Introduction |

Bill of materials |

Assembly

The parts list below is the default for Wilson TS, which uses all metric components and has a 200mm x 200mm x 200mm (XYZ) build volume.

There is an OpenOffice spreedsheet in the github repository which will assist in generating a BOM for other build volumes.

You can easily use other lengths of rods and extrusions if more convenient to source. I don't recommend trying to extend the Z axis up a lot though, because the stress on the lower frame mounts may become too much.

Also note that the Z axis lengths here were determined with my particular J-Head hot end, which sticks down about 40mm below the bottom of the extruder, and includes 3mm of glass on top of the heat bed.

Parts List

Mechanical parts

| Item |

Quantity |

Length / Note

|

| 2020 Extrusions (20mm square, t-slot)

|

| Vertical frame piece (sides) |

2 |

400mm |

|

| Horizontal frame piece (top and bottom) |

2 |

330mm

|

| Y axis piece |

2 |

400mm

|

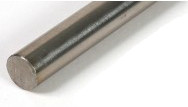

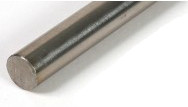

| M8 Smooth Rods

|

| X-Axis |

2 |

370mm |

|

| Y-Axis |

2 |

400mm

|

| Z-Axis |

2 |

350mm

|

| Threaded Rods

|

| M5 threaded rod for Z axis |

2 |

325mm |

|

| Belts & Pulleys

|

| Y axis GT2 timing belt (w=6mm) |

1 |

850mm |

(start with 1m in case this is a little off)

|

| X axis GT2 timing belt (w=6mm) |

1 |

930mm |

(start with 1m in case this is a little off)

|

| GT2 pulley |

2

|

| Nuts & Bolts

|

| M5 x 10mm machine screw |

51

|

| M5 hex nut |

2

|

| M5 t slot nut |

51

|

| M4 x 20mm machine screw |

7

|

| M4 hex nut |

7

|

| M3 x 10mm machine screw |

11

|

| M3 x 14mm machine screw |

24

|

| M3 x 30mm machine screw |

10

|

| M3 x 60mm machine screw |

2 |

These are for the hinged lever of the direct-dirve extruder. You may be able to use 50mm screws if your springs are shorter than 25mm

|

| M3 hex nut |

18

|

| M3 lock nut |

13

|

| M3 washer |

17 |

This number is approximate

|

| M2 x 16mm machine screw |

6 |

These and M2 nuts for mounting end stops

|

| M2 hex nut |

6

|

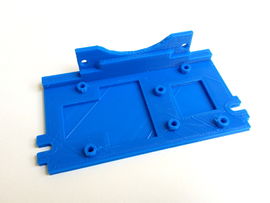

Printed Parts

| Printed Parts – Required

|

| X end idler |

1 |

|

| X tensioner |

1 |

|

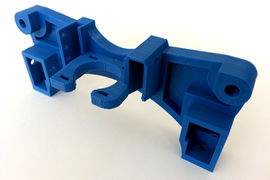

| X end motor |

1 |

|

| X carriage |

1 |

|

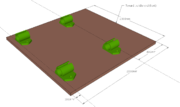

| Y bearing holder |

4 |

|

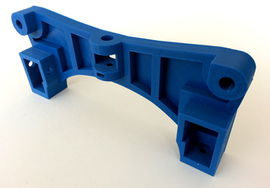

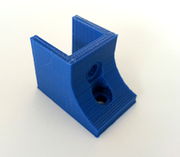

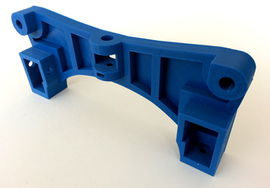

Z motor holder, left

Z motor holder, right |

1 of each |

|

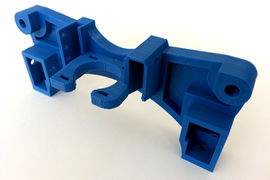

Z rod holder, left

Z rod holder, right |

1 of each |

|

| Z endstop holder |

1 |

|

| Idler bearing guide (pair) |

2 |

|

| Extruder body and idler |

1 |

|

| Extruder gear set |

1 |

|

| Extruder fan duct |

1 |

|

| Printed Parts – Required

|

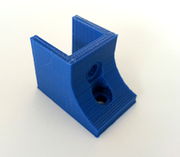

| Z rear bracket |

2 |

|

| Y end idler |

1 |

|

| Y end motor |

1 |

|

| Y belt holder |

1 |

|

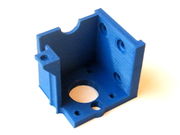

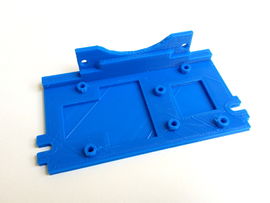

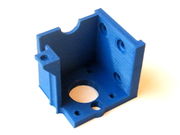

| Frame bracket |

4 |

|

| Printed Parts – Recommended

|

| RAMPS Electronics/Fan frame mount |

1 |

|

| Filament spool support |

1 |

|

| SMART display frame mount |

1 |

|

All other parts

| Everything Else

|

| NEMA17 Stepper motor |

5 |

48mm height, "high torque"

|

| Hot End (J Head) |

1

|

| MDF board (6mm thick) |

1 |

230mm by 230mm

|

| MK2, MK2a, etc Heat bed |

1

|

| Glass bed |

1 |

3mm borosilicate

|

| Controller (Mega/RAMPS, Rambo, etc |

1

|

| Endstop (limit) switch |

3

|

| LM8UU Linear bearing |

11 |

12th may be used if you put four in the X carriage (your option)

|

| 608ZZ roller bearing |

3 |

Used for geared extruder only

|

| 624 roller bearing |

3 |

Used for Y and X idler ends and one more for the direct drive extruder

|

| 5mm to 5mm shaft couplers |

2 |

Can also use 3/16" ID vinyl tubing

|

| 40mm x 40mm x 10mm fan |

1 |

This mounts on the extruder fan duct

|

| 80mm x 80mm fan |

1 |

This mounts on the side of the RAMPS mount to keep it cool

|

| Miniature zip ties |

20

|

| Extruder idler springs |

2 |

High tension is preferred

|

| Bed leveling springs |

4 |

Lower tension is ok

|

| Z axis adjustment spring |

1 |

this can be the same spring as either of the other types.

|

| Power Supply |

1 |

ATX supply with enough 12V amperage for your heat bed, or dedicated 12V supply 20A or more (30A recommended)

|

| M8 Hobbed bolt |

1 |

If you are using the geared extruder

|

| MK7 drive gear |

1 |

If you are using the direct drive extruder

|