Hydra-MMM Prototype

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: unknown

| Description | Prototype for multi-headed manufacturing machine

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

| FILE ID# | TYPE | DESCRIPTION | AVAILABLE FORMATS | CREATED/RESERVED BY |

|---|---|---|---|---|

| Your-File-Name | SOLID MODEL ASSEMBLY | These are CAD files for the Solid Model Assembly | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC) |

| Your-File-Name | CAD FILES FOR PARTS | These are CAD files for each part. | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC) |

| Your-File-Name | EVEN MORE FILES | These are are even more files. | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC)|- |

| Your-File-Name | SOLID MODEL ASSEMBLY | This is the final finished machine | N/A | --Example User 12:00, Tomorrow's Date, 20xx (UTC) |

Please edit this to put in your own files! --Sebastien Bailard 08:34, 10 September 2010 (UTC)

Contents

Project Background

Hydra is a multi-headed manufacturing machine that is originally being designed and built for ME463 (senior design) at Purdue University. The general idea is to make a personal manufacturing machine that will be able to perform multiple, simultaneous operations such as milling, additive prototyping, pcb fabrication, laser etching, etc. For the most part, current industrial workplaces have dedicated machines for each one of these functions. By having multiple independent toolheads on the machine, Hydra will be able to perform compound operations that are not possible on dedicated machines (ie FDM rapid prototyping and milling for more accurate part outlines). Hopefully the project will lead to potential discoveries of new manufacturing techniques through the use of compound operations, as well as create a very cost effective product for small business or educational institutions who cannot afford current commercial machines.

Please see: http://cpwebste.blogspot.com/ for more information about the build or https://sourceforge.net/projects/hydra-mmm/ for all future software and firmware releases

A second Reprap wiki development page at Hydra-MMM_Software_and_Firmware has been created to handle all details about the software and firmware for the machine.

Cartesian Robot Target Parameters

What we would like to accomplish with the robot. The goal is to have a very versatile machine that will have superior accuracy and power compared to a belt drive prototyper such as the Mendel, yet still maintain a high maximum printing speed.

500 IPM machining movement, 1000 IPM max speed

XYZ resolution of 2.5 mils (0.0025”)

3 mil (0.003”) max deflection under machining loads

18”x20”x8” build volume

Up to 4 independently controlled toolhead mounts

Progress

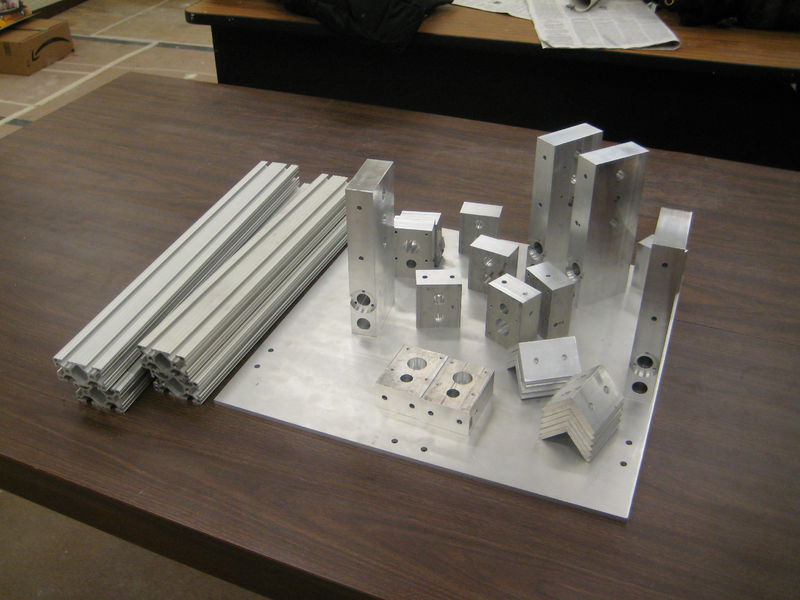

The team has spent at least 120 hours in the shop over the past month making the parts we have designed in the CAD model. Most parts are made from 6 or 7 series aluminum and are all being machined to tight tolerances on the mills we have available. A few pictures of the parts are below.

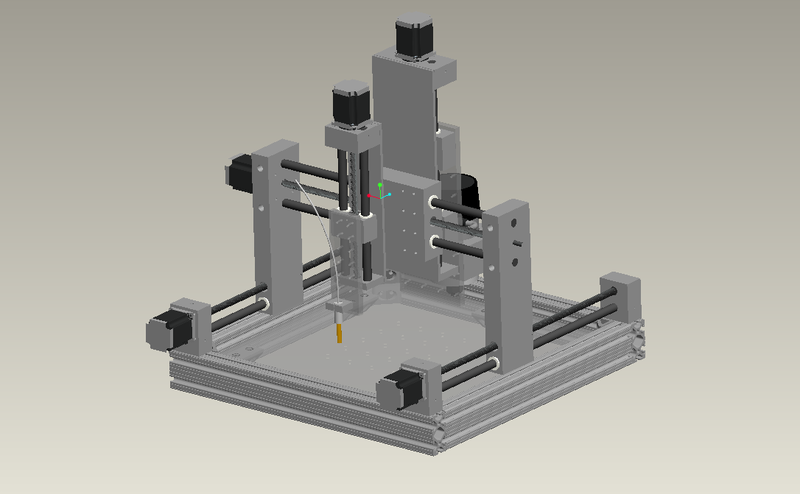

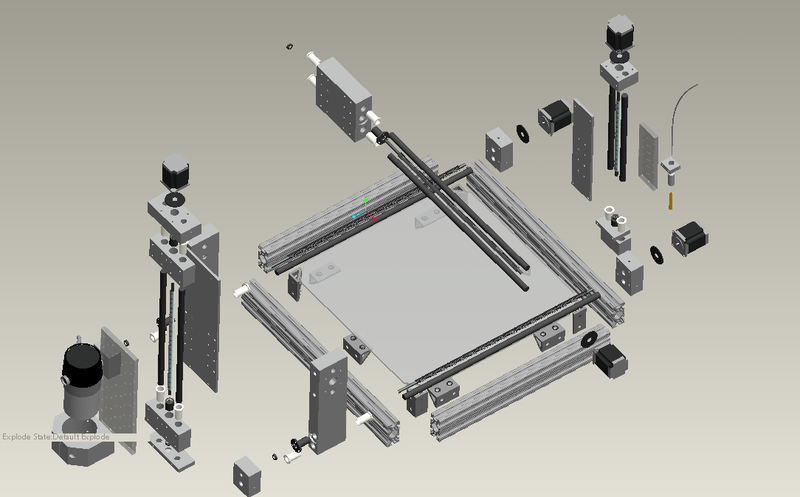

Rev4 CAD Drawings for the multi-headed machine (March 2010). Includes several different sized mounts for various sized attachments (spindle and bowden extruder shown)

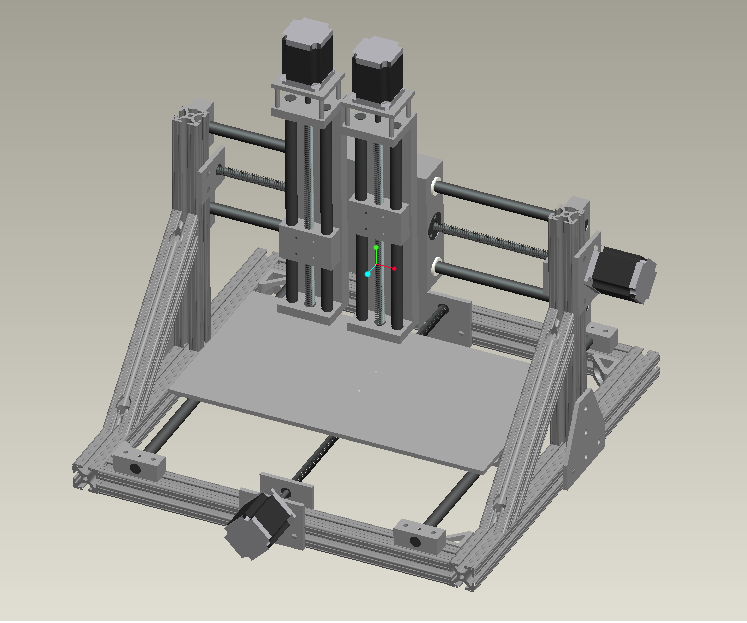

Exploded view showing all of the currently designed parts

Extruder side view. Spindle (Porter Cable) is mounted in a larger Z axis assembly on the opposing side of the X axis

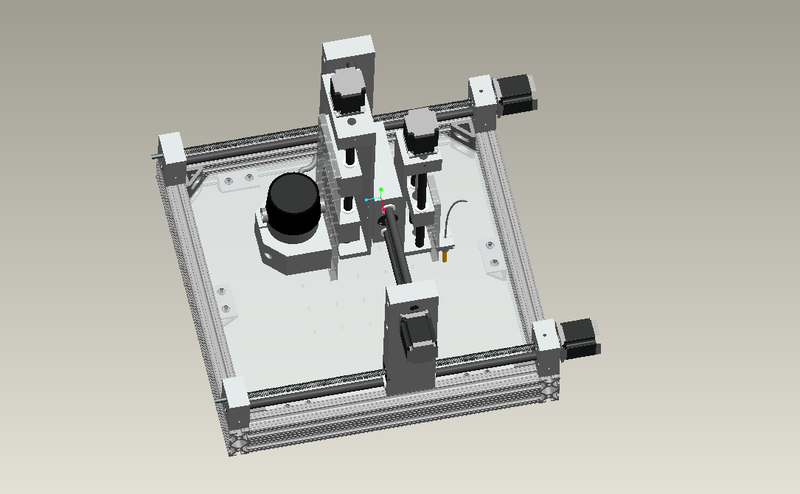

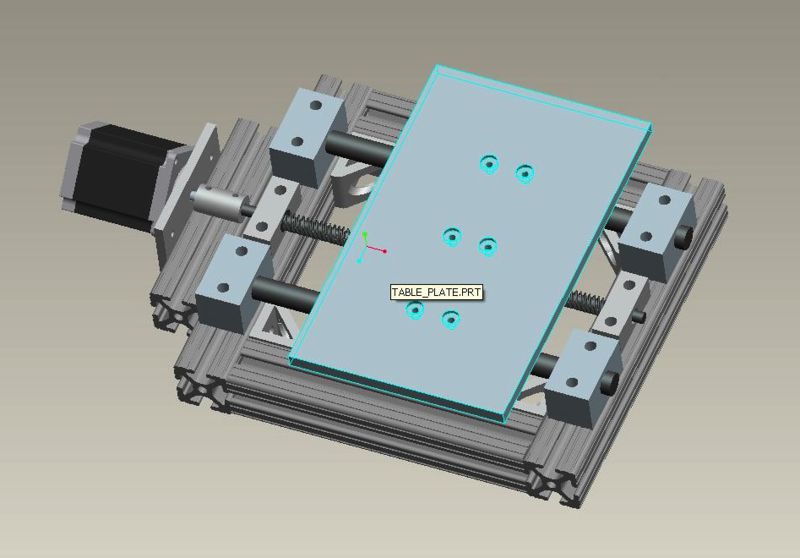

Top view of the machine showing build table size

Moving table concept showing multiple Z-axis toolhead mounts (Feb 2010)

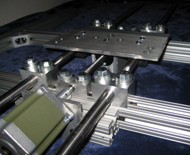

Test axis for determining if leadscrew and sleeve bearing system would perform as desired (Jan 2010)

Completed Design Analyses

Frame rigidity and table deflection

Guide rail strength and max deflection (used to size all rods)

Machining forces placed on toolhead (milling and drilling)

Sleeve bearing maximum stresses during operation

ACME screw calculations for force, deflection, max rpm, resonance, and resolution

Chopper driver MATLAB circuit analysis (loaded RL circuit with transient and decay)

Several CAD concepts in Pro/Engineer each with a priced BOM for evaluation

Barrel heater viability testing

Thermal model of FDM extruder assembly

Note: if anyone is interested in the actual files behind any of these analyses just let me know

Sounds good! Could you upload a zip? --Sebastien Bailard 00:56, 27 April 2010 (UTC)

Future Ideas

Build pick-and-place machine

Make attempt at automated prototyping using pick-and-place machine to remove plastic parts once they are done printing. May even try to do some kind of basic manipulation and assembly

Finish pass prototyping: fast FDM prototyping with large diameter nozzle and then use fine milling cutter to refine the layer outlines

Ability to create and recycle plastic material from HDPE (milk cartons) -- see Recyclebot

Heated build platform

Color 3D printing using either multiple extrusion heads with different color filaments or some kind of coloring system to color filament after it has left the nozzle