General Self-Building questions (hotend, leadscrews and building)

Posted by Toalla

|

General Self-Building questions (hotend, leadscrews and building) October 27, 2013 07:42PM |

Registered: 10 years ago Posts: 16 |

Hi, I keep researching about homemade 3d printers in order to make my own printer soon, in fact i already have some of the components.

I have some questions about technical aspects and I just would like you to tell me if I'm right with my guessings, if you would do the same or if you want to tell me about your experience:

Question 1- Mechanism:

The design i'm talking about uses leadscrews for the movement n the three axis (trapezoidal thread to ensure precission and les wobbling). I thought it would be much more expensive than common threaded rod or belts, but I found a web on UK where we can buy 1m 10x2 trapezoidal threaded rods for 12 pounds plus 5 pounds per nut and 12 more for the shipping, I think it's not that bad, what do you think?

Appart from that, is it a good idea to use these leadscrews for the 3 axis? Will it be noticeably slower? In summary, does it worth?

Question 2- Hot end:

For the hot end I already have a nozzle and the cartridge and thermistor, I just need the metal parts, so here comes the thing:

I first thought on making a simple heated block by drilling needed holes on a steel block, and making the thread needed, and I keep thinking on doing that.

For the thermal barrier I thought on taking a thin pipe and welding some washers on it to act like fims, but then I realized I would probably destroy the pipe while welding the washers. So now I'm thinking on making a copper thermal barrier because I can weld them with PLATEX (I dont know if it is used worldwide, so it's this).

Do you know if there's any problem with using copper for that? will I need anyway a ptfe barrier or something like that?

Question 3- Building design:

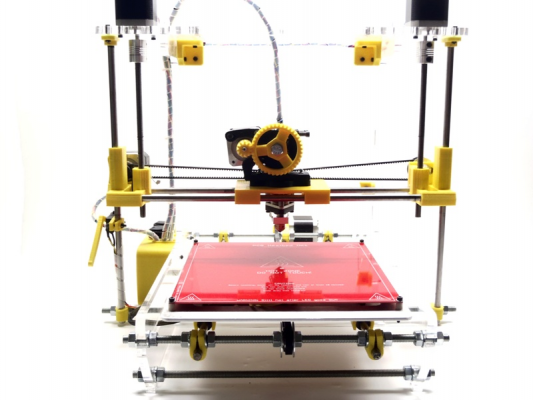

I'm purposing a design with 4 motors (3 axis, with leadscrew movement, not belts, and extruder). I have seen some designs where they use 2 motors for the same axis in both sides of the printer, like this:

Is it really necessary? Wouldn't it be the same to put the motor in just one side and on the other side a smooth rod with a good linear bearing? (more or less what is done on the other axes)

Thank you again, guys, I really learn a lot reading all the info you post on this forum

I have some questions about technical aspects and I just would like you to tell me if I'm right with my guessings, if you would do the same or if you want to tell me about your experience:

Question 1- Mechanism:

The design i'm talking about uses leadscrews for the movement n the three axis (trapezoidal thread to ensure precission and les wobbling). I thought it would be much more expensive than common threaded rod or belts, but I found a web on UK where we can buy 1m 10x2 trapezoidal threaded rods for 12 pounds plus 5 pounds per nut and 12 more for the shipping, I think it's not that bad, what do you think?

Appart from that, is it a good idea to use these leadscrews for the 3 axis? Will it be noticeably slower? In summary, does it worth?

Question 2- Hot end:

For the hot end I already have a nozzle and the cartridge and thermistor, I just need the metal parts, so here comes the thing:

I first thought on making a simple heated block by drilling needed holes on a steel block, and making the thread needed, and I keep thinking on doing that.

For the thermal barrier I thought on taking a thin pipe and welding some washers on it to act like fims, but then I realized I would probably destroy the pipe while welding the washers. So now I'm thinking on making a copper thermal barrier because I can weld them with PLATEX (I dont know if it is used worldwide, so it's this).

Do you know if there's any problem with using copper for that? will I need anyway a ptfe barrier or something like that?

Question 3- Building design:

I'm purposing a design with 4 motors (3 axis, with leadscrew movement, not belts, and extruder). I have seen some designs where they use 2 motors for the same axis in both sides of the printer, like this:

Is it really necessary? Wouldn't it be the same to put the motor in just one side and on the other side a smooth rod with a good linear bearing? (more or less what is done on the other axes)

Thank you again, guys, I really learn a lot reading all the info you post on this forum

|

Re: General Self-Building questions (hotend, leadscrews and building) October 27, 2013 08:31PM |

Registered: 10 years ago Posts: 162 |

It's possible to drive from one side, but you have an increased risk of binding. Basically, the rods can move through the bearing at a slight diagonal -- when you pull up on one side, you apply torque to the other side rather than upward force. You either have to drive in the center of the the smooth rods (so that the radial components of the torque balance) or have a system to drive on both sides like in the picture. It's not very good engineering to only drive on one side, much like the poor design choice done here. cheap-o kickstarter

Edited 1 time(s). Last edit at 10/27/2013 08:40PM by iquizzle.

Edited 1 time(s). Last edit at 10/27/2013 08:40PM by iquizzle.

|

Re: General Self-Building questions (hotend, leadscrews and building) October 27, 2013 08:46PM |

Registered: 10 years ago Posts: 32 |

|

Re: General Self-Building questions (hotend, leadscrews and building) October 28, 2013 03:55AM |

Registered: 10 years ago Posts: 103 |

I agree, it will be too slow on the x and y axis,

for instance, you cannot move the Y carriage at 250mm/s on a leadscrew, which is the speed that printers use for moves between extrusions.

There are a lot of moves between extrusions, and the extrusions themselves can happen at 40mm / s.

leadscrews are used for Z because it makes tiny, accurate movements, (0.3mm), once per layer.

have a look on youtube to see how fast it must move, that's not possible with screws, you do need belts,but they are very accurate/work well !

cheers,

for instance, you cannot move the Y carriage at 250mm/s on a leadscrew, which is the speed that printers use for moves between extrusions.

There are a lot of moves between extrusions, and the extrusions themselves can happen at 40mm / s.

leadscrews are used for Z because it makes tiny, accurate movements, (0.3mm), once per layer.

have a look on youtube to see how fast it must move, that's not possible with screws, you do need belts,but they are very accurate/work well !

cheers,

|

Re: General Self-Building questions (hotend, leadscrews and building) October 28, 2013 08:28AM |

Registered: 10 years ago Posts: 16 |

@iquizzle @Josh mp5 @DaveS

You all agree so I guess this may be a newbie mistake, it's just easier for me to understand the accuracy of the leadscrew and that's why, reading about all the problems people had with wobbling, I thought about using leadscrews on all the axes.

Anyway I assume that belts are not only the cheapest option but also the fastest and definitly the best option.

Now I have some doubts about belts (I admit I haven't researched so much yet since I've been centered on leadscrews): how do you attach the extruder to the belt? You simply paste it or link it, or is there any mechanism to transmit the motion?

Is there any problem with the belt that moves the heated bed? I guess it will need some kind of thermal insulation..

And could you tell me something about the hot end question?

Thank you all for your posts

You all agree so I guess this may be a newbie mistake, it's just easier for me to understand the accuracy of the leadscrew and that's why, reading about all the problems people had with wobbling, I thought about using leadscrews on all the axes.

Anyway I assume that belts are not only the cheapest option but also the fastest and definitly the best option.

Now I have some doubts about belts (I admit I haven't researched so much yet since I've been centered on leadscrews): how do you attach the extruder to the belt? You simply paste it or link it, or is there any mechanism to transmit the motion?

Is there any problem with the belt that moves the heated bed? I guess it will need some kind of thermal insulation..

And could you tell me something about the hot end question?

Thank you all for your posts

|

Re: General Self-Building questions (hotend, leadscrews and building) October 28, 2013 09:50AM |

Registered: 10 years ago Posts: 95 |

DaveS Wrote:

-------------------------------------------------------

> I agree, it will be too slow on the x and y axis,

>

> for instance, you cannot move the Y carriage at

> 250mm/s on a leadscrew, which is the speed that

> printers use for moves between extrusions.

> There are a lot of moves between extrusions, and

> the extrusions themselves can happen at 40mm / s.

>

When you say "too slow" do you just mean that it will take forever to print an item, or do you mean that it will not be possible to print at such a low speed?

(I'm hoping it's the former!)

...R

-------------------------------------------------------

> I agree, it will be too slow on the x and y axis,

>

> for instance, you cannot move the Y carriage at

> 250mm/s on a leadscrew, which is the speed that

> printers use for moves between extrusions.

> There are a lot of moves between extrusions, and

> the extrusions themselves can happen at 40mm / s.

>

When you say "too slow" do you just mean that it will take forever to print an item, or do you mean that it will not be possible to print at such a low speed?

(I'm hoping it's the former!)

...R

|

Re: General Self-Building questions (hotend, leadscrews and building) October 28, 2013 04:21PM |

Registered: 10 years ago Posts: 32 |

|

Re: General Self-Building questions (hotend, leadscrews and building) October 29, 2013 11:35AM |

Registered: 10 years ago Posts: 103 |

@robin2

when I say "too slow" I think I mean both...

printing larger things can take a couple of hours.. imagine if you have a printer that could only move at 30mm/s. It would take at least 8 hours for a print ?!

Think of the wear on the threads, going up and down for 8 hours every time you print one thing.

Think of waiting 8 hours to find out if the new bit of modelling you have done on the top of the Tardis is any good ? (that would be a Tardis measuring 70 x 70 x 120mm)

I think there are probably considerations of extrusion speed, i.e. how fast the melted plastic can evenly come out of the nozzle.

I have a feeling if you ask it to come out too slow, it's not going to come out evenly. I notice I get smoother sides at medium speeds, and not always smoother sides at slow speeds.

Also.. nozzles ooze.. they ooze a LOT. If it took 3 seconds to get from 1 part of your print to another, (it's quite normal to have moves that aren't printing),

your retract are going to have to be spot on, or you'll have ooze everywhere.

Anyway.. toothed belts are accurate. very accurate.

@toalla

Have a look at the build instructions for a mendel or a huxley on the reprappro website, the answers to your questions are quite straight forward, and don't involve jumping through such hoops.

It's all amazingly straight forward.

when I say "too slow" I think I mean both...

printing larger things can take a couple of hours.. imagine if you have a printer that could only move at 30mm/s. It would take at least 8 hours for a print ?!

Think of the wear on the threads, going up and down for 8 hours every time you print one thing.

Think of waiting 8 hours to find out if the new bit of modelling you have done on the top of the Tardis is any good ? (that would be a Tardis measuring 70 x 70 x 120mm)

I think there are probably considerations of extrusion speed, i.e. how fast the melted plastic can evenly come out of the nozzle.

I have a feeling if you ask it to come out too slow, it's not going to come out evenly. I notice I get smoother sides at medium speeds, and not always smoother sides at slow speeds.

Also.. nozzles ooze.. they ooze a LOT. If it took 3 seconds to get from 1 part of your print to another, (it's quite normal to have moves that aren't printing),

your retract are going to have to be spot on, or you'll have ooze everywhere.

Anyway.. toothed belts are accurate. very accurate.

@toalla

Have a look at the build instructions for a mendel or a huxley on the reprappro website, the answers to your questions are quite straight forward, and don't involve jumping through such hoops.

It's all amazingly straight forward.

|

Re: General Self-Building questions (hotend, leadscrews and building) October 29, 2013 06:07PM |

Registered: 10 years ago Posts: 125 |

I have seen a few builders that have used some kind of high tension string (braided fishing line / spectra line) instead of belts and they report the same accuracy as a belt driven machine. I use belts just because the mechanics of how they work is so simple and they have been tested and found to be the preferred method by almost all reprap builders. I think if everyone is already doing it then it probably works well. Of course innovation and trying new things is also important but the lead screw has already been tried and failed.

How do you attach the extruder to the belt and the heated bed?

Both items usually ride on a carriage, the carriage connects to the belts and then the extruder/heated bed are attached to that carriage. The carriage usually does not get hot.

Regards

Mike

How do you attach the extruder to the belt and the heated bed?

Both items usually ride on a carriage, the carriage connects to the belts and then the extruder/heated bed are attached to that carriage. The carriage usually does not get hot.

Regards

Mike

|

Re: General Self-Building questions (hotend, leadscrews and building) October 31, 2013 07:48PM |

Registered: 10 years ago Posts: 16 |

Sorry, only registered users may post in this forum.