how much weight can a prusa i3 x carriage handle?

Posted by lunarkingdom

|

how much weight can a prusa i3 x carriage handle? March 29, 2015 11:45PM |

Registered: 9 years ago Posts: 182 |

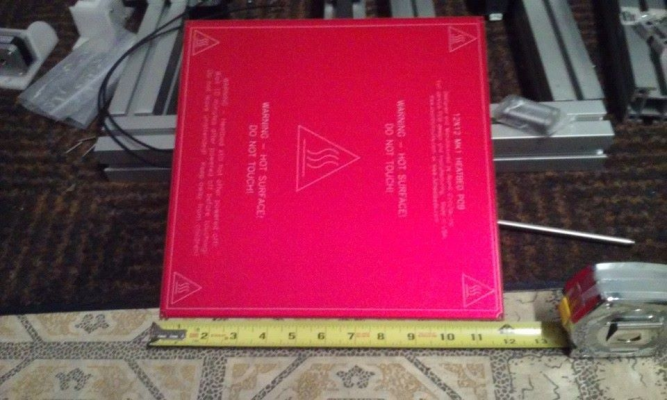

I am currently building a prusa i3 scale up with a 12 inch (300mm) hot bed, for rigidity I am looking at 2 pieces of 1/4 inch aluminum that are 12" x 14" to allow for the 3 point leveling system. My current setup uses .175 inch thick aluminum and it is warped/warping from the 4 point leveling system and the even thinner retainer plate that screws to the bearing blocks. My new build is using the same 8mm rod and bearing blocks and a nema 17 with a 20 tooth pully to move it back and forth.

Edited 1 time(s). Last edit at 03/29/2015 11:48PM by lunarkingdom.

Edited 1 time(s). Last edit at 03/29/2015 11:48PM by lunarkingdom.

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 04:10AM |

Registered: 9 years ago Posts: 1,011 |

Your picture does not looks like a Prusa i3, it's something else. Appreciate engineering is not scalable as wanted. If downscale makes no problem for well engineered machines, upscale is often a bad idea, except maybe if you stay around 5-10% of the original scale. The Prusa I3 Xcarriage flexes already a bit too much for a 200mm print bed with 8mm rods. You will need to overscale the rods anyways.

Don't think a machine as a design you can scale with a copy machine. It's not a wood crate. As dimension grows, everything from the first bolt to the last bearing must gain somewhere (stifness, strenght, torque, precision...). That includes parts cutting and assembly too. You may think a 40mm aluminium profile is two times better than a 20mm one. But a 400mm long 40mm profile may flex more than a 200mm long 20mm profile ! If a 200200mm machine works with 8mm rods, that same rods may not be enough if they are only 20% longer. You may think too a 300mm printbed is only 50% larger than 200mm, right ? But the printing surface is 2.25 times bigger ! Who cares about X carriage's load if the structure is not straight and/or stiff enough, the bed too heavy, and the plastic parts not precise enough ?

Appreciate that engineering a machine needs advanced calculations. That takes time, and maybe kind reprapers here don't have the time to do the calculations for you. If you're not skilled enough to calculate what's the maximum admissible load for a carriage for a 0.1mm layer, please don't play the sorcerer's apprentice. Don't try to build a machine prototype, buy a kit or get some skills. Or your can build a machine that can't work properly and loose time and money.

Edited 2 time(s). Last edit at 03/30/2015 04:14AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Don't think a machine as a design you can scale with a copy machine. It's not a wood crate. As dimension grows, everything from the first bolt to the last bearing must gain somewhere (stifness, strenght, torque, precision...). That includes parts cutting and assembly too. You may think a 40mm aluminium profile is two times better than a 20mm one. But a 400mm long 40mm profile may flex more than a 200mm long 20mm profile ! If a 200200mm machine works with 8mm rods, that same rods may not be enough if they are only 20% longer. You may think too a 300mm printbed is only 50% larger than 200mm, right ? But the printing surface is 2.25 times bigger ! Who cares about X carriage's load if the structure is not straight and/or stiff enough, the bed too heavy, and the plastic parts not precise enough ?

Appreciate that engineering a machine needs advanced calculations. That takes time, and maybe kind reprapers here don't have the time to do the calculations for you. If you're not skilled enough to calculate what's the maximum admissible load for a carriage for a 0.1mm layer, please don't play the sorcerer's apprentice. Don't try to build a machine prototype, buy a kit or get some skills. Or your can build a machine that can't work properly and loose time and money.

Edited 2 time(s). Last edit at 03/30/2015 04:14AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 09:29AM |

Registered: 9 years ago Posts: 182 |

Edited for offense taken where it was not meant to be.

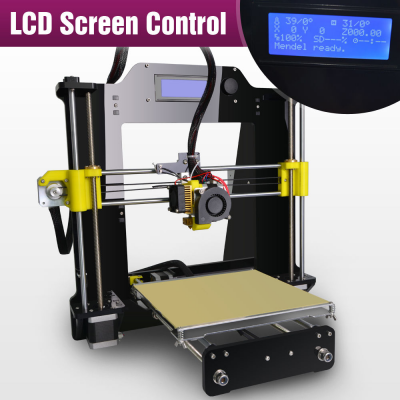

This is the prusa i3 that I previously bought, if you look at it I am building the same thing with an overbuilt frame for rigidity, the prusa i3 I bought is slowly falling apart because it has a frame made out of lexan.

Ultimately, the only thing in the picture in my first post that I do not consider to be upgradable is the frame, it is the maximum size I can fit in the area I have designated for my printer, the rest however can be improved if it needs to be.

Edited 1 time(s). Last edit at 03/30/2015 09:35PM by lunarkingdom.

This is the prusa i3 that I previously bought, if you look at it I am building the same thing with an overbuilt frame for rigidity, the prusa i3 I bought is slowly falling apart because it has a frame made out of lexan.

Ultimately, the only thing in the picture in my first post that I do not consider to be upgradable is the frame, it is the maximum size I can fit in the area I have designated for my printer, the rest however can be improved if it needs to be.

Edited 1 time(s). Last edit at 03/30/2015 09:35PM by lunarkingdom.

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 09:33AM |

Registered: 9 years ago Posts: 182 |

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 10:36AM |

Registered: 10 years ago Posts: 814 |

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 11:17AM |

Registered: 9 years ago Posts: 977 |

The message that Zavashier was trying to convey is that the Prusa i3 design is not easily up-scalable by more than a few percent along each axis, beyond that you'll need to recalculate and redesign the printer in part or as a whole, something that apparently you already got started on.

Now, I can see that you have already assembled an X-axis with longer 8mm rods, and your question about how much weight the x-carriage can handle is probably related to your intuition that the rods will flex in the middle and the carriage will not move parallel to the heatbed.

You have two ways to work out this problem, one is to calculate everything and the other is to simply measure the flex you have with and without a carriage weight of around 400g (the usual weight of a print head with the stepper). Tie a pen to your X-carriage, support your X-axis on both sides and simply slide it from end to end over a sheet of paper, that will already give you a good idea of how much your rods are flexing and whether they are adequate for your printer design or not.

Now, I can see that you have already assembled an X-axis with longer 8mm rods, and your question about how much weight the x-carriage can handle is probably related to your intuition that the rods will flex in the middle and the carriage will not move parallel to the heatbed.

You have two ways to work out this problem, one is to calculate everything and the other is to simply measure the flex you have with and without a carriage weight of around 400g (the usual weight of a print head with the stepper). Tie a pen to your X-carriage, support your X-axis on both sides and simply slide it from end to end over a sheet of paper, that will already give you a good idea of how much your rods are flexing and whether they are adequate for your printer design or not.

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 11:28AM |

Registered: 9 years ago Posts: 182 |

That is good advice, I do have linear rails and bearing blocks available from my workplace, my boss offered to kick me down some that are an older style they do not use any more if I need them which is cool. My only concern was that a nema 17 might not be able to move the extra friction as fast and I might have to upgrade what motors I am using so that is why I am using the 8mm rods first. I guess I will just build it the way I wanted to initially and upgrade the rods to linear rails if there is any sagging. Any suggestions on stronger motors that can successfully run on a ramps 1.4 platform to move the extra mass if needed would be appreciated.

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 12:23PM |

Registered: 9 years ago Posts: 1,011 |

Appreciate english is not my mother tongue. I appologize if what I wrote sounds harder to your ears than what I wanted to say. Please take what I wrote as some wise advices, even if it's not what you expected. Maybe this will help you to get me right. I note you have a long experience of prototyping. It's good obviously. The questions you asked let me know you still need to get some skills. That's what my message was all about. What I see, is someone who try to experiment a new machine (I mean something new even if it's based on a prusa i3 or any carthesian printer), and who don't have actualy enough skills to succeed. And I tryed to let you know. You're very confident and determined, it's ok. But as I see you already cut your frame before knowing exactly the load of what will be inside, I get affraid. You want to engineer the machine before to start, to don't have questions to ask on the fly.

I'm an engineer and since I was graduated, I engineer machines as a living. Everything is not scalable in the way each components reach quickly its limits. I try to explain it kindly. When you engineer a machine, your calculation leads you to the right component. You don't want to select a component that fits extra functionnality, because you don't need that, and because of the cost of course ! You select the right component, neither too much nor too little, with just a 10% margin to prevent any bad surprise. That's why an engineered machine is something fixed, it's not scalable at all.

I don't treat you like a kid. I will even take some time to explain you why physicaly a prusa i3 X is not scalable. I whish this will help you. Take for example the original prusa i3. A 8x320mm rod flexion is 0,05mm at it's centre with a dynamic load of 0.2N at it's centre. (Please note we're not talking about weight, but about force) You surely agree that value of flexion is not suitable to a machine meant to print 0.1mm layers. That's probably why rework versions of the prusa i3 uses now 10mm guides (wich is still not enough IMHO, the good diameter for a 200mm bed shoud be 12mm). Now, let's play with numbers and calculate the flexion of the same 8mm rod, with the same load and a lenght of 400mm. Now the flexion is 0.1mm ! For 80 little millimeters the flexion doubles. As you can see, you'd rather not upscale the X axis of a prusa i3. You will need to upgrade the guides to a larger diameter. That means redesign new carriage, new Xends, check transmission and check anything above the X axis, especialy the Z motion. QED

As you can see, upscaling a machine realy means engineering a new machine, wich is a full time job for weeks ! IMHO it overtakes the help you can get from a forum. You will have loads of calculations, interacting with eachother, and the result will be far away from the initial machine. I did not underestimate you, neither despise you at all, don't get me wrong, but I estimate well the tasks. That's why I warned you. Don't think I don't want to help you, or I won't spend my time to write here.

If someone is able to awnser the question "how much weight can a prusa i3 x carriage handle?" you should not listen, because the question have no sense at this point. It have no sense because it goes backwards and have no realationship whith the whole machine. What if the admissible dynamic load does only allows you to use a 15g nozzle without any wiring ? (actualy, it's not that far from reality) Will you transform your $1000 printer to a pen plotter ? I hope you won't be entraped by your previous choices, and I hope there's nothing you already bought which will be as costly as useless. If you want to succeed, you should take attention to the following, and go back to the (good) start. It's a friendly advice provided with care.

A machine awnsers a need. The need is to print with 2 hotends on a 12x12x12" surface ? Fine ! You want to start from the function, then add what's needed for the function to work right. So start from the nozzles. What's their weight ? What do you need around to make them work properly ? Don't forget the wiring, and you will know what's the weight and the size of your carriage. So you can calculate the dynamic load. NOW you can start to think about your Xaxis. (note it's exaclty the oposite of what you did) What rails/structure will you need to move you carriage on a straight line ? What will be the weight and size ? What will you need to hold them ? What will you need to move them ? And so on until the power cord...

I hope you appreciate better than the first time. Good luck, sincerely.

Good luck, sincerely.

Edited 5 time(s). Last edit at 03/30/2015 12:34PM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

I'm an engineer and since I was graduated, I engineer machines as a living. Everything is not scalable in the way each components reach quickly its limits. I try to explain it kindly. When you engineer a machine, your calculation leads you to the right component. You don't want to select a component that fits extra functionnality, because you don't need that, and because of the cost of course ! You select the right component, neither too much nor too little, with just a 10% margin to prevent any bad surprise. That's why an engineered machine is something fixed, it's not scalable at all.

I don't treat you like a kid. I will even take some time to explain you why physicaly a prusa i3 X is not scalable. I whish this will help you. Take for example the original prusa i3. A 8x320mm rod flexion is 0,05mm at it's centre with a dynamic load of 0.2N at it's centre. (Please note we're not talking about weight, but about force) You surely agree that value of flexion is not suitable to a machine meant to print 0.1mm layers. That's probably why rework versions of the prusa i3 uses now 10mm guides (wich is still not enough IMHO, the good diameter for a 200mm bed shoud be 12mm). Now, let's play with numbers and calculate the flexion of the same 8mm rod, with the same load and a lenght of 400mm. Now the flexion is 0.1mm ! For 80 little millimeters the flexion doubles. As you can see, you'd rather not upscale the X axis of a prusa i3. You will need to upgrade the guides to a larger diameter. That means redesign new carriage, new Xends, check transmission and check anything above the X axis, especialy the Z motion. QED

As you can see, upscaling a machine realy means engineering a new machine, wich is a full time job for weeks ! IMHO it overtakes the help you can get from a forum. You will have loads of calculations, interacting with eachother, and the result will be far away from the initial machine. I did not underestimate you, neither despise you at all, don't get me wrong, but I estimate well the tasks. That's why I warned you. Don't think I don't want to help you, or I won't spend my time to write here.

If someone is able to awnser the question "how much weight can a prusa i3 x carriage handle?" you should not listen, because the question have no sense at this point. It have no sense because it goes backwards and have no realationship whith the whole machine. What if the admissible dynamic load does only allows you to use a 15g nozzle without any wiring ? (actualy, it's not that far from reality) Will you transform your $1000 printer to a pen plotter ? I hope you won't be entraped by your previous choices, and I hope there's nothing you already bought which will be as costly as useless. If you want to succeed, you should take attention to the following, and go back to the (good) start. It's a friendly advice provided with care.

A machine awnsers a need. The need is to print with 2 hotends on a 12x12x12" surface ? Fine ! You want to start from the function, then add what's needed for the function to work right. So start from the nozzles. What's their weight ? What do you need around to make them work properly ? Don't forget the wiring, and you will know what's the weight and the size of your carriage. So you can calculate the dynamic load. NOW you can start to think about your Xaxis. (note it's exaclty the oposite of what you did) What rails/structure will you need to move you carriage on a straight line ? What will be the weight and size ? What will you need to hold them ? What will you need to move them ? And so on until the power cord...

I hope you appreciate better than the first time.

Good luck, sincerely.

Good luck, sincerely.Edited 5 time(s). Last edit at 03/30/2015 12:34PM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 01:37PM |

Registered: 9 years ago Posts: 182 |

Zavashier,

Thank you for clarifying, your choice of words in your earlier post make better sense knowing English is not your first spoken language, I apologize for taking offense. My goal is to have a 12x12x12 inch print area with one hot end. I achieve very good results printing with my current machine with a .4mm nozzle and the frame is as flimsy as cardboard, thus starting with a 500mm square extrusion frame, the rest can evolve into whatever it takes to get me printing. Thank you for the fact filled post, it helps!

Edited 1 time(s). Last edit at 03/30/2015 01:38PM by lunarkingdom.

Thank you for clarifying, your choice of words in your earlier post make better sense knowing English is not your first spoken language, I apologize for taking offense. My goal is to have a 12x12x12 inch print area with one hot end. I achieve very good results printing with my current machine with a .4mm nozzle and the frame is as flimsy as cardboard, thus starting with a 500mm square extrusion frame, the rest can evolve into whatever it takes to get me printing. Thank you for the fact filled post, it helps!

Edited 1 time(s). Last edit at 03/30/2015 01:38PM by lunarkingdom.

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 02:28PM |

Registered: 9 years ago Posts: 977 |

Apart from the mechanical design of your printer, you can take a look at this post in the Developers forum about other things you'll have to worry about:

Elements of 3D Printer Design

Elements of 3D Printer Design

|

Re: how much weight can a prusa i3 x carriage handle? March 30, 2015 09:27PM |

Registered: 9 years ago Posts: 182 |

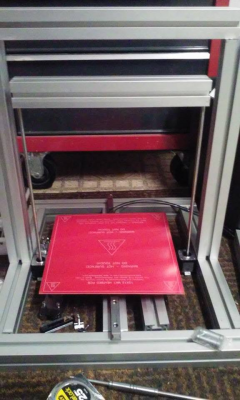

new (to me) parts:

data pdf for R1622 814 20:

[www.cmafh.com]

Edited 1 time(s). Last edit at 03/31/2015 12:13AM by lunarkingdom.

data pdf for R1622 814 20:

[www.cmafh.com]

Edited 1 time(s). Last edit at 03/31/2015 12:13AM by lunarkingdom.

|

Re: how much weight can a prusa i3 x carriage handle? March 31, 2015 06:30AM |

Registered: 9 years ago Posts: 1,011 |

That Bosch/Rexroth linear rail system is a good component. It will be very useful for your build. Is it the 15 or 20mm rail size ? How many of them do you have ?

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: how much weight can a prusa i3 x carriage handle? March 31, 2015 08:55AM |

Registered: 12 years ago Posts: 2,470 |

While the Bosch Rexroth rail systems are very neat and precise, they are also heavy. For the sled you can expect a mass of 350g that you have to move additionally to the heatbed and all mounting parts. This will lower achievable acceleration.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: how much weight can a prusa i3 x carriage handle? March 31, 2015 09:24AM |

Registered: 9 years ago Posts: 1,011 |

True, but on larger print areas, for many reasons (described above) you can't stay as light as you wish. I asked for the rails size to have informations on its weight. The best technique is still to do calculations then select the best possible component in weight and function. But maybe it could make an useful for a X carriage in a CoreXY environment for example.

Edited 1 time(s). Last edit at 03/31/2015 09:37AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Edited 1 time(s). Last edit at 03/31/2015 09:37AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: how much weight can a prusa i3 x carriage handle? March 31, 2015 09:58AM |

Registered: 9 years ago Posts: 182 |

|

Re: how much weight can a prusa i3 x carriage handle? March 31, 2015 07:46PM |

Registered: 9 years ago Posts: 182 |

|

Re: how much weight can a prusa i3 x carriage handle? April 02, 2015 12:12AM |

Registered: 9 years ago Posts: 182 |

Edited 1 time(s). Last edit at 04/02/2015 12:13AM by lunarkingdom.

Sorry, only registered users may post in this forum.