Are your reported temperatures accurate?

Posted by Alzibiff

|

Are your reported temperatures accurate? March 28, 2013 07:33AM |

Registered: 12 years ago Posts: 212 |

In another topic in this forum, RichRap made the following comment:

richrap Wrote:

-------------------------------------------------------

> Make sure you have your Hot-end and thermistor

> actually calibrated.....

When it comes to taking /giving advice on print problems and settings, I think that RichRap has hit the nail on the head with the comment above. Comparing temperatures - as seems VERY common - only make sense if we are all using a common calibration standard and I suspect we are not.

It would be interesting to learn how people go about confirming that the temperatures reported by whatever host software they use are accurate. That is, HOW do you "make sure that you have your Hot-end and thermistor accurately calibrated"?

Alan

Edited 1 time(s). Last edit at 03/28/2013 07:35AM by Alzibiff.

richrap Wrote:

-------------------------------------------------------

> Make sure you have your Hot-end and thermistor

> actually calibrated.....

When it comes to taking /giving advice on print problems and settings, I think that RichRap has hit the nail on the head with the comment above. Comparing temperatures - as seems VERY common - only make sense if we are all using a common calibration standard and I suspect we are not.

It would be interesting to learn how people go about confirming that the temperatures reported by whatever host software they use are accurate. That is, HOW do you "make sure that you have your Hot-end and thermistor accurately calibrated"?

Alan

Edited 1 time(s). Last edit at 03/28/2013 07:35AM by Alzibiff.

|

Re: Are your reported temperatures accurate? March 28, 2013 07:37AM |

Registered: 12 years ago Posts: 2,470 |

I did it in two steps. First i used kapton to fix a calibrated thermosensor to my hotend as near to the nozzle as possible and compared temperatures from 100° up to 250°. This proved to me that actual differences to what the firmware reported were <5°, something i can live with, especialy since the difference was nearly linear. Later i had the opportunity to use a thermal camera, which confirmed earlier results.

|

Re: Are your reported temperatures accurate? March 28, 2013 07:42AM |

Registered: 11 years ago Posts: 137 |

I'm pretty sure mine isn't accurate but it should be relatively accurate to its own readings. When I get new filament I don't take the sellers word for what I should print at. I do test prints at various temps to find what works. So the temp reading doesn't have to be accurate to what the real temp is as long as it can hold the temp at a specific point.

Like the filament I buy says it should extrude well at 170-180 but I have to get it to 200 before I get a good looking extrude and 220 b4 I get a good looking print. At 170-180 it barely extrudes any plastic and the gear on the extruder eats into the filament so the temp cant be accurate. I wont know for sure until I get a laser thermometer tho.

Once you get to know your printer and filament I dont think its really necessary to know the "real" temperature, except maybe to prevent overheating and melting your PEEK.

Like the filament I buy says it should extrude well at 170-180 but I have to get it to 200 before I get a good looking extrude and 220 b4 I get a good looking print. At 170-180 it barely extrudes any plastic and the gear on the extruder eats into the filament so the temp cant be accurate. I wont know for sure until I get a laser thermometer tho.

Once you get to know your printer and filament I dont think its really necessary to know the "real" temperature, except maybe to prevent overheating and melting your PEEK.

|

Re: Are your reported temperatures accurate? March 28, 2013 11:22AM |

Registered: 13 years ago Posts: 818 |

hendo420 Wrote:

-------------------------------------------------------

> I'm pretty sure mine isn't accurate but...

> I dont think its really necessary to know the "real"

> temperature, except maybe to prevent overheating

> and melting your PEEK.

Yes it does!

You have set me off now, get ready for some hot-end advice.

[richrap.blogspot.com]

-------------------------------------------------------

> I'm pretty sure mine isn't accurate but...

> I dont think its really necessary to know the "real"

> temperature, except maybe to prevent overheating

> and melting your PEEK.

Yes it does!

You have set me off now, get ready for some hot-end advice.

[richrap.blogspot.com]

|

Re: Are your reported temperatures accurate? March 28, 2013 11:31AM |

Registered: 13 years ago Posts: 818 |

A bit of a rant and advice below, do take a read as it has some good tips in it, from many, many experiences of sorting out hot-ends for people.

If anyone is going to quote temperatures about anything 3D Printer and filament related, especially on this forum, it really does help to know it's calibrated.

And it's very important to get the thermistor table correct in the firmware. And not just correct, make sure it has enough entries at the temperatures you are going to be printing at - this is becoming more of a problem as people push higher temperature materials through Stainless steel hot-ends - you really want to be using a thermocouple at this point.

So, Don't just make compensation for incorrect set up or calibration it in the host program. I have seen many people entering '265' degrees C into the host program because they 'know' that it's really only 190 at the hot-end. That just gets everything into a mess as the then max temperature setting in the firmware can easily trip if you don't have the PID settings dialed in and then people wonder why their prints look crap or fail or the firmware has shutdown the hot-end due to an over temperature because the thermistor table was not well enough defined with entries up to and beyond 265+ Degrees C - so it just ends up swinging the temperature all over the place.

Rules of setting up your hot-end -

1) - Check to see that the correct thermistor table is active in your firmware - If you don't know what thermistor you have, ask the seller, get another thermistr or in extreme cases work out the Beta Value and write your own table (the easiest thing is to get a known 100K 'RepRap' thermistor)

2) - If possible measure the temperature of the inside of your hot-end with a thermocouple - put it inside the barrel, right down at the hot-end tip.

You want to check it at about 165 and 220 degrees C - don;t worry if it swings about a bit - you will need to do step 5 below to get a stable PI control loop.

2 - If you don't have a thermocouple, you can do a comparison calibration with a temperature controlled soldering Iron - It's not ideal, but better than guessing.

- If you don't have a thermocouple, you can do a comparison calibration with a temperature controlled soldering Iron - It's not ideal, but better than guessing.

Set the soldering iron to 165 degrees and check readings at 5 degrees C increments. Put the soldering iron tip on the thermistor, see what it measures in the host program, if it's within a similar temperature (a few degrees of what you expect) all the way through the 165 to 220 degrees scale your thermistor table is correct and should work well when you install it in the hot-end.

2C) - If you don't have a thermocouple or soldering iron, than at the least you can do a 100 degrees C check with boiling water, just don't short out your thermistor wires, wrap the wires with kapton tape and use tin-foil or thin plastic so you can dip the thermistor in the boiling water.

3) - Make sure you install the thermistor well on the hot-end - sticking it on the side of the heater block with a few wraps of Kapton tape does not make a well installed thermistor!

The hot-end should have a small hole to insert the thermistor into, use it, or make one, if possible use some thermal insulation on the hot-end, ceramic tape, fiberglass wool or PTFE tape and more Kapton. I also add a copper wire wrapped around the now insulated heater block to hold the thermistor and heater element well in place.

4) - Exactly the same advice goes for the Resistor or heater element, make sure it's well secured, don't just use a bit of tape.

If you have a hot-end ready made up, look to see how it's been assembled, and re-make it if it's not done well.

5) - Make sure you run the M303 command on your hot-end - this will auto calibrate the PID setting for you and tell you what to enter in your firmware so your specific hot-end (and the way you have specifically installed it ) is set-up as beast as possible for printing - Don't skip this bit.

When it has finished auto tuning you will have settings that need to be entered into the Firmware and downloaded back to your electronics.

You should now have a well calibrated hot-end, with stable PID settings that won't swing about all over the place.

Your printer now has the potential to print well.

Last point - if at all possible, use a thermocouple rather than a thermistor on your hot-end - many new RepRap electronics have a direct input for one (MEGATRONICS for example)

That would almost make a good blog post if I added a few images...

Cheers,

Rich.

[richrap.blogspot.com]

If anyone is going to quote temperatures about anything 3D Printer and filament related, especially on this forum, it really does help to know it's calibrated.

And it's very important to get the thermistor table correct in the firmware. And not just correct, make sure it has enough entries at the temperatures you are going to be printing at - this is becoming more of a problem as people push higher temperature materials through Stainless steel hot-ends - you really want to be using a thermocouple at this point.

So, Don't just make compensation for incorrect set up or calibration it in the host program. I have seen many people entering '265' degrees C into the host program because they 'know' that it's really only 190 at the hot-end. That just gets everything into a mess as the then max temperature setting in the firmware can easily trip if you don't have the PID settings dialed in and then people wonder why their prints look crap or fail or the firmware has shutdown the hot-end due to an over temperature because the thermistor table was not well enough defined with entries up to and beyond 265+ Degrees C - so it just ends up swinging the temperature all over the place.

Rules of setting up your hot-end -

1) - Check to see that the correct thermistor table is active in your firmware - If you don't know what thermistor you have, ask the seller, get another thermistr or in extreme cases work out the Beta Value and write your own table (the easiest thing is to get a known 100K 'RepRap' thermistor)

2) - If possible measure the temperature of the inside of your hot-end with a thermocouple - put it inside the barrel, right down at the hot-end tip.

You want to check it at about 165 and 220 degrees C - don;t worry if it swings about a bit - you will need to do step 5 below to get a stable PI control loop.

2

- If you don't have a thermocouple, you can do a comparison calibration with a temperature controlled soldering Iron - It's not ideal, but better than guessing.

- If you don't have a thermocouple, you can do a comparison calibration with a temperature controlled soldering Iron - It's not ideal, but better than guessing.Set the soldering iron to 165 degrees and check readings at 5 degrees C increments. Put the soldering iron tip on the thermistor, see what it measures in the host program, if it's within a similar temperature (a few degrees of what you expect) all the way through the 165 to 220 degrees scale your thermistor table is correct and should work well when you install it in the hot-end.

2C) - If you don't have a thermocouple or soldering iron, than at the least you can do a 100 degrees C check with boiling water, just don't short out your thermistor wires, wrap the wires with kapton tape and use tin-foil or thin plastic so you can dip the thermistor in the boiling water.

3) - Make sure you install the thermistor well on the hot-end - sticking it on the side of the heater block with a few wraps of Kapton tape does not make a well installed thermistor!

The hot-end should have a small hole to insert the thermistor into, use it, or make one, if possible use some thermal insulation on the hot-end, ceramic tape, fiberglass wool or PTFE tape and more Kapton. I also add a copper wire wrapped around the now insulated heater block to hold the thermistor and heater element well in place.

4) - Exactly the same advice goes for the Resistor or heater element, make sure it's well secured, don't just use a bit of tape.

If you have a hot-end ready made up, look to see how it's been assembled, and re-make it if it's not done well.

5) - Make sure you run the M303 command on your hot-end - this will auto calibrate the PID setting for you and tell you what to enter in your firmware so your specific hot-end (and the way you have specifically installed it ) is set-up as beast as possible for printing - Don't skip this bit.

When it has finished auto tuning you will have settings that need to be entered into the Firmware and downloaded back to your electronics.

You should now have a well calibrated hot-end, with stable PID settings that won't swing about all over the place.

Your printer now has the potential to print well.

Last point - if at all possible, use a thermocouple rather than a thermistor on your hot-end - many new RepRap electronics have a direct input for one (MEGATRONICS for example)

That would almost make a good blog post if I added a few images...

Cheers,

Rich.

[richrap.blogspot.com]

|

Re: Are your reported temperatures accurate? March 28, 2013 02:43PM |

Registered: 11 years ago Posts: 137 |

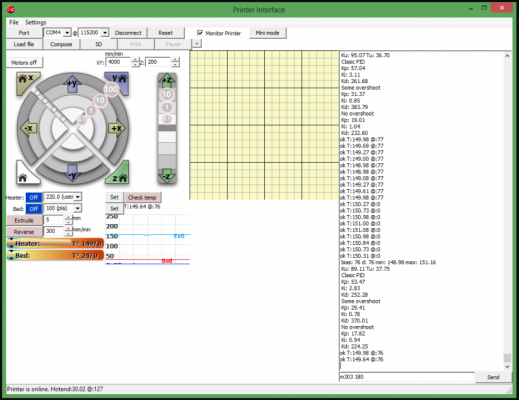

How long does the M303 auto tuning last? Mines been running for almost 10 minutes now.

Also, you said I will have settings that need to be entered into my firmware. How do I go about doing this?

Pardon my not googleing b4 asking.

[www.make-something.com]

[blog.lincomatic.com]

Edited 1 time(s). Last edit at 03/28/2013 02:57PM by hendo420.

Also, you said I will have settings that need to be entered into my firmware. How do I go about doing this?

Pardon my not googleing b4 asking.

[www.make-something.com]

[blog.lincomatic.com]

Edited 1 time(s). Last edit at 03/28/2013 02:57PM by hendo420.

|

Re: Are your reported temperatures accurate? March 28, 2013 03:28PM |

Admin Registered: 11 years ago Posts: 1,063 |

somthing to add to richraps's blog post is that if you temptable is innaccurate chances are it's in accurate in a non linear fashion so the pid loop has a difficult time controlling temperature because it sees small temperature changes as huge ones and constantly over compensates, the pid loops are a pain to get going properly, but if they temp table is accurate you can get the pid loop to hold a temperature with 1 - 2c even under quite a bit of load

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Are your reported temperatures accurate? March 28, 2013 03:58PM |

Registered: 11 years ago Posts: 42 |

Even with good calibrated readings any reference to temperatures given by other people are only ballpark figures to me, there are so many variables that influence extruding i allways test and tweak for myself. As long as the temperature is stable i don't mind if it's of compared to others... Americans can print to, and they use a completely different scale

|

Re: Are your reported temperatures accurate? March 28, 2013 05:00PM |

Registered: 11 years ago Posts: 137 |

|

Re: Are your reported temperatures accurate? March 28, 2013 05:24PM |

Admin Registered: 11 years ago Posts: 1,063 |

an hour and a half is bit much, how hot is the hotend getting?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Are your reported temperatures accurate? March 28, 2013 05:50PM |

Registered: 11 years ago Posts: 137 |

|

Re: Are your reported temperatures accurate? March 28, 2013 06:25PM |

Admin Registered: 11 years ago Posts: 1,063 |

is it giving you 3 values "p" "i" "d"

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Are your reported temperatures accurate? March 28, 2013 06:31PM |

Registered: 11 years ago Posts: 137 |

Yes, I finally stoped it and took the latest one that said Clasic PID and put it in my start gcode.

|

Re: Are your reported temperatures accurate? March 28, 2013 07:06PM |

Registered: 13 years ago Posts: 818 |

The M303 command usually takes about 5 minutes on Marlin RC2/3 - it may well just loop over and over on earlier Marlin Releases.

You need to put these values into the configuration.h and re-make your firmware.

It's about line 130 in recent Marlin releases -

// If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it

// Ultimaker

#define DEFAULT_Kp 22.2

#define DEFAULT_Ki 1.08

#define DEFAULT_Kd 114

[richrap.blogspot.com]

You need to put these values into the configuration.h and re-make your firmware.

It's about line 130 in recent Marlin releases -

// If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it

// Ultimaker

#define DEFAULT_Kp 22.2

#define DEFAULT_Ki 1.08

#define DEFAULT_Kd 114

[richrap.blogspot.com]

|

Re: Are your reported temperatures accurate? March 29, 2013 10:00AM |

Registered: 13 years ago Posts: 7,616 |

M303 calibrates PID, so target temperatures are reached more quickly and held more stable. It does not calibrate the accuracy of reported temperature vs. true temperature.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

Sorry, only registered users may post in this forum.