Excalibur Hotend

Release status: Working

| Description | full metal hot end with cooling fan

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

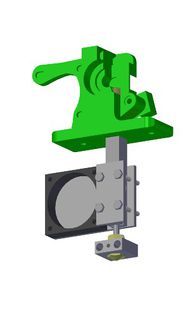

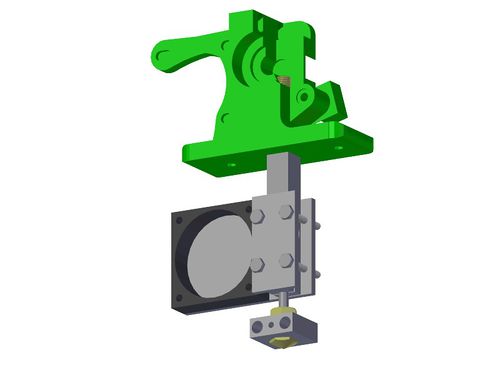

Introduction

The Excalibur Hotend derives from its precessor, the Organ Pipe Hotend and before that the Longsword Hotend.

The main difference between the Excalibur Hotend and the Organ Pipe Hotend is that is has no single pipe anymore. Instead it has a barrel and a separate nozzle.

Barrel and nozzle can be exchanged very rapidly, allowing swift changes of material types (e.g. from ABS to PLA) without having to clean the barrel each time.

Excalibur Hotends and Organ Pipe Hotends are compatible. That means that if you already have an Organ Pipe Hotend, you only need to make the barrel and nozzle.

The Excalibur Hotend can be made without any lathe. A drill press will do.

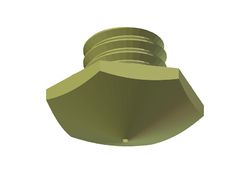

The Barrel

The barrel consists of the following parts:

| Quantity | Description | Specifications |

|---|---|---|

| 1 | tube | stainless steel, Length: 65 mm, OD: 4 mm, ID: 3.5 mm |

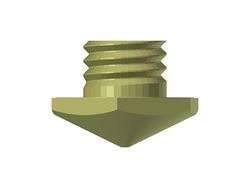

| 1 | hex screw | brass, M6 x 5mm |

Tools you need:

- Drill press

- Blowtorch

- Soldering paste

- 4 mm metal drill

- center drill

- drill press vice

Drill a 4 mm hole through the screw. A center drill might be helpful. It is a good idea not to put the drill but the screw into the chuck of the drill press.

Next take a center drill and use its 60° tapering to chamfer the hole of the screw. This is useful for inserting the steel tube as well as putting the soldering paste into.

Now you have to solder the parts together. I use a small blowtorch and some soldering paste for that. At 610°C the solder melts. It isn't difficult at all. But be careful not to burn yourself. I drilled a 4.1 mm hole into an aluminium cube and put the cube into a vice when soldering. The hole holds the stainless steel tube.

It is a good idea to make more than one barrel as you may want to change between different types of material.

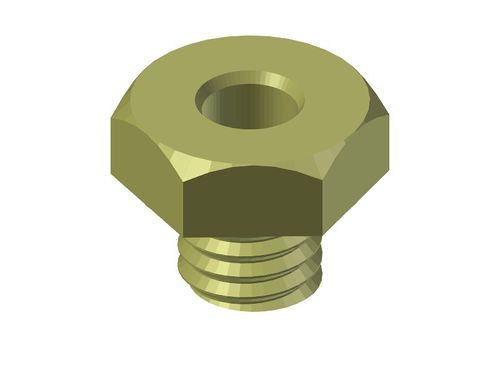

The Nozzle

The nozzle consists of the following parts:

| Quantity | Description | Specifications |

|---|---|---|

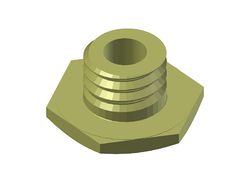

| 1 | hex screw | brass, M6 x 5mm |

Tools you need:

- Drill press

- 0.5 mm PCB drill with mini chuck

- 3.5 mm metal drill

- center drill (optional)

- nozzle sharpening tool

- drill press vice

Drill a 3.5 mm hole into the shaft of the screw 8 mm deep (if the screw is 9 mm long). A center drill might be helpful. It is a good idea not to put the drill but the screw into the chuck of the drill press.

Now use the nozzle sharpening tool to taper the head of the screw. Just put the screw into the chuck of the drill press and sink it down into the center of the tool.

(The two black parts are cylindrical milling cutters. They do not rotate.)

Drill a 0.5 mm hole into the tip of the screw head. Usually I do this by putting the screw into the chuck of my drill press and place a 0.5 mm PCB drill under the tip. For holding the drill I use a mini chuck which I bought at a watchmakers supply shop. The chuck has a shaft which I fixate in a small vice. I use approx. 600 rpm when drilling the hole.

Now your nozzle is ready.

It is a good idea to make more than one nozzle as you may want to change between different nozzle diameters or types of material.

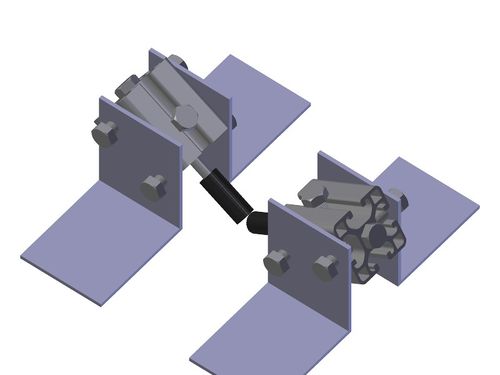

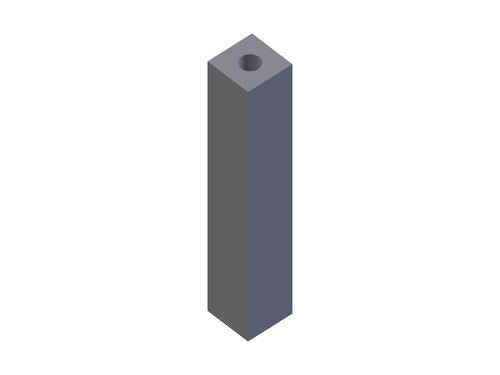

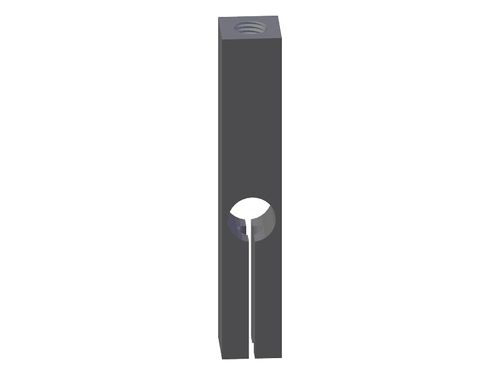

The Cooling Bar

The cooling bar consists of two parts:

| Quantity | Description | Specifications |

|---|---|---|

| 1 | square profile | aluminium, 10 x 10 x 58 mm |

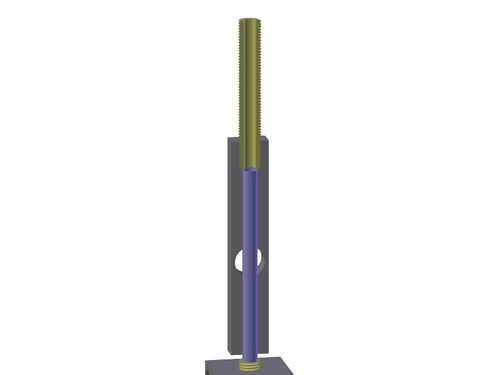

| 1 | threaded rod | brass, Length: 40 mm, M6 |

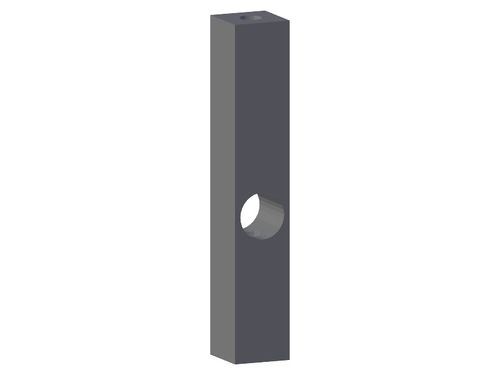

Here you see a cut through the cooling bar.

Later the bar will hold the barrel which is just clamped into the "chuck" allowing very rapid changes of barrels.

Tools you need:

- Drill press

- 8 mm metal drill

- 5 mm metal drill

- 3.2 mm metal drill

- long 4.1 mm metal drill

- center drill (optional)

- drill press vice

- hacksaw

- M6 tap

At first drill a 3.2 mm hole through the M6 threaded rod. Again put the rod into the chuck of the drill press for this and put the drill in a vice below. A center drill might be helpful.

Next drill a 4.1 mm hole at length through the square profile.

At 25 mm from the bottom up drill a 8 mm hole in horizontal direction.

Now take a hacksaw and saw a slit from the bottom to the 8 mm hole. This will be your "chuck" holding the barrel.

Drill a 5 mm hole from the top 8 mm deep. With a tap cut a M6 thread into it.

At last screw the threaded rod into the square profile. Glue them together later after you made sure the pipe aligns well. I use UHU Endfest 300 for it, but JB Weld might do as well.

The Heater Block

For the heater block you need:

| Quantity | Description | Specifications |

|---|---|---|

| 1 | cube | aluminium, 20 x 20 x 8 mm |

Tools you need:

- Drill press

- 5.2 mm metal drill

- 5 mm metal drill

- 2.5 mm metal drill

- center drill (optional)

- drill press vice

- M6 tap

Here is a cut through the block:

The Cooling Plates

The cooling plates consist of the following parts:

| Quantity | Description | Specifications |

|---|---|---|

| 1 | plate | aluminium, 60 x 40 x 3 mm |

| 1 | plate | aluminium, 20 x 40 x 3 mm |

| 8 | screw | M3 |

| 8 | nut | M3 |

Tools you need:

- Drill press

- 3 mm metal drill

The Fan

Use a 40 x 40 mm fan 12V.

Sources

- solder paste from Bengs Modellbau: http://www.bengs-modellbau.de/werkzeug/loetzubehoer/silberlotpaste.php

- stainless steel tubes from Ebay: http://www.ebay.de/itm/ws/eBayISAPI.dll?ViewItem&item=221146411608