Is a heat spreader really necessary

Posted by leadinglights

|

Is a heat spreader really necessary December 17, 2014 08:06AM |

Registered: 12 years ago Posts: 1,450 |

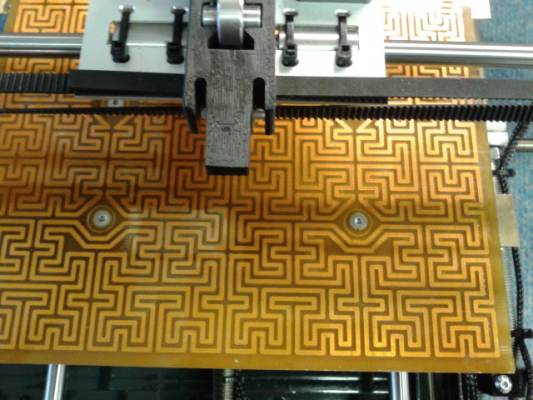

I see that the typical build stage consists of an aluminium heat spreader, the heater and a glass plate. I had to ask myself if this is really needed and built a stage with no heat spreader. I have done maybe 50 or 60 prints now on that printer and have noticed no problems either with the build stage moving or with uneven heat on the surface.

I think you can see above that there is nothing under the heater (except a layer of metalised bubble film for insulation). The glass build stage is pulled doen onto the heater and the support screws which are visible.

The question is, is the heat spreader/plate really needed or have I just got lucky.

Mike

I think you can see above that there is nothing under the heater (except a layer of metalised bubble film for insulation). The glass build stage is pulled doen onto the heater and the support screws which are visible.

The question is, is the heat spreader/plate really needed or have I just got lucky.

Mike

|

Re: Is a heat spreader really necessary December 17, 2014 08:41AM |

Registered: 12 years ago Posts: 2,470 |

A heat spreader is only really neccesary if you have a heat source that is very different in shape and/or area of coverage than the printbed. If it heats evenly and is the same shape as the printbead you don't need a heat spreader.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Is a heat spreader really necessary December 17, 2014 08:42AM |

Admin Registered: 12 years ago Posts: 2,569 |

Never used an aluminum plate myself. Why do you think it is needed ?

My sandwich looks like this, from top to bottom :

Printed part

Garolite plate (for adhesion)

Glass plate (to avoid flexing)

Heater pcb

Insulation made of glass wool wrapped in kapton tape (to avoid wasting heat on the unused side)

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

My sandwich looks like this, from top to bottom :

Printed part

Garolite plate (for adhesion)

Glass plate (to avoid flexing)

Heater pcb

Insulation made of glass wool wrapped in kapton tape (to avoid wasting heat on the unused side)

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Is a heat spreader really necessary December 17, 2014 08:49AM |

Admin Registered: 11 years ago Posts: 1,063 |

Quote

DeuxVis

Never used an aluminum plate myself. Why do you think it is needed ?

My sandwich looks like this, from top to bottom :

Printed part

Garolite plate (for adhesion)

Glass plate (to avoid flexing)

Heater pcb

Insulation made of glass wool wrapped in kapton tape (to avoid wasting heat on the unused side)

thats quite the sandwich, all i've got is kapton heater - 3mm aluminium sheet - glass

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Is a heat spreader really necessary December 17, 2014 08:58AM |

Registered: 10 years ago Posts: 869 |

Required? No. Beneficial? Maybe. With your heated bed design, it probably heats fairly uniformly. If you used a bed that had heating elements that were spaced farther apart, or used power resistors, etc then a spreader likely would help even out the hot spots. It would also act as a buffer to help smooth out temperature changes with it's increased thermal mass. This is a two edged sword though because it will also take longer to heat, cool, and change temperatures if you want to drop the temp after the first layer or two.

In the end, do what works best for you. Since you're not having problems, I wouldn't worry about it. If you start to have problems, or you were having problems to begin with, then you could explore the possibility

In the end, do what works best for you. Since you're not having problems, I wouldn't worry about it. If you start to have problems, or you were having problems to begin with, then you could explore the possibility

|

Re: Is a heat spreader really necessary December 17, 2014 09:03AM |

Admin Registered: 12 years ago Posts: 2,569 |

Quote

thejollygrimreaper

Quote

DeuxVis

Never used an aluminum plate myself. Why do you think it is needed ?

My sandwich looks like this, from top to bottom :

Printed part

Garolite plate (for adhesion)

Glass plate (to avoid flexing)

Heater pcb

Insulation made of glass wool wrapped in kapton tape (to avoid wasting heat on the unused side)

thats quite the sandwich, all i've got is kapton heater - 3mm aluminium sheet - glass

I agree, but when I first switched to garolite as a surface I tried to get rid of the glass and got all my prints mysteriously fail - until I realised garolite + pcb was not rigid enough.

I could probably replace the glass by an aluminium heat spreader which could be thinner, now that you mention it.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Is a heat spreader really necessary December 17, 2014 09:08AM |

Admin Registered: 12 years ago Posts: 2,569 |

Now that I started thinking about it... garolite is quite similar to some PCB substrates.

Maybe I could combine the heater and printing surface there - but I would need a quick disconnect system for the heater power, I need to flex the plate to detach my parts after printing.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Maybe I could combine the heater and printing surface there - but I would need a quick disconnect system for the heater power, I need to flex the plate to detach my parts after printing.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Is a heat spreader really necessary December 17, 2014 09:09AM |

Registered: 12 years ago Posts: 1,450 |

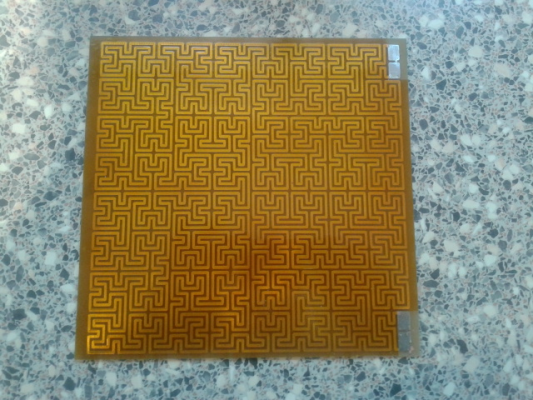

Just checking before comitting the next stage of my latest printer. Since this is one where the build stage moves in both X and Y I am trying to minimalise the moving mass. A short video of ploting out the new heater on Youtube [www.youtube.com]

and photo of the new heater made from the marked out PCB material. The supports this time will be soldered to the copper layer on the back.

Mike

and photo of the new heater made from the marked out PCB material. The supports this time will be soldered to the copper layer on the back.

Mike

|

Re: Is a heat spreader really necessary December 21, 2014 02:23PM |

Registered: 10 years ago Posts: 172 |

Sorry, only registered users may post in this forum.