User:Drewgolterman/Blogs

Contents

- 1 Blog 1: Thingiverse

- 2 Blog 2: Open Source Ecology Project Discussion

- 3 Blog 3: Kansas Teen Uses 3-D Printer to Make Hand for Boy

- 4 Blog 4: Blog 2 Reflection

- 5 Blog 5: 3D-Printing Timeline Review

- 6 Blog 6: Next Steps

- 7 Bonus Blog 1: 3D Scanning and Autodesk 123D Catch

- 8 Blog 7: 3D Printing Affordable Research Equipment

- 9 Blog 8: Intellectual Property Article

- 10 Blog 9

- 11 Blog 10

- 12 Blog 11

- 13 Blog 12: Blog 5 Reflection

- 14 Blog 13: Blog 7 Reflection

- 15 Blog 14: Blog 8 Reflection

- 16 Blog 15: Blog 11 Reflection

Blog 1: Thingiverse

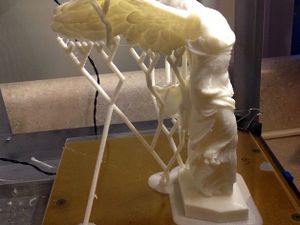

A. Something amazing/beautifulFor an object that is amazing/beautiful, I chose to share this print of the Winged Victory of Samothrace. The statue itself is very beautiful, and I thought that it was amazing how it could be replicated so precisely. The Thingiverse user who created this, downeym, described how he used the following link (Link) to print the statue with minimal support material. And the following is a link to the Thingiverse article itself (Link).

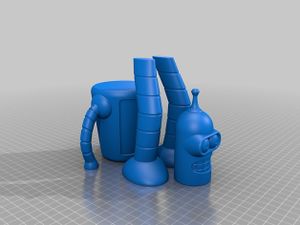

For something that is funny and strange, I decided to share this figurine of Bender, from the TV show Futurama, which I found on Thingiverse. I have been a fan of the TV show for a while and I find Bender's character to be hilarious. Here is a link to the article for this print (Link).

When I was searching for something that was useless, I decided to type in "useless" to see what I would find, and I indeed found something extremely useless. This picture to the left is a one-sided die. And it is meant so that you can load it with a weight. For what purpose? I do not know. The link to this Thingiverse page is here.

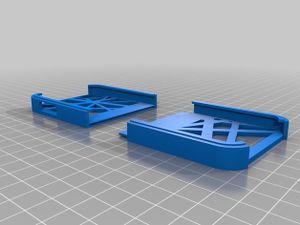

I thought that this print of an Ipod 5 case would be extremely useful for me because I have been looking for a case that fits my own, but most of the Ipod cases sold are for previous generations. I thought that I could print this one for myself once I learn to download stl's and use the printers more effectively. The link to the Thingiverse article for this is here.

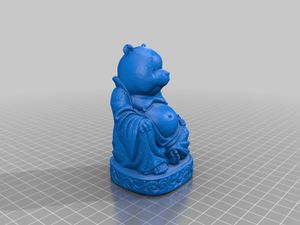

This surprised me because I could not imagine why someone would think to make a play on words of "Buddha" and "Winnie the Pooh." But apparently somebody did, and they then decided to create "Winnie the Poodha." This is one of the stupidest ones that I found on Thingiverse but it also made me laugh, which is why I included it for the last picture to share. Here's the link for this one.

Here's the link for this one. http: //www.thingiverse.com/thing:115029

Blog 2: Open Source Ecology Project Discussion

A: I think that the open source ecology project has an enormous potential. As Marcin stated in the video that was provided, people often become trapped in the “consumer” mentality of only looking at options that are presented to them rather than seeking their own solutions. By practicing an open source system of information with hardware, people can start being more productive by learning how to find their own solutions rather than being forced into seeking a select few “consumer” options, which may be against their interest in cost and feasibility. Also, the open source community has a large potential for developing communities that need cheap, feasible options for growing their economy.

However, after reviewing some of the project directions that are available, such as the CEB press (http://opensourceecology.org/wiki/CEB_Press) and the LifeTrac (http://opensourceecology.org/wiki/LifeTrac) I had some doubts about the feasibility of these projects for unskilled people. Although the designs that OSE offers are very simplified, they still might be overwhelming for someone who has never had any experience in mechanical construction. Given enough time to research the design, find the appropriate parts and reach out to experienced individuals, I think that these projects could be completed, but I have had doubts about their “one day goal.” The “one day goal” is their goal to create new designs that have the ability to be assembled in only a day. When they run the test of time that it takes to assemble these machines, I think they are overlooking how much more effort it may be for someone who is inexperienced with machinery and the possible bias that they have in being the designers of these machines. Since they are the most familiar with their own design, they are bound to assemble it quicker than anybody else can. The program’s most recent efforts, as shown in this video (http://vimeo.com/81154935), have included creating “work shops” for people to attend in order to learn how to build these essential machines. If Open Source Ecology wants to truly make an impact, I think that these workshops are the key way to teach other people how to assemble the open source machines. By having access to experienced machinists and builders, those who attend these workshops will not only be able walk away with their own machines, but they will also be able to learn essential skills from the leaders of these workshops. I think that in order to be successful in their mission, the open source community would not only have to provide access to the designs for these machines, but they would also have to provide access to people who are experienced in working with the machine components.

B: The New Yorker article, which can be found here, seems to focus on painting a quirky and eccentric picture of Marcin rather than actually weighing the pros and cons of his work. And as far as I can read from the article, the writer put very little effort into exploring the potential benefits of open source communities, such as the sharing of knowledge and ecological progress in developing countries, and focused more on Marcin’s unique background, views and projects. The writer also tends to assert the more pessimistic qualities of OSE’s efforts rather than inquiring about their potential. For example, she states that Marcin has faced “a dearth of skilled acolytes: the people who show up at his farm typically display more enthusiasm for his ideas than expertise with a lathe or a band saw.” But rather than mention that Marcin is attempting to combat this problem with his “workshops,” which are meant to educate these unskilled people, she simply mentions this fact as a way of seemingly discrediting Marcin’s efforts. Although the author has a point to address critical issues, such as how to train unskilled people, she scarcely addresses the potential benefits of OSE’s projects.

Marcin’s response to this article can be found here. After reading the response, I think that it was an appropriate way to address several “misconceptions” that were presented in the New Yorker article. Marcin states that the goals of his project are idealistic, but nevertheless they are necessary to address common worldly issues such as material scarcity. He also addresses the writer’s tendency to give him the air of being a “luddite” or leader of a “commune,” which would both carry negative connotation in the eyes of readers because they are associated with outlandish characteristics. However, Marcin continues to uphold the “one day goal” again, which I still happen to think is unrealistic for anyone other than the designers themselves. I continue to think that he underestimates the amount of work that will be involved for unskilled people. In my opinion, I think that he should have addressed this concern more directly in his response to show that he is considering the implications of teaching people the necessary skills to build OSE’s designs.

C: I have never had any professor that would be involved with agriculture, however I think that my previous ME 480 professor, Yash Tambawala, may have an interest in the mechanical design part of the project. The class that he taught was “Mechanical Analysis of Linkages.” I think that he would have had an interest in the researching these open source designs because they are directly related to some of the examples that we have studied in class. Also, if we had the opportunity to build one of them, it would be a great way of exercising the skills that we learned in class. However, I think that he may be leaving the Penn State MNE department this semester.

Aside from Professor Tambawala, I would also consider some of the Mechanical Engineering professors that are involved with linkages and mechanical design, because these topics relate directly to the open source designs that Marcin has shared. Also, the fact that they can be assembled with readily available materials (for the MNE Department) such as steel tubing, cables and hydraulics demonstrates that they would be a great project for a college-level environment.

Blog 3: Kansas Teen Uses 3-D Printer to Make Hand for Boy

When Mason Wilde was looking to create a hand for Matthew, he slightly adjusted the design that was originally created by Ivan Owen and Richard Van. These two men met online and were working to create mechanical fingers for Van, after he had lost part of his hand in an accident with a table saw. During their progress, a woman from South Africa contacted them and asked them to attempt to create a mechanical hand for her son, who was born without fingers on his right hand. They first created this hand out of metal parts that they had machined. After testing the design, they then chose to make a more refined 3D-printed version, after being donated a 3D-printer by Makerbot. After creating a more sound design, they uploaded the design with instructions to Thingiverse. The first 3D-printed version was uploaded in January of 2013.

If someone wished to create their own prosthetic hand, they could start by modifying the design that was uploaded here.

Here are some related news articles that discuss the "Robohand."

-American Society of Mechanical Engineers

Blog 4: Blog 2 Reflection

When reviewing the blogs of my classmates, I found that many of them had the same concerns that I had about the feasibility of unskilled people creating OSE's designs. Many of the articles reiterated that a lot of the designs will still require additional training for those who attempt to complete them. However, many of them were also able to see the potential benefits of having an open source system of designs, and they still generally liked the idea despite its unrealistic goals.

An interesting point that I would not have thought of on my own was brought up by Yuchao Yuan, who mentioned the issue of safety. If these designs are produced and not subject to certain standards, they may pose a potential threat to those who are assembling them, especially if they are unskilled people using power machinery. The project itself is already under enough criticism for its idealistic goals. If a fatal accident was to happen because of one of OSE's designs, that could cause a lot of negative publicity.

Also, I thought that Tom Vassa brought up a reasonable point in his blog response that I did not think of. He mentioned that the OSE project may not have as big of an audience as most of its supporters may think it will have. The reason that it will not have as big of an "audience" is that many of the unindustrialized areas that could potentially use the knowledge that OSE offers also may not have access to the proper tools that they will need to complete these projects. It seems to me that if someone truly wanted to help a developing area, they would have to send expertise as well as the design information from OSE. Someone who knows what kind of tools they need, how to get them and how to assemble the projects would need to help people in such areas.

Another thing that I never would have thought about, but read in Zachary Cameron's Blog response, is the help that OSE would offer people who are suffering in a Fallout situation. A potential apocalypse in the near future did not cross my mind at all. Even though it is highly unlikely, I thought that Zachary's assertion about population growth was thought provoking.

I also liked how Eva Abeniacar mentioned in her blog response that the New Yorker should be more "open" with their articles.

And lastly, I enjoyed reading about Nate Myer's opinion, because I liked hearing the view of someone who is familiar with the financial hassle that farmers must deal with when it comes to buying new equipment. I can understand why people sometimes criticize OSE's goals for being to idealistic when they claim to be a "Civilization Starter Kit," however I do not think that this should deter people from seeing the potential that it could have for those who are skilled with the proper tools and who can benefit from cost-effective, DYI equipment.

Blog 5: 3D-Printing Timeline Review

1. When reviewing the timeline, I would say that the single most important event was Charles Hull's role in technically creating the first "3D-Printer," which he referred to in terms of "Stereolithography." Although this was only the early development of 3D-Printers, and credit can also be given to those who made the technology more widely known in later years, Hull's contribution is vital to 3D-Printing's growth. Another significant event was in 1996, when the first major release of 3D printers from Z Corp, Stratasys, and 3D Systems was made to the public, thus spreading knowledge about 3D-Printing technology.

However, in terms of important events for the general public, I think that one of the most important events was the creation of open-source systems for people to learn, such as the RepRap blog (2005) and Thingiverse (2008). If the idea of having an "open source" community is to grow, it definitely needs resources such as RepRap and Thingiverse to help others develop their own skills.

And lastly, I think that another important event was when a lower jaw bone was printed for an 83-year-old patient in 2012. I think that this was significant because it not only demonstrated the bio-medical uses of 3D-Printing, but it also received a good deal of media attention, thus spreading knowledge about the technology even further.

2. On April 9th, 2012 an article was published by Time Tech. It was titled "The Delicious Future: 3D Chocolate Printer Finally Available for Purchase." I do not think that this a good example of an "important" event. I enjoy reading about the different things that people have found to print, but when it comes to printing food, I do not think that it is worth the time and investment. I understand that it might be note-worthy because every little bit of media coverage that the general public sees spreads the knowledge of 3D-Printing technology a little more; however, I think that it is hard to take something like 3D-printing chocolate seriously. And I also think that it only becomes a topic of jokes when other people discuss 3D-printing. My opinion might change when people find a more economical way to produce food with a 3D-Printer, but until then, it just seems like they are printing food just for the fun of printing something unusual. Also, I find it funny how the title uses the word "finally," as if people have been waiting for years for someone to make chocolate in unnecessarily complex geometries.

3. The one thing that I think I would like to talk more about in the future is using 3D-Printing for the purposes of making affordable medical prosthetics. An example of this is the famous "Robohand" that was uploaded to Thingiverse. When I learned about how people sometimes cannot receive a prosthetic because of the cost of making it, I felt as though the obvious route to take would be to research how to make cheap, reproducible products for patients in need. Aside from the Robohand, there was another place on the timeline (November 29, 2013), where it discussed research to create more affordable prosthetic eyes for patients. I think that I may like to do some additional research in this area and see if I can add anything else to the timline, concerning prosthetics.

Also, relating to medical applications of 3D-printing, I added an article to the timeline about how scientists were able to develop a method for 3D-printing skins cells onto burn victims. This is under the date July 21st, 2013.

Blog 6: Next Steps

There are many things that our class can do to take the next steps and progress. Among them, I think it would be really important to start investing more time in dual extruders. The reason that I think this is important is because it will allow us to print objects that require extensive support material, thus allowing the class to explore their own interests further. I know from my own experience that I have already been limited to making certain prints that do not require support material. Many of the prints that originally caught my eye, when I was doing research, were not printable because they required support material. Also, in my previous design classes, this problem also limited my ability to develop as many prototypes as I would have liked. Last year, in my product design and development class, I had to create an impeller for a handheld vacuum by 3D-printing it. Ideally, I would have liked to create several designs and test them all for efficiency, but I was limited to creating one high quality print in the learning factory or printing a very brittle, simplified design on a single extruder 3D-printer that my friend let me borrow. I think that dual extruder printers should be invested in because it will not only enhance the capabilities of EDSGN 497J, but it will also provide much more capabilities to students in classes where they must create several prototypes for their designs.

Another thing that I would like to see in the class, is more investment into 3D-scanning and modeling of existing 3D objects. I think that this is a worthy investment for the future because it will allow students to replicate objects that currently exist and it also has many upcoming applications in the world, particularly in bio-medical applications. The topic has been of a personal interest to me and I have actually been hoping to start becoming familiar with the 3D-scanner that is in the class now. The reason that I started thinking about this is because I have seen a couple of applications on phones that allow for people take a 3D scan of almost anything. But the thing that had really drew me in was a TED talk with Anthony Atala. During his speech, he mostly talked about the potential to 3D print organs in the future, but he briefly mentioned a really cool application for 3D-scanning as well. He mentioned how wounds may be able to be healed by first scanning them with a precision scanner and then using a 3D-printer to print a layer of cells onto the wound. There have been many advances in this area, especially in the previous year. I was able to find this following article that discusses the application for generating high-quality skin grafts (3D-Printed Skin Grafts).

I am sure that there are many other areas that the class could invest their time and effort in, but overall, I would be the most excited to see some development in dual extruders and 3D-scanners in the classroom.

And on a side note, if you have not guessed from reading my blogs, I am very interested in the bio-medical applications of 3D-Printing, so I just wanted to share this link. I think that it gives a good summary of the areas where 3D-printing will impact healthcare the most.

Bonus Blog 1: 3D Scanning and Autodesk 123D Catch

I was doing some research on 3D scanning recently. The reason that I was doing research on this in particular is because I have been interested in 3D printing in bio-medical applications. Much advancement has been made in 3D scanning areas of damaged skin and replacing these areas with living skin cells. If you read my previous two blogs, you will see that I shared a couple articles about this in particular. I think that this is an amazing advancement in bio-printing because I feel as though it will be one of the first areas to truly make an impact on real patients. Significant results have already been produced by testing the technique on mice, as you can read in this article. 3D-printed wound areas have shown to heal faster on mice than normal grafted wounds on other mice. Also, if this is applied to humans in the near future, one of the most prominent benefits is that it will eliminate the need for a donor site to remove skin from. A visual of this type of bio-printing application can be seen here at Anthony Atala's TED talk at 8 minutes into the video.

Anyway, after doing a little research, my friend gave me this TED talk to watch because he knew that I was interested in 3D-scanning applications Link. In this TED talk, Blaise Agüera discusses the advantage of having a universal database of images that numerous people can share. Using various algorithms, these images can then be stitched together to make a single 3D-modeled universe. If you watch the video, you will see that he uses the Notre-Dame Cathedral as an example. I thought that this was particularly interesting because it showed not only how technology can be used to model 3D environments and objects that would otherwise be difficult to replicate, but it also showed how communities can come together to share their "collective knowledge" to contribute to this single 3D universe that has been created with PhotoSynth.

Anyway, after that, I started to do further research to find what types of applications I could use for myself. After a digging a little further, I was able to find several applications that allowed users to take various pictures of single objects and then stitch them together to create a 3D model.

One of these applications (which I actually had the opportunity to try out), is called Autodesk 123D Catch. As of now, it is a free application that can take about 20+ pictures that are centered around a single object, combine them together, generate a 3D model and then allow the user to further edit the model as he or she sees fit.

-A brief introductory video to AutoDesk 123D can be viewed here.

Having used Autodesk applications in several of my previous jobs, I already had an AutoDesk account, which is required to use this application. So I downloaded the mobile version for Ipods, Iphones and Ipads (which is free...for now) and I decided to try it out. Ultimately, I decided that object with the best shape and texture for the app would be one of my work boots.

I placed my work boot in the hallway of my apartment, and I took roughly 40 photographs of the boot from several different angles, heights and distances. After doing so, these images were analyzed by AutoDesk 123D and made into one single 3D model. However, this only happened after about an hour and a half of processing.

Now, you may view the model that I created on my Recent Work page on my Autodesk Profile.

If you click "3D View" below the image, you should be able to rotate around the model and zoom in and out as you wish.

After creating this model, I then started to research how to take this model and turn it into a printable STL file. This can be done by downloading AutoDesk's computer program here and then downloading the file that was created underneath your Autodesk profile.

Unfortunately, this is where I started to have problems. I was able to easily find some instructions on how to create a printable STL file from Autodesk 123D in this instructables article. However, when I tried to edit some of the excess material in my 3D model, I found that 123D crashed on my computer whenever I tried to delete some of the surrounding surfaces. This may be due to me installing the software incorrectly, but as of right now, I have been unable to go any further with creating an STL file. However, I do plan on pursuing this goal further.

So far, I have only used this Autodesk application and unfortunately, being the product of a major software company, 123D is a closed source application. Whenever someone uses that application, the photographs that they take are uploaded to a cloud, where they are analyzed, formed into an object and then sent back to the user. However, in my research I found an article that offers some great suggestions about open-source alternatives to Autodesk 123D.

And lastly, I would like to say that if there are any other students who wish to work on a project like this together with 3D-scanning/3D-modelling, please let me know. I would be happy to start a cool project with someone else. Another one of my goals was to successfully use the 3D-scanner in the back of the classroom.

Also, here's another video that briefly shows the process of capturing models and editing them in the Autodesk software. Link

Blog 7: 3D Printing Affordable Research Equipment

I think this area is definitely worth the time investment. One of the main advantages of 3D printing is being able to create something that may typically require manufacturing equipment in a convenient, on-demand manner. It is only logical that scientists will start to look into the areas of their research where they may be able to cut costs. If something can easily be 3D-printed for a fraction of the commercial cost, there is no reason to not pursue it.

Personally, I had trouble thinking of research equipment that would be easily 3D-printed, so I did a little research on what some of Pearce's suggestions were. Some of the examples that he used in other articles were pipettes, fluid flow gauges, microscope structures and much more. In fact, he shared some of the commonly used items from Thingiverse in this Link.

Pearce even has his own instruction videos, such as this one.

Overall, I think that it is exciting to see how cheap equipment may now be available to much more people than ever before. Personally, I think that this may have a large application in areas of surgical equipment. Undeveloped communities in other counties may be lacking the resources to buy expensive, high-quality surgical equipment from some of the main industry leaders. If they were able to 3D-print their own equipment, it may help with costs and expand their horizons when it comes to the types of procedures that they can perform. A good example of how 3D-printing can affect the surgical field can be seen here.

Blog 8: Intellectual Property Article

Patent- A temporary monopoly granted by the government to an inventor to exclude others from using an invention.

Trademark- A trademark is an exclusive right granted by a government to a trademark owner to use a specific name or symbol in association with a class of products or services.

Trade Secret- A trade secret is information used in a trade or business that offers its owner a competitive advantage and that can be kept secret. A trade secret is not a right conferred by a government but is the result of vigilance on the part of an organization in preventing the dissemination of its proprietary information.

Copyright- A copyright is an exclusive right grated by a government to copy and distribute an original work of expression, whether literature, graphics, music, art, entertainment, or software.

These definitions were copied from Ulrich's Product Design and Development (5th Edition)

Patents focus on inventions, while copyrights focus on works of expression. Bother patents and copyrights are granted by the government. On the other hand, trade secrets are not granted by the government because these are trade advantages that are only known to the particular business or company that owns them. It is the owner's responsibility to keep these unknown. And lastly, a trademark is right to a symbol or name, granted by the government, so that it may be used in association with a specific group of products or services.

The five I's are identified in this article as Infringement, Identification, Impractical, Impossible and Irrelevant. And these are the implications that 3D-Printing presents when being able to print things with any functionality and without control. The chances of infringement will be extremely high because virtually anyone with a 3D printer will be able to print anything, despite whether it is patented or not. Also, when information is shared so readily, it is also extremely difficult to identify who certain designs, codes or prints may belong to. And in addition to being difficult to identify who certain advancements belong to, it will just be impractical and impossible to do so. When the point is reached that information is being shared so openly with other communities, this will cause IP enforcement to become irrelevant altogether.

The article argues that Intellectual Property rights will become extremely difficult to enforce and eventually become futile in the near future. The articles states that it will bring the end of intellectual property all together.

I completely agree with the assertion that 3D printing will make IP enforcement extremely difficult, however I do not think that IP protection will deteriorate to the point that it will be nonexistent. I believe that in order to avoid becoming extremely inefficient, IP offices will have to be less restrictive in certain areas of their IP agreements, but they will not stop all together. For example, IP offices may stop targeting individual makers who wish to create patented inventions for recreational or academic purposes, but they will continue to target registered businesses to make sure that industry leaders are protected. The process for enforcing an IP right may become extremely inefficient because of the open source community, but I really doubt that they will disappear anytime soon.

Personally, I think that creative commons is a step towards a more efficient method of protecting intellectual property. It was created with good intentions, which are to make an easy method for people to protect their work and share it at the same time. It is something that should be used as a model for the future, as open source communities continue to grow. However, my only concern with creative commons would be ensuring that they have the ability to enforce the rights that they create. It may not be a concern when an individual maker decides to create a patented object for recreational purposes, but I was curious about how Creative Commons would enforce these rights if a business was to steal something from someone else and profit from it. This may not be a problem if the inventor willingly shares his or her progress, but if it is someone who specifically did not wish to share a component of his or her invention, it would concern me.

Blog 9

1. When I first started my search for suppliers for filament, I came across a page on the RepRap Wiki that had a long list of suppliers, accessible links and in some cases reviews of their product. Here is that link to the Printing Material Suppliers. And as I started to search suppliers that would provide good quality PLA and ABS, I came across some links that described what to look for in good quality product. This link describes the importance of using a supplier that provides a good tolerance for their filament. The same website also created this article about the different companies that produce different extruders/printers and the type of filament that they require.

And as I started to look for actual suppliers and reviews, one of the first places that I happened to stop was on Amazon. I have used Amazon many times in the past, not only for my own purchases, but also for purchases that I had to make for other engineering projects. Many of the suppliers from Amazon may not be their own company, but the advantage about using Amazon that I have always liked is that you can read hundreds of customer reviews and get a sense of which sellers are trustworthy. Usually, if enough research is done on a seller from Amazon, you will be able to find a product that is extra cheap and good quality. I have had this experience with buying products such as water heaters and thermometers. However, the disadvantage is that some sellers may not consistently have product available on Amazon. But just from a short search, I was able to find this seller, who is selling 1kg of PLA filament for about $29, which is relatively cheap. And in addition to this, the seller has almost all positive reviews and has taken the precaution of warning his customers about tolerance issues. In this case, the product itself has a good tolerance, but it is different from the nominal dimensions of some other filament, and the seller warns about this at the bottom of his or her page.

I then started to research other suppliers that may have good credentials. I came across a website called RepRap Walmart. After reading some reviews about this website, I found that they had unbeatable prices for buying in stock and their products usually had good tolerances and little air bubbles. However, doing a little deeper research, I found many reviews such as this one saying that their product would never stick to the bed and often tends to glob. Although some of the other reviews were better than the first one, I ultimately decided not to pursue this website any longer because of how mixed they were.

I have also found that the generally most renown suppliers have been Ultimachine, Protoparadigm and MakerBot. However, the cost of these are generally higher (about $42/kg, $38/kg and $48/kg respectively). But their product is much more consistent and high quality.

I also found that Toybuilder Labs had relatively good reviews and had a competitive price of $33 per kg for PLA spools (at a sale price).

I also checked out some of the Chinese suppliers from Alibaba in this link. Many of these rolls are good for buying in stock because the total cost comes to about $20-$25/kg. I had some trouble finding reviews for some of the suppliers from this sight, however, my general consensus is that you get what you pay for. Although many of these companies from Alibaba are much lower in cost, they seem to have less positive reviews and more complaints about the composition of their filament, similar to the RepRap Walmart. Because many of the reviews are mixed, I think that someone may be able to work with this filament if they have experience with calibrating printers based on the quality of the filament, however it seems to me that some of the general qualities that are at risk are the ability to attach to the bed, attached to other filament and the ability to create straight, consistent surfaces (as demonstrated in the article the I previously linked about the importance of good tolerances).

2. When using dual extruders, one could use material for the actual print and another material for the support. The best material to used for this support material would either be PVA (Polyvinyl Alcohol) OR HIPS (High-Impact Polystyrene) both of these materials are dissolvable in limonen or hot water. Using these materials will allow use to create prints with geometries that are more complex. Personally, I would have liked to have a printer that had support material when I was in ME 340 so that I could print an impeller with internal cavities.

Generally, I found that PVA was much more expensive than HIPS. When I was researching, I found some approximate prices for individual spools at 3D2Print, which charged about $68 per kg for PVA and about $47 per kg for HIPS. I also found that 3D Inspot charged about $33 per kg for HIPS. This has also been consistent with other sites such as 3DP Artistry, who charge the same price for one kg of HIPS.

When reviewing the advantages of HIPS and PVA, there are several things to consider. Although it may be easy to say that we should choose HIPS because it is generally less expensive, it requires a heated build platform and it has a narrower range of extrusion temperature. This may require putting a lot of effort into creating out new dual extruders. However, if some cost analysis was done, we could possibly estimate how long it would take to pay off our investment in the printers by building them to use HIPS (as opposed to if we just used PVA). But despite this, we also have to consider our ventilation situation. Source recommend printing with HIPS in a generally well-ventilated area. Thus, given the circumstances, I personally think that it would be better to use PVA, because it would be better for the class and the club to "get their feet wet" with creating dual extruders.

3. I would personally use Amazon.com. The reason for this is as I stated before, you can always go through the reviews, find a good deal from a trusted buyer, and more often than not you will be satisfied with the product that you buy. However, this is just considering my own needs. If someone were to buy stock for a classroom, this would be different. You may not have the personal time to go through several reviews to buy 15 to 20 spools. In this case, I think that I may use Toybuild Labs. They seemed to have good quality products while being less expensive than Ultimachine, Protoparadigm and MakerBot.

Blog 10

After searching the RepRap Wiki, I found a very helpful page about Hot Ends that informed me about the different suppliers and variations. This page was also very helpful because it immediately told me about whether each hot end was made for a direct extruder or a bowden extruder. Although we have not developed many bowden extruders as of now, they are definitely an investment for the future because of how fast they are capable of printing. Our projects concerning hot tips for bowden extruders have been recorded here and more information about bowden extruders can be read here. The faster acceleration allows the printer to create a finer surface finish as well. Although there may be some retraction problems with the cable, these problems can usually be addressed through careful calibration of the machine. So, when I searching for hot tips, I kept in mind that the hot tips that we used should either be usable by both direct and bowden exruders, or be compatible with the use of an adapter. All of the hot tips that were listed on the RepRap page that I listed were either usable with both systems or able to be adapted with 3D-printed parts. Also, all of these hot tips that are listed are either compatible with 1.75mm filament or 3mm filament, which is what we typically use. And although not all of them do so, most of them have nozzle diameters that are either 0.35mm or 0.5mm, which is typically what we use.

As I was looking through some of these models and keeping cost in mind, the Arcol v4 model and the J-Head Mk V model stood out to me because they both seemed to satisfy our need in the classroom and they both could be found on the internet for relatively cheap. These design could easily be found and modified by students in the class. However, they may cause problems if students wish to print at higher temperatures than usual. Although both of these models have heatsinks, they have not been known to be as effective as some other models in dissipating heat.

If cost was not an issue, I would personally like to look into getting the following Pico Model. This model has extremely efficient heat sink capabilities and is very small too. It is capable of being applied to both bowden and direct extruders and it can fit a variety of nozzle diameters (including 0.35mm and 0.5mm). It's heat dissipating capabilities are so good, that it can print up to 500 degrees Celsius.

Blog 11

The show and tell that I found to be the most intriguing was Sam and Brian's presentation about bioprinting. I think that some of the advancements that they discussed are truly amazing, and of all of the areas that 3D-printing has the ability to impact, I think that health care will be one of the most dramatic ones. Even if we are not printing actual cells, 3D-printing first impacted healthcare by offering extremely efficient ways to create cheap prosthetic limbs/organs for those who cannot afford other, more expensive products. A perfect example of this is the boy from Kansas who was provided a cheap prosthetic alternative by a high-school student. Although such an invention may not be of the best quality, the impact that such as simple design has on this boy's life shows the potential that it has when more advanced designs are created in the future. Other cases of printing prosthetics has been seen in printing eyes, skulls and bone replacements.

However, Sam and Brian's focus was on the potential for printing actual organs, cells and tissues. And it is very exciting to hear about the advancements in recent years, such as the case of the 3D-printed ear, the crude 3D-printed kidney and the cases in which skin cells were 3D-printed onto live lab mice. Although some of these experiments are further along in advancement than the rest of them, much progress is being made day to day and I think that it is important to make them known to raise support for them. I also enjoyed hearing about the potential to 3D-print a heart and bones in the future.

Also, it was really awesome to hear their goals for 3D-printing a 2D layer of E. Coli cells. I think that this will really encourage other students with an interest in 3D-printing to pursue the topics that they are really passionate about, even if they are in a field (such as bio-printing) that seems too advanced for undergraduate level students.

Blog 12: Blog 5 Reflection

As I was reading the blogs of my teammates, I was amused to see that Eric and I shared the same opinion that the chocolate 3D printer was an extremely unimportant event that was recorded anyway. He also mentioned that the 3D-Printer costed $5,000, which I think we can both agree is a bit much to pay for a printer that will only print semi-recognizable chocolate sculptures. Although some companies may be able to reduce the cost of food printers in the future and there may be a market for 3D-Printed food, I feel as though it will still only be a novelty product. If at some point food printers are made to be more economical and convenient, I would be interested. But until then, I think that food printers are only an over-priced novelty product.

When reading Brian’s blog, I thought that his comment about what topics received the most press was funny. In response to the question, “What objects get a lot of press?” Brian responded, “Hands down, anything that involves food or guns. Food is food and any way to make it another way will get the US community all excited. Guns are a big topic because it is a controversial one.” Although it was a humorous response, I also thought that it was insightful to how the media sometimes portrays 3D-printing. It only seems like you hear about 3D-printing in the mass media when there’s an extremely stupid breakthrough (for example, developing the first krispy kreme 3D-printer) or an extremely controversial breakthrough (such as making open-source gun designs). I think that there could be plenty more substantial stories about 3D printing in the media than either of these topics. It is rare that you see mass media articles about how 3D-printing could revolutionize important industries such as healthcare.

And speaking of healthcare, I enjoyed reading Sam’s article about the first occurrence of 3D-printing blood vessels. Although I am extremely interested in bioprinting, I happened to miss this article when I was searching through the timeline. I also completely missed the article about powering “Bio-bots” on 3D-printed rat cells. Although this may be extremely inefficient for now, I actually thought that the future focus of the article was cool, because it talked about using this technology to create “bio-bots” that would seek out toxins to neutralize in organisms. The article for this can be found here.

When I was searching through other blog responses, I thought that it was cool that Sam Carrol mentioned direct laser sintering of metal (DSLM) as an important event. When I was writing my own response for this blog, I tended to overlook some of these advancements because I immediately thought of the founding of 3D-printing (Charles Hull’s contributions) as the most “important” of the events on the timeline, and I consequentially forgot to research some more interesting advancements such as DSLM. Sam also made a good point to state that advancements in 3D-printing metal are extremely important because more industries would be interested in created metal products of complex geometries rather than plastic parts.

As I searched through some more articles, I found that Ben's comment about this link to be quite accurate in describing how completely useless it is. I cannot imagine why someone would spend days printing this just to make a physical recording of a speech that already exists in several other digital forms.

I also think that Chai did the most extensive research through the timeline. His blog includes several different occurrences for about six or seven different topics such as 3D-scanning, security concerns, the rise of Thingiverse and Mendel. I would suggest checking out his blog because of how thorough it is.

I also thought that Mitch Egnleka did a very thorough and noteworthy job and tracking the progression of 3D-printing technology through the years in his article, mentioning specific key events and referring to some of major patents that affected the industry.

I agreed with Anthony's comment about how using 3D-printing may be somewhat useless when explaining physics, because one can just as easily create a model without 3D-printing and still grasp the same concepts by using other visual aids instead of spending the time to 3D-print a model.

Blog 13: Blog 7 Reflection

Blog 7 was concerning the use of 3D-printers to make cheap, useful laboratory equipment, particularly in underdeveloped communities. When I read Brian’s response in Blog 7, I thought that he made an insightful comment when he stated, “it seems as though there is a lot of education that needs to be incorporated into this operation in order for it to be successful.” And this stuck out to me because this has been my main criticism of open-source projects in the past. Although I completely support the effort to make affordable, feasible equipment available to underprivileged communities, I think that a lot of open-sources communities overlook the fact that many people require being taught how to use these open-source resources before they can actually utilize them to their full potential. Previously, when I was reviewing the open-source ecology effort, I made a similar statement, saying that the available resources are useless unless you have people who are willing to reach out to underdeveloped communities and teach them how to create the projects that are detailed online. This could most easily be done through the “workshops” that are offered by open-source ecology. And to visually make this point, this particular image came to mind as I was writing this.

And my teammate, Sam, made another good point in saying that many people in developing nations simply would not have the funds to invest in a 3D-printer that would cost several hundreds of dollars. However, after reading Sam’s response, I began to think about how open-source communities could possibly create donation campaigns to install 3D-printers in hospitals of third world countries and contribute funds to send volunteering engineers to other countries to teach the people in these hospitals and laboratories how to use 3D-printers. Jessica Mewkalo also made a similar comment, concerning cost and education, asking how even if many developing nations had the funds to buy these cost-effective 3D-printers, would they have the education to use them properly?

In my own blog response, I believe that I became too excited about the idea of helping underdeveloped nations and overlooked some of the initial problems, such as the issue of properly educating people about the available 3D-printing resources. Reading the articles of my classmates was refreshing because it gave me a new ideas about how open-source communities could expand their sphere of influence in underdeveloped nations. I really believe that organizations such as Engineers Without Borders and other organizations with similar goals should start reaching out to hospitals, universities and other research institutes in order to teach them about the readily-available advantages of 3D-printing.

Kevin Moyer, Nam Phama and Graham Deever wrote about the AFM microscope, stating the problem that most other students found with the article, which was that it was misleading. The article title seemed to assert that the instructions for creating an inexpensive AFM microscope were readily on the internet and available for anyone to find, however this was not the case. Kevin, said that he did a quick search to see if he could find the instructions somewhere else, but it was unsuccessful. Personally, I had the same experience. And although I think that finding a cheaper way to make highly expensive lab equipment is awesome, the problem that I stated previously still remains, that people in developing nations will still need extensive training and education before being able to implement such technology. But again, do not mistake my attitude as being a pessimistic one, because I think that there is a lot of potential for college students and charitable organizations to reach out to such communities and offer their expertise to help them create cost-effective equipment.

And Kyle Casterline brought up the important point in his response that although many bulk parts of the AFM microscope can be 3D-printed, he finds it hard to believe that the parts that require the most precision can be printed and used in a properly functioning microscope. I too see this a difficult obstacle that people who are just learning to use a 3D-printer would have to overcome.

The one thing that I would have liked to have done is to review some of the specific instructions about how this AFM microscope could be constructed to see how truly feasible it would be for someone who does not have an engineering background, however I have not been able to find details about its construction online.

Blog 14: Blog 8 Reflection

I decided not to comment on the first part of blog 8 because it included simply retrieving information and reiterating it from the internet and from the provided article.

When reviewing the opinion-related blog responses of my teammates, I found that they had similar opinions to my own. They seemed to think that the concept behind creative commons was a good idea, but they did not seem to know how creative commons would enforce their own rules. Eric stated, “I'm not sure how CC goes about protecting their users content, but they seem to have a good understanding of what IP is and how it should be treated.” And my teammate, Sam, stated, “while some IP practices will be used to protect a product for commercial purposes, there will still be ways for DIY'rs to gain access to the product in a fully legal way. The implications of this are not clear currently, but may slightly alter Hornick's prediction.”

Personally, I wrote in my own blog response that I thought the purpose of creative commons was built with good intentions, but if there was to be some serious infringement on someone’s rights to an idea, I do not know how creative commons would enforce a punishment on the individual or company that stole the idea for commercial purposes. Although I generally believe that large companies enforce their rights to certain inventions too readily sometimes, I also believe that there needs to be a way to protect the small-time start-up businesses that may have discovered a new invention through their own honest effort. I think that creative commons makes a good point to allow its users to protect certain parts of their inventions while sharing others with open-source communities, but I doubt its ability to truly protect the ideas of a small-time inventor.

Zachary A. Cameron wrote in his blog response, “Creative Commons appears to me to be a catalyst to the end of intellectual property, providing shortcuts and backdoors to expanding the public domain. They seem to be on the forefront of the liberation of free information for the masses and are propelling the ability of individuals to explore and create more freely. Overall it seems like a step into the future and is helping foster a culture that will become more readily available to share ideas which will probably be hosted mainly by the internet.”

I mostly agree with this statement. And although I think that Creative Commons serves a good purpose for some applications, I still think that there needs to be a more secure way of protecting genuinely hard-working entrepreneurs.

Nam Pham had similar concerns, stating "Personally, I do think Creative Commons have the potential to help with legal sharing of copyright materials in the future...Nevertheless, this is only efficient if it works alongside with other copyright licenses as there is no such thing as a perfect solution to a problem."

Tom Vassa also expressed some doubt about Creative Commons, stating that it "is a step in solving the problems we will see in the near future. But, that is because it again relies on the goodwill of consumers. We channel our money into an entity that provides benefits in the form of shared works. It works in this case because the entire public benefits from its output, so there is nothing for anyone to steal. This certainly cannot work for everything..."

When reviewing some of the blog responses, I also found that Lee Schwartz wrote almost exactly the same opinoin that I expressed in my blog, stating "In my opinion, creative commons presents a better method of ensuring the protection of intellectual property rights. The intentions behind its creation seem to consist of making an easier way for people to protect their work while allowing it to be shared as well. I think that as open source communities continue to grow that creative commons would make for a good model for the open source community to follow. I was curious about how Creative Commons would protect and enforce the rights of the owner if a business were to steal something and turn a profit from it. Overall, I think that creative commons is a great compromise that allows for the protection of IP rights while still allowing inventions to be shared in an open source way."

However, even though most students expressed similar doubts that I had, not too many people denied the potential of creative commons to impact the open source community. Yuchao Yuan stated "This will help the 3D printing find a place to both protect their works and continue the spirit of sharing."

Blog 15: Blog 11 Reflection

When reviewing what my teammate, Eric, wrote in his blog 11 response, I thought that he wrote an insightful and reasonable opinion about the topic of 3D-printing homes. To be honest, I did not give this topic a lot of thought in the past because I saw it as being so widely impractical on all levels, but Eric brought out some positive and negative aspects of the topic that I did not consider before. In his response, Eric stated, “The structural capacity of 3d printed material is most definitely sufficient for all of aforementioned. However, I personally believe that it would be most efficient to limit the 3d printing to only the structural components. In example, the framework of a house could be prefabricated by 3d printing and assembled upon a foundation...3d printing could revolutionize the concept of prefabs, but I doubt it would ever be a viable option for a complete construction of a home. As for bridges, the structural beams are already prefabricated, so its not too crazy to believe that these beams could be 3d printed and installed in a similar fashion. This is assuming these 3d printed scaffolds can in fact withstand pressures of up to 280 MPa...I don't believe we'll ever be driving along a road watching large machines print out homes along the countryside. It just doesn't provide enough incentive to justify changing the way we construct homes nowadays. What I do see is a rise in the 3d print prefabrication of large structural components.”

This gave me a new perspective on the topic, because it made me think of the components of civil structures that could be created separately and then assembled with 3D-printing methods, whereas I previously would not have even considered this as a viable possibility. Eric also shared this article, which I thought was particularly interesting.

Several other students (Eva Vivu, Vinny Lachini and Zach Cameron) also wrote about the topic of 3D-Printing buildings and had similar opinions about its application.

My other teammate, Sam, mentioned the show and tell that I did about 3D scanning apps with 123D Catch.

For blog 11, the other show and tell that a lot of students mentioned frequently (including myself) was Sam and Brian’s show and tell about bioprinting. Kevin Moyer stated, “One of my favorite show and tells was done by Sam and Brian about Bio-printing Developments. I had been interested in the Fab@Home printer project, as well as the possibilities of printing other materials like living tissue. From the multicellular scaffolding that allowed vasculature from Harvard, to the printed ear from Cornell, it was encouraging to hear of the recent advancements and possibilities.” I could not agree more with Kevin, and I have mentioned several times in my past blogs how I think that 3D-printing has the most potential to impact the healthcare industry. In fact, one of the reasons that I wanted to do more research with 3D-scanning in class is that I found a fascinating article about how 3D-scanning was used to 3D-print skin cells into their proper place on lab mice. This method of treating severe burns has the potential to replace traditional skin graft methods of treatment in the future.