resistor type

Posted by f3rDz

|

resistor type May 21, 2013 09:58PM |

Registered: 11 years ago Posts: 88 |

|

Re: resistor type May 21, 2013 11:34PM |

Registered: 13 years ago Posts: 1,797 |

Vitreous enamel refers to the protective coating over the wire wound resistor. I think cemented axial just references the outside material used on the resistor. Vitreous enamel coating lasts at higher temps and does not break down as easily. I am not 100% positive but I think the other type uses regular winding lacquer coating. Not sure of what material.

I have used both types, the cemented type are available locally. Although I cannot be sure of what brand of cement resistors mine were, they did not last that long at all.

I have used both types, the cemented type are available locally. Although I cannot be sure of what brand of cement resistors mine were, they did not last that long at all.

|

Re: resistor type May 22, 2013 07:00AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Although I cannot be sure of what brand of cement resistors mine were, they did not last that long at all.

I'd guess this cement is too much of an thermal insulation, so they over-heat too much inside. High power resistors are not made to deliver heat, but to withstand high currents, after all.

The thinner the coating of a wirewound resistor is, the better. As long as the coating can withstand some 400 °C (which silicone coatings don't).

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: resistor type May 22, 2013 11:01AM |

Registered: 14 years ago Posts: 177 |

|

Re: resistor type May 22, 2013 11:27AM |

Registered: 13 years ago Posts: 1,797 |

it is true that enamel resistors need to be changed, this is why i now use alligator clips as my crimp connector to attach to the resistor. This is in case of failure i can be up and running in minutes. I have not had a failure in over 3 months.

btw i have had a cartridge heater fail on me. the wire contact broke off.

i find that reducing the pwm to 220 and entirely coating the resistor with silver paste even on the sides of the resistor, then inserting it into aluminum block helps. also wrapping resistor in aluminum so even the sides have contact with aluminum help. make sure to coat the outside of resistor with ptfe tubing or shrink tubing.

my systems currently run at 19.5 to 21v using laptop supplies. i have switched to using 8.2ohm 3w resistors, and they last quite a bit longer. I run at high temps and at a higher voltages.

I do like cartridge heaters, but it is more important that i can source parts quickly in case of any issues.Even though i have multiple printers I hate being down for 2 weeks on a printer just because a part is overseas somewhere. I can pick up 25 resistors for about 15$, and get them overnight if i need to or wait 3 days and have them affordable shipped.

I'm a bit hesitant from past experiences to rely entirely on the quality out of china, or hong kong. lost packages, or painful return processes on large batch purchases are memories you don't forget very easily.

btw i have had a cartridge heater fail on me. the wire contact broke off.

i find that reducing the pwm to 220 and entirely coating the resistor with silver paste even on the sides of the resistor, then inserting it into aluminum block helps. also wrapping resistor in aluminum so even the sides have contact with aluminum help. make sure to coat the outside of resistor with ptfe tubing or shrink tubing.

my systems currently run at 19.5 to 21v using laptop supplies. i have switched to using 8.2ohm 3w resistors, and they last quite a bit longer. I run at high temps and at a higher voltages.

I do like cartridge heaters, but it is more important that i can source parts quickly in case of any issues.Even though i have multiple printers I hate being down for 2 weeks on a printer just because a part is overseas somewhere. I can pick up 25 resistors for about 15$, and get them overnight if i need to or wait 3 days and have them affordable shipped.

I'm a bit hesitant from past experiences to rely entirely on the quality out of china, or hong kong. lost packages, or painful return processes on large batch purchases are memories you don't forget very easily.

|

Re: resistor type May 22, 2013 11:44AM |

Registered: 11 years ago Posts: 88 |

^^^^ i can feel you.

after waiting for more than a month, my cartridge heater arrived but wrong specs. i ordered a 12v but got a 24v. luckily i also ordered some resistors (both cemented and enameled) also overseas but with a quicker turn around period.

hence the reason for this question.

i was told going the 24v path is a good option. but i will be holding off on it until i have lots of printers.

will using a single 8.2ohms be better than using 2-6.8 in parallel?

after waiting for more than a month, my cartridge heater arrived but wrong specs. i ordered a 12v but got a 24v. luckily i also ordered some resistors (both cemented and enameled) also overseas but with a quicker turn around period.

hence the reason for this question.

i was told going the 24v path is a good option. but i will be holding off on it until i have lots of printers.

will using a single 8.2ohms be better than using 2-6.8 in parallel?

|

Re: resistor type May 22, 2013 12:18PM |

Registered: 11 years ago Posts: 88 |

|

Re: resistor type May 22, 2013 12:43PM |

Admin Registered: 15 years ago Posts: 1,470 |

f3rDz Wrote:

-------------------------------------------------------

> @jamesdaniel,

>

> how do you heat your heatbed with laptop power

> supplies? doesnt heatbeds require around 11 amps?

I don't know about him, but I power my heated beds with 115V mains current, switched with an SSR.

-------------------------------------------------------

> @jamesdaniel,

>

> how do you heat your heatbed with laptop power

> supplies? doesnt heatbeds require around 11 amps?

I don't know about him, but I power my heated beds with 115V mains current, switched with an SSR.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: resistor type May 22, 2013 05:03PM |

Registered: 13 years ago Posts: 1,797 |

my main heated bed shown in some of my videos is using gen3 electronics and 12v power thru and thru (450 watt supply just verified it is 500watt)

as for my 20v systems, the one that i use a heated bed has a seperate12v, 10 or 12amp supply, and a 20v supply for everything else. with ramps you can do this this way.the separate supply is a LCD TV power brick.

one of these will do the trick if you are interested. no vested interest in the seller, so please shop around

[www.ebay.com]

Edited 3 time(s). Last edit at 05/23/2013 04:23AM by jamesdanielv.

as for my 20v systems, the one that i use a heated bed has a seperate12v, 10 or 12amp supply, and a 20v supply for everything else. with ramps you can do this this way.the separate supply is a LCD TV power brick.

one of these will do the trick if you are interested. no vested interest in the seller, so please shop around

[www.ebay.com]

Edited 3 time(s). Last edit at 05/23/2013 04:23AM by jamesdanielv.

|

Re: resistor type May 23, 2013 06:35AM |

Registered: 13 years ago Posts: 7,616 |

Quote

it is true that enamel resistors need to be changed

Opinions differ drastically on this. So far I'm not sure what's the cause.

@Stoffel15 and @nophead, both known for high quality work, apparently find enameled resistors to be reliable. Both glue such a resistors into an aluminium or brass block with fire cement ( = exhaust putty).

@Triffid_Hunter and you, also known for good knowledge, have apparently burned quite a few of them. What are you doing different?

From the technical side, a heater cartridge is a piece of wire casted into a piece of tube. Almost identical to what you get when glueing an enameled resistor into a heater block. Resistors have their coating as a possible thermal barrier, cartridges have some (possibly small) air gap (hole bigger than the cartridge).

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: resistor type May 23, 2013 06:45AM |

Registered: 14 years ago Posts: 3,742 |

Quote

Traumflug

@Stoffel15 and @nophead, both known for high quality work, apparently find enameled resistors to be reliable. Both glue such a resistors into an aluminium or brass block with fire cement ( = exhaust putty).

No longer entirely true, Stoffel15 now uses heater cartridges exclusively for his new V3 all metal hot ends!

Edited 1 time(s). Last edit at 05/23/2013 06:46AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: resistor type May 23, 2013 07:27AM |

Admin Registered: 17 years ago Posts: 7,879 |

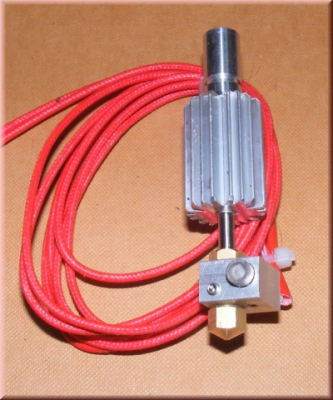

I think cartridge heaters are supposed to be a push fit into a high tolerance hole and then they expand when hot to make a good thermal connection. Reprap practice seems to be to use a clearance hole and grub screw, which would leave an air gap. Having the ends sticking out is probably not best practice either.

I still haven't had any vitreous enamel ones fail when cemented in. I haven't had any silicone ones that come with J-Head fail either, although I had my doubts about them being suitable.

[www.hydraraptor.blogspot.com]

I still haven't had any vitreous enamel ones fail when cemented in. I haven't had any silicone ones that come with J-Head fail either, although I had my doubts about them being suitable.

[www.hydraraptor.blogspot.com]

|

Re: resistor type May 23, 2013 07:33AM |

Registered: 13 years ago Posts: 1,797 |

will using a single 8.2ohms be better than using 2-6.8 in parallel?

do you mean in series?

as for 8.2ohms at 24v and 20 v.

8.2ohms is 24v/8.2ohm=2.92A

2.92A*24=70watts.

20v/8.2ohm=2.43A

2.43*20v=48.6watts

both respectable and able to easily be powered, but i think 70watts is too much for a 3watt resistor.

6.8 ohm in parallel is

3.4ohms. 24v/3.4ohms=7.05A

7.05A*24=169.2watts - definitely a risk of resistor burn out

or 6.8 in series

6.8*2=13.6

24v/13.6ohms =1.76A

1.76A*24=42.24 watts

it seems if you are to use 6.8ohms you would be wiser to use resistors in series totaling 13.6ohms resistance, if you are truly at 24v.

I use 8.2 ohms at 20v. 48.6watts this is why i use 8.2ohms instead of 6.8ohm resistors.

I read somewhere that the average energy required for heating up extruders is 30-40watts.

hope this helps!

do you mean in series?

as for 8.2ohms at 24v and 20 v.

8.2ohms is 24v/8.2ohm=2.92A

2.92A*24=70watts.

20v/8.2ohm=2.43A

2.43*20v=48.6watts

both respectable and able to easily be powered, but i think 70watts is too much for a 3watt resistor.

6.8 ohm in parallel is

3.4ohms. 24v/3.4ohms=7.05A

7.05A*24=169.2watts - definitely a risk of resistor burn out

or 6.8 in series

6.8*2=13.6

24v/13.6ohms =1.76A

1.76A*24=42.24 watts

it seems if you are to use 6.8ohms you would be wiser to use resistors in series totaling 13.6ohms resistance, if you are truly at 24v.

I use 8.2 ohms at 20v. 48.6watts this is why i use 8.2ohms instead of 6.8ohm resistors.

I read somewhere that the average energy required for heating up extruders is 30-40watts.

hope this helps!

|

Re: resistor type May 23, 2013 02:14PM |

Registered: 11 years ago Posts: 205 |

nophead Wrote:

-------------------------------------------------------

...

> Having the ends sticking out is probably not best

> practice either.

>

...

About that, the standard for active part of ceramic cartridges is 4/5 of length, with 1/10 cold on each end so no real heat loss.

Whether both ends should have an insulated cover is another question.

-------------------------------------------------------

...

> Having the ends sticking out is probably not best

> practice either.

>

...

About that, the standard for active part of ceramic cartridges is 4/5 of length, with 1/10 cold on each end so no real heat loss.

Whether both ends should have an insulated cover is another question.

Sorry, only registered users may post in this forum.