MM PLD

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: Prototype

| Description | Fast prototyping tool for multiple material structures in the micrometer range

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Contents

Multi-Material, Sequentially Masked Pulsed Laser Deposition

Motivation

Current micro and nanofabrication processes rely on a vast set of tools and technical capabilities, which usually implies a considerable capital expense and severely limits accessibility to such capabilities in many regions of the world. Small research organizations may acquire some of the tools required, but the fabrication process for standard devices require a substantial number of difficult and error-prone steps which take enormous amounts of know-how and optimization procedures in order to perform with an acceptable rate of success.

General Idea

The main goal is to generate an affordable, and easy to use system which allows the deposition of a wide range of materials in a geometrically controlled way, effectively enabling the creation of heterostructures with a wide range of functionality. Such a device may become a powerful tool for materials science research, and could also sustain interesting developments in distributed and participative manufacturing.

To implement such capabilities, the combination of the following techniques/ideas has been devised, with a particular twist ;)

Pulsed Laser Deposition

Pulsed Laser Deposition is a technique in which mass is transferred in a controlled atmosphere from a target to a substrate by means of irradiating the former with a high energy pulse of light. The energy transfered induces out of equilibrium thermal processes in the target, resulting in the formation of a plasma 'plume' which has a stoichiometry closely matched to the target composition.

While it's not the technique of choice for industrial device fabrication (mainly due to film quality and complications associated with large area deposition, see this section), the ability to deposit a wide range of materials has made it the workhorse for many research regarding complex materials (oxides, nitrates, dichalcogenides, etc) and the applications of some interesting effects (ferroelectricity, superconductivity, …) that they show. An often overlooked characteristic of this technique is the ease of coupling of the energy over the target: one can control with exquisite precision the amount, rate, placement an timing of the energy transferred from the laser.

A very comprehensive account of the technique is the book Pulsed Laser Deposition of Thin Films , while a more up to date account can be found in [1]. A recent practical and very illustrative review paper can be found on [2].

Shadow Mask Lithography

Stencil Lithography refers to the use of a usually solid mask with some defined apertures placed either in contact or some distance away from a substrate during a deposition process which effectively allows the spatially selective transfer of material. While this technique is seldom used in industry due to it’s practical resolution limitations, the spatial modulation of mass flow through an aperture is an inherently clean process which imposes very few limitations on the nature of the deposited species, as opposed to conventional resist based optical or e-beam lithography, where etching processes need to be carefully tailored to avoid undesired interactions, specially when there are underlying layers with very different physicochemical characteristics. It offers a series of benefits such as mask reusability, ease of manipulation, avoidance of resist contamination, loose constraints associated with substrate characteristics and the relative ease of implementation of dynamic lithography schemes, where the pattern moves with respect to the substrate allowing a grater deal of flexibility and some unprecedented capabilities regarding spatially tailored thickness and compositional variations.

Here are some reviews and relevant publications [3][4][ https://doi.org/10.3390/mi8040131]

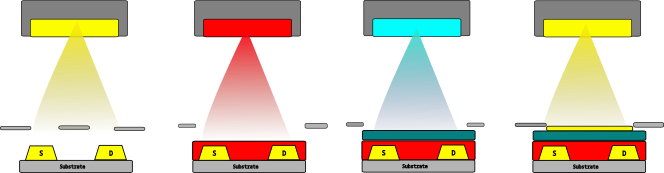

The twist: Multimaterial PLD with sequential shadow masking

Now, while the ability to generate a patterned deposition is in itself quite useful, and a basic building block of any device integration, it`s still far away for the aforementioned objectives. But consider the possibility of being able to repeatedly perform such process with different materials and geometries, without breaking the controlled atmosphere nor requiring any manipulation of the substrate. This would enable, in principle, a completely bottom up approach to semiconductor (among other technologies) device fabrication.

There are indeed some articles describing similar ideas: check for example [5], [6], [7] or [8]. A more complete bibliography of related subject may be found on [9].

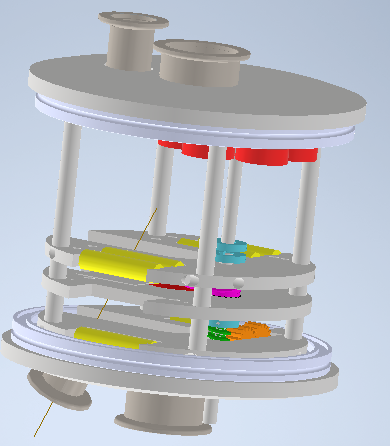

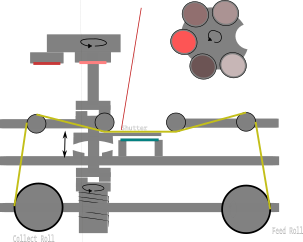

Now the proposed approach is based on something quite similar to roll to roll processing, but with the different masks riding on the web. Then one could use a standard multi-target carousel (mine was originally based on this design) to repeatedly deposit multiple structures in a single cycle.

The current approach uses a 30 micrometer thick aluminum foil as masking element, which is micromachined ( example) using a relatively inexpensive fiber laser marking machine [10], with a nominal resolution a bit over a micrometer. However, due to aspect ratio considerations, the mask apertures are limited to about 20 micrometers as a critical feature size. In any case, there are several resolution enhancement techniques which may be used to shrink the size of actual deposits. Here's an example, and the characteristics of the matter flow generated by PLD may lend themselves to quite novel schemes. (TODO: elaborate)

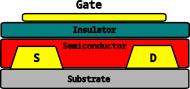

An example: Thin Film Transistor

So for illustrating how this may work, lets consider the fabrication of a bottom contacts, top gate thin film transistor. (This is of course a massive oversimplification of actual processes. The Art of Analog Layout by Alan Hastings is a quite friendly introduction, while Planar Process Primer is a bit more thorough. In any case, the technique is probably better suited for SOI devices.)

Basically we have 3 different materials arranged in 4 layers, each with its particular pattern. So in a standard fabrication flow, we may try something like this:(TODO)

While in the proposed system, we may load 3 different targets onto the carousel and use a set of masks which are moved in front of the substrate for each of the targets in the following way:

Implementation

So the first implementation was a modification of an existing system. Since I don't think the configuration was very hobbyist friendly, I will only document it briefly in MM PLD - v0. But I lost access to the vacuum chamber and laser, so a completely new iteration was needed.

Now the main advantage of being able to design a new chamber is that I could accommodate the system in such a way that machining the mask in-situ was possible. This has some important advantages:

- The masking system is essentially self-aligned: as long as the sample and tape doesn't move, the mask pattern positional repeatability is only determined by the galvo system, which is designed by serious people

- Corrections could be made on the fly

- The actuation system becomes much simpler: No mask adjustments are needed, and if dynamic shadow masking is not desired, you only need that the tape move on one direction.

But evidently it came with some tradeoffs:

- Some particulates could fall over the substrate, messing the pattern transfer, and

- The ablation in vacuum could produce a vapor phase (cool effect) which may coat windows (bad) and targets (worse)

Fortunately, the solutions to the aforementioned problems are considerably easier: You can keep the substrate relatively clean with a shutter 3, and the coating of different surfaces because of the mask machining could be hindered by an inert gas partial pressure.

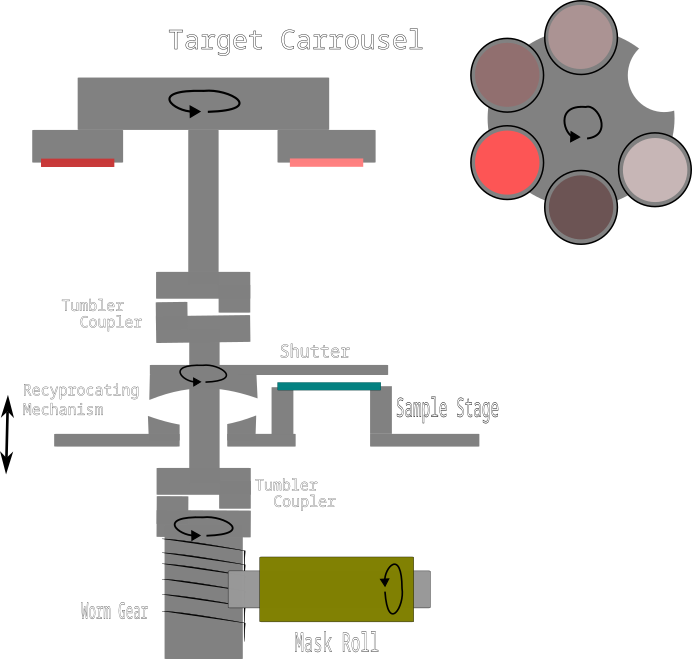

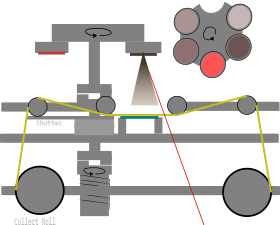

PLD SAP: Main mechanism

The system is based on a single rotary feedthrough which is coupled to the target carousel. It holds 5 25mm targets, and has an aperture to expose the mask to the beam for defining the apertures.

Now I've kind of copied a simple yet ingenious mechanism design shown in Warden, Robert M, 2006, which I found from this video. Its basically a rotational coupler with about 340 degrees of backlash, allowing oneself to disengage movement on any subsequent stage by rotation on the opposite direction. 4

So when the shutter is engaged, it rotates around the shaft and in certain positions push the 'sample stage' (which is kinematically mounted by a variant of the Kelvin Coupling) downwards a few millimeters, giving room for some clearance between mask and substrate.

Then, another coupler connects the shaft rotation with a worm gear which drives the tape mechanism.

Therefore, the machine operation is roughly as follows:

- The shaft is rotated in a given direction, until the tape is translated enough to completely cover the substrate

- Changing the rotation direction, the shutter is placed between tape and substrate

- A valve isolates the high vacuum pump, and a certain pressure of inert gas is let onto the chamber. Then the mask apertures are micromachined according to the preestablished design.

- When the mask is ready, the chamber is reevacuated (and possibly a particular atmosphere is set for the deposition). Then the shutter is moved back to a position where the substrate again in it's preestablished height.

- Changing direction again, the carousel is actuated to generate a given deposit from one or more targets sequentially, according to the layers needs. Then the process is repeated.

Vacuum Chamber

If laser ablation is performed under a standard atmosphere, the mean free path of the travelling species is so short that the vapor phase nucleates, generating relatively macroscopic particulates, and a diffusive mass transport dominates, which is also not ideal.

To get an idea of why it's important, here are some rules of thumb (taken from Building Scientific Apparatus from Moore, Davis and Coplan) for understanding how gases behave at a given pressure (they can be deduced from kinetic theory, but I lack inline math :| )

The average speed energy of an air molecule at 20°C is about 500 m/s , with a mean free path which is about 5/P(mtorr) cm. So, for example, the MFP is about 5 cm at 1 mtorr, and roughly 5 meters at 10^-5 torr.

Considering that the diameter of a molecule is about 3*10^-8 cm, and that for most clean surfaces the probability of a particle 'sticking' to it after a colision is between 0.1 and unity, one may find that the time in which a monolayer is formed over a surface is about 2.5*10^-6 / P(torr) seconds, which basically means that keeping a surface clean for practical amounts of time requires pressures in the order of 10^-9 torr.

While those may be the ideal conditions for film deposition, for a first iteration I think that pressures in the orden of 10^-6 should be enough. That means that we require a high vacuum pump, but we can get away with using relatively inexpensive KF and ISO flanges.

The chosen geometry of the chamber was a cylinder, given that it behaves well under external pressures, is relatively easy to fabricate and has there are many readily available components. If you are building your own chamber, please beware that vessels under external pressures behave quite differently than when the pressure is internal; the modes of failure are nonlinear and thus the vessel´s wall should be thicker. I used the ASME code section VIII for the calculations.

Practical Implementation and Geometric considerations

The basic design choices are:

- Substrates size should be below 25mm. There are standard waffers of that diameter, and the overall cost scales heavily with size.

- Given the usable area, the tape width was chosen to be about 40mm, allowing it to cover the whole substrate and leaving a safe margin for structural integrity.

- Target size was also chosen to be 25mm, for target availability and mainly to allow thickness compensation schemes.

- For a first iteration, an ISO160 based main chamber was chosen. It's easier to use and modify than CF flanges, and the pressure range attainable is more than enough for a proof of concept.

Therefore, the main structure is basically a cylinder with a diameter of 149mm, which should fit in the 6', 2.5mm walled stainless steel tube used as a chamber.

The deposition takes place along the axis of the structure, with a target-substrate distance of about 70mm.

Lasers

Along with the access to the suitable vacuum equipment, perhaps the greatest hurdle for the implementation of the technique is the availability of a powerful pulsed laser. While the effect of ablation was initially demonstrated with a ruby laser, the technique is usually performer with either excimer or (frequency multiplied) Nd-YAG sources, with recent development taken advantage of the pulse durations achievable with Ti-Sapphire lasers. Such equipment usually is prohibitively expensive for an individual tinkerer.

Now the physics behind laser ablation are quite complex and not completely understood. There is a competition between several thermal and non-thermal processes which depend on the characteristics of the radiation (wavelength, spatial profile, pulse shape, etc.) and the target (absorption coefficient, thermal properties, structural properties among others). A very comprehensive introduction of the different effect may be found on Laser Processing and Chemistry by D. Bauerle.

A number which is often quoted as the order of magnitude for the ablation threshold of most materials is a power density of about 10^8 Watts/cm^2. While it sounds like a lot (and it sort of is...), currently a lot of laser markers which use a doped fiber as lasing medium with pulses in the 10^-8 s range and energies in the order of 10^-3 Joules per pulse have become easily available. With an out of the envelope calculation, one may see that a spot size of about 300 X 300 microns is enough to reach the desired power densities. In fact, the requirements may me much less stringent as neither the energy distribution during the pulse nor the spatial profile of the beam are very uniform.

I've done tests with a 1064nm laser which nominally outputs 10ns pulses at a repetition rate of about 30 kHz for a total power of about 2W, which implies an energy per pulse of about 6 * 10^-5 Joules, giving a peak power in the order of 10^3 Watts only. But given that the optics allows for a very tight spot, I could achieve ablation of a Molybdenum target without much complications. (In effect, if the marker is capable of generating patterns with reliefs, it should be good indication of it's ability to ablate a given material).

The added advantage of such marker systems is that the come with a really high quality galvanometric deflection and lens, which enables the quick and precise positioning of the beam. This is quite important for eventual thickness compensation schemes, which on themselves somewhat avoid the need of constantly rotating the targets. The only related difficulty has to do with the fact that the target's normal isn't aligned with the optical axis, and therefore the beam goes out of focus as you raster over the target. A dynamical focusing scheme is needed to compensate. (Elaborate)

Substrate Heater

Now if we actually intend to generate devices with decent performance metrics, not only the film composition is relevant but also it's morphology (essentially meaning surface roughness, degree of crystalinity, ...) at the very least.

One of the relevant parameters that influence the film morphology is the substrate temperature. One may think about it in the following way:

During deposition, molecules impinge onto the substrante and start moving (with a rate which depends on substrate-adatom interaction and surface morpholgy) until they coalesce into an island or similar structure. If the substrate is 'cold', the adatoms have low mean kinetic energy, and thus its equilibrium position is mostly determined by this process, while a higher temperature make it more favourable for atoms to keep moving until they reach their equilibrium position (ideally in some sort of lattice). Of course you can only turn up the heat until a certain point, where some of the more volatile components of the film might begin evaporating. While some oxides require substrate temperatures over 1000°C for its optimal deposition conditions, one would rarely use such high temperatures for multiple material deposition. Perheps the 800°C could be a reasonable goal.

There are several ways to actually heat up the substrate. The more standard ones uses resistive (joule) heating, which is relatively easy to implement but gets a bit more complicated if heating under oxydizing atmospheres is required. Also it's relatively innefficient, and the temperature field can depart substantially from uniformity. Other options rely on radiative heating, usually with halogen lamps close to the substrate.

Efficiency is specially relevant when you consider that under low pressure environment the thermal conductivity of gases falls to neglible values, which leaves oneself with either exclusively radiative heat transfer or active cooling, which is highly non trivial for moving parts in a vacuum. So it's quite important to minimize the amount of power coupled onto the chamber.

An interesting solution to explore might be the usage of laser light to heat up the substrate exclusively (or perhaps a small susceptor). While at this moment you must be thinking that I'm obsessed with lasers, there are several reasons why they might be the cheaper/easier/most effective option.

TODO: Temperature profiles, laser planar floating zone refining, references

Use cases

Multilayers

The availability of a set of different sources for ablation opens the possibility of fabricating a multilayer structures, which have a broad set of intrinsically interesting properties; as well as quite a bit of technical applications such as optical coatings (which may used as filters or mirrors with finely tuned spectral response over broad regions of the EM spectrum), semiconducting lasing devices and the experimental realization of quantum wells (including it’s practical applications such as bistable optical switches, high electron mobility transistors and resonant tunneling diodes), superlattices.

Heterostructures

The ability to almost arbitrarily pattern a region with a given material allows, at least in principle, the fabrication of a wide variety of devices such as junctions (pn, pin, Schottky barriers), volatile and non volatile memory elements (including ferromagnetic and ferroelectric elements, among others), thin film transistors, resistive elements, two terminal switches, light sources, photodetectors, electro-optic switches, waveguides, sensors and MEMS is relatively straightforward and opens up a vast array of pathways for fundamental and applied research. The justification behind this statement is that virtually any structure built by standard techniques is generated precisely by a sequence of processes which locally change the properties of a material system, either by doping, deposition or selective etching. (There are clear trade offs regarding resolution and perhaps some additional complexity in the mask designs).

Furthermore, the ease of application of each subsequential feature may prove to be an interesting capability to inexpensively explore a wider variation on the integration architecture of several such devices. For example, 3D integration of circuit elements doesn’t seem too far away from reach when the selective deposition of non active fillers may allow interconnection between several (hopefully epitaxial) layers. This of course comes with a substantial amount of challenges, but at least in principle the tool should be capable of generating such features.

There is a lot of functionality which is usually not discussed when talking about semiconductor devices. The book Complete Guide to Semiconductor Devices[11] can give you an idea.

Combinatorial Libraries, Parallel Experiments

The development process of complex functional materials require navigating through a usually vast experimental variable space, where not only the particulars of the material composition are relevant, but also process parameters such as deposition conditions (substrate temperature, atmosphere, annealing steps, laser intensity). Even by using orthogonal experiments schemes the amount of samples needed to get an idea of how each of the variables influences the film ordevice characteristics and function may require several samples. A traditional set of sequential experiments not only has the problem of introducing random errors due to the non-concurrent nature of the fabrication process, but also may require unpractical amounts of capital and time. Inspired by the pharmaceutical industry technique of combination synthesis for drug discovery and early experiments on phase-mapping [12], the generation of different sites in the same substrate with a reduced set of masks has become a effective and efficient method to generate an understanding of composition-structure-properties relations in unknown material systems. Check [13] for a neat example.

Integration

(TODO: Discussion on how a system which overcomes complications regarding material processing incompatibilities may extend the degree of local integration between silicon based electronics and other systems, namely photonics, other families of inorganic semiconductors, biological tissues/interfaces, etc., with the enormous benefits in performance and scalability that such integration may provide for diverse areas)