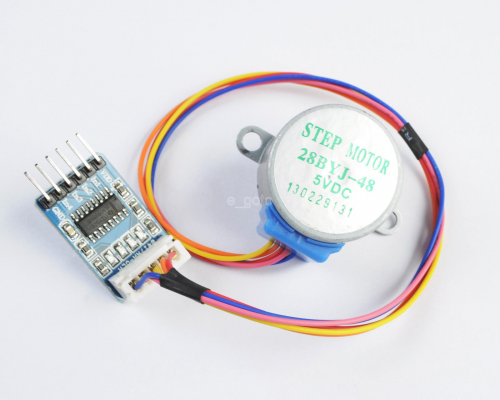

Use this TINY stepper motor to feed material?

Posted by superfan

|

Use this TINY stepper motor to feed material? July 04, 2014 10:52PM |

Registered: 11 years ago Posts: 2 |

With the speed reduction mechanism, it can make great torque.

The most attractive thing is the weight and price.

Anyone tried this?

http://www.ebay.com/itm/1pcs-Stepper-Motor-Driver-Board-ULN2003-5V-4-phase-5-line-/371093596653?pt=LH_DefaultDomain_0&hash=item5666e6e9ed

The most attractive thing is the weight and price.

Anyone tried this?

http://www.ebay.com/itm/1pcs-Stepper-Motor-Driver-Board-ULN2003-5V-4-phase-5-line-/371093596653?pt=LH_DefaultDomain_0&hash=item5666e6e9ed

|

Re: Use this TINY stepper motor to feed material? July 05, 2014 09:26AM |

Registered: 10 years ago Posts: 790 |

At maximum, you get 16.7oz/in. That's just the friction torque.

Your pull in torque is a measly 4.2oz/in.Recommended extruder torque is 50oz/in or more.

Extremely low friction gearing and super slow movement is the only way to implement that I can see.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Your pull in torque is a measly 4.2oz/in.Recommended extruder torque is 50oz/in or more.

Extremely low friction gearing and super slow movement is the only way to implement that I can see.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Use this TINY stepper motor to feed material? July 05, 2014 01:20PM |

Registered: 9 years ago Posts: 569 |

|

Re: Use this TINY stepper motor to feed material? July 05, 2014 02:09PM |

Registered: 13 years ago Posts: 1,797 |

this looks like it is a tin can style gear reduction model

another issue is the speed of retraction and control of stepper with limitations of stator and physics of inertia. the speed of change of the motor will have it lagging behind the moved of the tool motion. this means uneven deposits of filament around area of acceleration. this has been discussed before, also with the size of teeth at the end of stepper you will have trouble getting bite on the other gear or a geared plastic part that will not deform on the shaft end

looking at the specs max pulses per second is 1000, on average most steppers are about 3000, and then you have a 1/64 gear reduction, meaning that this motor has a max speed of about 1/3*1/64 or 1/200 the the speed of a normal stepper.

Edited 3 time(s). Last edit at 07/05/2014 02:17PM by jamesdanielv.

another issue is the speed of retraction and control of stepper with limitations of stator and physics of inertia. the speed of change of the motor will have it lagging behind the moved of the tool motion. this means uneven deposits of filament around area of acceleration. this has been discussed before, also with the size of teeth at the end of stepper you will have trouble getting bite on the other gear or a geared plastic part that will not deform on the shaft end

looking at the specs max pulses per second is 1000, on average most steppers are about 3000, and then you have a 1/64 gear reduction, meaning that this motor has a max speed of about 1/3*1/64 or 1/200 the the speed of a normal stepper.

Edited 3 time(s). Last edit at 07/05/2014 02:17PM by jamesdanielv.

|

Re: Use this TINY stepper motor to feed material? July 06, 2014 05:03PM |

Registered: 10 years ago Posts: 240 |

I agree with the others, the extruder is one place you do not want to skimp on.

Also, you want a fast retract speed and gear reduction will kill that, especially when used with a weak motor. Using a bowden makes the problem even worse.

I always recommend people get as strong of an extruder as they can.

Also, you want a fast retract speed and gear reduction will kill that, especially when used with a weak motor. Using a bowden makes the problem even worse.

I always recommend people get as strong of an extruder as they can.

|

Re: Use this TINY stepper motor to feed material? September 04, 2014 03:38PM |

Registered: 9 years ago Posts: 135 |

Sorry to resurrect an old thread, but would it be a good idea to use a small motor at the end of your tube in a Bowden set-up? As in the main force against the filament is on the stationary end, but also have a smaller motor that is used on the moving end of the tube to help overcome friction in the tube and keep the filament from compressing/stretching in the case of flexable filaments?

|

Re: Use this TINY stepper motor to feed material? September 04, 2014 11:26PM |

Registered: 9 years ago Posts: 105 |

|

Re: Use this TINY stepper motor to feed material? September 05, 2014 01:20AM |

Registered: 11 years ago Posts: 564 |

By my calculations, an extruder motor only requires about 0.2w of output power (10mm^3/sec max flow rate, ~5kgf for extruding 1.75mm dia filament). This little stepper looks like maybe a 1 or 2w (output power) motor, so in theory, it could have enough power. I wouldn't actually recommend trying this, mind you, but in theory... Someone ought to check my calculations, though.

|

Re: Use this TINY stepper motor to feed material? September 05, 2014 02:03PM |

Registered: 9 years ago Posts: 135 |

Miertam, I was figuring that the stall torque on a tiny motor like this wouldn't be enough to damage filament. Just enough to provide a constant pull or constant push as the filament feeds or retracts. Before I was thinking of using a tiny printed air vane motor I found on Thingiverse (http://www.thingiverse.com/thing:620) under fairly low pressure for it. Not enough push to really grind the filament, just enough for a little push.

Though even so, there's nothing wrong with getting the two synchronized speed-wise.

Though even so, there's nothing wrong with getting the two synchronized speed-wise.

|

Re: Use this TINY stepper motor to feed material? September 05, 2014 09:41PM |

Registered: 9 years ago Posts: 105 |

Sorry, only registered users may post in this forum.