Help to a newbie

Posted by mrcool2k

|

Help to a newbie August 05, 2012 10:31AM |

Registered: 11 years ago Posts: 10 |

Hello,

I'm a newbie in this area and my interest in this 3D printers is too know if it can reduce my prototype and maybe my low budget and low quantity production in matter of time and maybe money.

Actually my problem is that takes too much time to build a machine because of the case (shell) time to produce, and normally I make all the concepts in Sketchup and the time to produce the case takes 2 weeks and about 300€ for each prototype (with the problem that we need 2 or 3 samples to get job done), and a lot time to correct operational problems since 2 weeks is too much time and have a lot of waiting times.

So I want your help is to know if I can make some "shell" for my machines with 1,20m x 0,5m x 0.6m, even if I can make then as a "Lego" system is good enough for me, but unfortunately I cannot find any kit with 0.5mx0.5mx0.5m contruction area or more.

Another problem is the resolution, because I need clean rounded surfaces and I'm not sure if a printer 3D can have a definition of <0.1mm with high quality finish.

My idea is to have a printer making one of the "lego" parts of the machine system overnight reducing my time from 2 weeks to 2 days.

For this, the machine has to have some stable and some quality to work 2 or 3 days in a row.

Adding the prototype capabilities, if it can have quality enough to make a 3 to 5 machines per month, than this can be perfect for me.

Do you recommmend any kit for this specs?

Thanks for all the help you can provide me.

I'm a newbie in this area and my interest in this 3D printers is too know if it can reduce my prototype and maybe my low budget and low quantity production in matter of time and maybe money.

Actually my problem is that takes too much time to build a machine because of the case (shell) time to produce, and normally I make all the concepts in Sketchup and the time to produce the case takes 2 weeks and about 300€ for each prototype (with the problem that we need 2 or 3 samples to get job done), and a lot time to correct operational problems since 2 weeks is too much time and have a lot of waiting times.

So I want your help is to know if I can make some "shell" for my machines with 1,20m x 0,5m x 0.6m, even if I can make then as a "Lego" system is good enough for me, but unfortunately I cannot find any kit with 0.5mx0.5mx0.5m contruction area or more.

Another problem is the resolution, because I need clean rounded surfaces and I'm not sure if a printer 3D can have a definition of <0.1mm with high quality finish.

My idea is to have a printer making one of the "lego" parts of the machine system overnight reducing my time from 2 weeks to 2 days.

For this, the machine has to have some stable and some quality to work 2 or 3 days in a row.

Adding the prototype capabilities, if it can have quality enough to make a 3 to 5 machines per month, than this can be perfect for me.

Do you recommmend any kit for this specs?

Thanks for all the help you can provide me.

|

Re: Help to a newbie August 05, 2012 12:29PM |

Registered: 17 years ago Posts: 824 |

Welcome,

With time, all of your questions will be answered. Let me address your post in the most general terms, and maybe someone else can give more specific answers.

RepRap machines are hobby-grade machines, but the output they produce can rival, and exceed commercial 3D printers of this kind (using plastic filament).

You will not be able to obtain smooth surfaces using any of these printers, without additional processes. These include sanding, vapor baths, and filler application (usually involves sanding).

With time, all of your questions will be answered. Let me address your post in the most general terms, and maybe someone else can give more specific answers.

RepRap machines are hobby-grade machines, but the output they produce can rival, and exceed commercial 3D printers of this kind (using plastic filament).

You will not be able to obtain smooth surfaces using any of these printers, without additional processes. These include sanding, vapor baths, and filler application (usually involves sanding).

|

Re: Help to a newbie August 05, 2012 12:43PM |

Registered: 12 years ago Posts: 147 |

Can you not vacuum form these shells?

Printing at .5x.5x.5 in any quality will take considerable time and will take countless hours of tuning to be able to print at that size reliably.

Printing parts this size will likely take a week with no guarantee of usable parts. There are printers which have printed huge objects such as chairs and boats, but the quality is poor unless you make the layers a feature of the design (the chair looks beautiful with stacked layers).

Printing at below <0.1mm layer height will take weeks not days, as for X and Y 0.1mm quality is a result of your mechanics (belts, pulleys and stepper motors) which is very achievable.

I'm not saying it can't be done but it is a massive task for these hobby printers, and commercial printers will take even longer!

Printing at .5x.5x.5 in any quality will take considerable time and will take countless hours of tuning to be able to print at that size reliably.

Printing parts this size will likely take a week with no guarantee of usable parts. There are printers which have printed huge objects such as chairs and boats, but the quality is poor unless you make the layers a feature of the design (the chair looks beautiful with stacked layers).

Printing at below <0.1mm layer height will take weeks not days, as for X and Y 0.1mm quality is a result of your mechanics (belts, pulleys and stepper motors) which is very achievable.

I'm not saying it can't be done but it is a massive task for these hobby printers, and commercial printers will take even longer!

|

Re: Help to a newbie August 05, 2012 05:59PM |

Registered: 11 years ago Posts: 10 |

First thanks a lot for sharing your experience.

My prototype shells for my machines are big but I'm thinking in frabrication with 10mm thick only, so maybe I did not need so much time, give some more examples to see it if are totally "undoable".

Anyway and to get better idea of what I can do, can you please let me know how much +/- centimeter cubic I can make with a 0.1mm tolerance in an hour?

If you have any opinion about Leapfrog Creatr , please let me know.

Thanks for your help!

Edited 1 time(s). Last edit at 08/05/2012 06:03PM by mrcool2k.

My prototype shells for my machines are big but I'm thinking in frabrication with 10mm thick only, so maybe I did not need so much time, give some more examples to see it if are totally "undoable".

Anyway and to get better idea of what I can do, can you please let me know how much +/- centimeter cubic I can make with a 0.1mm tolerance in an hour?

If you have any opinion about Leapfrog Creatr , please let me know.

Thanks for your help!

Edited 1 time(s). Last edit at 08/05/2012 06:03PM by mrcool2k.

|

Re: Help to a newbie August 07, 2012 07:29AM |

Registered: 11 years ago Posts: 10 |

Does anyone knows many cc/h a RepRap/Ultimaker can do with 0,1mm X/Y resolution and layer thickness?

Does anyone knows a RepRap Kit with build area more than Ultimaker (210x210x220mm [L/W/H]) ?

Thanks for any information you can provide.

Edited 2 time(s). Last edit at 08/07/2012 07:41AM by mrcool2k.

Does anyone knows a RepRap Kit with build area more than Ultimaker (210x210x220mm [L/W/H]) ?

Thanks for any information you can provide.

Edited 2 time(s). Last edit at 08/07/2012 07:41AM by mrcool2k.

|

Re: Help to a newbie August 07, 2012 08:37AM |

Registered: 12 years ago Posts: 147 |

A MendelMax has one of the largest stock build platforms and is particularly easy to scale in the X direction, Y and Z are linked so will have to be scaled together. We are talking quite some cost to upgrade the bars to at least 10mm or replace them with linear slides.

As far as cc/hr, it is very dependent on your speed and the density of fill. So you must choose strength vs time and speed vs quality, this will heavily depend on your setup. An Ultimaker is probably the best at this task as I am presuming it is just one solid shell, without complex details. Unfortunately the ultimaker is not really scalable, is certainly overpriced and lacks a heated bed for large prints.

Your best bet is a MendelMax, scaled or not which can reach pretty high speeds and is fairly solid and jitter free.

As far as cc/hr, it is very dependent on your speed and the density of fill. So you must choose strength vs time and speed vs quality, this will heavily depend on your setup. An Ultimaker is probably the best at this task as I am presuming it is just one solid shell, without complex details. Unfortunately the ultimaker is not really scalable, is certainly overpriced and lacks a heated bed for large prints.

Your best bet is a MendelMax, scaled or not which can reach pretty high speeds and is fairly solid and jitter free.

|

Re: Help to a newbie August 07, 2012 02:08PM |

Registered: 15 years ago Posts: 332 |

|

Re: Help to a newbie August 08, 2012 05:59AM |

Registered: 11 years ago Posts: 10 |

yydoctt Wrote:

-------------------------------------------------------

> A MendelMax has one of the largest stock build

> platforms and is particularly easy to scale in the

> X direction, Y and Z are linked so will have to be

> scaled together. We are talking quite some cost to

> upgrade the bars to at least 10mm or replace them

> with linear slides.

>

> As far as cc/hr, it is very dependent on your

> speed and the density of fill. So you must choose

> strength vs time and speed vs quality, this will

> heavily depend on your setup. An Ultimaker is

> probably the best at this task as I am presuming

> it is just one solid shell, without complex

> details. Unfortunately the ultimaker is not really

> scalable, is certainly overpriced and lacks a

> heated bed for large prints.

>

> Your best bet is a MendelMax, scaled or not which

> can reach pretty high speeds and is fairly solid

> and jitter free.

Thanks a lot, but MendelMax (print volume 215x235x190mm) is quite expensive (1295USD) and is not made in UE (more import tax + VAT + transport [more than 1500€] + difficulties to receive future replacement parts), do you have any opinion about Orca v.043 Printed Volume (25 x 22 x 19 cm (or 10 x 8,5 x 7,5 inches) ) - less than 1000€ (NL made, with VAT and Transport to Portugal)?

Edited 6 time(s). Last edit at 08/08/2012 06:22AM by mrcool2k.

-------------------------------------------------------

> A MendelMax has one of the largest stock build

> platforms and is particularly easy to scale in the

> X direction, Y and Z are linked so will have to be

> scaled together. We are talking quite some cost to

> upgrade the bars to at least 10mm or replace them

> with linear slides.

>

> As far as cc/hr, it is very dependent on your

> speed and the density of fill. So you must choose

> strength vs time and speed vs quality, this will

> heavily depend on your setup. An Ultimaker is

> probably the best at this task as I am presuming

> it is just one solid shell, without complex

> details. Unfortunately the ultimaker is not really

> scalable, is certainly overpriced and lacks a

> heated bed for large prints.

>

> Your best bet is a MendelMax, scaled or not which

> can reach pretty high speeds and is fairly solid

> and jitter free.

Thanks a lot, but MendelMax (print volume 215x235x190mm) is quite expensive (1295USD) and is not made in UE (more import tax + VAT + transport [more than 1500€] + difficulties to receive future replacement parts), do you have any opinion about Orca v.043 Printed Volume (25 x 22 x 19 cm (or 10 x 8,5 x 7,5 inches) ) - less than 1000€ (NL made, with VAT and Transport to Portugal)?

Edited 6 time(s). Last edit at 08/08/2012 06:22AM by mrcool2k.

|

Re: Help to a newbie August 08, 2012 06:03AM |

Registered: 11 years ago Posts: 10 |

james glanville Wrote:

-------------------------------------------------------

> Could you modify the design to use roughly-cut

> panels of sheet material with 3d printed

> corners/sides? That would be an easy way to cut

> down dramatically on the printed part size.

Yes, I really thought in reducing some parts and reuse other existent materials, but unfortunately I want to develop and prototype some mounts for internal components of my machines like small printers, LCD and PCBs and I need the bigger volume possible to have the minimum parts to reduce human errors.

Thanks for your comment and I'll try to reduce my parts.

-------------------------------------------------------

> Could you modify the design to use roughly-cut

> panels of sheet material with 3d printed

> corners/sides? That would be an easy way to cut

> down dramatically on the printed part size.

Yes, I really thought in reducing some parts and reuse other existent materials, but unfortunately I want to develop and prototype some mounts for internal components of my machines like small printers, LCD and PCBs and I need the bigger volume possible to have the minimum parts to reduce human errors.

Thanks for your comment and I'll try to reduce my parts.

|

Re: Help to a newbie August 08, 2012 06:24AM |

Registered: 12 years ago Posts: 147 |

You can do a lot worse than an Orca, they are not a community favourite and their website has had a fair number of complaints on very slow shipments, but that's hopefully behind them now. I haven't seen any complaints in months (have a search of these and their forums).

If you did want to go down the MendelMax route you could always consider self sourcing or half sourcing one, it depends on your time, but it will/should cost less than an Orca.

If you did want to go down the MendelMax route you could always consider self sourcing or half sourcing one, it depends on your time, but it will/should cost less than an Orca.

|

Re: Help to a newbie August 08, 2012 07:59AM |

Registered: 11 years ago Posts: 10 |

yydoctt Wrote:

-------------------------------------------------------

> You can do a lot worse than an Orca, they are not

> a community favourite and their website has had a

> fair number of complaints on very slow shipments,

> but that's hopefully behind them now. I haven't

> seen any complaints in months (have a search of

> these and their forums).

>

> If you did want to go down the MendelMax route you

> could always consider self sourcing or half

> sourcing one, it depends on your time, but it

> will/should cost less than an Orca.

Sorry but what you want to mean with "self sourcing or half sourcing one" ? I have a 2/3 months window so I think that time is not the biggest problem. My idea is to have the biggest/best quality for a 1000€ 3d printer.

Edited 1 time(s). Last edit at 08/08/2012 07:59AM by mrcool2k.

-------------------------------------------------------

> You can do a lot worse than an Orca, they are not

> a community favourite and their website has had a

> fair number of complaints on very slow shipments,

> but that's hopefully behind them now. I haven't

> seen any complaints in months (have a search of

> these and their forums).

>

> If you did want to go down the MendelMax route you

> could always consider self sourcing or half

> sourcing one, it depends on your time, but it

> will/should cost less than an Orca.

Sorry but what you want to mean with "self sourcing or half sourcing one" ? I have a 2/3 months window so I think that time is not the biggest problem. My idea is to have the biggest/best quality for a 1000€ 3d printer.

Edited 1 time(s). Last edit at 08/08/2012 07:59AM by mrcool2k.

|

Re: Help to a newbie August 08, 2012 05:26PM |

Registered: 12 years ago Posts: 147 |

Self sourcing is finding all the parts yourself - mainly locally, and ordering specialist parts such as hot ends and electronics. This can save you a lot of money over a kit (depending on how competitively priced they are and how long you spend shopping around for the best deals).

Half sourcing would be buying a mechanical kit or several smaller kits and bringing them altogether (such as buying a RepRap Prusa frame and mechanics kit and adding electronics).

For a MendelMax you can source your own extrusions (not necessarily from Misumi), this way you can change the size of the printer. It's fairly easy to scale, in fact very easy in the X direction. Then you can buy a series of kits from Europe for belts, pulleys, electronics, motors, etc and tie it in with some locally sourced rods and printed parts.

I think people overestimate the time required to self-source, it's not actually that time-consuming, 2 to 3 months is plenty of time (and allows you to order some pretty cheap things from China!)

Half sourcing would be buying a mechanical kit or several smaller kits and bringing them altogether (such as buying a RepRap Prusa frame and mechanics kit and adding electronics).

For a MendelMax you can source your own extrusions (not necessarily from Misumi), this way you can change the size of the printer. It's fairly easy to scale, in fact very easy in the X direction. Then you can buy a series of kits from Europe for belts, pulleys, electronics, motors, etc and tie it in with some locally sourced rods and printed parts.

I think people overestimate the time required to self-source, it's not actually that time-consuming, 2 to 3 months is plenty of time (and allows you to order some pretty cheap things from China!)

|

Re: Help to a newbie August 09, 2012 10:43AM |

Registered: 11 years ago Posts: 10 |

yydoctt Wrote:

-------------------------------------------------------

> Self sourcing is finding all the parts yourself -

> mainly locally, and ordering specialist parts such

> as hot ends and electronics. This can save you a

> lot of money over a kit (depending on how

> competitively priced they are and how long you

> spend shopping around for the best deals).

> Half sourcing would be buying a mechanical kit or

> several smaller kits and bringing them altogether

> (such as buying a RepRap Prusa frame and mechanics

> kit and adding electronics).

>

> For a MendelMax you can source your own extrusions

> (not necessarily from Misumi), this way you can

> change the size of the printer. It's fairly easy

> to scale, in fact very easy in the X direction.

> Then you can buy a series of kits from Europe for

> belts, pulleys, electronics, motors, etc and tie

> it in with some locally sourced rods and printed

> parts.

>

> I think people overestimate the time required to

> self-source, it's not actually that

> time-consuming, 2 to 3 months is plenty of time

> (and allows you to order some pretty cheap things

> from China!)

Thanks a lot.

Can you please provide some links from where I should start buying some of the parts?

-------------------------------------------------------

> Self sourcing is finding all the parts yourself -

> mainly locally, and ordering specialist parts such

> as hot ends and electronics. This can save you a

> lot of money over a kit (depending on how

> competitively priced they are and how long you

> spend shopping around for the best deals).

> Half sourcing would be buying a mechanical kit or

> several smaller kits and bringing them altogether

> (such as buying a RepRap Prusa frame and mechanics

> kit and adding electronics).

>

> For a MendelMax you can source your own extrusions

> (not necessarily from Misumi), this way you can

> change the size of the printer. It's fairly easy

> to scale, in fact very easy in the X direction.

> Then you can buy a series of kits from Europe for

> belts, pulleys, electronics, motors, etc and tie

> it in with some locally sourced rods and printed

> parts.

>

> I think people overestimate the time required to

> self-source, it's not actually that

> time-consuming, 2 to 3 months is plenty of time

> (and allows you to order some pretty cheap things

> from China!)

Thanks a lot.

Can you please provide some links from where I should start buying some of the parts?

|

Re: Help to a newbie August 10, 2012 07:11AM |

Registered: 12 years ago Posts: 147 |

Where in the EU are you?

I would go to webchat.freenode.net (IRC) and join the #RepRap and #MendelMax channels to talk to others who have/are self sourcing. There are lots of good links and great advice available. Others may give you different advice on which printer to build as well and may have more compelling reasons, they may also tell you 3D printing is possibly not the best technology for printing such big shells and will go through the reasons behind it (such as warping, time, reliability, cost, etc).

IRC is the quickest way to get started as many developers hang out there (MendelMax and Mendel Prusa creators for example).

Good luck

I would go to webchat.freenode.net (IRC) and join the #RepRap and #MendelMax channels to talk to others who have/are self sourcing. There are lots of good links and great advice available. Others may give you different advice on which printer to build as well and may have more compelling reasons, they may also tell you 3D printing is possibly not the best technology for printing such big shells and will go through the reasons behind it (such as warping, time, reliability, cost, etc).

IRC is the quickest way to get started as many developers hang out there (MendelMax and Mendel Prusa creators for example).

Good luck

|

Re: Help to a newbie August 13, 2012 02:35PM |

Registered: 11 years ago Posts: 10 |

I'm from Portugal.

If I want to make a MendelMax with 10mm rods and +50mm in all axis (265x295x240mm) where I should buy the parts altered for this situation?

yydoctt Wrote:

-------------------------------------------------------

> Where in the EU are you?

> I would go to webchat.freenode.net (IRC) and join

> the #RepRap and #MendelMax channels to talk to

> others who have/are self sourcing. There are lots

> of good links and great advice available. Others

> may give you different advice on which printer to

> build as well and may have more compelling

> reasons, they may also tell you 3D printing is

> possibly not the best technology for printing such

> big shells and will go through the reasons behind

> it (such as warping, time, reliability, cost,

> etc).

>

> IRC is the quickest way to get started as many

> developers hang out there (MendelMax and Mendel

> Prusa creators for example).

>

> Good luck

If I want to make a MendelMax with 10mm rods and +50mm in all axis (265x295x240mm) where I should buy the parts altered for this situation?

yydoctt Wrote:

-------------------------------------------------------

> Where in the EU are you?

> I would go to webchat.freenode.net (IRC) and join

> the #RepRap and #MendelMax channels to talk to

> others who have/are self sourcing. There are lots

> of good links and great advice available. Others

> may give you different advice on which printer to

> build as well and may have more compelling

> reasons, they may also tell you 3D printing is

> possibly not the best technology for printing such

> big shells and will go through the reasons behind

> it (such as warping, time, reliability, cost,

> etc).

>

> IRC is the quickest way to get started as many

> developers hang out there (MendelMax and Mendel

> Prusa creators for example).

>

> Good luck

|

Re: Help to a newbie August 21, 2012 09:45AM |

Registered: 11 years ago Posts: 10 |

|

Anonymous User

Re: Help to a newbie September 24, 2012 03:50AM |

|

Re: Help to a newbie September 24, 2012 04:21AM |

Registered: 11 years ago Posts: 11 |

If all you need is a case or shell for your machine, then buy large sheets of abs plastic

http://www.interstateplastics.com/search.php?withinsite=1&searchtext=abs%20sheets&utm_source=google&utm_medium=cpc&kw=abs%20sheets

Use a heat gun (similar to a very powerful hair dryer) to soften the abs sheets and heat form the sheets over a wood model you carved with a knife. In a couple of hours, you should have your prototype. Voila!

Before there were 3D printers, that was how we old farts did prototyping, by carving stuff out of wood and heat forming abs sheets over the wood forms.

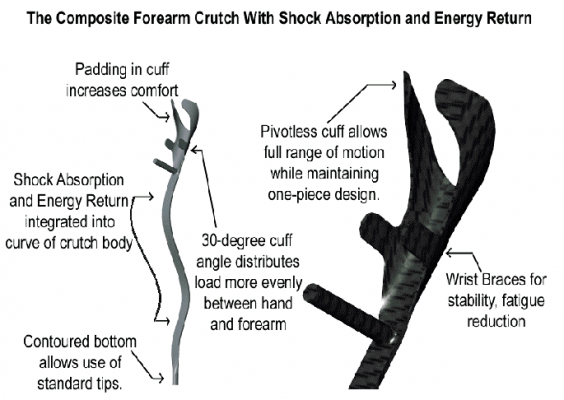

crutches made by this method:

http://www.interstateplastics.com/search.php?withinsite=1&searchtext=abs%20sheets&utm_source=google&utm_medium=cpc&kw=abs%20sheets

Use a heat gun (similar to a very powerful hair dryer) to soften the abs sheets and heat form the sheets over a wood model you carved with a knife. In a couple of hours, you should have your prototype. Voila!

Before there were 3D printers, that was how we old farts did prototyping, by carving stuff out of wood and heat forming abs sheets over the wood forms.

crutches made by this method:

Sorry, only registered users may post in this forum.