Mendel (90) with extruder motor(s) at end of X carriage?

Posted by gsport

|

Mendel (90) with extruder motor(s) at end of X carriage? October 21, 2013 08:44AM |

Registered: 12 years ago Posts: 124 |

Hi,

Been off the forum for a while, printer has been working pretty well and used regularly for mocking things up etc but just been using it as a tool and not keeping up with developments.

I am now thinking of making a new one, probably Mendel 90 ish using Birch ply and with a very tall Z axis (since going to a bigger bar diameter and bearings on this shouldn't bend under its own weight it should be the easiest axis to extend, and I have a few jobs where I need more height).

But I remember when I was first building my current printer that someone was experimenting with putting the extruder motor at the end of the X carriage and using a square bar to drive a wade's type design without the weight of the motor being on the main carriage. This seemed like a great idea to me at the time. Most of the advantage of a lighter carriage and faster print speed but without the (possible) hassles of a bowden set up.

Did anything ever come of this? IS there some reason why it isnt as good idea as it at first appears?

I was thinking of using hex bar (8mm AF ?), possibly with three little deep-groove bearing units to engage it (MR74zz 4x7x2.5 ?) so that there was minimal backlash and resistance to X axis movement...

For a dual extruder set up, one bar could be run on each side of the head..

George

Been off the forum for a while, printer has been working pretty well and used regularly for mocking things up etc but just been using it as a tool and not keeping up with developments.

I am now thinking of making a new one, probably Mendel 90 ish using Birch ply and with a very tall Z axis (since going to a bigger bar diameter and bearings on this shouldn't bend under its own weight it should be the easiest axis to extend, and I have a few jobs where I need more height).

But I remember when I was first building my current printer that someone was experimenting with putting the extruder motor at the end of the X carriage and using a square bar to drive a wade's type design without the weight of the motor being on the main carriage. This seemed like a great idea to me at the time. Most of the advantage of a lighter carriage and faster print speed but without the (possible) hassles of a bowden set up.

Did anything ever come of this? IS there some reason why it isnt as good idea as it at first appears?

I was thinking of using hex bar (8mm AF ?), possibly with three little deep-groove bearing units to engage it (MR74zz 4x7x2.5 ?) so that there was minimal backlash and resistance to X axis movement...

For a dual extruder set up, one bar could be run on each side of the head..

George

|

Re: Mendel (90) with extruder motor(s) at end of X carriage? October 22, 2013 04:37AM |

Registered: 10 years ago Posts: 273 |

How did you intend to engage the hex bar onto the small cog of the extruder without causing lateral friction.

i.e The X Carriage needs to slide up and down the length of the hex bar. i.e is there some special bearing that has 6 small rollers (one per side of the hex bar), that would allow this motion.

Personally I've always wondered why the extruder motor was as large as it is.

I can push manually filament though the hot extruder, when changing the filament, at a fairly rapid pace without exerting loads of force.

Perhaps just having a smaller stepper motor for the extruder and use a light weight gearing system, instead of the large plastic cogs (albeit this is not a very REPRAP solution)

i.e The X Carriage needs to slide up and down the length of the hex bar. i.e is there some special bearing that has 6 small rollers (one per side of the hex bar), that would allow this motion.

Personally I've always wondered why the extruder motor was as large as it is.

I can push manually filament though the hot extruder, when changing the filament, at a fairly rapid pace without exerting loads of force.

Perhaps just having a smaller stepper motor for the extruder and use a light weight gearing system, instead of the large plastic cogs (albeit this is not a very REPRAP solution)

|

Re: Mendel (90) with extruder motor(s) at end of X carriage? October 22, 2013 04:52AM |

Registered: 10 years ago Posts: 11 |

|

Re: Mendel (90) with extruder motor(s) at end of X carriage? October 22, 2013 07:40AM |

Registered: 12 years ago Posts: 124 |

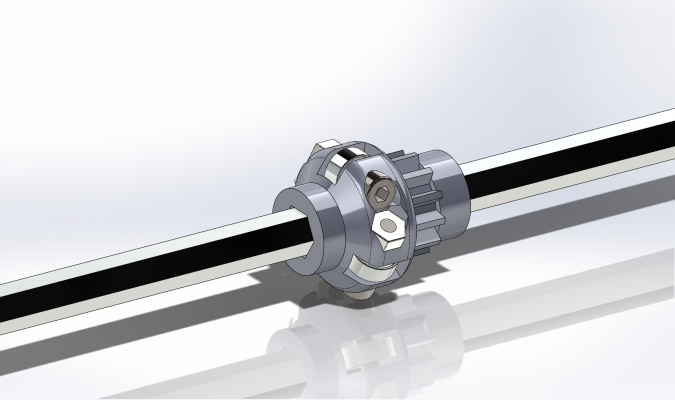

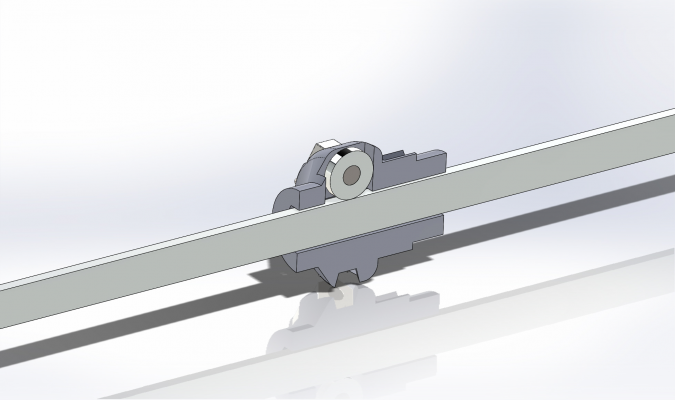

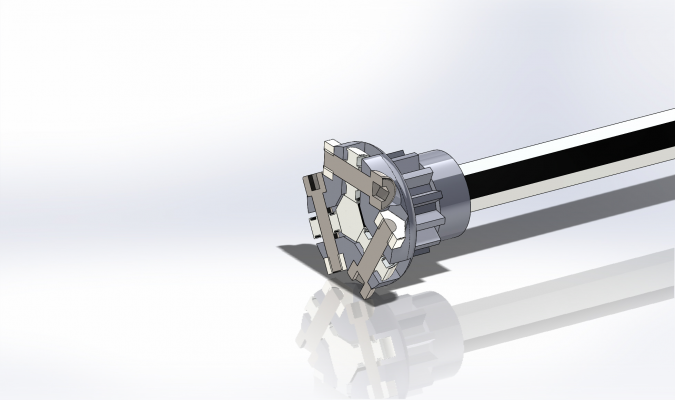

This is the sort of thing I was thinking of. (please excuse the very rough nature of this model it was just to work out spacings, I haven't included washers and obviously need to build it up into a full assembly)

A printed small gear with a spider to hold 3 bearings that run as idlers on the 8mm AF hex bar. This is modeled on MR104 ZZ bearings which are 4mm bore 10mm OD and 4mm wide. This means that the overall outside diameter of the part is about 30mm.

In this model, the ends are 17mm to sit inside 6803 bearings (17 x 26 x 5) which would be held in the main carriage on some sort of eccentric boss to allow adjustment for mesh with the main gear of the extruder. This would obviously mean that the hex bar itself would need some sort of flexible coupling to allow misalignment with the drive motor.

It might need one of the idler bearings to be adjustable, but I dont think so.

I hope this makes sense.

A printed small gear with a spider to hold 3 bearings that run as idlers on the 8mm AF hex bar. This is modeled on MR104 ZZ bearings which are 4mm bore 10mm OD and 4mm wide. This means that the overall outside diameter of the part is about 30mm.

In this model, the ends are 17mm to sit inside 6803 bearings (17 x 26 x 5) which would be held in the main carriage on some sort of eccentric boss to allow adjustment for mesh with the main gear of the extruder. This would obviously mean that the hex bar itself would need some sort of flexible coupling to allow misalignment with the drive motor.

It might need one of the idler bearings to be adjustable, but I dont think so.

I hope this makes sense.

|

Re: Mendel (90) with extruder motor(s) at end of X carriage? October 22, 2013 05:11PM |

Registered: 10 years ago Posts: 273 |

Gsport

The 3d models look fantastic, but I thnk you need another set of 3 bearings at the other side of the cog, otherwise the sideways force of the cog meshing with the big cog on the extruder will push the unsupported end against the hex bar

Also you need to keep this traveller lined up with the big extruder cog, and I'm not sure that just relying on th herring bone teeth would work

The 3d models look fantastic, but I thnk you need another set of 3 bearings at the other side of the cog, otherwise the sideways force of the cog meshing with the big cog on the extruder will push the unsupported end against the hex bar

Also you need to keep this traveller lined up with the big extruder cog, and I'm not sure that just relying on th herring bone teeth would work

|

Re: Mendel (90) with extruder motor(s) at end of X carriage? October 22, 2013 05:15PM |

Registered: 12 years ago Posts: 124 |

Sorry, only registered users may post in this forum.