Reducing Y carriage (print bed) mass ??

Posted by rogerclark

|

Reducing Y carriage (print bed) mass ?? October 22, 2013 06:44PM |

Registered: 10 years ago Posts: 273 |

Hi,

My kit MendelMax uses 10mm MDF as the Y carriage, and on top of that is the heated PCB and the glass.

It strikes me that this assembly is quite heavy, i.e probably at least 750g.

I've been contemplating drilling large holes in the MDF, at non structural points to remove material (this is a trick often used in model aircraft to reduce weight).

I also did the calculations about replacing with 3mm Aluminium , but it looks like Aluminium is not any lighter than MFD.

I'm using 5mm glass. Has anyone managed to use any thinner glass without it breaking ?

Thanks.

My kit MendelMax uses 10mm MDF as the Y carriage, and on top of that is the heated PCB and the glass.

It strikes me that this assembly is quite heavy, i.e probably at least 750g.

I've been contemplating drilling large holes in the MDF, at non structural points to remove material (this is a trick often used in model aircraft to reduce weight).

I also did the calculations about replacing with 3mm Aluminium , but it looks like Aluminium is not any lighter than MFD.

I'm using 5mm glass. Has anyone managed to use any thinner glass without it breaking ?

Thanks.

|

Re: Reducing Y carriage (print bed) mass ?? October 22, 2013 07:56PM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Reducing Y carriage (print bed) mass ?? October 22, 2013 08:48PM |

Registered: 12 years ago Posts: 124 |

The glass on my bed is also from a picture frame, but is just 1.8mm thick. Not had any problems with it, but it is on a 4mm aluminium plate.

MDF is a terrible material really as it tends to creep and has very poor stiffness for it's weight, if you put holes in it it may well distort. 8-10mm birch ply would be good, and you could cut out some triangles to save weight.

An aluminium honeycomb like Alucore might be a nice solution, we only need little bits that might well be classed as "off cuts" if you can find someone who uses it.

George

MDF is a terrible material really as it tends to creep and has very poor stiffness for it's weight, if you put holes in it it may well distort. 8-10mm birch ply would be good, and you could cut out some triangles to save weight.

An aluminium honeycomb like Alucore might be a nice solution, we only need little bits that might well be classed as "off cuts" if you can find someone who uses it.

George

|

Re: Reducing Y carriage (print bed) mass ?? October 22, 2013 10:18PM |

Registered: 10 years ago Posts: 273 |

Thanks guys.

I did think about swapping the MDF (supplied in my kit) for plywood, but couldn't see any benefit, as the characteristics of MDF were very similar as far as I can tell.

My glass is directly on top of the heated PCB, so I guess I could try getting some picture frame glass - actually I have some old picture frames and a glass cutter, so I supposed I could put on some protective goggles etc and have a go at cutting it to size if I feel brave ;-)

I could probably get hold of some aluminium plate from a metal dealer, though it seems to be hard to get hold of anything above about 2mm thickness, from my local suppliers.

I have general issues with the Y rail stiffness as my MendelMax is 1.5 and not 1.5+, so just uses 2 off 8mm steel rods attached by plastic brackets, and these are easy to deform downwards (but as the weight of the items I'm printing, probably never gets in excess of a few hundred gramms its not a major issue at the moment - is more of a known issue I have.

Anyway. thin glass looks like the next best thing to try.

Thanks again.

I did think about swapping the MDF (supplied in my kit) for plywood, but couldn't see any benefit, as the characteristics of MDF were very similar as far as I can tell.

My glass is directly on top of the heated PCB, so I guess I could try getting some picture frame glass - actually I have some old picture frames and a glass cutter, so I supposed I could put on some protective goggles etc and have a go at cutting it to size if I feel brave ;-)

I could probably get hold of some aluminium plate from a metal dealer, though it seems to be hard to get hold of anything above about 2mm thickness, from my local suppliers.

I have general issues with the Y rail stiffness as my MendelMax is 1.5 and not 1.5+, so just uses 2 off 8mm steel rods attached by plastic brackets, and these are easy to deform downwards (but as the weight of the items I'm printing, probably never gets in excess of a few hundred gramms its not a major issue at the moment - is more of a known issue I have.

Anyway. thin glass looks like the next best thing to try.

Thanks again.

|

Re: Reducing Y carriage (print bed) mass ?? October 23, 2013 01:42PM |

Registered: 12 years ago Posts: 1,450 |

I managed to cut the weight of my Y carriage on an early Prusa from 1.4kg to 0.48kg and made it much stiffer.

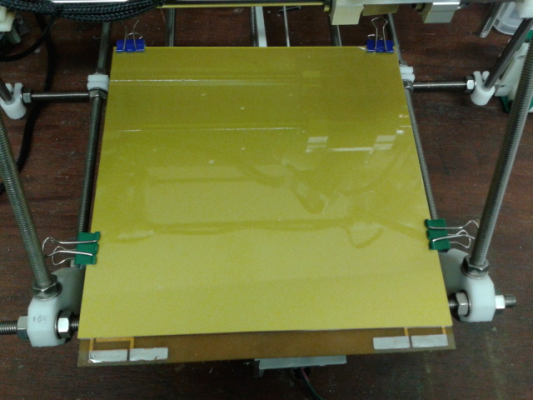

The first thing I did was eliminate the glass plate - I used a 2mm aluminium plate which doubles up as a heat spreader for the heater. This is covered in a layer of Kapton, 200 mm wide. Note that anodised aluminium sheet is normally harder than non anodised sheet

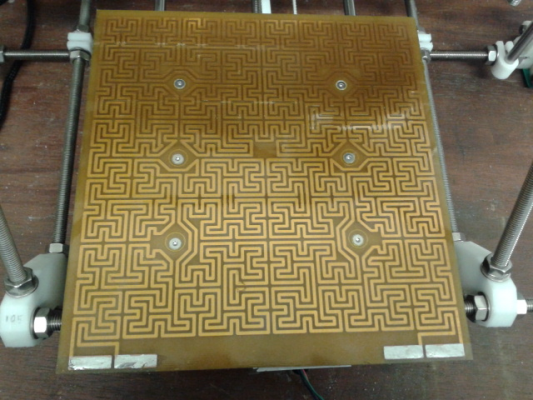

The heater is directly underneath that, it is a 1.6mm double sided FR4 PCB etched with two paralell tracks to give either 12V or 24V operation. The load is taken out at 6 points quite far in from the edge so that flexing in the center is reduced.

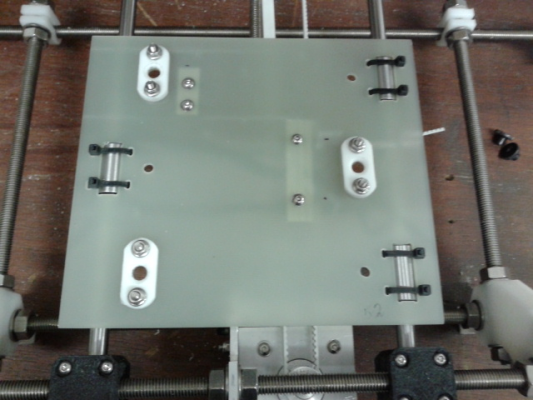

The carriage is machined from 2mm FR4 epoxy glass fiber. There are three spring loaded points, just visible as holes, and therr PTFE plates into which 6mm cylindrical pillers fit. Note that the attachemnt points - where the adjusting springs fit, are as close as possible to the bearings. All dynamic loads are taken out in the plane of the FR4

This has not yet been used in anger as I am working up a retracting autoleveler, but trials with a DTI show it to be nearly twich as rigid as the old Y bed/carriage

Mike

The first thing I did was eliminate the glass plate - I used a 2mm aluminium plate which doubles up as a heat spreader for the heater. This is covered in a layer of Kapton, 200 mm wide. Note that anodised aluminium sheet is normally harder than non anodised sheet

The heater is directly underneath that, it is a 1.6mm double sided FR4 PCB etched with two paralell tracks to give either 12V or 24V operation. The load is taken out at 6 points quite far in from the edge so that flexing in the center is reduced.

The carriage is machined from 2mm FR4 epoxy glass fiber. There are three spring loaded points, just visible as holes, and therr PTFE plates into which 6mm cylindrical pillers fit. Note that the attachemnt points - where the adjusting springs fit, are as close as possible to the bearings. All dynamic loads are taken out in the plane of the FR4

This has not yet been used in anger as I am working up a retracting autoleveler, but trials with a DTI show it to be nearly twich as rigid as the old Y bed/carriage

Mike

|

Re: Reducing Y carriage (print bed) mass ?? October 24, 2013 04:49AM |

Registered: 10 years ago Posts: 273 |

Sorry, only registered users may post in this forum.