No Ooze Nozzle

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: prototype

| Description | nozzle end to stop ooze

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

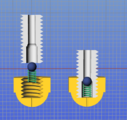

The No-ooze-nozzle is a hotend with a mechanical valve, which opens only when there is pressure from the extruder cold end. By having this ball-valve gate, oozing can be reduced. I am noting that this measure is not enough to totally shut out oozing, because there is still some room in between the valve and the extruding bore.

Oozing is a universal problem of FDM 3D printers, which perhaps all users experience. Not only is it just a little annoying for single extrusion machines, but it's a critical problem for dual (or more) extrusion machine. The oozed plastics mess the model, and demands the use of intricate countermeasures. Countermeasures means both hardware & software countermeasures.

Dual Extrusion Ooze Countermeasures

One hardware countermeasure is the one that shift the nozzle from the printing position so that the ooze doesn't touch the model. However it's a hefty load for your hotend and neither does it stop the nozzle from oozing, so you still need the prime pillar or the ooze shield.

Another measure is to have one nozzle to extrude multiple filaments, like the Diamond Hotend or the E3D Cyclobs. However because the plastics mix in the barrel, you still need software countermeasure, namely a prime pillar.

You could also cool down the idle hotend, but it doesn't totally prevent oozing, and it takes time to reheat when printing again.

Another bad thing is, because of the significant weight of the toolchanger for dual extrusion, once you modify your machine to dual extrusion, it's likely that you'll also have to compromise your single-extrusion speed, too.

All in all with dual extrusion you are likely to waste a lot of material and time.

No More ****!!

With the No Ooze Nozzle, you will no more need to mess with these countermeasures:

- ooze shield

- prime pillar

- tool change retraction

- cooling the idle hotend

- tool changer (like a servo)

How it Looks

The No ooze nozzle has a lean structure which comprise only 4 components. Below is a Makerbot hotend nozzle compatible design example.

How it Works

The gimmick is simple. the nozzle is closed when there is no pressure, and open when there is. Note that some retraction is needed, as residual pressure does leave the valve open. The opening force of the ball valve is adjusted to about 1N.

Notice

The shortcoming of this nozzle is that you will need some higher pressure to jerk the valve open, relative to a normal hotend nozzle. The valve & the spring are also obstacles of the plastics flow. High power geared extruder motors are recommended.

The adjustment of the opening force of the valve is REALLY crucial. If it had exceeded 1.5N, you will likely get hardly any plastic flowing. If you have less than 0.5N, it will start oozing. Machining of inconsistent center of 0.1 mm is enough for leaking. These are because molten plastics have very low surface tension. So the barrel & the nut must be very carefully machined, and polished for fewer flow resistance.

Had cleared all the precision requirements, the author has attained 80mm/sec at 0.2mm layer height with the temperature of 200 degrees Celsius and a 0.4 diameter nozzle with PLA.

It is recommended that you do not waste your time by sourcing it from an unreliable manufacturer.

How to get it

It is not yet commercially available. You will (typically) need the following tools to machine out a no ooze nozzle:

- drilling machine

- 2mm drill

- 3mm drill

- 2mm reamer

- 3mm reamer

- 2.5mm ball-end cutting router bit

Purchase these BOM items from your locally available stores.

- 2.5mm ball

- spring (length = 4, 5coils, OD=2.6mm, 2N/mm)

- M6 acorn nut

- M6 plain screw, (length = 13mm)

- 2.5mm ball

Video

The video is a demonstration of the nozzle extruding PLA, and then retracting about 3mm. The temperature of the hotend is kept at 200 degrees, and a bowden cable of 40cm was used. Fewer retraction will be needed for direct mount extruders.

<videoflash type="vimeo">204679648</videoflash>

Handling & Maintenance

Sometimes when the nozzle is clogged, you want to unscrew only the acorn nut for maintenance, but the whole assembly comes off the hotend. Or, vise verse, sometimes you want to unscrew the whole assembly for replacement, but only the acorn nut comes off the hotend.

To unscrew the part where you want, first prepare a wet sponge, and then raise the temperature of the hotend to the relevant melting temperature. Then,

- to unscrew only the acorn nut, touch the heater block with the sponge and cool it, then unscrew the acorn nut.

- to unscrew the whole assembly, touch the end of the nozzle with the sponge and cool it, then unscrew the acorn nut.

Hint: the cooled side is tight, and the hot side is loose. This is for thermal expansion and the stickiness of the plastic.