User:Tmt5147/Blog

Main | About Me | Class Blog

Contents

- 1 Blog 1: Thingiverse

- 2 Blog 2: Open Source Ecology project

- 3 Blog 3: Kansas Teen uses 3D printer to make had for boy

- 4 Blog 4: Blog 2 Review

- 5 Blog 5: RepRap Media Timeline

- 6 Blog 6: Whats Next

- 7 Blog 7: Read and Respond

- 8 Blog 8: IP and 3DP

- 9 Blog 9: Filament

- 10 Blog 10: Hot Tips

- 11 Blog 11: Show and Tell

- 12 Blog 12: R&R Blog 5

- 13 Blog 13: R&R Blog 7

- 14 Blog 14: R&R Blog 8

- 15 Blog 15: R&R Blog 11

Blog 1: Thingiverse

A.Something beautiful

To me, there is nothing more beautiful than a fresh layer of snow on the ground(as long as I have nowhere to be of course). That being said, this 3D printed snowflake tree ornament is something I would put on my tree in a heartbeat. Source

B.Something funny/strange

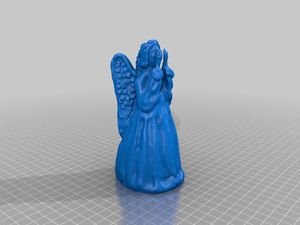

This is a tree topper in the shape of a weeping angel. I found this funny because as a Doctor Who fan, a weeping angel is not something I would want it my house if it were real so I would never put it on my Christmas tree. Source

C.Something useless

Gestural 3D printing, as it is described sounds pretty much useless. Yes it is cool that you can use a kinect to track your movements and then print out the outline but what use is there? A lumpy smiley face is about all you can do. Source

D.Something useful

Everyone loves music, me included, so this parametric music box would be a cool use. Yes, it wont change the world but it would be a cool thing to give a child. As they grow up, you can print out new snippets of songs for them. Source

E.Something that surprised me

I did not expect to see a customizable lithopane on thingiverse. Never crossed my mind to be honest. In this case, the surprise is good and I already have a few pictures in mind that I would love to turn into these. Source

Blog 2: Open Source Ecology project

Marcin is the man behind the Open Source Ecology project. His idea is to take many machine we use today such as tractors, brick makers and even 3D printers and make open source versions of them that are reparable by the use. His thought behind this is it opens up many to better technology that they will now be able to afford and maintain. Overall, I think this is a good idea and will result in a positive outcome for some people. Open source is a great way to quickly get ideas into the hands of others who will either use them or in some cases even improve upon them. Sadly, I don't know if it will have as big of an impact as he hopes.

Although this is a great idea and already has created many open source designs source, there is only so much open source can do. If someone does not have experience with the tools needed to repair or create these machines, they wont be able to do anything until either they have access to that knowledge or someone close enough to them does the hard part.

The New Yorker magazine wrote an article about Marcin's OSE Project. Summary: Marcin is a 41 year old Polish-American who has spent the past 5 years building industrial machines from scratch. He believes that everyone should be able to have access to the tools needed to work the land. In 2003 he started the O.S.E website to collect the best techniques for creating sustainable communities and three years later he bought a farm in Missouri. He built his own tractor after his old one repeatably broke down. His new tractor cost him $7,000 to build and is roughly equivalent to a $45,000 John Deer. After his success, he posted a list of 50 machines he believes could cheaply provide everything a small community needed to exist. While trying to make 6 tractor in 60 days, his team ran into many problems. Everything from hurt workers to misaligned holes plagued the group. As these projects continue, the common theme is endless struggle. Often called a dictator by those who work with him, conflicts in how things should be done arise. Each video showed the hardship the team faced and after a comment about living conditions was posted, even his girlfriend left. Between the lack of creature comforts and lack of skill, many were frustrated. Article

Overall, this article pointed out many of the things wrong with Marchin's Project. He was very set in his ways to the point of alienating others, didn't give those he worked with any of the money earned from sales of equipment, and didn't do much to improve living conditions. It is not surprising that so many of the people who came to help left. Marchin did respond to the New Yorker magazine article. Source He addressed many of the problems pointed out in the article. Although it doesn't seem like he was just rationalizing things, it may come off to some as such. He did show that he is truly invested in his idea and will do what needs to be done to see it to fruition.

To start something similar at PSU would require people who are truly devoted to the idea. This type of project would require a lot of time, effort, and capital. I personally can not think of specific people for such a job but I would look for people ready to drop what they are doing so they could devote much of their time to the project.

Blog 3: Kansas Teen uses 3D printer to make had for boy

Mason Wilde, a 16 year old Louisbugh High School (Kansas) junior 3D printed a prosthetic hand for a family friend's 9 year old son. The boy was born with only a thumb on his right hand and this prosthetic allows him to grasp things by flexing his wrist. He printed it at the Makerspace at his public library. The parts for this hand can be accessed at here. There is much research going on to look at the viability of 3D printing prosthetic. If you search for news articles on the topic, you will find over 51,000 results. Much good can come from this. Prosthetic are expensive and must be refitted and remade whenever the user grows or changes weight. 3D printing could allow for a cheaper and better fitting prosthetic. Original_Article

Blog 4: Blog 2 Review

As seen above, blog 2 was written about the Open Source Ecology project. For those who don't want to scroll up, the Open Source Ecology project is a project set up by Marcin Jakubowski with the intent of making open source designs for 50 different machines. These range from tractor to brick presses. The idea is to reduce the cost of these machines by allowing them to be created at home. This would allow more people to use them and to make more of the land they have. If you want to see what I think of the idea, please scroll back to blog 2. Reading through what my classmates reactions were, I noticed many similarities. Many thought his project had problems and that the magazine article written about it was on the harsh side. A few students brought up points that did not cross my mind originally that I think are good.

Drew Golterman brought up that Marcin's "One Day Goal" may not be accurate. Just because the designer of a product and assemble it in a day does not mean that everyone can. Unless he takes that into account, many will struggle for days trying to put his designs together. This is not a huge deal but should be thought about to make sure he does not lead anyone astray.

Kyle Casterline also had a good point: Safety. When companies create and market a product, they must meet set safety standards. These open source designs most likely will not include many of those features. They may not have as strong as a roll cage or a gas tank that will not puncture. Although the lack of these standards do bring down prices, they may endanger those who uses these tools if this lack of safety is not disclosed.

The last remark that stuck out to me was by Nate Myer: While discussing Marcin's response to the magazine article, Nate brought up the when Marcin claims that they(the group) are "not letting idealism prevent us from achieving our goals." Kyle called BS saying that deciding not to have electricity until they can make it themselves may be letting his own idealism prevent him from achieving his goals. By creating a nice environment to work an live, the OSE Project could take off and do a lot of good but people don't want to live in filth. Until that changes, I believe Marcin and his project will not go anywhere fast.

Blog 5: RepRap Media Timeline

Looking through all the links on the timeline page, it is easy to see how much has changed in the 3D printing world. Starting with Charles Hull's development of Stereolithography in 1984 all the way to the Hershey Company working with 3D Systems to print candy, this timeline outlines many achievements in 3d printing technology, some more important than others.

One of the most important in my opinion, is the launch of Thingiverse in November of 2008. Although not an advancement of printing technology itself, this was a huge step in bringing 3D printers to the masses. Most people have little to no experience with CAD software. In the past, this was due to the high price of the software itself but even with the advent of google sketch up, most lack the technical skill to design a part let alone one that is functional and printable. Thingiverse changes this but being an online repository of already made models. It doesn't take long to realize just how diverse the selection in. With Thingiverse online, anyone can download a file of something they want and need without needing any engineering skill. One day, it could be just as easy as downloading a news article. thingiverse

Although filled with cool advancements, not everything is worthwhile. One article, titled Big-Hearted Maker-Folk Rush to the Aid of Homeless Hermit Crabs is about one of those less than useful projects. It talks about the use of 3d printers to make shells for hermit crabs. The article points out many flaws in the plan including that hermit crabs eat some of their shell. Even pla which is made from corn is not something anything should eat. The article can be viewed here.

One topic I would love to look into more is how 3D printers can revolutionize music making. One article, which can be viewed here, is about making a guitar with a 3D printer. Complicated shapes can be made with this method which could endow an instrument with an acoustic edge compared to the competition.

The media timeline can be viewed in its entirety here.

Blog 6: Whats Next

There are a couple good directions that this 3D printing class could go from here. One way would be to a money earning path. Instead of the current set up of printing parts for EDSGN classes for free, maybe there is a way to start a 3D printing service for the campus. Someone could submit a part and we would print it for a fee. The money earned could then be used to make more printers,improve the ones we have, or go further in other ideas.

I think another thing would be putting more people to work on filament creation, not just recycling. PLA pellets are much cheaper than PLA filament. If had a way to make good quality filament ourselves, we would have the possibility of saving a lot of money. Plus, if we start a 3D printer movement on campus, we would need a lot more filament then we use today so the savings would be multiplied

Blog 7: Read and Respond

This weeks blog required me to read and respond to two articles.

The first article can be seen here

This article is about 3d printing low cost lab equipment. In the article they give the example of a $2000 colourimeter printed for $50. It also mentioned a way to make cost cheaper coming from a supplier. You pay the development cost plus the cost of the device for the first unit and after that you just pay the cost. In this case, if it cost $3000 dollars to develop, you would pay $3050 for the first ad $50 for each unit purchased in addition. The printer parts we make for this class could be seen as examples of cheap research equipment. We are developing ways to make these printer sustainable and in the process are also doing it at a lower price because we are able to make parts ourselves that would otherwise be high in cost.

The second article can be seen here

This is a cool, and normally expensive, piece of equipment. Having access to one of these could help with medical diagnostics around the world, not just in poor areas. Looking at the design, many of the parts look as if they could be 3D printed. Some parts should stay metal but all of the Lego parts could be models designed in a CAD program and printed. This may make the design even better. This relates to the first article because it is taking a normally expensive piece of equipment. Open source would be important to this if there is a need to refine the design. If not, and they have a business plan set up already, they could still do good with a close sourced design.

Blog 8: IP and 3DP

Copyright: Protects the expression of an idea, not the idea itself.

Trademark: A word or symbol that designates the source or sponsorship of a particular good or service. Ex: Dell

Patent: Protects the ideas themselves, not just the expression of the idea. Anything useful, non-obvious, and new can be patented.

Trade Secrets: Like copyright but does not need to be filed or registered. You just have to show you are protected it.

The article "3D printing and the Future (or Demise) of Intellectual Property" can be found here.

The five I's:

Infringement: When anyone can 3D print things with virtually any functionality, the risk of IP infringement away from control will become increasingly high.

Identification: Infringement away from control will be increasingly difficult to identify.

Impractical/Impossible: It will be increasingly impractical or impossible to enforce IP against infringement away from control.

Irrelevant: IP will become increasingly irrelevant.

The proliferation of consumer 3D printers will make it hard, if not impossible to enforce current IP standards. The I's bring into question how applicable these current standards are. If they no longer apply, what does?

I think there is still a place for Copyrights, Trademarks, Patents and Trade secrets but the items that fall under their protection will change. Some ideas will now be too common to be patentable. Also, it could be that when you buy a product, such as a blender, you will also be buying the rights to make your own replacements parts, but not to sell them. This would be one way to get around patent issues.

Creative Commons is a great way to legally share and build upon the work of others. It could speed up the advancement of many new device because many people would be working at the same time to make it better. It fits into the scope of 3D printing and what can be done with them.

Blog 9: Filament

1) Just like a standard printer, 3d printers need ink, plastic filament in this case. Filament runs anywhere from cheap to expensive depending on material, quality, and distributor. A few good places to get is Amazon's 3D printing shop. Just be sure to read the reviews if it is coming from a supplier you have never heard before. Often if the price is to good to be true, it is. Another good place is Makergear.com. They sell printers, filament and parts. Their filament is more expensive but they have a great customer service team and only sell high quality stuff.

2) In my opinion, the best choice for our printers is HIPS. Although not biodegradable, it is non-toxic and does dissolve in limonene. Also unlike PVA, it does not turn to tar at 210 degrees C. This would destroy and tip and seeing how the class is non-experienced people playing with printers, it may be best to use something more forgiving. HIPS filament tends to be expensive, makerbot sells it for $65/kg but I saw a few sources, which will remain unnamed because I don't know how good they are, who sell it for under $40/kg

3) For me, I would use Makergear and amazon(carefully looking over suppliers) as my main source for filament. The best bet is to read reviews on each particular site to see what luck others have had. Sometimes a specialty filament from a good source may not be great but that does not mean everything else they sell is bad.

Blog 10: Hot Tips

Hot tips are the part of a 3D printer that heats the filament and then extrudes it into a thin strip that is laid out on the bed/part. There are many option available. You can make your own or buy one from a company like Makergear who sells everything you need for a 3d printer. You also have a choice of temperature sensor, thermistor or thermocouple. With all of these options, it can get confusing so I'll try to help make things clearer.

1) Decide what size filament you will use. There are two standard varieties, 3 mm and 1.75 mm. 3 mm is a sturdier filament but takes more force to extrude while 1.75 mm is more likely to snap (especially with PLA) but requires less force to extrude so you can have a smaller extruder stepper.

2)Next decide what size nozzle you want. standard sizes are .25 mm, .35 mm, .4 mm and .5 mm. The smaller the size the finer detail you can print but also the longer it takes to print and small nozzles tend to more finicky or just don't work with certain materials. I would suggest .35 mm.

3)Where to buy/find designs? I would suggest Makergear but that is because I have a makergear M2 and they have a history of good tips. They have a version 4 that is due out any time now (current version is 3b) that should allow for better prints and higher temperatures. There is a nice Hot End Comparison guide on the reprap wiki located here.

Blog 11: Show and Tell

I enjoy when people do show and tells in class. It is nice seeing recent news about 3D printing that you would have missed otherwise. The one that really made me think was about companies using 3d printers including the Hershey Company. I have read articles about it before but the show and tell really made me think. Questions were asked like why are they doing this now. Why not wait till others perfect it and then go off of theirs. It made you see why companies would be willing to spend money on something that may or may not make anything for them.

Blog 12: R&R Blog 5

Blog five was to look through the reprap timeline and see what posts and you thought were good and which were meaningless. Everyone had different opinions on which were the really good posts but some of the main ones were things like printers having the ability to print 50% of the parts needed to build a new one. Thingiverse also popped up a few times with people which makes sense. Having a repository where anyone can download a model without needing modeling experience is great.

Blog 13: R&R Blog 7

The feelings on this article were a mixed bag. People in our class brought up good arguments for both side. Although it is great to end the monopoly of pricing on some parts, companies also need money to pay for R&D that goes into products. Without this, some things may be passed by as companies will see no profit in it.

Blog 14: R&R Blog 8

Obviously, everyone had pretty much the same definitions +/- a word or two but the meaning was all there. Blog 8 was all about intelectual property and what it means in a world full of 3d printers (I'll give you a hit, it gets a little hazy). No one I read seemed to have a perfect solution to the problem at hand. There is no easy way to protect peoples ideas while at the same time allowing freedom to inovate which could lead to new product that range from useful to lifesaving.

Blog 15: R&R Blog 11

A few students mentioned my second favorite presentation, 123D catch. The ability to take photos of an object and create a 3d model could change the way we design things in the future. Anyone who has a cell phone or digital camera could now design and print any object they have at home. No longer would you need expensive modeling programs.

On the other hand, these programs need to come a long way before they are truly usable. Like most scanned data, there is a lot of noise in the model which has to be cleaned up which is a time consuming and sometimes very difficult task. In many cases, it is easier just to model a part yourself unless it is something with many features like a statue.

Note to Eva, yes, that was me who talked about 3d printing buildings. You were correct.