Homemade 3D printer - problems with the filament size and ABS temp

Posted by daniel.jimenez

|

Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 06:30PM |

Registered: 10 years ago Posts: 10 |

Hi

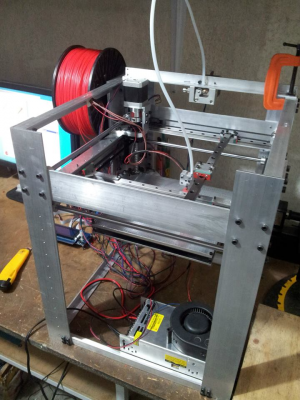

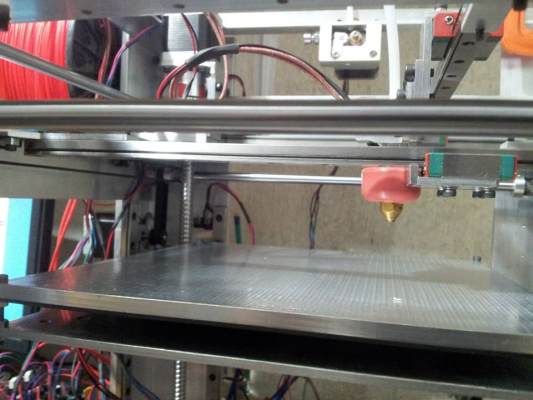

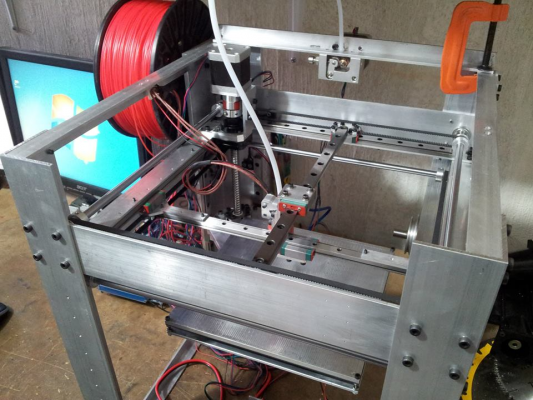

I have design and build a 3d printer, here are some picture and a video of it, I did all the part on my homemade CNC router that I did also.

I have not printed anything yet because, I had some problems with the diameter of my filament, I saw that the 1.75mm filament was about 2mm diameter on some places , and the extruder is jammed several times because of that

, and the extruder is jammed several times because of that

I also have doubts with the extruder hot end temperature, I saw that the extruder external thermistor reading is very different than the temperature inside the "melting chamber", I was also having problems with the extruder, and I think that the temperature could be the possible cause.

I have two questions, I hope that you can help me with those please.

Do you know where to buy good quality filament?

Which is the temperature of the ABS inside the melting chamber?

Here are the pictures:

You can see a video here also:

[www.youtube.com]

Thanks for the help, I will post more updates once I solve the problem with the filament and the extruder.

Kind regards

Daniel Jimenez

I have design and build a 3d printer, here are some picture and a video of it, I did all the part on my homemade CNC router that I did also.

I have not printed anything yet because, I had some problems with the diameter of my filament, I saw that the 1.75mm filament was about 2mm diameter on some places

, and the extruder is jammed several times because of that

, and the extruder is jammed several times because of that

I also have doubts with the extruder hot end temperature, I saw that the extruder external thermistor reading is very different than the temperature inside the "melting chamber", I was also having problems with the extruder, and I think that the temperature could be the possible cause.

I have two questions, I hope that you can help me with those please.

Do you know where to buy good quality filament?

Which is the temperature of the ABS inside the melting chamber?

Here are the pictures:

You can see a video here also:

[www.youtube.com]

Thanks for the help, I will post more updates once I solve the problem with the filament and the extruder.

Kind regards

Daniel Jimenez

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 06:40PM |

Registered: 11 years ago Posts: 1,171 |

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 06:45PM |

Registered: 10 years ago Posts: 1,381 |

Nice printer!

ABS, (Acrylonitrile butadiene styrene, Type: extruded):

Drying Temperature:

Range: 70°C to 93.3°C, (158ºF to 200ºF)

Average: 80.9°C, (178ºF ).

Dry time:

Range: 2 to 4 hours.

Average: 3.2 hours.

Glass-transition temp:

Range: 108°C to 109°C.

Average: 108°C, (226.4ºF ).

Wikipedia: 105°C, (221ºF ).

Begin testing around this temp:

Substrate/bed temperature: <105°C, (221ºF ).

Enclosure temperature: <105°C, (221ºF ).

Machine parameters:

Extrude temp (RepRap): 210 C ~ 240 C

ABS, (Acrylonitrile butadiene styrene, Type: extruded):

Drying Temperature:

Range: 70°C to 93.3°C, (158ºF to 200ºF)

Average: 80.9°C, (178ºF ).

Dry time:

Range: 2 to 4 hours.

Average: 3.2 hours.

Glass-transition temp:

Range: 108°C to 109°C.

Average: 108°C, (226.4ºF ).

Wikipedia: 105°C, (221ºF ).

Begin testing around this temp:

Substrate/bed temperature: <105°C, (221ºF ).

Enclosure temperature: <105°C, (221ºF ).

Machine parameters:

Extrude temp (RepRap): 210 C ~ 240 C

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 07:11PM |

Registered: 12 years ago Posts: 115 |

Hi Daniel, I agree with A2 - Nice Printer, you obviously have spent a lot of time building it.

You should purchase at least a couple of lbs of "good" filament from a reliable and reputable supplier Ultimachine, Lulzbot, and Makerbot (with a much higher markup) all purchase from the same extruder so the quality should be the same.

The extruder w/Bowden extruder setup works, but with a direct drive nema 17 setup, you won't be able to develop high enough force on the filament to use any wide / off spec filament. I would recommend using a geared extruder like a Greg's / Wade's extruder if you want to use cheaper filament a lot. I have seen the hot end you are using , but haven't tried it out yet, I would check the diameter of the filament feed tube, to make sure it is large enough for the filament. Filament (expecially PLA or undried abs) swells when heated.

You should supply some of your specs that you are trying to run the printer at: Speeds, temperatures, nozzle diameter, etc...

Correct me if I am wrong, but your display seems to say you are at 320°C for the extruder temp, which is far too high for ABS. For Ultimachine / Lulzbut ABS, I use 230°C, so you might have inverted the temp digits. At 320°C ABS cooks into a tar like glue and starts to burn.

Anyway, good luck, it's a process. You have the hardest part doen (getting a machine actually built).

You should purchase at least a couple of lbs of "good" filament from a reliable and reputable supplier Ultimachine, Lulzbot, and Makerbot (with a much higher markup) all purchase from the same extruder so the quality should be the same.

The extruder w/Bowden extruder setup works, but with a direct drive nema 17 setup, you won't be able to develop high enough force on the filament to use any wide / off spec filament. I would recommend using a geared extruder like a Greg's / Wade's extruder if you want to use cheaper filament a lot. I have seen the hot end you are using , but haven't tried it out yet, I would check the diameter of the filament feed tube, to make sure it is large enough for the filament. Filament (expecially PLA or undried abs) swells when heated.

You should supply some of your specs that you are trying to run the printer at: Speeds, temperatures, nozzle diameter, etc...

Correct me if I am wrong, but your display seems to say you are at 320°C for the extruder temp, which is far too high for ABS. For Ultimachine / Lulzbut ABS, I use 230°C, so you might have inverted the temp digits. At 320°C ABS cooks into a tar like glue and starts to burn.

Anyway, good luck, it's a process. You have the hardest part doen (getting a machine actually built).

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 07:14PM |

Registered: 10 years ago Posts: 10 |

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 07:31PM |

Registered: 10 years ago Posts: 10 |

Thanks a lot Beekeeper and A2!

Yes, I have spend some time building this printer, I really liked doing this stuff.

Thanks for the information on the temperatures and the tips, that really helps a lot.

Looks like I have an offset on the temperature, this could be because I put the thermistor really close to the heating wire inside the hot end, I measure 320 on the display, but when I read the temperature inside the melting chamber with a multimeter the temperature reads are between 230 and 250, I am using a 100k thermistor and selecting 7 or 1 on the Marlin firmware, I will try to move the thermistor or add a kapton layer in order to get a more close to the reads of the multimeter.

I will buy some filament from the suppliers that you recoomended, the hole on the extruder hot end is 1.85mm and my filament is sometimes 2mm, at this point I can't feed it even using my hand.

These are the spec of the machine and my desired printing speeds:

0.4 nozzle diameter.

I would like 100mm/s when printing, but I don't know if the extruder is fast enough ( I think that the temperature will be in function of this)

Yes!, this is a very cool process of learning and solving problems on the way , thanks!

, thanks!

Yes, I have spend some time building this printer, I really liked doing this stuff.

Thanks for the information on the temperatures and the tips, that really helps a lot.

Looks like I have an offset on the temperature, this could be because I put the thermistor really close to the heating wire inside the hot end, I measure 320 on the display, but when I read the temperature inside the melting chamber with a multimeter the temperature reads are between 230 and 250, I am using a 100k thermistor and selecting 7 or 1 on the Marlin firmware, I will try to move the thermistor or add a kapton layer in order to get a more close to the reads of the multimeter.

I will buy some filament from the suppliers that you recoomended, the hole on the extruder hot end is 1.85mm and my filament is sometimes 2mm, at this point I can't feed it even using my hand.

These are the spec of the machine and my desired printing speeds:

0.4 nozzle diameter.

I would like 100mm/s when printing, but I don't know if the extruder is fast enough ( I think that the temperature will be in function of this)

Yes!, this is a very cool process of learning and solving problems on the way

, thanks!

, thanks!

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 07:37PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 07, 2014 07:51PM |

Registered: 10 years ago Posts: 10 |

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 09, 2014 03:09AM |

Registered: 13 years ago Posts: 1,797 |

nice printer!. i notices some vibrations form the x/y axis.

you can eliminate some of the resonance on the x/y gantry by use belt tensioners. I think the belts are a little bit loose.

also what material are you using for the cold region of nozzle? that hot end has not been proven as far as i know and it is only the heater and nozzle. not cold region is included., and i have never seen it used in action.

read here about operating principles : [reprap.org]

Edited 1 time(s). Last edit at 01/09/2014 03:15AM by jamesdanielv.

you can eliminate some of the resonance on the x/y gantry by use belt tensioners. I think the belts are a little bit loose.

also what material are you using for the cold region of nozzle? that hot end has not been proven as far as i know and it is only the heater and nozzle. not cold region is included., and i have never seen it used in action.

read here about operating principles : [reprap.org]

Edited 1 time(s). Last edit at 01/09/2014 03:15AM by jamesdanielv.

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 09, 2014 12:17PM |

Registered: 10 years ago Posts: 10 |

Hi James

Thank you!

Ok, I will try to tight more the belts, I thought that it was running good because I am running a program that prints a little gear with little tooths and it was changing the direction very quickly, maybe this contributes to the resonance.

In which part or the video could you see the resonance? in order to see it with more detail.

I have seen those belt tensioners that you mention, I already ordered some of them, but they will take some time to arrive.

I saw the link that you posted, thanks for the information, but I still have a couple of doubts,

Does the "cold region" is the same as the "cold end"?

If not, what is the "cold region"?

Could you give me an example of the cold region in another extruder?

The aluminium is preventing the heat to spread on the carts and guides, I can put my finger on the part that connect the x and y guide.

Thank you!

Ok, I will try to tight more the belts, I thought that it was running good because I am running a program that prints a little gear with little tooths and it was changing the direction very quickly, maybe this contributes to the resonance.

In which part or the video could you see the resonance? in order to see it with more detail.

I have seen those belt tensioners that you mention, I already ordered some of them, but they will take some time to arrive.

I saw the link that you posted, thanks for the information, but I still have a couple of doubts,

Does the "cold region" is the same as the "cold end"?

If not, what is the "cold region"?

Could you give me an example of the cold region in another extruder?

The aluminium is preventing the heat to spread on the carts and guides, I can put my finger on the part that connect the x and y guide.

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 09, 2014 12:43PM |

Registered: 10 years ago Posts: 10 |

One more update on the filament!!

A couple days ago I tried to clean my nozzle with acetone and also do some ABS juice in order to do something useful with the poor tolerances abs.... but not even for that that abs was useful!!

The abs does not dissolved complety!, I saw a white plastic bulk on the bottom and the abs on the nozzle also was there even after 2 days on the acetone!

I think that the abs also was not real abs!

I hope to have better luck with the filament that I ordered, I really hope!, that one was not cheap!

Edited 1 time(s). Last edit at 01/09/2014 02:02PM by daniel.jimenez.

A couple days ago I tried to clean my nozzle with acetone and also do some ABS juice in order to do something useful with the poor tolerances abs.... but not even for that that abs was useful!!

The abs does not dissolved complety!, I saw a white plastic bulk on the bottom and the abs on the nozzle also was there even after 2 days on the acetone!

I think that the abs also was not real abs!

I hope to have better luck with the filament that I ordered, I really hope!, that one was not cheap!

Edited 1 time(s). Last edit at 01/09/2014 02:02PM by daniel.jimenez.

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 09, 2014 01:35PM |

Registered: 10 years ago Posts: 32 |

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 09, 2014 02:04PM |

Registered: 10 years ago Posts: 10 |

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 09, 2014 02:19PM |

Registered: 11 years ago Posts: 544 |

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 10, 2014 01:12AM |

Registered: 10 years ago Posts: 10 |

Hi,

This is the result from the ABS juice that I tried to do with the two filaments that I bought, looks a the very different results on acetone... I think that one of those ( if not both ) is not ABS

Now I have a new filament from a good source, I will post the result for this as well

This is the result from the ABS juice that I tried to do with the two filaments that I bought, looks a the very different results on acetone... I think that one of those ( if not both ) is not ABS

Now I have a new filament from a good source, I will post the result for this as well

|

Re: Homemade 3D printer - problems with the filament size and ABS temp January 24, 2014 06:10PM |

Registered: 10 years ago Posts: 10 |

Hi

I have some updates... I am finally prinitng!!

You can see a video here:

[www.youtube.com]

Thanks a lot for the comments and advices!, those were really helpful!, I modified the extruder and added a pulley to gain 2.5 more torque and also added a cold region for the hot end, those really made the difference!!! thanks for this Beekeeper and Jamesdanielv !

!

Now I am using the printer and enyoing it , I will keep making it more improvements.

, I will keep making it more improvements.

I saw that I can run the printer faster than in the video, the extruder works really nice now, I will keep calibrating the printer!!

Kind regards

Victor Jimenez

I have some updates... I am finally prinitng!!

You can see a video here:

[www.youtube.com]

Thanks a lot for the comments and advices!, those were really helpful!, I modified the extruder and added a pulley to gain 2.5 more torque and also added a cold region for the hot end, those really made the difference!!! thanks for this Beekeeper and Jamesdanielv

!

!Now I am using the printer and enyoing it

, I will keep making it more improvements.

, I will keep making it more improvements.I saw that I can run the printer faster than in the video, the extruder works really nice now, I will keep calibrating the printer!!

Kind regards

Victor Jimenez

Sorry, only registered users may post in this forum.