RepRap Interface Standard

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

RepRap Interface Standard defines interfaces between the various components of a printer. Like an interface between carriage and extruder, between extruder and hotend, between bed base and heated bed and so on. Effectively we have such standard interfaces already, but they're neither discussed nor defined.

With interfaces defined, components become exchangeable. If an extruder complies with extruder-hotend interface standard and a hotend does as well, a user can rely on both of them fitting and working together. No longer guessing by blurred pictures or even buying many versions just to find one that fits.

Discussion Thread in the RepRap forum

Contents

Intentions

- Easily port new features implemented in one printer to another printer.

- Ease the enhancement of printers by changing only one module and not having to invent/build/maintain a new printer thereby lowering the entry bar for new developers.

- Not to invent new interfaces, instead document those interfaces that are commonly used.

- Standard interfaces come with a price. So 100% compatible is not as important as new functionality. If a module needs to break the interface then that should be clearly stated. Best possible compatibility is still the target.

Definitions

A complete printer consists of a combination of modules. Each module has a different responsibility. All together let the printer work correctly.

A Module might have sub modules. This allows for more variation. Several types of sub modules may be available. They all must be able to work with their main module.

If modules or sub modules do not comply to all the stated requirements, or if they require more from the other modules in the printer then defined here then these modules must be declared as not fully compatible. The additional requirements or the not met requirements must be stated. Otherwise the module may not be declared to be fully or partly compatible to this standard.

RIS 1

Controller Feature Set

The electronic module provides the home for the firmware that drived the printer. CPU and Motor driver ICs are part of the electronics package. RIS 1 defines just the feature set. Not part of this definition is, wether electronics is singe-board or distributed to several boards.

Required Features

- Power supply for all other modules.

- Support for at least 4 (four) stepper motors.

- Support for at least 3 (three) endstops compliant with #RIS 2.

- Connectors and support for 1 (one) thermistor-type temperature sensor.

- Connectors and support for 1 (one) heating element of at least 60 watts.

- A description to which interface standards connected devices should comply to.

This defines wether a controller has sufficient features to drive a particular printer. It does not define wether your electronics runs at 3.3 V or 5 V and also not wether heaters and stepper motors run at 12 V, 24 V or some other voltage, so distinct controllers complying with this standard may require different devices to be connected to them.

Optional Features

These are often found on existing electronics, but not required to comply with RIS 1:

- connectors for Fans (optional)

- UART/RS232 Serial Interface (optional)

- USB interface to controlling PC. (optional)

- SD Card Slot for printing without PC.(optional)

RIS 1a

Controller Feature Set with Heated Bed Support

Required Features

- All of #RIS 1.

- Additionally connectors and support for a second thermistor-type temperature sensor.

- Additionally connectors and support for a second heating element of at least 180 watts.

RIS 2

Endstop Electronics Interface

An endstop is a sensor making the controlling electronics aware that a mechanical carriage has reached a specified position. On engagement, signal voltage changes from Low to High or from High to Low. Typically they're used to find a carriages' home position.

Electronic Properties

| Supply Voltage VCC | Signal Voltage VS Low | Signal Voltage VS High | |

|---|---|---|---|

| RIS 2 / 5V | 5.0 ±0.5 V | < 1.0 V | 3.0 V ... 5.5 V |

| RIS 2 / 3.3V | 3.3 ±0.3 V | < 1.0 V | 2.3 V ... 3.6 V |

Connector

The header for the connector has 3 male electrical pins, spaced at 2.54 mm. A latch makes sure the connector is inserted the right way. The header is a Molex KK100 or compatible (very common in electronics stores).

Pinout:

+---+ latch +---+ | | | Vs | GND | Vcc | +-----------------+

This pinout matches RAMPS, Generation 7 Electronics and others.

This pinout do NOT match Sanguinololu Rev. 1.3a.

RIS 3 Endstop Mechanical Interface

Mechanical Properties

(insert drawing showing two holes 3.3mm dia., 19mm apart (matches the commonly used TCST2103), a board about 50mm x 25mm around it and direction and approximate position of engagement. Showing the board defines the maximum space allowed to be occupied by an endstop, being it an opto or a mechanical endstop)

TBD

(TBD = "to be defined")

Here below things to consider, but not worked out, yet.

Motor_Shield_Standard

External motor shields of the A4988 and DRV8825 form factor.

To define the benefits and drawbacks versus motor drivers on the main PCB board.

To provide a blank template for new development.

Other motor shields, of different form factor

temperature sensor - heated bed

The temperature sensor for a heated bed must fit into the holding mechanism defined in the heated bed module. The temperature sensor must either create a voltage that represents the temperature in a range of 0-3.3V or 0-5V depending on the supplied Voltage. A pt1000 would be an example for such a sensor.

- Nope. A PT1000 is a resistor and doesn't deliver any kind of voltage. --Traumflug (talk) 02:57, 15 April 2014 (PDT)

- What I wanted to say is that the sensor creates a Signal as a voltagelvel for an ADC. Voltage delivering in the sense of power supply was not what I wanted to say. Do you have a better wording?--JustAnotherOne (talk) 06:55, 15 April 2014 (PDT)

temperature sensor - extruder

The temperature sensor for a extruder must fit into the holding mechanism defined in the print head module. The temperature sensor must either create a voltage that represents the temperatur in a range of 0-3.3V or 0-5V depending on the supplied Voltage. A pt1000 would be an example for such a sensor.

heating element - heated bed

The heater for a heated bed must fit into the holding mechanism defined in the heated bed module. The heater must be able to withstand a voltage of up to 24V.

heating element - extruder

The heater for a extruder must fit into the holding mechanism defined in the print head module. The heater must be able to withstand a voltage of up to 24V.

RIS 1: Print head

This Module transforms the raw material(PLA, ABS,..) so that is can be deposited on the printbed to from the print. If the intention is not to create a 3d printer but a CNC mill then the milling head will be a print head module.

mechanical interface

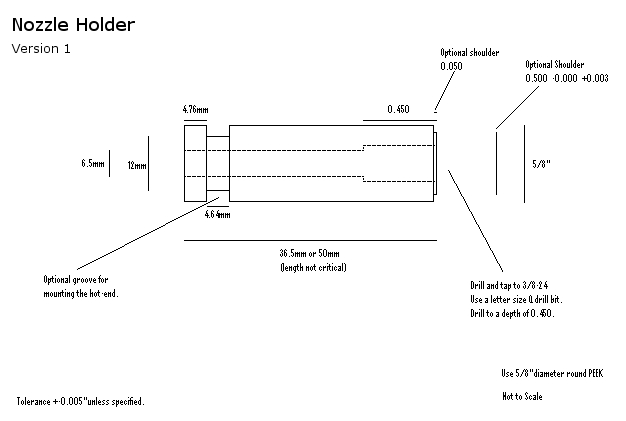

This is a standard for many Hot end designs such as the Jhead. 4.64 mm wide with an OD of 12mm, using 5/8" stock

RIS 1: (Heated)Printbed

The print bed is the platform that the printer uses to create the print on.

mechanical interface

For a Cartesian bot like a mendel-derivative, the standard is the Prusa PCb Heatbed.

PCB Heatbed MK1 is developed by Josef Průša

- 200 mm x 200 mm active heated area

- 209 mm center-to-center mounting holes (outside the active area). The holes are M3, usually using standoffs to mount to the Y carraige, such as you would use when attaching a motherboard to a PC case.

- 214 mm x 214 mm total PCB size

RIS 1: Mechanic

The big parts of the printer that allow the print head to move in 3 dimensions relative to the printbed.

mechanical interface

so that the others can be mounted into it?

electrical interface

- (Stepper) Motors

Existing Modules

In this section all existing Modules can be listed.

Electronics

Extruder

(Heated)Printbed

Mechanic

Pages yet to join into here

- Groove Mount

- Combinatorics Problem suggests that, in general, having standard interfaces between "layers" of a stack can help accelerate the rate of improvements.

- File Formats lists many more-or-less standard file formats used in the RepRap toolchain.

- Vertical X Axis Standard