Pandora

Release status: experimental

| Description | Large format 3D printer

|

| License | public domain

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Pandora: ancient Gk. Bringer of "all gifts", creation of Maker god Hephaestus.

Contents

What it is, and what it is for

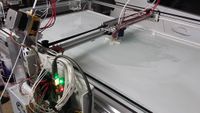

Pandora is a large format RepStrap with a build volume of approximately 450 x 850 x 900mm. It is built of aluminium V-slot extrusion, with CoreXY gantry geometry at the top face, and a bed that lowers away from the extruder on leadscrews.

Its purpose is to print body parts for velomobiles (streamlined bicycles) and perhaps other light but bulky structures.

Progressive build pictures

Problems encountered

The bed is a piece of float glass, sitting on a foam core board. It weighs 9kg. Homing such a large bed is problematic. Any missed steps on one motor will cause it to go out of level. Unfortunately the Rambo doesn't support independent leveling (where each side has its own endstop). I'm building a counterweight for both sides, which will ease some of the friction in the nut blocks. From here, the next step is to connect the Z motors in series rather than Rambo's default parallel (to get more current into them) and/or to replace them with Nema23's.

Printing

With the bed counterweighted, the Z-axis moves more smoothly. About 75% of the weight is balanced by the counterweights. The glass is cold, and sucks heat away from the print, making adhesion chancy. These prints were done in PLA with diluted PVA wood glue smeared on the glass. Some tweaking is required, as the plastic strings and blobs up a little. The Z-min endstop was replaced with an IR Z-probe on the carriage, which allows for grid levelling (with the G29 command)

Next steps

A heated bed, of course! The problem is the size: 6 Hictop heat plates would fit really nicely, but at a price. 8 Mk3 Alu heat plates would also do, or some larger plates with multiple heater PCB's bonded to them. Silicone heaters were the solution (Keenovo on eBay) at 240V, controlled by a solid state relay, they save the need for a large 24V power supply, which would have been much more expensive than the 24V heat PCB's. There are four plates, each with two 200W silicone heaters (only two have been bought so far). Each plate will be controlled by a separate switch, so we don't heat up areas not being printed on. The heaters are 200x200mm with a central hole for a thermistor, which is stuck on with a bit of Kapton tape and heatsink compound.