Those ebay extruders

Posted by Vince

|

Those ebay extruders November 06, 2013 06:06AM |

Registered: 10 years ago Posts: 61 |

A few months ago when I was having extruder issues with my new mendelmax I ordered one of these:

Extruder

During the wait for it to arrive I got the old one to work fairly well so haven’t got around to changing it yet. I have more experience now and doubt this new one will work well.

I cant fault the construction, very well made but it’s a small motor driving the filament directly so expect it will stall.

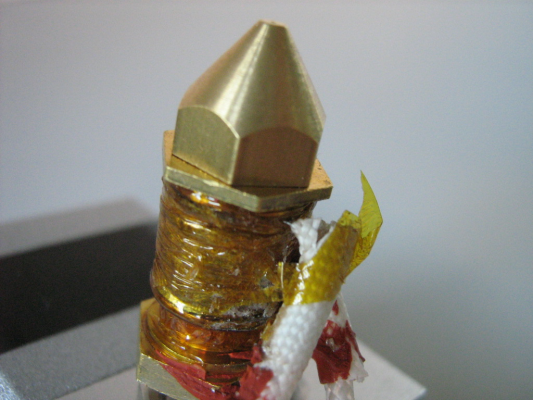

How about those orange hot ends? They look like they should be ok.

I hope at least I can modify it with gears etc to make it work.

Any feedback welcome

Extruder

During the wait for it to arrive I got the old one to work fairly well so haven’t got around to changing it yet. I have more experience now and doubt this new one will work well.

I cant fault the construction, very well made but it’s a small motor driving the filament directly so expect it will stall.

How about those orange hot ends? They look like they should be ok.

I hope at least I can modify it with gears etc to make it work.

Any feedback welcome

|

Re: Those ebay extruders November 06, 2013 09:18PM |

Registered: 11 years ago Posts: 1,171 |

I've seen those and I think they are the same ones on the China makerbot knock offs.

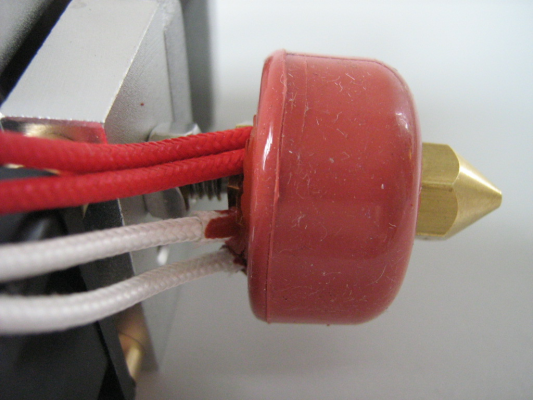

They 'look' well made but to would be concerned about the motor. It does say it's not for 3mm and that may be why they can get away with a smaller motor. I think it would be worth trying. The red is a molded silicone heater and if made right should be a good idea, while they would take a little longer to come to heat they should not cool down while printing and should not have any issues breaking due to vibration.

It's a very 'RepRap' like design but should work OK.

They 'look' well made but to would be concerned about the motor. It does say it's not for 3mm and that may be why they can get away with a smaller motor. I think it would be worth trying. The red is a molded silicone heater and if made right should be a good idea, while they would take a little longer to come to heat they should not cool down while printing and should not have any issues breaking due to vibration.

It's a very 'RepRap' like design but should work OK.

|

Re: Those ebay extruders November 06, 2013 09:40PM |

Registered: 11 years ago Posts: 34 |

|

Re: Those ebay extruders November 07, 2013 02:00AM |

Registered: 10 years ago Posts: 273 |

|

Re: Those ebay extruders November 07, 2013 10:10AM |

Registered: 10 years ago Posts: 61 |

I have had it for a while now but havent fitted it, mostly because I sorted out the problems with the old one.

It is very well made and looks good quality but I wont know how it works unitl I put it in my new-build printer, probably in a week or two.

The motor is a 42HB34F08AB. Hot end and nozzle look good. The nozzle will unscrew easilly without disconnecting wires. This is a pain on the J head when you ged bad plastic.

Im expecting it to be a bit weak pushing in the filament but it may just be ok with 1.75mm.

Will keep you posted.

It is very well made and looks good quality but I wont know how it works unitl I put it in my new-build printer, probably in a week or two.

The motor is a 42HB34F08AB. Hot end and nozzle look good. The nozzle will unscrew easilly without disconnecting wires. This is a pain on the J head when you ged bad plastic.

Im expecting it to be a bit weak pushing in the filament but it may just be ok with 1.75mm.

Will keep you posted.

|

Re: Those ebay extruders November 07, 2013 02:48PM |

Registered: 10 years ago Posts: 273 |

|

Re: Those ebay extruders November 08, 2013 06:04AM |

Registered: 10 years ago Posts: 61 |

|

Re: Those ebay extruders November 08, 2013 07:31PM |

Registered: 10 years ago Posts: 273 |

@Vince,

on this thread [forums.reprap.org] about direct drive extruders, uncle_bob noticed that some eBay extruders seem to use a thermocouple instead of a thermistor.

If yours is like this, you're probably going to have to replace the termocouple with a thermistor if possible, or use some sort of interface as we don't think that thermocouples are compatible with normal electronics like RAMPS

on this thread [forums.reprap.org] about direct drive extruders, uncle_bob noticed that some eBay extruders seem to use a thermocouple instead of a thermistor.

If yours is like this, you're probably going to have to replace the termocouple with a thermistor if possible, or use some sort of interface as we don't think that thermocouples are compatible with normal electronics like RAMPS

|

Re: Those ebay extruders November 10, 2013 10:40PM |

Registered: 10 years ago Posts: 18 |

|

Re: Those ebay extruders November 10, 2013 11:31PM |

Registered: 10 years ago Posts: 273 |

Thanks Isos

I was tempted to buy one, even if I had to replace the thermocouple with thermistor, but it sounds like they are not really intended for use on 3D printers at all.

Perhaps they are designed for some lower temperature application.

(BTW. Just had a 24V PSU arrive from an eBay supplier and it went up in smoke when I connected it, so I guess its buyer beware, especially on eBay)

I was tempted to buy one, even if I had to replace the thermocouple with thermistor, but it sounds like they are not really intended for use on 3D printers at all.

Perhaps they are designed for some lower temperature application.

(BTW. Just had a 24V PSU arrive from an eBay supplier and it went up in smoke when I connected it, so I guess its buyer beware, especially on eBay)

|

Re: Those ebay extruders November 11, 2013 04:53PM |

Registered: 10 years ago Posts: 61 |

|

Re: Those ebay extruders November 12, 2013 01:55AM |

Registered: 10 years ago Posts: 273 |

|

Re: Those ebay extruders November 17, 2013 08:49AM |

Registered: 10 years ago Posts: 61 |

Assuming Ive bought a dud I will need another extruder for my new printer which is comeing on nicely. If I had the time it would be quite interesting to develop an extruder but with 101 current projects I just want to buy something.

Obiviously my Mendel has a extruder but it has been a bit troublesome and I dont like having to disconnect the wires to clean it.

So, any recomendations for a good reliable ABS extruder (that works with the Ramps) would be appreciated.

Thanks

Obiviously my Mendel has a extruder but it has been a bit troublesome and I dont like having to disconnect the wires to clean it.

So, any recomendations for a good reliable ABS extruder (that works with the Ramps) would be appreciated.

Thanks

|

Re: Those ebay extruders November 17, 2013 12:08PM |

Registered: 10 years ago Posts: 18 |

QU-BD extruders are finicky. Some people have no trouble, but a great many suffer jamming issues that are very difficult to resolve.

A typical Greg's Wade Extruder seems to give typically reliable results. I recently tried a more expensive option: [www.ebay.com] and I liked it a lot. All-metal, a lot of torque, and easy to take apart.

From my experience though, if you're going to spend a little more money on one component, buy a good hot end. I've spent countless hours screwing around with low-quality hot ends that jam or work poorly. Check out the Arcol, E3D, Budaschnozzle, J-Head, and other models that have a lot of feedback.

|

Re: Those ebay extruders November 18, 2013 10:14AM |

Registered: 10 years ago Posts: 61 |

I have just connected up the heater on my ebay extruder.

I have to say it seems fine. I had no way of monitering the temp but it was extruding ABS when pushed through by hand with very light pressure.

It was using 1.9A giving 23W. The force required to push the filament through was so light this thing may end up working after all. Of course it could have been way to hot but it didnt burst into flames.

anyone know what hole size is required to put a thermister in?

I have to say it seems fine. I had no way of monitering the temp but it was extruding ABS when pushed through by hand with very light pressure.

It was using 1.9A giving 23W. The force required to push the filament through was so light this thing may end up working after all. Of course it could have been way to hot but it didnt burst into flames.

anyone know what hole size is required to put a thermister in?

|

Re: Those ebay extruders November 18, 2013 03:00PM |

Registered: 11 years ago Posts: 253 |

@ Isos

that NEMA 11 motor on a 19:1 reduction, with about a 1/2 inch drive wheel, should only give about 10-15 RPM or 1 full revolution per 4-6 seconds.

That is about 1.5 inch of filament in 4-6 seconds.

It seems to me that overall printer head speed would be greatly limited by this low filament speed.

What have you experienced with that drive system?

What are the steps/mm settings in your firmware?

Are you using 16 microsteps or less, and if less, is there motor noise?

That drive system looks very interesting, except for the cost and what I estimate to be a slow max feedrate.

Would love to see a video of it running at max feed to get a sense of it.

Dave

that NEMA 11 motor on a 19:1 reduction, with about a 1/2 inch drive wheel, should only give about 10-15 RPM or 1 full revolution per 4-6 seconds.

That is about 1.5 inch of filament in 4-6 seconds.

It seems to me that overall printer head speed would be greatly limited by this low filament speed.

What have you experienced with that drive system?

What are the steps/mm settings in your firmware?

Are you using 16 microsteps or less, and if less, is there motor noise?

That drive system looks very interesting, except for the cost and what I estimate to be a slow max feedrate.

Would love to see a video of it running at max feed to get a sense of it.

Dave

|

Re: Those ebay extruders November 18, 2013 04:01PM |

Registered: 10 years ago Posts: 273 |

@vince,

The wiki has details on the size of the thermistor ( [reprap.org] ), but there is more than one size. I think you're going to need to measure the thermistor you intend to use, then look in your drills and find the next size up.

Then fit it using heat sink compound.

BTW. I can't remember if you determined if these have a PTFE liner. It sounds like they are OK for ABS, I wonder if they are any good for Nylon, which I though needed a higher temperature and possibly Not a PTFE liner ?

Thanks

Roger

The wiki has details on the size of the thermistor ( [reprap.org] ), but there is more than one size. I think you're going to need to measure the thermistor you intend to use, then look in your drills and find the next size up.

Then fit it using heat sink compound.

BTW. I can't remember if you determined if these have a PTFE liner. It sounds like they are OK for ABS, I wonder if they are any good for Nylon, which I though needed a higher temperature and possibly Not a PTFE liner ?

Thanks

Roger

|

Re: Those ebay extruders December 08, 2013 06:17AM |

Registered: 10 years ago Posts: 61 |

(also posted on direct drive extruders)

Well I have my Ebay extruder working OK(ish).

I drilled out a 1.5mm hole in the brass body and inserted a thermister. It takes a little longer than my J head to get to temp but there is no smoke or flames and will go well over 240 if required.

Im using it with 1.75mm filamant and if I try to stop it pulling through there is lots of extra torque available. I currently dont have its cooling fan wired up.

The nozzle is .3mm. On object walls its almost impossible to see the layers, also the interlayer adhesion is exellant.

What is not so good is flat surfaces and vertical holes. There is a lot of 'smudging' going on which looks like over-extruding but is still there if I turn the flow right down..

Im guessing it may be due to the wide nozzle end (compared to hole dia and layer thickness). 2mm vertical holes will mostly get filled my the smudging. Perhaps the wide flat nozzle base is spreading out the ABS, giving nice walls and good bonding but poor flat surfaces.

I will try to shape the nozzle end today and see it it improves.

Well I have my Ebay extruder working OK(ish).

I drilled out a 1.5mm hole in the brass body and inserted a thermister. It takes a little longer than my J head to get to temp but there is no smoke or flames and will go well over 240 if required.

Im using it with 1.75mm filamant and if I try to stop it pulling through there is lots of extra torque available. I currently dont have its cooling fan wired up.

The nozzle is .3mm. On object walls its almost impossible to see the layers, also the interlayer adhesion is exellant.

What is not so good is flat surfaces and vertical holes. There is a lot of 'smudging' going on which looks like over-extruding but is still there if I turn the flow right down..

Im guessing it may be due to the wide nozzle end (compared to hole dia and layer thickness). 2mm vertical holes will mostly get filled my the smudging. Perhaps the wide flat nozzle base is spreading out the ABS, giving nice walls and good bonding but poor flat surfaces.

I will try to shape the nozzle end today and see it it improves.

|

Re: Those ebay extruders December 08, 2013 04:13PM |

Registered: 10 years ago Posts: 273 |

Hi Vince,

What slicer are you using. I find Slic3r gives me the cleanest prints, but is not able to slice all objects.

Perhaps using different slicer setting may help with the smudging

Edit.

I think if its an all metal hot end, that the fan is essential.

I made the mistake of turning mine off, on my all metal hot end, and the filament inside the feeder tube ended up becoming molten and eventually blocked the whole extruder.

It was tricky to clean it all out.

Edited 1 time(s). Last edit at 12/08/2013 04:46PM by rogerclark.

What slicer are you using. I find Slic3r gives me the cleanest prints, but is not able to slice all objects.

Perhaps using different slicer setting may help with the smudging

Edit.

I think if its an all metal hot end, that the fan is essential.

I made the mistake of turning mine off, on my all metal hot end, and the filament inside the feeder tube ended up becoming molten and eventually blocked the whole extruder.

It was tricky to clean it all out.

Edited 1 time(s). Last edit at 12/08/2013 04:46PM by rogerclark.

|

Re: Those ebay extruders December 10, 2013 05:32AM |

Registered: 10 years ago Posts: 61 |

I am using Slic3r. Its not that, the same test pieces print fine on the Mendel but that is a 0.5 hole and this one is 0.3, or supposed to be but it does have a wide flat base which I am suspicious of.

I read somewhere about using a layer height no greater than 60% of dia, is that right. I use .3 on the mendel and .2 on my new one

I may start a topic on nozzle shape.

I read somewhere about using a layer height no greater than 60% of dia, is that right. I use .3 on the mendel and .2 on my new one

I may start a topic on nozzle shape.

|

Re: Those ebay extruders December 10, 2013 02:41PM |

Registered: 10 years ago Posts: 273 |

|

Re: Those ebay extruders December 10, 2013 06:12PM |

Registered: 10 years ago Posts: 61 |

Roger, its really working very well now.

I was convinced it was a 0.3mm nozzle but when I cleaned it up today there was a big 4 on the side. I reset the slicer to 0.4 and huge improvement.

The next huge improvement was messing about with nozzle temp. I think my thermister is reading way too low. It still feeds down to 190 with ABS so I set it to 205. Much better prints now.

So at the moment I cant fault this ebay extruder at all.

Not sure how to check and calibrate my thermister. How do I find a known temp around 240deg?

I have the same one on the bed and stuck it in boiling water. It said 95, close enough I guess but that error could depart more at high temps. Well as long as I know what number prints best.

I was convinced it was a 0.3mm nozzle but when I cleaned it up today there was a big 4 on the side. I reset the slicer to 0.4 and huge improvement.

The next huge improvement was messing about with nozzle temp. I think my thermister is reading way too low. It still feeds down to 190 with ABS so I set it to 205. Much better prints now.

So at the moment I cant fault this ebay extruder at all.

Not sure how to check and calibrate my thermister. How do I find a known temp around 240deg?

I have the same one on the bed and stuck it in boiling water. It said 95, close enough I guess but that error could depart more at high temps. Well as long as I know what number prints best.

|

Re: Those ebay extruders December 11, 2013 05:40AM |

Registered: 10 years ago Posts: 61 |

|

Re: Those ebay extruders December 11, 2013 05:49AM |

Registered: 11 years ago Posts: 195 |

|

Re: Those ebay extruders December 17, 2013 04:27AM |

Registered: 10 years ago Posts: 273 |

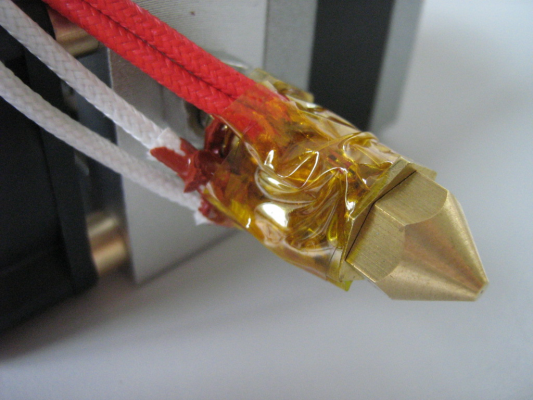

Hi Vince,

My extruder came today. I'm not sure if its the same as yours, as I don't think its possible to drill a hole to attach the thermistor

I took the rubber insulation off the hot end, and have removed the thermocouple wire which was wrapped around the tube above the nozzle.

The heating element appears to be resistance wire wound around the threaded tube just above the nozzle.

I've measured the resistance of the "heater" and its around 6 ohms, which should be OK. Albeit possibly lower power than a normal cartridge style heater (as the cartridge ones i have are 4 ohms).

I think the best thing I can do is just to tape a thermistor to the threaded tube, with Kapton tape, and try to made sure its well attached.

Then refit the insulation (not sure what its made of but it looks like rubber)

BTW. On mine, the heater wires and the thermocouple wires were held in place by some stiff copper wire. I will probably replace the wire, as I had to cut it to remove it.

Also, on my extruder, there was some form of aluminium tape wrapped around the outside of the threaded tube, and heater wires + thermocouple, i.e immediately next to the "rubber" outer insulation.

I don't have any aluminium tape, and I'm not sure if any local companies sell it, so I may end up just warping aluminium foil in its place and hope it stays on even though its not glued in place, as the rubber insulation is quite tight and would probably keep it all in place.

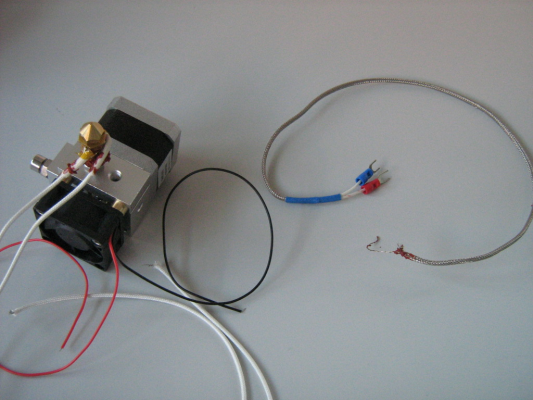

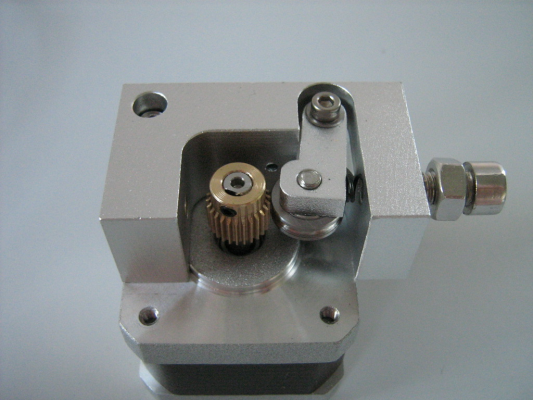

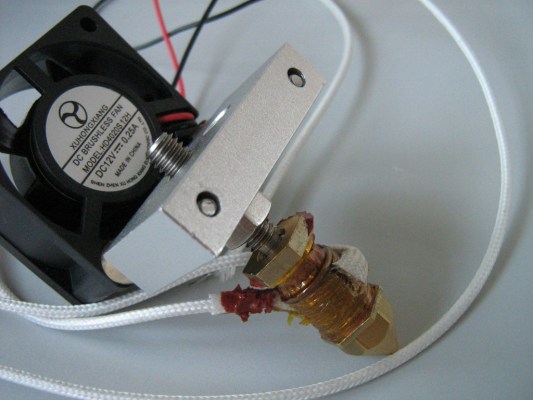

Also BTW. In case anyone is interested.

Here is a picture of the extruder drive cog

And here is the the fan etc

My extruder came today. I'm not sure if its the same as yours, as I don't think its possible to drill a hole to attach the thermistor

I took the rubber insulation off the hot end, and have removed the thermocouple wire which was wrapped around the tube above the nozzle.

The heating element appears to be resistance wire wound around the threaded tube just above the nozzle.

I've measured the resistance of the "heater" and its around 6 ohms, which should be OK. Albeit possibly lower power than a normal cartridge style heater (as the cartridge ones i have are 4 ohms).

I think the best thing I can do is just to tape a thermistor to the threaded tube, with Kapton tape, and try to made sure its well attached.

Then refit the insulation (not sure what its made of but it looks like rubber)

BTW. On mine, the heater wires and the thermocouple wires were held in place by some stiff copper wire. I will probably replace the wire, as I had to cut it to remove it.

Also, on my extruder, there was some form of aluminium tape wrapped around the outside of the threaded tube, and heater wires + thermocouple, i.e immediately next to the "rubber" outer insulation.

I don't have any aluminium tape, and I'm not sure if any local companies sell it, so I may end up just warping aluminium foil in its place and hope it stays on even though its not glued in place, as the rubber insulation is quite tight and would probably keep it all in place.

Also BTW. In case anyone is interested.

Here is a picture of the extruder drive cog

And here is the the fan etc

|

Re: Those ebay extruders December 17, 2013 11:00PM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Those ebay extruders December 17, 2013 11:07PM |

Registered: 10 years ago Posts: 273 |

jamesdanielv

I've not tried it yet, but @vince seems to have a similar model and says it works for him.

As you say, its only designed for 1.75mm filament.

I actually have alternative drive cogs (not sure if you call them cogs in this instance), which I can try if the one that was supplied with the extruder doesnt work.

I have a "MK8" stepstuder cog thing, which is much smaller and hence would give higher torque, but again is only designed for 1.75mm as it has a semicircular groove for the filament cut into the cog.

I also have a cog thing from RobotDigg, which is like the one supplied with the extruder but had much sharper teeth.

This morning, I have replaced the thermocouple with a thermistor and re-assembled (easier said than done), but I've not had chance to test if it even gets hot, as I have to setup a separate test rig, as I don't want to dissassemble my only working printer (my MendelMax) just yet

I'll post photos later

I've not tried it yet, but @vince seems to have a similar model and says it works for him.

As you say, its only designed for 1.75mm filament.

I actually have alternative drive cogs (not sure if you call them cogs in this instance), which I can try if the one that was supplied with the extruder doesnt work.

I have a "MK8" stepstuder cog thing, which is much smaller and hence would give higher torque, but again is only designed for 1.75mm as it has a semicircular groove for the filament cut into the cog.

I also have a cog thing from RobotDigg, which is like the one supplied with the extruder but had much sharper teeth.

This morning, I have replaced the thermocouple with a thermistor and re-assembled (easier said than done), but I've not had chance to test if it even gets hot, as I have to setup a separate test rig, as I don't want to dissassemble my only working printer (my MendelMax) just yet

I'll post photos later

|

Re: Those ebay extruders December 18, 2013 05:41AM |

Registered: 10 years ago Posts: 273 |

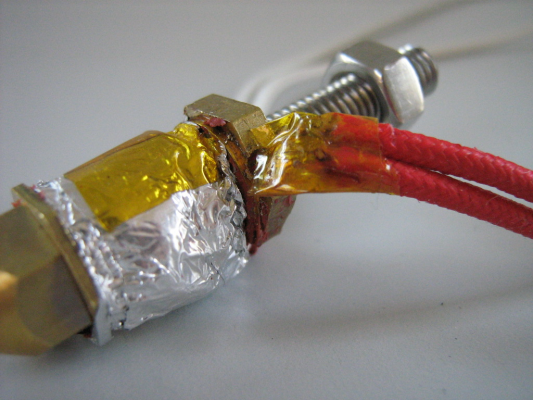

Update.

I replaced the thermocouple with a thermistor (red wires in this photo), and wrapped kapton tape around.

Then as the original shielding included some aluminium tape (which I don't have) I wrapped cooking foil around, and taped it in place with Kapton tape

I then refitted the "rubber" thing that went on the outside.

The heater works OK, however there is a fundamental problem having the termistor or the even the thermocouple outside the resistance wire.

What is happening, is that when the Ramps (Marlin) applies power to the heater, the termistor registers very quick increase in temperature, but when I measured the the temperature on the nozzle, its hardly changing at all.

So the RAMPS (Marlin) turns off the power after a few secs and the temperature drops rapidly.

I've currently got a problem with the 12v PC ATX PSU that I'm using for this, as it doesn't like the ramps turning the power on and off, and the PSU trips out.

So I've not been able to even see if the hot end eventually will reach the desired temperature.

I think that I may need to replace the heater etc with a normal aluminium block, but I don't have any spare at the moment, so I'm going to need to order some (probably from RobotDigg).

I may see if I can get the PSU to hold on for a bit longer by giving it a bit more background load. Currently I'm running a strep of LED lights to act as general loads but it doesnt look like this is enough. even though its around 600mA. I have a 50W halogen bulb that may do the trick

I'll keep you guys posted

Update.

I fixed my PSU issue by giving a few amps load on 5V, however I can't get the hot end to actually get above around 70 deg C, as because of the issues described above.

I'm not sure how @vince got his to work. Hi Vince, I'll PM you ;-)

Coincidentally, I get a rather nasty smell from the hot end, I'm not sure if its something to do with the tape that they used to hold the resistance wire in place or more worrying if its the rubber external thing that is smelling.

But it looks like I need to replace the hot end part with a traditional version. I think I may have something I can bodge to do the job, but I'm not sure at the moment, and its not that easy for me to get hold of a small chunk of aluminium apart from possibly at a metal recycler.

Edited 2 time(s). Last edit at 12/18/2013 06:14AM by rogerclark.

I replaced the thermocouple with a thermistor (red wires in this photo), and wrapped kapton tape around.

Then as the original shielding included some aluminium tape (which I don't have) I wrapped cooking foil around, and taped it in place with Kapton tape

I then refitted the "rubber" thing that went on the outside.

The heater works OK, however there is a fundamental problem having the termistor or the even the thermocouple outside the resistance wire.

What is happening, is that when the Ramps (Marlin) applies power to the heater, the termistor registers very quick increase in temperature, but when I measured the the temperature on the nozzle, its hardly changing at all.

So the RAMPS (Marlin) turns off the power after a few secs and the temperature drops rapidly.

I've currently got a problem with the 12v PC ATX PSU that I'm using for this, as it doesn't like the ramps turning the power on and off, and the PSU trips out.

So I've not been able to even see if the hot end eventually will reach the desired temperature.

I think that I may need to replace the heater etc with a normal aluminium block, but I don't have any spare at the moment, so I'm going to need to order some (probably from RobotDigg).

I may see if I can get the PSU to hold on for a bit longer by giving it a bit more background load. Currently I'm running a strep of LED lights to act as general loads but it doesnt look like this is enough. even though its around 600mA. I have a 50W halogen bulb that may do the trick

I'll keep you guys posted

Update.

I fixed my PSU issue by giving a few amps load on 5V, however I can't get the hot end to actually get above around 70 deg C, as because of the issues described above.

I'm not sure how @vince got his to work. Hi Vince, I'll PM you ;-)

Coincidentally, I get a rather nasty smell from the hot end, I'm not sure if its something to do with the tape that they used to hold the resistance wire in place or more worrying if its the rubber external thing that is smelling.

But it looks like I need to replace the hot end part with a traditional version. I think I may have something I can bodge to do the job, but I'm not sure at the moment, and its not that easy for me to get hold of a small chunk of aluminium apart from possibly at a metal recycler.

Edited 2 time(s). Last edit at 12/18/2013 06:14AM by rogerclark.

|

Re: Those ebay extruders December 19, 2013 03:38PM |

Registered: 10 years ago Posts: 273 |

Yet another update in case anyone is interested.

I tried wrapping a load of aluminium foil outside the central core, which uses resistance wire to heat, in the hope that as the foil was also in contact with the metal of the nozzle end and also the other end of the heated area, that this would allow the thermistor to read correctly.

However this didn't really improve things very much, if at all.

So I drilled a hole into the top of the heater part of the unit.

and fitted the thermistor using heat sink compound.

Initially I thought the results were similar to what I had before, but it did appear to heat more slowly (as sensed by the thermisor)

So I suspected that measuring the nozzle temperature using my infra red thermometer could be at fault and attached a thermocouple probe to the nozzle instead, and it read much higher temperatures than the IR one. (I should have done this before, but normally the IR thermometer gives reasonably accurate results).

Overall, I now don't really know if it was necessary to drill the hole, or whether the problems I had were purely my miss measurement of the nozzle temperature.

However looking at the speed to increase of temperature as sensed with the thermisor in a drilled hole, it is much slower than when the thermistor was just taped outside the heating wire.

So although I think just replacing the thermocouple with a thermistor (in exactly the same location) will probably work; drilling a hole and actually sensing the temperature of the bass is probably the best method.

One thing to note when drilling the hole. The brass section seems to be a machined tube which is threaded on the inside and outside, and another threaded tube links this to the main thermal block heat sink - which is made of steel (or more likely stainless steel).

When drilling into the bass, there doesn't seem to be too much chance of drilling right through the stainless steel inner tube, as the stainless steel is much harder than the brass, so if drilling slowly by hand, its easy to notice when the drill no longer seems to be making much headway, i.e when its got to the stainless steel.

Next step is to wire up the motor and try extruding !

Edited 1 time(s). Last edit at 12/19/2013 06:08PM by rogerclark.

I tried wrapping a load of aluminium foil outside the central core, which uses resistance wire to heat, in the hope that as the foil was also in contact with the metal of the nozzle end and also the other end of the heated area, that this would allow the thermistor to read correctly.

However this didn't really improve things very much, if at all.

So I drilled a hole into the top of the heater part of the unit.

and fitted the thermistor using heat sink compound.

Initially I thought the results were similar to what I had before, but it did appear to heat more slowly (as sensed by the thermisor)

So I suspected that measuring the nozzle temperature using my infra red thermometer could be at fault and attached a thermocouple probe to the nozzle instead, and it read much higher temperatures than the IR one. (I should have done this before, but normally the IR thermometer gives reasonably accurate results).

Overall, I now don't really know if it was necessary to drill the hole, or whether the problems I had were purely my miss measurement of the nozzle temperature.

However looking at the speed to increase of temperature as sensed with the thermisor in a drilled hole, it is much slower than when the thermistor was just taped outside the heating wire.

So although I think just replacing the thermocouple with a thermistor (in exactly the same location) will probably work; drilling a hole and actually sensing the temperature of the bass is probably the best method.

One thing to note when drilling the hole. The brass section seems to be a machined tube which is threaded on the inside and outside, and another threaded tube links this to the main thermal block heat sink - which is made of steel (or more likely stainless steel).

When drilling into the bass, there doesn't seem to be too much chance of drilling right through the stainless steel inner tube, as the stainless steel is much harder than the brass, so if drilling slowly by hand, its easy to notice when the drill no longer seems to be making much headway, i.e when its got to the stainless steel.

Next step is to wire up the motor and try extruding !

Edited 1 time(s). Last edit at 12/19/2013 06:08PM by rogerclark.

|

Re: Those ebay extruders December 19, 2013 07:01PM |

Registered: 11 years ago Posts: 34 |

Sorry, only registered users may post in this forum.