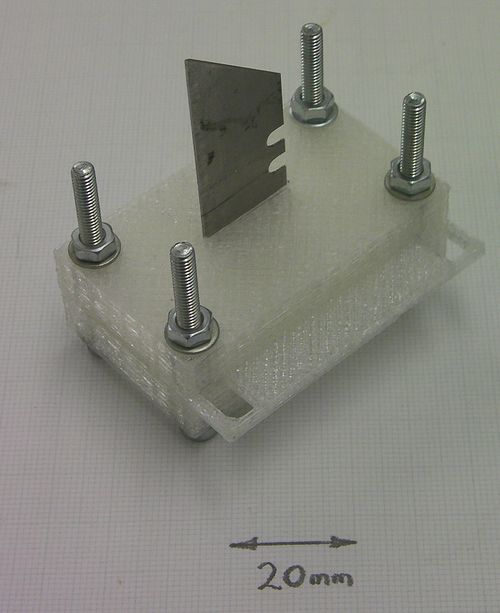

Belt splitter jig

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Mendel uses belts which are only 5 mm wide, but stock belts for the suggested pitch (5 mm) usually come in either 10 mm or 15 mm widths. The belt splitter jig is needed to split these wide belts.

The two RP part files can be found at:

<videoflash type="vimeo">7027330|640|480</videoflash>

BOM

| Name | Qty/assembly | Total Qty | Type |

| belt-width-adjuster_1off | 1 | 1 | RP |

| belt-split-jig-bracket-universal_2off | 2 | 2 | RP |

| Box cutter/Stanley blade | 1 | 1 | Blade |

| M4x40 cap | 4 | 4 | Fastener |

| M4 nut | 4 | 4 | Fastener |

| M4 washer | 8 | 8 | Fastener |

Assembly

BLADE WARNING: Use leather gloves or be prepared to lose fingers.

This is what it should look like, though the belt has been omitted for clarity. The bit sticking out the side slides in to accommodate different belt widths and clamps when all four screws are tightened.

Operation

BLADE WARNING: Use leather gloves or be prepared to lose fingers.

Assemble with the belt in place. Tighten bolts. Work the blade into the belt.

Insert blade fully. It is safest to clamp the whole assembly in a vice, then pull belt through.

The wire that stops the belt stretching and that is buried in it run in a helix. It is not a stack of loops. So watch when you have been once round with the blade and stop. You will find that the two halves are still held together by the wire. Cut that back and trim and tidy the edge with wire cutters. You must avoid a step in the edge, as that may catch as the belt is in use.

Back to Mendel mechanical construction root.