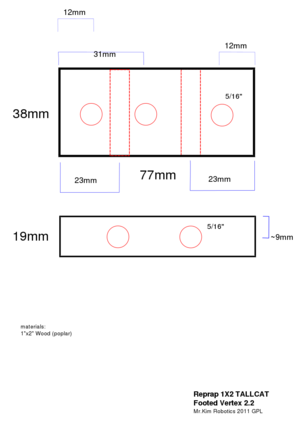

1X2 Tallcat

Release status: Working

| Description | Elegant Wooden RepStrap

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Description:

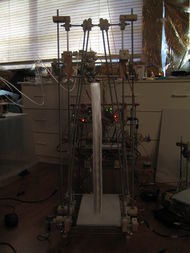

Shoot for the Moon!

The 3ft tall TALLCAT has a vertical build area of 640mm.

This is a scaled up Pyramid Repstrap made with all 1-Dimensional 90 degree cuts.

The 1X2 and 1X2 TALLCAT are RepRap class 3D-printers that can be built with access to only a drill-press and hand-saw. The parts for the entire system can be made with one-dimensional tools, straight cuts and common materials.

First Test:

607mm tall single-walled tube(40mm diameter).

Z-Step: 0.30mm

Print Time: 5hr40min

This machine is made by: mrkimrobotics.com This web site is not reachable as of 20111019

Design:

The TALLCAT turns its biggest weakness, long flexible rods, into a strength by using the flex to triangulate the frame into a pyramidal structure. The rods bend out of the way of the z-bearing blocks as they ascend from the inside of the pyramid to the outside. This makes full end-to-end travel possible even with a highly acute frame.

Improvements:

- Eliminated frame spacers.

- Eliminated 45mm M3 bolts.

- Eliminated 25mm X-motor spacers.

- No more asymmetrical countersinks.

- Lower Table increases active Z-Travel.

- X-Travel increased to 160mm.

- Lighter X-Assembly.

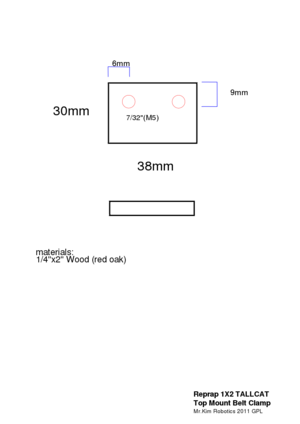

- Simple pinch belt clamp has easy tension adjust and requires no through holes in the belt.

New:

- Vinyl shaft stops

- Dual Pivoting footed vertex allows adjustable bearing block alignment.

Status:

- The Y-Carriage version is working.

- The stepper-driven conveyor-y-axis is physically sound but the control system is still being developed so it is experimental.

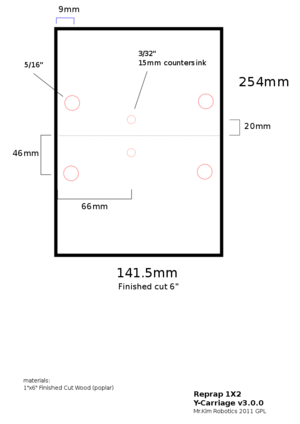

Y-Carriage v3.0:

Version 3.0 has been reduced to a single part.

The v3 y-carriage integrates an adjustable build platform and bearing assembly in a single layer.

This design uses:

(1) board

(4) holes

(4) 3"-5/16" carriage bolts

(8) 608 bearings

(12) 5/16" washers

(16) 5/16" nuts

Belt Clamp:

(2) #6 x 1" wood screws

(2) M4 nuts for spacers

(2) M4 fender washers

Notes:

To allow the belt to reach the higher mount point of the build platform, (3) 608 pulleys are mounted on the threaded frame rods. The timing belt faces outward so the smooth side rides on the pulleys.

The low belt pulley will require feet or a slightly extended footed vertex for clearance.

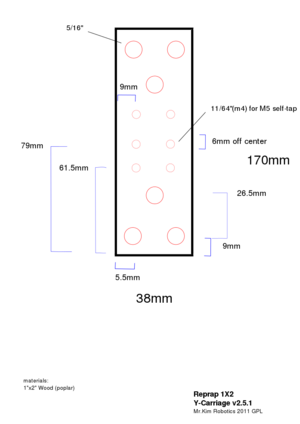

Y-Carriage v2.0:

This version uses traditional toothed timing belts and a 1x2 only Y-carriage design.

Video:

Changelog: v2.5.1 26.5mm spacing for 5//16" rail. Dual table supports. Center belt mount.

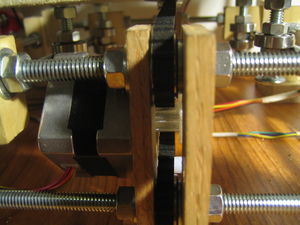

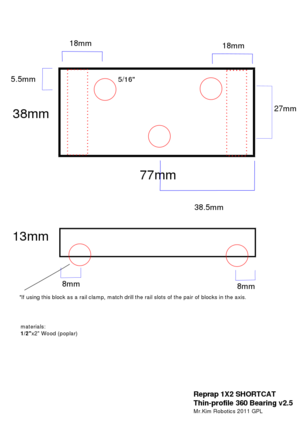

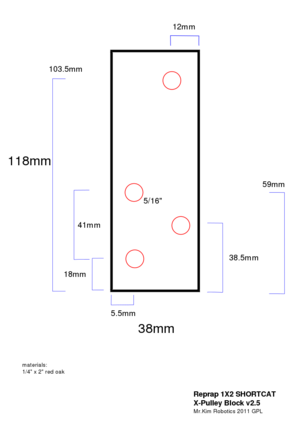

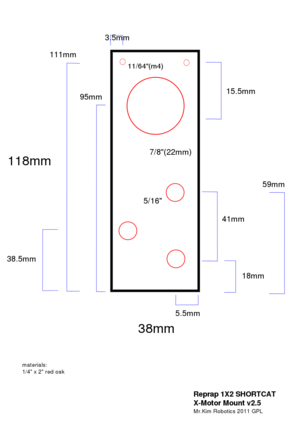

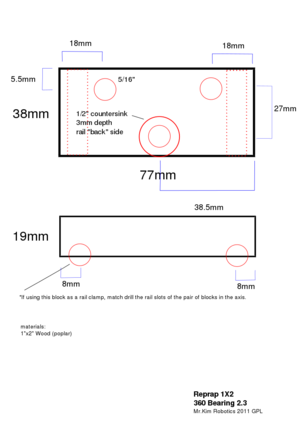

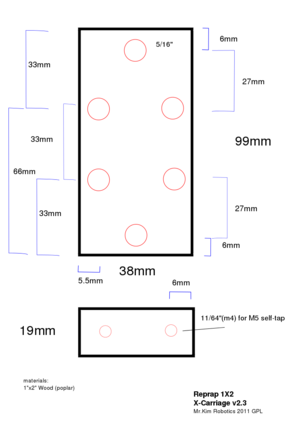

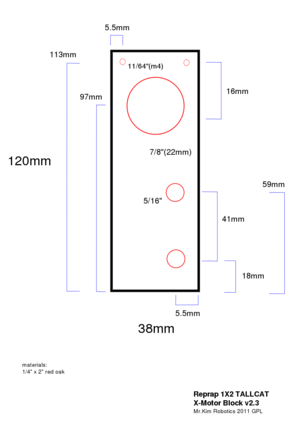

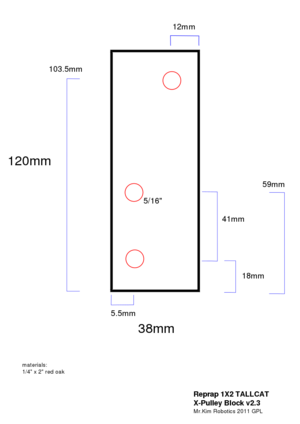

Thin-profile x-assembly v2.5.0:

The Thin-profile x-assembly has even clamping pressure.

Notes: The holes can be match drilled or bolts can can be used to register the blocks.

Hardware:

(6) 2"-5/16 bolt

(10) 608 bearings

(13) 5/16" nut

(8) 5/16" washer

(2) 11mm DIY M3 tefon standoffs

360 bearing stack assembly order:

Two capture stacks:

Bolt with no washer, motor mount clamp plate, 360 bearing block, washer, 608 bearing, nut, 608 bearing, nut.

One draw down stack:

Bolt with no washer, motor mount clamp plate, 360 bearing block, washer, nut, free space, 608, washer, nut.

Leadscrew nuts:

(2) 5/16" nut

x-idle pulley:

(1) 1"-5/16 bolt

(1) 5/16" fender washer

(2) 5/16" washer

(1) 608 bearing

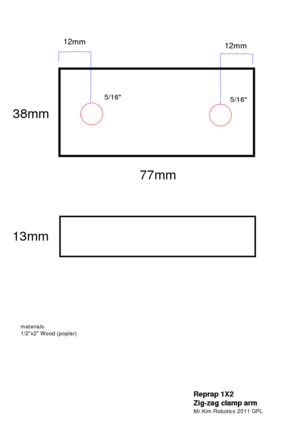

Zig-zag leadscrew clamp:

Over-tightening the zig-zag clamp will cause it to twist and bind the leadscrew nut.

Placing (8) washers between the zig-zag arms will keep it from twisting.

Washers on the rail between the 360 bearing block and the inner zig-zag arm can sometimes also reduce the twisting.

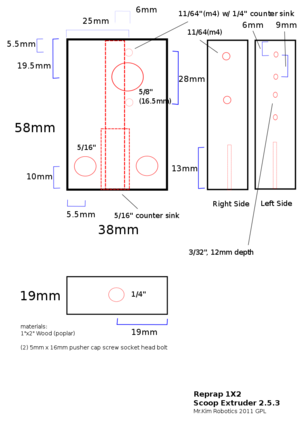

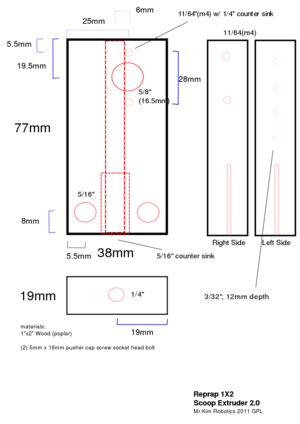

Scoop Extruder v2.5.3:

Version 2.5.3 experiments with a shorter 58mm body to make the central bore easier to drill.

It is slightly more compact and has a shorter distance after the drive gear.

Parts Y-Conveyor Version:

This is the original set of parts for the conveyor-belt y-axis version.

note: The v2.5 Thin profile x-assembly from the Shortcat has replaced the older x-assembly.

Hardware:

Frame:

(4) 36"-5/16"-18 Threaded Rod Zinc

(2) 36"-5/16" round rod

(9) 12"-5/16"-18 threaded rod

Leadscrews:

(2) 36"-5/16"-18 Threaded Rod Zinc

Y-axis rails:

(2) 12"- 5/16" round rod

X-axis rails

(2) 5/16" round rod 350mm length

Notes:

The basis for this group can be found under the 1x2 project.