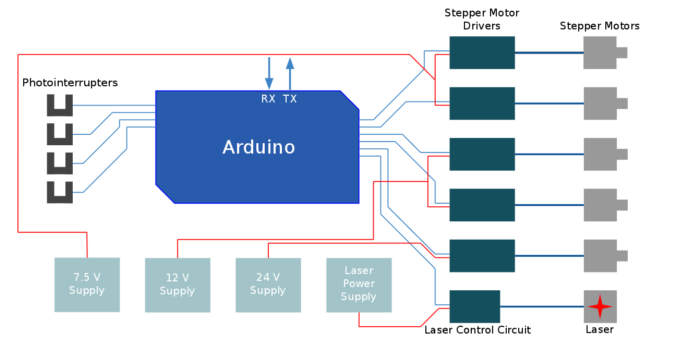

Electronics

An early implementation of the control electronics. The five Pololu A4983 stepper motor drivers (now discontinued) are configured simply to provide speed and direction control here and there are no optical endstops hooked up yet. The shutter control circuit is a simple transistor circuit with a diode to catch back EMF from the solenoid.

The biggest problem with this system is the cost of the laser controller. Used ILX Lightwave diode controllers cost between $1,200 and $2,500, which is prohibitively expensive for the 3D printing community. I was fortunate enough to be able to borrow for the summer during which I worked on this project. I've seen cheap laser diode drivers for sale on eBay that claim to be able to drive 405nm and 808nm diodes at 1 Watt, which is approaching the power at which I was operating.

Lost Wax Casting

Videos

<videoflash type="vimeo">29566951</videoflash> <videoflash type="vimeo">29564093</videoflash> <videoflash type="vimeo">29560030</videoflash> <videoflash type="vimeo">34234394</videoflash>