|

Spectra Line Considerations: Grip and 'Walking' Sideways October 21, 2014 06:14PM |

Registered: 10 years ago Posts: 363 |

Since learning about using Spectra lines in place of belts I've been quite intrigued with the idea so have been reading what I can find and watching YouTube for examples of Spectra line in action.

Some of the concerns I have are:

1. GRIP - Can the Spectra line grip a smooth/toothed pulley strongly enough to push a typical Mendel90/Prusa style X carriage (lighter or heavier Y carriage depending on how it's made) with a stepper motor on it at up to 200mm/sec for non-printing moves? I have no dreams of printing close to that speed but that's how fast I'd like to run the non-printing moves.

The line I have is Chinese from eBay and is black and seems slippery (but seems to be real Poly-Ethylene line) so I'm not sure how well this will grip an aluminum pulley (solid or toothed). I thought it would be quite easy to apply some sticky substance to the line which turns on the pulley. Grip should be enhanced by that but could an adhesive introduce other issues?

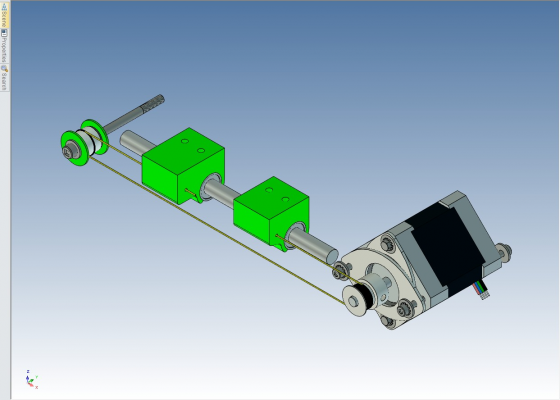

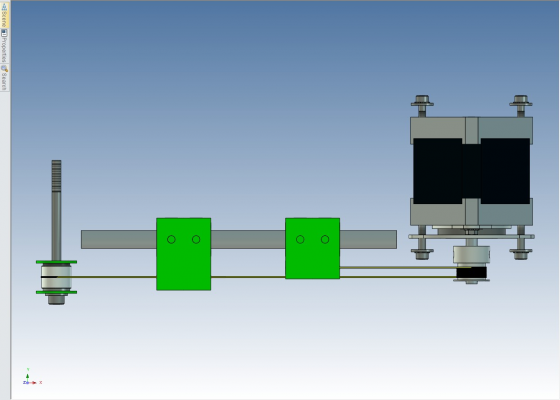

2. WALKING - Videos and some discussion seems to show/discuss the line that is wrapped on a pulley walking left and right (i.e. sideways) as the pulley turns. If I offset the line attachment points at opposite sides/ends of the X carriage - as in the images below - should walking be eliminated? Granted that the motor shaft is perfectly aligned I'm not sure how the wrapped line on the motor pulley could walk sideways in this situation.

I haven't tested these two issues - and testing would surely confirm/deny my concerns and might be the only way to find out - but before going ahead I thought it would be nice to hear from others who may have crossed these bridges before. It could save some work trying something that is doomed to fail.

Some of the concerns I have are:

1. GRIP - Can the Spectra line grip a smooth/toothed pulley strongly enough to push a typical Mendel90/Prusa style X carriage (lighter or heavier Y carriage depending on how it's made) with a stepper motor on it at up to 200mm/sec for non-printing moves? I have no dreams of printing close to that speed but that's how fast I'd like to run the non-printing moves.

The line I have is Chinese from eBay and is black and seems slippery (but seems to be real Poly-Ethylene line) so I'm not sure how well this will grip an aluminum pulley (solid or toothed). I thought it would be quite easy to apply some sticky substance to the line which turns on the pulley. Grip should be enhanced by that but could an adhesive introduce other issues?

2. WALKING - Videos and some discussion seems to show/discuss the line that is wrapped on a pulley walking left and right (i.e. sideways) as the pulley turns. If I offset the line attachment points at opposite sides/ends of the X carriage - as in the images below - should walking be eliminated? Granted that the motor shaft is perfectly aligned I'm not sure how the wrapped line on the motor pulley could walk sideways in this situation.

I haven't tested these two issues - and testing would surely confirm/deny my concerns and might be the only way to find out - but before going ahead I thought it would be nice to hear from others who may have crossed these bridges before. It could save some work trying something that is doomed to fail.

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways October 22, 2014 09:25AM |

Registered: 10 years ago Posts: 1,401 |

Some fish lines are rated for over 50kg. And more, so yes they can move heavy carriages without problems.

Both pulleys need to be smooth or you are risking cutting the line.

You need to allow "walking" (sliding) of the line to prevent entanglement. There will always be some imperfections in alignment because of the type of parts we use and the normal bending of shafts.

Although fish lines are simple to implement and relatively cheaper that timing belts, they depend exclusively on friction and tension to operate and so they are less reliable and harder to calibrate. (I started with fish lines and quickly switched to timing belts)

There is nothing wrong with experimenting and failure, is the best way to learn and understand how stuff works and the only way to find real alternatives to current systems. I always encouraged my kids to try and fail because is the only way to develop an analytical mind.

Edited 1 time(s). Last edit at 10/22/2014 09:34AM by ggherbaz.

Both pulleys need to be smooth or you are risking cutting the line.

You need to allow "walking" (sliding) of the line to prevent entanglement. There will always be some imperfections in alignment because of the type of parts we use and the normal bending of shafts.

Although fish lines are simple to implement and relatively cheaper that timing belts, they depend exclusively on friction and tension to operate and so they are less reliable and harder to calibrate. (I started with fish lines and quickly switched to timing belts)

There is nothing wrong with experimenting and failure, is the best way to learn and understand how stuff works and the only way to find real alternatives to current systems. I always encouraged my kids to try and fail because is the only way to develop an analytical mind.

Edited 1 time(s). Last edit at 10/22/2014 09:34AM by ggherbaz.

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways October 23, 2014 03:23PM |

Registered: 10 years ago Posts: 363 |

Thank you ggherbaz. This is precisely the type of response I was looking for; theory combined with experience. While I fully agree with you that experimenting is the way to learn and understand in this case I'll likely skip on to designing with belts. The more I think of using line in my design the less likely I think it would work out well. Maybe some day I'll look at them again ..

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways November 10, 2014 04:19PM |

Registered: 10 years ago Posts: 153 |

The way to deal with it is to have the string knotted onto the pulley in the middle. This way, when it winds and unwinds it will walk left and right, but always remain centred. By doing it this way, your pulley will have to be wide enough to accomodate the string when the carriage is at the ends of the linear rails.

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways November 10, 2014 10:30PM |

Registered: 10 years ago Posts: 553 |

The printrbot simple used to (not sure if they still do) use spectra for their drives. They used what looked like a dremel sanding bit for the drive pulley. Not sure if it caused any fraying or anything like that, but seems like a decent solution for grip.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways November 11, 2014 11:48AM |

Registered: 11 years ago Posts: 253 |

Summer 2013, I played around with corexy, and concluded it needs precision everywhere, especially in the motor pulley concentricity.

This is just my perspective and how I approached it. There are many crafty people having success where I could not.

The large (28x23x28inch) printer was designed in Solidworks, and has features to build as either a belt/cartesian or a cable/corexy. The sheetmetal based CAD designs are available from me, just PM.

I used SAVA cable from Carl Stahl, 2032SN, which is SAVA .813 mm diameter, 120 lb break, 133 stranded stainless, nylon coated. super silky feel, infinite bend life over my pulley diameter. expensive at $1.75/ft, 250ft minimum. It goes down to about $0.60/foot when you get around 5000 feet order size.

To stop the line walking up and down, I used a friction ladder on the motor end. Back then, there was a thread mentioning this concept coming from ferris wheel drive mechanisms, and Rob Povey did quick axis concept with blue string. I wound it both crossing and straight, and both had the grip needed. Also, since my axis are very long, the walking is very significant if a ladder isn't used. Note: The slots to move the motor at the ladder area are useless for tensioning the cable, as the friction is too much when laced. We tensioned the cable at the print head by pulling it manually, then securing with set screws.

The skate bearing, (8x22x7) was custom made by VXB, with 3 precision ground grooves. They may provide them to anyone, but we bought 100 at $1.75each. It held the cable at three elevations, which we selectively used all over the cable path, on custom posts we made. We kept the cable running straight/parallel/perpendicular to all the X/Y movements. Changing angles and non direct lines of motion create a changing tension that can build up over large movements.

I made the motor drive pulleys on a Taig Micro lathe, but had a very minor error in concentricity. I could see a slight wobble and as the motors turn for X/Y motions, there would be an accumulating error seen at the head. The slant picture shows that small parts could be made well, but larger items would have a slant. The conclusion was that as one motor drives the motion, it is rooted by the other motor and referenced to it. If one motor has a bad pulley, the radius varies and errors add up. The errors don't unwind back to zero as you go back along a path, especially on 45 degree infills and curves.

We abandoned the corexy and cable drive system and shifted to GT2 belts and regular X/Y motions. If I were to tackle corexy again, I'd use belts and make a smaller printer frame.

This cable drive system is a bitch to lace and tension.

Edited 1 time(s). Last edit at 11/11/2014 12:14PM by davew_tx.

Dave

Praxis3D, Kickstarter campaign X-truder,

This is just my perspective and how I approached it. There are many crafty people having success where I could not.

The large (28x23x28inch) printer was designed in Solidworks, and has features to build as either a belt/cartesian or a cable/corexy. The sheetmetal based CAD designs are available from me, just PM.

I used SAVA cable from Carl Stahl, 2032SN, which is SAVA .813 mm diameter, 120 lb break, 133 stranded stainless, nylon coated. super silky feel, infinite bend life over my pulley diameter. expensive at $1.75/ft, 250ft minimum. It goes down to about $0.60/foot when you get around 5000 feet order size.

To stop the line walking up and down, I used a friction ladder on the motor end. Back then, there was a thread mentioning this concept coming from ferris wheel drive mechanisms, and Rob Povey did quick axis concept with blue string. I wound it both crossing and straight, and both had the grip needed. Also, since my axis are very long, the walking is very significant if a ladder isn't used. Note: The slots to move the motor at the ladder area are useless for tensioning the cable, as the friction is too much when laced. We tensioned the cable at the print head by pulling it manually, then securing with set screws.

The skate bearing, (8x22x7) was custom made by VXB, with 3 precision ground grooves. They may provide them to anyone, but we bought 100 at $1.75each. It held the cable at three elevations, which we selectively used all over the cable path, on custom posts we made. We kept the cable running straight/parallel/perpendicular to all the X/Y movements. Changing angles and non direct lines of motion create a changing tension that can build up over large movements.

I made the motor drive pulleys on a Taig Micro lathe, but had a very minor error in concentricity. I could see a slight wobble and as the motors turn for X/Y motions, there would be an accumulating error seen at the head. The slant picture shows that small parts could be made well, but larger items would have a slant. The conclusion was that as one motor drives the motion, it is rooted by the other motor and referenced to it. If one motor has a bad pulley, the radius varies and errors add up. The errors don't unwind back to zero as you go back along a path, especially on 45 degree infills and curves.

We abandoned the corexy and cable drive system and shifted to GT2 belts and regular X/Y motions. If I were to tackle corexy again, I'd use belts and make a smaller printer frame.

This cable drive system is a bitch to lace and tension.

Edited 1 time(s). Last edit at 11/11/2014 12:14PM by davew_tx.

Dave

Praxis3D, Kickstarter campaign X-truder,

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways November 12, 2014 08:49AM |

Registered: 11 years ago Posts: 374 |

@davew, speaking from my own experience developing (and selling) a cable drive corexy machine, what I see in your last picture isn't positioning error due to pulley eccentricity. I think you don't have enough grip on the cable and it's slipping. I saw exactly the same thing until I went to a wrap pattern that can't slip (wrapped through the middle of the pulley). And I too thought I had sufficient tension that "there's no way this sucker is slipping".

One way you can test this is to make a mark on the pulley and at the same point on the cable, run a test, then check if the marks are offset.

One way you can test this is to make a mark on the pulley and at the same point on the cable, run a test, then check if the marks are offset.

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways November 12, 2014 10:50AM |

Registered: 11 years ago Posts: 253 |

Thanks, I may reassemble a machine and try to figure out an anchored cable solution. We move so far on X and Y that it might be impossible with our diameter.

We did increase the tension late in the life of the machine, and I think it did improve it a bit, but then the pulley issue as deemed the culprit.

The cable was so tight, it sounded like a guitar string.

Could pulley issues cause something similar? We just made an assumption and moved on.

Dave

Praxis3D, Kickstarter campaign X-truder,

We did increase the tension late in the life of the machine, and I think it did improve it a bit, but then the pulley issue as deemed the culprit.

The cable was so tight, it sounded like a guitar string.

Could pulley issues cause something similar? We just made an assumption and moved on.

Dave

Praxis3D, Kickstarter campaign X-truder,

|

Re: Spectra Line Considerations: Grip and 'Walking' Sideways November 13, 2014 07:15PM |

Registered: 11 years ago Posts: 205 |

Sorry, only registered users may post in this forum.