User:Ypc5015/Blog

Main | About Me | Class Blog

For this class we write weekly blogs on a variety of topics that have to do with 3D printing.

Contents

Blog 1: Thingiverse

We need to search Thingiverse and explore some printed items witch satisfy these descriptions:

A) Something amazing/beautiful

This Gyrornament is such a cool deco that let me think of two ancient Chinese item; The first one is Hexagon Cap Bottle, a Yuanmingyuan precious pottery vase with a smaller one inside but cannot take out; The second one is the Universal instrument(maybe you can only see the picture), this structure can let the core layer sustain the same direction regardless of the outside direction and position change, which can easily use to navigation.

Still, I love this design because of its beautiful, interesting and amazing.

Highly recommend to watch this video!

B) Something funny or strange

This Strawberry Stem Remover is a good idea to invent tools to remove strawberry stem, because if we use our hands to do so, the strawberry will embed into our fingernail which is pretty uncomfortable and hard to clean. But this design is a little strange, because I think the manipulation is not comfortable and easy to slide. if this item cannot make people feel comfortable and convenient, people will not try to adapt it and change their habit.

C) Something useless

In fact I used this Cable Holder (Cable Clip) 2 years ago, just curious about its design and experience, but I feel very bad. First, a plate surface stuck on a projected item looks like strange and inconvenient; Second, the double side tape cannot perfectly connect the table and holder, because the holder is made by rubber, the tape can move on it; Third, if I want to remove the holder, the table will leave a black stain and hardly clean it. I prefer to simply use tape stick the cables directly on the table.

And I think the material should be soft, so normal hard plastic 3D printer may not available.

As to solve the problem of mass cables, maybe the second picture about Diagrid Bracelet can be a good idea. Using some soft elastic material to build that kind of structure which can be easily elongate and recover its original shape by itself.

There is a good TED about a kind of fantastic material: Skylar Tibbits: The emergence of "4D printing"

D) Something useful

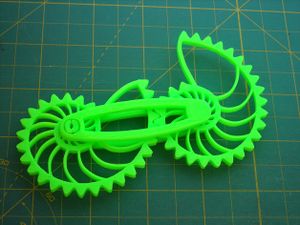

One of the most inspiring things that 3D printing brings to an engineering student is printing gears of any shape, so we no longer concern much about the gear modulus and size, so the motion transmission design becomes much more easier, and it also reduces the limitation of products shape that standard gears bring to.

Look at these fantastic examples:

Nautilus Gears With Modified Bar

E) Something which surprised me

Watch this Escher's "Penrose stairs" carefully!

The world of 3D printing is full of innovation, I'm eager to know more about this technology!

Blog 2: OSE project

We were asked to research about OSE projects and respond to the following:

A) General impressions of the OSE project.

B) The New Yorker magazine recently had a fairly critical article regarding Marcin's OSE project. Find/link the New Yorker magazine's article which about Marcin's OSE project and summarize its critique, and response to this article and Marcin's response.

C) Imagine we want to create capabilities similar to what Marcin has made at PSU (something like an OSE student club, or another effort). I don't think the administration or trustees would support such a thing, but there might be professors who are interested in supporting such a thing. Do you know any of them? What do they do, and why do you think they would be interested in such a project? Imagine you are looking for allies to do such a thing. Whom is on your list and why?

Here are my responses:

A) My first impressions of the OSE project is surprise, just like the TED words: Ideas Worth Spreading. It's definitely a good idea to involve much more people into the designing field to contribute their ideas, and good for them to be knowledgeable through a scientific effective way. However, as for its feasibility of the manufacturing part, I hold the negative position based on the following reasons.

First, to make most of the design into reality, we need considerable knowledge of various fields to prevent danger, just following the video on OSE website is not sufficient for us to finish it, especially when these machines need strong power to drive. It's pretty OK for them just design it on paper or digital picture, and spread their ideas with others, but building up a big machine need to let experienced experts do. (It's not as easily as cooking!) For example, look at this Powercube, we can build it for fun, or for studying purpose, but we can hardly design it by ourselves and do some improvement, not only because of its difficulty, but also limited to the different materials each person used.

Second, much of their works are just waste of resources. each of their project is very sophisticated if you want to realize it as perfect as possible. We need to calculate the economic balance between the cost of building the machine and final benefit of it brings to us, including the energy consumption, material, labor input, and so on. It could be even significantly hard when accounting take into account. As for an engineer, we need to check each bolt force, circuit power, and pipe strength to ensure safety. Not everyone can endure the horrible workload even within a test level devices, not to mention the industrial equipment.

Anyway, I think Marcin's idea about OSE is great since he encourage more people to contribute their thoughts to make our life more colorful, but it's not necessary to inspire everyone to manufacture their idea by them own.

(Interestingly, This video about Factor e Farm Spring Cleaning Sprint, the 1'28" the upper picture was photoshoped, I don't why he did this instead of posting the original photo.)

B) Here is the New Yorker magazine's article about Marcin: The Civilization Kit This article said that the people who show up at his farm typically display more enthusiasm for his ideas than expertise with a lathe or a band saw, and his dream is too idealism to realize.

As far as I'm concerned, OSE does have some problems, but we cannot say it is not worth to do. As the article said, some people showed their interest on his ideas, and OSE has so many fans working for it happily, so it means OSE created many value for our society. Although people didn't showed much enthusiasm for his expertise, we cannot say OSE is failed, after all OSE is not a technical school, it is a way to let people exchange ideas, learning technology, and make new friends who have similar interest. As for this angle, OSE did very good.

Marcin's response is here: New Yorker - Article Response He said that New Yorker misunderstood what OSE were doing and what their aim was. He said OSE building up an open source innovation system to educate and inspire people to do so through "one of a systems perspective that results in responsibility." They were striving to optimize production to One Day of build time while involving a non-alienating social and learning process. And they are building a recreation center, which indicates that their condition is optimism.

As Marcin said, they've invited economics/industrial design specialists to collaborate with, it means this kind of open source design is relatively difficult for most of people, especially when the production time and financial issues take into account. But still, as I mentioned before, it will be a good way for education and innovation, since it can involve more brains to do so, but I'm not optimism with the manufacturing part.

Reader's response for Emily's article: http://www.newyorker.com/magazine/letters/2014/02/03/140203mama_mail, the reader said OSEr are too naïve about technology, and open source hardware design is not as easy as software does, and only technology alone cannot fix the problem they want to solve.

C) In my point of view, the most possible professors that might support such a thing are Timothy Simpson and Matthew Parkinson.

The first one, Prof. Simpson, is the leader of the Engineering Design & Optimization Group and the member of the Center for Innovative Materials Process. He impressed me favorably because he did so many researches about innovation and product design, his paper like Strategic Product Design for Multiple Global Markets, and From User Requirements to Commonality Specifications, An Integrated Approach to Product Family Design, and so on, clearly indicate that he loves hardware design and greatly support innovation activities. It not only is a good idea for us to create capabilities similar to what Marcin has made at PSU, but also a good chance for Prof. Simpson to do what he like to do.

The second one is Prof. Parkinson, the leader of OPEN Design Club, may shows strong interest in this open source hardware design idea. According to his research like Techniques, tools, and representations for solving design problems considering anthropometry, and Interdisciplinary Graduate Design Programs, Results and Recommendations from a NSF Workshop, the key words of his academic interests is anthropometry, design, and education, which have a big part intersect with our idea.

I arrived Penn State only for less than a month, so I just know these professors through website introduction and their papers. But I'm applying for my graduate program and they are the professors that I want to working for, so I think I will contact them later and talk about my plan about innovation.

Blog 3: Prosthetic Hand

We were asked to read Kansas teen uses 3-D printer to make hand for boyand response the following questions:

A) Who created this design and when/where was it done?

B) If you wanted to make one, where would you go to get it?

C) How many news articles can you find which reference this technology?

Here are my responses:

A) As the sentence on the article "Owen co-designed the original 3-D printer Robohand with Richard Van As, a South African woodworker." , "The two agreed, and the Robohand prototype, made of metal, was born in November 2012." , "The first 3-D printer version was made in January 2013, and Van As and Owen put free instructions online." The design was made by Richard Van As and Ivan Owen in November 2012, and printed it in January 2013, Owen had the interview at Bellingham, Wash. And Manson Wilde printed it at the Johnson County Library for the boy, Matthew, the 3-D printer was located in an area called the Makerspace that opened nearly a year ago.

B) The easiest way to make one is download it through this page Complete set of mechanical anatomically driven fingers, and print it at Penn State by myself.

But I think the reasonable way to make it is to find someone really need this thing first, and later scan his or her hand in a natural condition via some 3D-scaning app or holography so that do get a perfect shape of the hand in a 3D image. After that, download a proper 3D prosthetic hand file, adjust the scale to fit the user's size, and replace the attaching side with the scan 3D image, ergonomically correct the image under the consideration of the 3D printer performance. Then we can print it, and polishing it according to some realistic reason, assembling all the part. Finally put it into use and get feedback from user for revising and improving.

C)

Related to prosthetic hand

Teenager 3D-Prints Prosthetic Hand for Adorable 3rd Grader in Need is for the same person.

How a $100 arm is giving hope to Sudan's 50,000 war amputees

3D-printed prostheses give hope to amputees in war-torn Sudan

Kindhearted Techies 3D Print Prosthetics for Ducks With Disabilities

WT engineering students make difference with 3D printer

Using 3-D printing to address the need for prosthetics in Uganda

MakerBot Endeavors to Transform Universities into Innovation Centers

Related to artificial organs

Growing artificial organs: Medicine’s next big thing?

Defeating aging, and the avenues ahead of us: Part 3

Rise of the machines and other tech & media trends for 2014

Boston Company Developing Synthetic Organs

http://www.onlinetmd.com/tmd0214-printing-tissue-organs.aspx

Blog 4: Reflect on the Thoughts of Classmates

Lee Schwartz

Lee has some great point worth thinking: 1. The large companies are more tend to against the project since they won't let this kind of competitors easily beat them. So we need to analyze others commends for OSE carefully. 2.People are required enough knowledge so that they can participate the OSE project easily and safely.

Todd Troutman

He mentioned this project "didn't give those he worked with any of the money earned from sales of equipment, and didn't do much to improve living conditions." So the final goal of Maicin's seems far from achieved.

Drew Golterman

Drew discussed the “one day goal”, which is their goal to create new designs that have the ability to be assembled in only a day. He said people who are familiar with their design can assemble their design quickly. But as I thought, it is the design process that spend most of the time but not the assemble. China is the manufacturing plant for the world, and assembling is only one process that easy to learn. So "one day goal" could be a kind of design philosophy that every designer trying to achieve.

Kevin Moyer

Kevin mentioned a point that can be easily ignored, that is how important the leadership role for the team. Many classmates thought OSE was very hard because of the followers were lacking of professional knowledge, but most of didn't taken leadership into consideration. In OSE, we cannot deny that Marcin is a great full-time leader for this project, and the importance of leader to the team can never be exaggerated.

Sam Carroll

Sam gave us a good point: If this open source revolution is to really change the world, it needs to be adapted and replicated by more than people inside the OSE structure. It seems most of impact ideas spread should overcome many obstacles, and OSE is facing this kind of thing, so we need to give it some time and watching the tendency so that the result will represent in frond of our eyes.

Anthony Fanelli

Anthony said that " In today’s world so much emphasis in product design is put into aesthetics even though it doesn’t affect the performance of the machine." I think it's a great perspective especially in Penn State, Industrial Design and Mechanical Design have large part related but belongs to different department, and they all serve to product design. My favorite professors Simpson and Parkinson also work to different department but they write academic papers together. Penn State is trying to bridge the gap between Engineering and Economy (or Management?), why we don't bridge the gap between Industrial Design and Mechanical Design? I think the feasibility is worth discussing.

Jarred Glickstein

Jarred referred to a good point, OSE opened a door for those who were lacking of techniques and could only do something simple and boring and less beneficial to learn some useful and scientific knowledge, and let them think about their requirements of lives. But still, I think it's not a fundamental thing, it need some knowledge and skills, which can hardly gain with low cost (open source programing learning can be learnt without economic cost).

Jessica Mewkalo

Jessica said OSE may lead to millions jobs elimination and companies out of business, but save people's money. Yes this project may impact out existed economy, but it is a good thing since it just proved that OSE did better than companies, and people are more prefer to cheap product even it's not very good. So OSE may urge enterprises innovation to cater to customers preferences.

Blog 5: Look through the RepRap Media timeline page

In this blog we need to look through the RepRap Media timeline page and attempt to identify the most significant events from the last few years. and Make sure picked and point out at least one entry which you find:

1) An event very important in the progression of 3D printing technology (open source or not)

2) A not so important event in the progression of this technology (something overhyped perhaps?)

3) Something which I found interesting which you would like to think or speak more about.

What projects continue to receive coverage/press over time?

1. Thingiverse:

2008 November; Thingiverse is launched;

2011 September 20; Article on the Make blog about a working AR-15 magazine on thingiverse.

2013 January 24; RoboHand is uploaded to Thingiverse.

2013 November 11; Smartrap [201] Summary: Brook Drumm released his design of a reprap based off of the printrbot simple on thingiverse.

As the first website where people can upload their own 3D models for people to print out, open sourcing at its finest, thingiverse won the most people's favorate and highly accelerated the development of open source 3D printing, and opened the minds of people's to let them become more creative.

2. Mendel:

2009 October 2; A second generation design, known as "Mendel", prints its first part.

2011 Fall 2011; Open Hybrid Mendel Design is tested at Penn State University Park Campus.

2013 October 9; RepRapPro Sponsors 3D Printing Exhibition at the London Science Museum. Summary: The Science Museum of London will be featuring prints from the Huxley and Mendel RepRap printers in the 3D: Printing the Future exhibition.

Mendel is currently the most popular Reprap 3D printer at Penn State, and also a successful one for a novice entering the 3D printing world, so the more people working for this kind of 3D printer, the more opportunity this one could gain opportunity to develop, and easily receive coverage/press over time.

3. 3D scanner:

2012 July 17; 3D Printers In The Library; Toward a FabLab in the Academic Library. Summary: The DeLaMare Science & Engineering Library at the University of Nevada, Reno has added two 3D printers, a 3D scanner, and supporting software available for general use to the school community.

2012 November 12; 3D-Printing Photo Booth Makes You Into an Action Figure. Summary: A photo booth in Japan will scan your body and create a figurine of you. It can be a maximum of 8 inches tall and doesn't have the precision yet to pick up on shiny jewelry, earrings, mesh items, or glasses. Customers must pose for about 15 minutes for the machine to collect their body data.

2012 December 6; A 3D-printing popup store (3DEA) opens in NYC for the holidays. Attractions include a body scanner and ornament design competition.

2013 April 26; 3D Scanners Reproduce Real Life.

2013 September 4;All-in-one 3D printer-and-scanners.

2013 December 8; Scientists develop new app to turn mobile phones into 3D scanners

3D scanner is experiencing a great advancement when 3D printing technology is explosion.

4. 3D printing crime and security

2006 January 12th; 'Printcrime' a short story about RepRap by Cory Doctorow.

2012 July 16; 3D printed keys used to hack high security handcuffs.

2012 October 25;With ‘Safe Haven,’ Desktop Weaponeers Resume Work on 3D-Printed Guns.

2013 April 26; 3D-Printed Guns Can't Be Stopped.

2013 November 7; World's first 3D printed metal gun

3D printing greatly enhanced product design, at the same time, some crim around 3D printing begin to appear. But we cannot say that 3D printing isn't worth doing, like all other technology, some people always want to do some bad things through a new way, what we can do is using lawful means to control the criminals.

What projects seem to have slowed or stopped?

2012 August 6; New machine prints stone using sand and binding agent

It seems only one issue related to print stone.

2012 September 21; 3D Print Wood with Laywood Filament

As far as I'm concern, wood printing is not a good idea since it's hard to change the shape as our will, and make it to small pieces and bind them together is also seems not necessary.

Something which I found interesting and liked to think more about.

2009 October 2; A second generation design, known as "Mendel", prints its first part

As I see, "Mendel" is a remarkable milestone of 3D printing history, it's a great idea to let 3D printer print itself within reusable material, which can easily let more and more people learn 3D printing and enjoy their own printer. It named after a great biologist which means this kind of printer can replicate itself and make evolution, which just like endow life to 3D printer and everyone can do something to make it become better and better, just like Linux.

Bonus Blog 1: Monitoring system design for 3D printer Mendel

on 2/4/2014, David mentioned that 3D printer didn't know it's broken when it working, I have some ideas but haven't find out the feasibility.

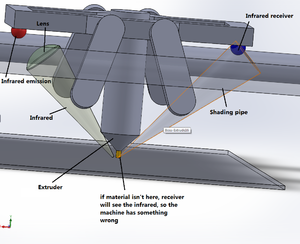

First we need to define what conditions of 3D printer can be treated incorrect. According to these days working with 3D printers, there are so many incorrect situations like wire disconnection, temperature improperness, material stops extruding and motor stuck. But there is only one result: the outer shape of what we are building is incorrect. So the simplest way to solve it is to let the system watch and know the flaw on the model and response for it. Fortunately, the flaw always starts from the nozzle, (suppose the beginning of printing is correct and excessing extrude will not occur.) so we just need to place sensors to "watch" the nozzle.

The first picture is using infrared sensor to find out whether the nozzle is extruding or not, the lens and shading pipe are optional, just make sure there is enough accuracy and avoid interference. When the material isn't at the nozzle, the receiver will see the infrared and tell the SCM. And when the SCM let the printer stop extruding, the "broken" interruption will not be triggered, it's easy to realize by modifying the program. It won't happen that the material shades the infrared light but the nozzle has already stopped extruding and the material doesn't touch the model, because the melted material has enough surface tension and viscosity, so the probability of the occurrence of the event is very small.

The second picture has similar design but based on the different idea: the circle infrared distance sensor is to measure the change on the model surface. Suppose the nozzle is moving left and extruding, the infrared emission on the left side will send a signal and get a distance feedback, after a very short time, the infrared emission on the right side arrived at the same place and send a same signal, and get another feedback to compare with the first one, if the first one is greater, the machine will know it's working properly.

The third picture is the design about monitor for 3D printer, the size of camera should be larger and the size and shape of mirrors should be changed, but it just show how it works. the camera can watch the nozzle directly and also the image of the other side of nozzle through the reflection of mirror, because we just need to analyze several pixels of different positions around the nozzle. The problem of this idea maybe the vibration of printer and the camera focal length (add a lens can fix it). My goal was not to find out which part of printer was broken, but to stop the printer when the printing model is incorrect.

Since I haven't done anything about monitoring image analysis, I wish to work with someone interested in the same area this semester. Maybe we can use another type of sensors, or define the incorrectly working condition in another way so that to use other technical solutions, or even focus on solving a specific problem of 3D printer. So that's what I think about your problem, hoping to discuss with you.

Here is also part of David's response:

One difficulty with monitoring the nozzle alone would be that there are other mechanical failures , or outright printing defects, which would not be observed by judging the nozzle alone.

That being said, most of OUR problems are related to extruder misbehavior and so such a system would still be of some use to us. The extruder sometimes pauses with good reason, we would have to synch this logic algorithm to match its expectations from the GCode.

I think your second method could be tried, but the cooling mechanisms might disrupt the logic. I guess more importantly: Does such a sensor exist on the shelf? We would be hard pressed to make our own, and we can't attach the IR camera to the printer for anything more than short filming efforts.

If we could get the parts for method one, this might also be a route. I worry that the filament will not work with IR (you will probably want a visible or uv LED)