Design question relating to fillets.

Posted by Dark Alchemist

|

Design question relating to fillets. September 16, 2012 09:02AM |

Registered: 11 years ago Posts: 1,277 |

I have looked at a lot of schematics that gives me every single detail and measurements except for the fillets. Now how do I determine what size of fillets (or chamfers as the case may be) did they use? Heck, one better is if I have the actual part in my hand and see a fillet how do I know what to put in my cad program?

|

Re: Design question relating to fillets. September 16, 2012 07:22PM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Design question relating to fillets. September 16, 2012 07:42PM |

Registered: 11 years ago Posts: 477 |

Huh, I could almost swear I posted an answer earlier, but I may have done what I sometimes do and cast it off presuming someone would know better. Not black art, just reverse engineering.

1) explode, then convert the arc segments to a polyline, copy and mirror until you achieve a circle, measure the radius from opposing vertices

(this of course presumes that you have an STL rather than the original file to work with (where I suspect you already know how to measure the radius)

2) use a digital/dial/old-fashioned vernier to measure a printed part and accept any deviation from the actual value.

3) contact the author of part in question and ask

1) explode, then convert the arc segments to a polyline, copy and mirror until you achieve a circle, measure the radius from opposing vertices

(this of course presumes that you have an STL rather than the original file to work with (where I suspect you already know how to measure the radius)

2) use a digital/dial/old-fashioned vernier to measure a printed part and accept any deviation from the actual value.

3) contact the author of part in question and ask

|

Re: Design question relating to fillets. September 16, 2012 07:51PM |

Registered: 11 years ago Posts: 1,277 |

Well, these parts are either real tangible parts (not printed parts) or are in schematic form. Why in the heck a schematic would give every single dimension (over dimensioned if you put all of them in) and leave out the fillets is beyond me.

1) So, if I have a schematic how do I determine the fillet size?

Your #2 I don't understand and my digital calipers is on the way to be here this week but 2) With a real tangible part how do I get what the fillet size is?

Edited 2 time(s). Last edit at 09/16/2012 07:53PM by Dark Alchemist.

1) So, if I have a schematic how do I determine the fillet size?

Your #2 I don't understand and my digital calipers is on the way to be here this week but 2) With a real tangible part how do I get what the fillet size is?

Edited 2 time(s). Last edit at 09/16/2012 07:53PM by Dark Alchemist.

|

Re: Design question relating to fillets. September 16, 2012 08:06PM |

Registered: 11 years ago Posts: 477 |

By schematic, do you mean a 2D model or 3D, (as in sketchup/etc...can't quite remember what you use, but as I recall, it's one of the nice ones). Either way, presumably you mean a CAD file of some sort. If paper, you're on your own...

I'm not sure what measuring tools you have in your cad program. In sketchup, I can use the measure tool. In autocad, (presuming I can back the file into autocad) I can measure in a variety of ways.

If the file is an STL, then the curves have been reduced to a set of straight lines and vertices. since a fillet is (generally) a 90 degree section of a circle, isolate the arc segments of that fillet by exploding the component, strip the section out, set it down onto the origin so that the tinal vertex sits against one axis and the start on another, then flip/copy until you have a circle (or just measure from the origin to the vertex resting against an axis.) It's really pretty straightforward.

Regarding direct measurement. You can use a rule to hold against the flat, then use the calipers to measure the apparent axis of revolution that produced the arc. It is a bit more of an estimation rather than a precise measurement but more often than not, people use pretty "normal" values for fillets, so a close measure will yield a logical value.

Regarding why? Meh. oversight, not a drawing meant for machining the part. purposeful obscuration, stupidity, assumption that fillets are simply meant to round off otherwise sharp blunts...idk. it's not that big a deal to me. I'm not trying to literally steal someone else's intellectual property, just learn from it

Sorry if this sounds like magic. tain't so.

I'm not sure what measuring tools you have in your cad program. In sketchup, I can use the measure tool. In autocad, (presuming I can back the file into autocad) I can measure in a variety of ways.

If the file is an STL, then the curves have been reduced to a set of straight lines and vertices. since a fillet is (generally) a 90 degree section of a circle, isolate the arc segments of that fillet by exploding the component, strip the section out, set it down onto the origin so that the tinal vertex sits against one axis and the start on another, then flip/copy until you have a circle (or just measure from the origin to the vertex resting against an axis.) It's really pretty straightforward.

Regarding direct measurement. You can use a rule to hold against the flat, then use the calipers to measure the apparent axis of revolution that produced the arc. It is a bit more of an estimation rather than a precise measurement but more often than not, people use pretty "normal" values for fillets, so a close measure will yield a logical value.

Regarding why? Meh. oversight, not a drawing meant for machining the part. purposeful obscuration, stupidity, assumption that fillets are simply meant to round off otherwise sharp blunts...idk. it's not that big a deal to me. I'm not trying to literally steal someone else's intellectual property, just learn from it

Sorry if this sounds like magic. tain't so.

|

Re: Design question relating to fillets. September 16, 2012 08:28PM |

Registered: 11 years ago Posts: 1,277 |

It's paper, lol.

Like I know how tall and how wide and even how deep to the micrometer but not the fillets, lol. I would think I could figure it out from the dimensions.given but I don't know the formula.

I use Solidworks.

Now with a tangible item if it is square and I know |_ and the apex is now moved in rounding the part I should be able to find what fillet was used but this reverts to the same formula that just having a schematic needs.

Like I know how tall and how wide and even how deep to the micrometer but not the fillets, lol. I would think I could figure it out from the dimensions.given but I don't know the formula.

I use Solidworks.

Now with a tangible item if it is square and I know |_ and the apex is now moved in rounding the part I should be able to find what fillet was used but this reverts to the same formula that just having a schematic needs.

|

Re: Design question relating to fillets. September 16, 2012 09:33PM |

Registered: 11 years ago Posts: 477 |

Hmm..If you know some of the measurements, then you can do a comparison. for instance, suppose you know some length, (let's call it X). then you measure right off the paperwork both the known item and the fillet (from the apparent center to the outside of the fillet.

(Xknown/Xmeasured)*filletmeasured should equal the actual fillet measurement.

(Xknown/Xmeasured)*filletmeasured should equal the actual fillet measurement.

|

Re: Design question relating to fillets. September 16, 2012 09:47PM |

Registered: 11 years ago Posts: 1,277 |

The problem with that is that you can't measure a paper schematic and damn hard to measure a real fillet. I could have sworn there was a formula for this and it might lie within arcs. Know X? Know Y? Can measure the Arc (fillet)? Then the difference of the apex where X and Y used to meet to that of the new apex (peak of the Arc) is part of the equation I am sure of but been a long time since I was in school and did any mechanical work to remember.

|

Re: Design question relating to fillets. September 16, 2012 10:55PM |

Registered: 11 years ago Posts: 477 |

|

Re: Design question relating to fillets. September 16, 2012 11:16PM |

Registered: 11 years ago Posts: 1,277 |

I don't think that would work since the cord is straight line and what I have is X (width) and Y (height) and an arc connecting the two that I need to know what its length is.

I am still searching.

I loaded up SW and did a little test and I was spot on. X 76mm Y 78mm add a 10mm fillet and the lines were now 66 and 68. So, the hardest part will be in knowing exactly where the point is on a piece of paper or where it is on a tangible item.

Edited 2 time(s). Last edit at 09/16/2012 11:30PM by Dark Alchemist.

I am still searching.

I loaded up SW and did a little test and I was spot on. X 76mm Y 78mm add a 10mm fillet and the lines were now 66 and 68. So, the hardest part will be in knowing exactly where the point is on a piece of paper or where it is on a tangible item.

Edited 2 time(s). Last edit at 09/16/2012 11:30PM by Dark Alchemist.

|

Re: Design question relating to fillets. September 17, 2012 07:53AM |

Registered: 12 years ago Posts: 62 |

print yourself a circle template, the kind used for drafting back in the old days. Or go buy one, they are about $10

Then set the circle template on your drawing and line up the radius on the drawing to the best fitting radius from the circle template, this method works very well having used it many times.

Then set the circle template on your drawing and line up the radius on the drawing to the best fitting radius from the circle template, this method works very well having used it many times.

|

Re: Design question relating to fillets. September 17, 2012 08:16AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Design question relating to fillets. September 17, 2012 11:49AM |

Registered: 11 years ago Posts: 1,277 |

I have gathered this much by looking at SW and seeing 1.41 and trying to remember where I had seen that number from so many times in my life. It is the square root of 2, duh, which is the hypotenuse of a right triangle whose other sides are 1 and 1 which if you look at the points of the fillet would make the base of a triangle.

Now, what does the above have anything to do with a fillet? Take the distance between those two points (the base of the imaginary triangle the is really the new end points of the X and Y lines) and divide by 1.41 and that is your fillet arc's radius.

Edited 1 time(s). Last edit at 09/17/2012 11:51AM by Dark Alchemist.

Now, what does the above have anything to do with a fillet? Take the distance between those two points (the base of the imaginary triangle the is really the new end points of the X and Y lines) and divide by 1.41 and that is your fillet arc's radius.

Edited 1 time(s). Last edit at 09/17/2012 11:51AM by Dark Alchemist.

|

Re: Design question relating to fillets. September 17, 2012 09:21PM |

Admin Registered: 15 years ago Posts: 1,470 |

Dark Alchemist Wrote:

-------------------------------------------------------

> I would have done that but no schematic is to

> scale and these are the modern schematics not the

> old school blueprint type.

So then find the circle that matches, and scale it appropriately. Your schematics do have the scale on them, right?

Or do what you said in your last post

-------------------------------------------------------

> I would have done that but no schematic is to

> scale and these are the modern schematics not the

> old school blueprint type.

So then find the circle that matches, and scale it appropriately. Your schematics do have the scale on them, right?

Or do what you said in your last post

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Design question relating to fillets. September 18, 2012 06:50AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Design question relating to fillets. September 18, 2012 07:53PM |

Registered: 15 years ago Posts: 123 |

Well, anyway the different parts on the schematic are drawn to scale with each other, right? Is there a point to a schematic if that's not true? If you know the length of one of the other portions of the schematic, then do the circle stencil trick as suggested, and also measure the length of a line that is dimensioned.

You should be able to come up with a conversion factor and get a pretty accurate dimension. Remember also that usually these things have standard sizes unless the fillet is functional in some specific way in which case it aught be dimensioned. What I'm saying is if you get an answer of like 1.023 mm the real thing is probably 1 mm diameter unless the rest of the part is dimensioned in inches in which case it's likely 1/64 of an inch or whatever the closest "common" fraction ends up being. I've used this trick on a variety of mechanical parts and usually it works out.

How accurate do you need to be for these fillets can't you just pick a size that looks approximately right?

Good luck with this project!

You should be able to come up with a conversion factor and get a pretty accurate dimension. Remember also that usually these things have standard sizes unless the fillet is functional in some specific way in which case it aught be dimensioned. What I'm saying is if you get an answer of like 1.023 mm the real thing is probably 1 mm diameter unless the rest of the part is dimensioned in inches in which case it's likely 1/64 of an inch or whatever the closest "common" fraction ends up being. I've used this trick on a variety of mechanical parts and usually it works out.

How accurate do you need to be for these fillets can't you just pick a size that looks approximately right?

Good luck with this project!

|

Re: Design question relating to fillets. September 19, 2012 06:14AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

Is there a point to a schematic if that's not true?

From [en.wikipedia.org]:

A schematic diagram represents the elements of a system using abstract, graphic symbols rather than realistic pictures.

[www.hydraraptor.blogspot.com]

|

Re: Design question relating to fillets. September 19, 2012 10:39AM |

Registered: 11 years ago Posts: 253 |

My experience with drawings/schematics, is that the full dimensioning style is being replaced with critical dims only.

Because the world now moves so quickly to manufacturing, often a supplier will just use the CAD model to cut his molds, or tooling.

The drawing is a reference, and we actually state that the 3D data is the master definition.

We use only a handful of dimensions on even the most complicated of part.

Form/Fit/Function in the assembly is also critical.

In the past (early 90's and before), a drawing was a complete instruction set to describe every aspect, because there was no 3D data to drive the CNC mills.

Compound curves used graphs, equations, or a multitude of detailed/dimensioned cross sections.

The drawing had to stand alone, without an engineer sent along with it, and fully describe the end part, to the minutest of detail.

I'd personally just approximate the fillet. I rarely see such a feature be critical.

I'd like to see the part you are concerned about also.

Dave

Because the world now moves so quickly to manufacturing, often a supplier will just use the CAD model to cut his molds, or tooling.

The drawing is a reference, and we actually state that the 3D data is the master definition.

We use only a handful of dimensions on even the most complicated of part.

Form/Fit/Function in the assembly is also critical.

In the past (early 90's and before), a drawing was a complete instruction set to describe every aspect, because there was no 3D data to drive the CNC mills.

Compound curves used graphs, equations, or a multitude of detailed/dimensioned cross sections.

The drawing had to stand alone, without an engineer sent along with it, and fully describe the end part, to the minutest of detail.

I'd personally just approximate the fillet. I rarely see such a feature be critical.

I'd like to see the part you are concerned about also.

Dave

|

Re: Design question relating to fillets. September 19, 2012 10:57AM |

Registered: 11 years ago Posts: 1,277 |

I wasn't concerned about any particular part per se' but more of what you described as a huge shift away from the blueprints and schematics I am used to where everything (you even had to check that the dot wasn't just a drip from your morning coffee or was it defined someplace) was laid out. How would a shop know that a fillet was 4.5mm or 6mm without it being spelled out?

|

Re: Design question relating to fillets. September 19, 2012 11:28AM |

Registered: 11 years ago Posts: 253 |

We now are very used to quoting entire assemblies from just the 3D data. Things like a laser printer, or a Petabyte rack enclosure.

It drives us crazy, but customers can have the 3D design long before the drawings are made.

Often the drawings show up somewhere after tooling is started, when the engineers have time to get to them.

Sometimes, the supplier has to make the drawings, and they can add whatever they think is worthwhile inspecting.

It's all in the CAD now.

As recently as 2003-ish, we had a company come to us with 300 PDF drawings and wanted us to start tooling immediately.

We had to tell them that the conversion from PDF to ProEngineer would take several months of work.

They were baffled and upset by the delays and costs. Shocked that PDF was not good enough, but we explained that our equipment used 3D data and not document formats. I was shocked that this company didn't know this without being told.

The work flow in the manufacturing industry starts with 3D data and not a Word document or a paper copy.

It drives us crazy, but customers can have the 3D design long before the drawings are made.

Often the drawings show up somewhere after tooling is started, when the engineers have time to get to them.

Sometimes, the supplier has to make the drawings, and they can add whatever they think is worthwhile inspecting.

It's all in the CAD now.

As recently as 2003-ish, we had a company come to us with 300 PDF drawings and wanted us to start tooling immediately.

We had to tell them that the conversion from PDF to ProEngineer would take several months of work.

They were baffled and upset by the delays and costs. Shocked that PDF was not good enough, but we explained that our equipment used 3D data and not document formats. I was shocked that this company didn't know this without being told.

The work flow in the manufacturing industry starts with 3D data and not a Word document or a paper copy.

|

Re: Design question relating to fillets. September 19, 2012 11:32AM |

Registered: 11 years ago Posts: 1,277 |

Yes, but that information should be laid out in a 2d schematic for at least the engineers to look at else I smell why there are so many automobile recalls for instance.

Plus, if a company is going to publish a schematic or even a drawing with a ton of dimensions on it make sure to have all of them listed.

Plus, if a company is going to publish a schematic or even a drawing with a ton of dimensions on it make sure to have all of them listed.

|

Re: Design question relating to fillets. September 19, 2012 12:17PM |

Registered: 11 years ago Posts: 477 |

A shop that legitimately receives a customer's manufacturing drawing(s) for production of a customer's part(s) should expect to receive drawings with any required values provided. And they still do today in 2012, just like they did in 2002, 1992, 1982, and so on, although more often than not today, they receive that drawing in electronic form rather than on vellum.

|

Re: Design question relating to fillets. September 19, 2012 12:24PM |

Registered: 11 years ago Posts: 253 |

A 2D schematic is not something we ever create, in product development anyways.

I've worked with a ton of electrical teams over the years, and not even they use 2D schematics. It's all computer driven now.

It's amazing a car can be made given the lax attitudes toward perfection.

I think that's why the Japanese cars and German cars are so well made.

Attention to detail and pride in work.

I've worked with a ton of electrical teams over the years, and not even they use 2D schematics. It's all computer driven now.

It's amazing a car can be made given the lax attitudes toward perfection.

I think that's why the Japanese cars and German cars are so well made.

Attention to detail and pride in work.

|

Re: Design question relating to fillets. September 19, 2012 03:18PM |

Registered: 12 years ago Posts: 313 |

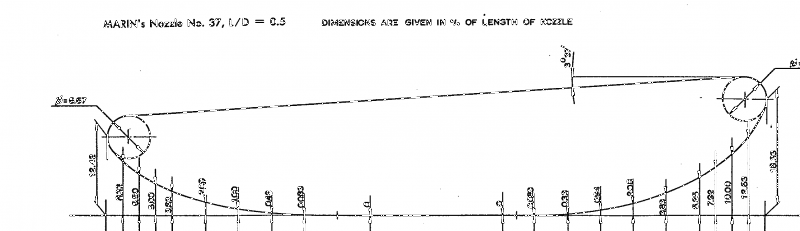

I had a fairly similar problem. I wanted to create a 3D model of a Kort nozzle but the best data I found was this cross-section:

(open in a new tab if necessary)

This actually has the fillets defined exactly, but the rest of the curves are not. I tried to figure out how to digitize this from just the numeric data, but eventually I just took the GIF, loaded it into Inkscape and handcrafted a spline along the profile outline in the blueprint. It's probably close enough to the original... This is the result.

(open in a new tab if necessary)

This actually has the fillets defined exactly, but the rest of the curves are not. I tried to figure out how to digitize this from just the numeric data, but eventually I just took the GIF, loaded it into Inkscape and handcrafted a spline along the profile outline in the blueprint. It's probably close enough to the original... This is the result.

|

Re: Design question relating to fillets. September 19, 2012 03:46PM |

Registered: 11 years ago Posts: 477 |

ttsalo: And that's the way it's done. If one method doesn't work, the smart use another or pay someone who is to do so for them.

-------------

FWIW, Dave, Paper is still presented to both contractors and customers on occasion, although usually only for design review meetings as part of a review package, as well as for deliverables (it is pretty standard to provide at least a few "hard copies" of the engineering documentation to a customer, including mechanical drawings and electrical schematics, as well as BOMs, manuals, troubleshooting guides, etc.) or for site or production work as references. Paper is far more convenient in many cases than using a computer, pad or not.

As for 2D electrical schematics, they're routinely used on production floors during wiring of assemblies. Not everything is limited to printed circuit boards or automation. And smaller job shops or similar do use paper prints for machinists even at the various shop areas at NASA. There are still humans involved and most machinists that operate non-cam machining tools rely on printed drawings. Were these printers a true production part, there would be wiring schematics for the workers to follow, I guarantee it. And anyone who has worked with or in production knows it too.

The vellum comment was a joke, due to its largely antique value in today's world.

-------------

FWIW, Dave, Paper is still presented to both contractors and customers on occasion, although usually only for design review meetings as part of a review package, as well as for deliverables (it is pretty standard to provide at least a few "hard copies" of the engineering documentation to a customer, including mechanical drawings and electrical schematics, as well as BOMs, manuals, troubleshooting guides, etc.) or for site or production work as references. Paper is far more convenient in many cases than using a computer, pad or not.

As for 2D electrical schematics, they're routinely used on production floors during wiring of assemblies. Not everything is limited to printed circuit boards or automation. And smaller job shops or similar do use paper prints for machinists even at the various shop areas at NASA. There are still humans involved and most machinists that operate non-cam machining tools rely on printed drawings. Were these printers a true production part, there would be wiring schematics for the workers to follow, I guarantee it. And anyone who has worked with or in production knows it too.

The vellum comment was a joke, due to its largely antique value in today's world.

Sorry, only registered users may post in this forum.