Hotbed flatness, voodoo or scientific method?

Posted by lunarkingdom

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 01:36AM |

Registered: 11 years ago Posts: 5,780 |

Quote

thetazzbot

so what i have is one static screw with a spacer in one corner, and three adjusters in the remaining corners.

When you adjust the screw diagonally opposite the spacer, what do you think the bed is going to do? If the corner with the spacer were free to move, the bed plate would pivot about the other diagonal. Since you have fixed the corner with a spacer, instead of pivoting about the other diagonal, the plate will bend about that diagonal. How can you level the bed by bending it? This is why using four screws to level the bed is a bad idea- it makes no sense and it requires a lot of screwing around to make it only sort-of work.

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 02:23AM |

Registered: 11 years ago Posts: 1,277 |

I said two I meant three or more specifically that plane geometry states "Any three noncollinear points can define a plane (that is if ALL three points TOGETHER are noncollinear)".Quote

the_digital_dentist

I challenge you to draw two points such that I cannot draw a straight line between them.

Quote

A plane can be defined by four different methods:

A line and a point not on the line

Three non-collinear points (three points not on a line)

A point and a normal vector

Two intersecting lines

Two parallel and non-coincident lines

I changed my wording above as I am still a little bit not sure of the 3 points must be non collinear thing but does that mean all three or does that mean any of the 3 points? Remember this is 2d for a plane of infinite size so that is what tricks me up all the time.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 02:29AM |

Registered: 11 years ago Posts: 1,277 |

Agreed, but I still do not get how my bed can be almost dead flat (within a few microns up against a speed square, a composite square, and a laser/digital level flat part) but that one corner droops when on the bed. Take it off and it is flat with the rest of the corners. With four screws I can see what I was doing because I saw that in the home position and made it level but the opposing side would then droop and when I raised that up it made my bed all sorts of warpped. With three screws I do not have that problem but that home position, being in free space, is left there drooping with no way to level it it up. I wonder why it is drooping when only on the bed? My boro glass, over just the MK2B, did the same exact thing. So, even with a 6mm hunk of metal on top it is still going to droop I think.Quote

the_digital_dentist

Quote

thetazzbot

so what i have is one static screw with a spacer in one corner, and three adjusters in the remaining corners.

When you adjust the screw diagonally opposite the spacer, what do you think the bed is going to do? If the corner with the spacer were free to move, the bed plate would pivot about the other diagonal. Since you have fixed the corner with a spacer, instead of pivoting about the other diagonal, the plate will bend about that diagonal. How can you level the bed by bending it? This is why using four screws to level the bed is a bad idea- it makes no sense and it requires a lot of screwing around to make it only sort-of work.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 03:46AM |

Registered: 10 years ago Posts: 175 |

Hi,

Don't read the whole post(sorry)

We just started building our 18the printer(most of them for friends). Almost all are i2 models. Almost all of them use a glass surface(4mm) on top of the heatbed.

Don't know about other countries, but our glass is pretty flat. (Belgium, glass is from Saint-Gobin, France)

The only thing we do is clean and degrease the glass surface using glasscleaner(I'll take it off the printer of course), sticks like hell. I myself use multiple glass sheets because it takes to long for the parts to come of the glass. So while it's cooling, next part is already printing. After about 15 to 20 minutes parts just pop off the glass.

And BTW our printers work just fine, gives good quality prints, no warping at all(even large prints) and cost about 400€ to build.

My very first i2 was assembled exactly 2 years ago, prints every single day, still doing it's job, no changes have been made, nor replacements were needed.

Chris

Don't read the whole post(sorry)

We just started building our 18the printer(most of them for friends). Almost all are i2 models. Almost all of them use a glass surface(4mm) on top of the heatbed.

Don't know about other countries, but our glass is pretty flat. (Belgium, glass is from Saint-Gobin, France)

The only thing we do is clean and degrease the glass surface using glasscleaner(I'll take it off the printer of course), sticks like hell. I myself use multiple glass sheets because it takes to long for the parts to come of the glass. So while it's cooling, next part is already printing. After about 15 to 20 minutes parts just pop off the glass.

And BTW our printers work just fine, gives good quality prints, no warping at all(even large prints) and cost about 400€ to build.

My very first i2 was assembled exactly 2 years ago, prints every single day, still doing it's job, no changes have been made, nor replacements were needed.

Chris

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 04:35AM |

Registered: 11 years ago Posts: 1,277 |

Nice, but not revelant to this discussion though.Quote

chriske

Hi,

Don't read the whole post(sorry)

We just started building our 18the printer(most of them for friends). Almost all are i2 models. Almost all of them use a glass surface(4mm) on top of the heatbed.

Don't know about other countries, but our glass is pretty flat. (Belgium, glass is from Saint-Gobin, France)

The only thing we do is clean and degrease the glass surface using glasscleaner(I'll take it off the printer of course), sticks like hell. I myself use multiple glass sheets because it takes to long for the parts to come of the glass. So while it's cooling, next part is already printing. After about 15 to 20 minutes parts just pop off the glass.

And BTW our printers work just fine, gives good quality prints, no warping at all(even large prints) and cost about 400€ to build.

My very first i2 was assembled exactly 2 years ago, prints every single day, still doing it's job, no changes have been made, nor replacements were needed.

Chris

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 06:58AM |

Registered: 10 years ago Posts: 175 |

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 07:05AM |

Registered: 11 years ago Posts: 1,277 |

Well, it pertains but didn't say how you managed it. I have an I3 Rework from hell as not a soul can figure out wth is wrong with it so I can't even make it flat with 3 screws instead of 4. It isn't the boro glass nor the heat spreader it is something weird. [edit: So, in my case it would be Voodoo to make it flat as it is already cursed.]Quote

chriske

Oops...!

I thought it was all about hotbed flatness..?

Hmm.. I should have posted just the first three lines.

Chris

Edited 1 time(s). Last edit at 07/02/2015 07:08AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 09:39AM |

Registered: 9 years ago Posts: 396 |

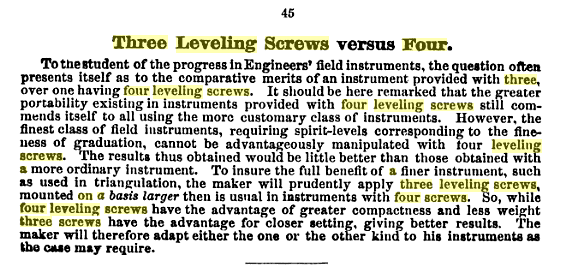

It is not illogical to have four leveling screws vs three. Although it is agreed that three give a finer adjustment.

From "Engineering Surveying & Mining Instruments

By C. L. Berger & Sons"

Survey levels come in three and four screw varieties.

Bed leveling procedure for three level screws

As for my configuration, where I have one corner tied down, it doesn't give me any headaches. i level it in clockwise order and i do it twice (edit: I think I might change this approach). i don't have to repeat the procedure unless i change something hardware-wise. I have ensured the bars are paralel and perpendicular. So, yeah, while some may dispute the arrangement, it is good enough for me. I could drill a hole for a 3 screw arrangement. Since I have not used that setup yet, I can't compare the effort/results.

Edited 3 time(s). Last edit at 07/02/2015 09:47AM by thetazzbot.

From "Engineering Surveying & Mining Instruments

By C. L. Berger & Sons"

Survey levels come in three and four screw varieties.

Bed leveling procedure for three level screws

As for my configuration, where I have one corner tied down, it doesn't give me any headaches. i level it in clockwise order and i do it twice (edit: I think I might change this approach). i don't have to repeat the procedure unless i change something hardware-wise. I have ensured the bars are paralel and perpendicular. So, yeah, while some may dispute the arrangement, it is good enough for me. I could drill a hole for a 3 screw arrangement. Since I have not used that setup yet, I can't compare the effort/results.

Edited 3 time(s). Last edit at 07/02/2015 09:47AM by thetazzbot.

|

Re: Hotbed flatness, voodoo or scientific method? July 03, 2015 02:25AM |

Registered: 11 years ago Posts: 1,277 |

I had a long thing here but removed as I found out nothing I thought was right.

I worked on it some more and it is still bad. Since I am getting Frog plate rock that has to go for sure. I will not touch the machine anymore until I replace that frog plate and the horrible rock but I am so afraid that rock is due to a piss poor Prusa design of having those bearings so close together. If this next purchase of 40 dollars doesn't help I am done and will save up for something else that is not a Prusa. I hate to say it but I am seriously starting to think this is where it is headed. wasted time and money. *shrug*

Edited 3 time(s). Last edit at 07/03/2015 05:48AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

I worked on it some more and it is still bad. Since I am getting Frog plate rock that has to go for sure. I will not touch the machine anymore until I replace that frog plate and the horrible rock but I am so afraid that rock is due to a piss poor Prusa design of having those bearings so close together. If this next purchase of 40 dollars doesn't help I am done and will save up for something else that is not a Prusa. I hate to say it but I am seriously starting to think this is where it is headed. wasted time and money. *shrug*

Edited 3 time(s). Last edit at 07/03/2015 05:48AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 03, 2015 09:59AM |

Registered: 11 years ago Posts: 5,780 |

Quote

thetazzbot

It is not illogical to have four leveling screws vs three. Although it is agreed that three give a finer adjustment.

The number of screws isn't the whole story. The surveying instruments your quote refers to were most likely very rigid assemblies (every surveying transit I've even seen was), and the way the four screws were attached and how they adjusted the height of the 4 support points was probably quite different from your large, flexible print bed. Anchoring one corner instead of allowing it to float on a spring/screw almost guarantees that the bed will have to bend at that point if not along the opposite diagonal. It may be "good enough", but that doesn't make it "good". Anchoring one corner is saying "this is the Z=0 height of the bed". If it isn't level at that height the bed will have to bend because you're going to force it to be level by adjusting the other screws to different Z positions.

I believe the proper way to level a 4 point suspension is to level the diagonals, first one, then the other. You use the fact that the plate will tilt along the diagonals to level it, instead of trying to force it to bend along the diagonals. This assumes, of course, that all four points can move, and the plate is rigid. I'm not sure there is a proper way to level a four point system when one point is held fixed, so your method is probably as good (or bad) as any other.

You may consider this a small matter, as are many of the compromises (and design errors) made to make printers very inexpensive. Each compromise, no matter how small, impacts the overall reliability of the machine. It's a simple probability calculation. Let's say the Z screws use threaded rods which work "most of the time" and only occasionally cause binding that ruins a print. Maybe 95% of the time they work OK. Now lets say your bed is flat enough and the leveling scheme works (i.e. you successfully get prints to stick through completion) 95% of the time. Now let's include the "reliability" of a computer connection between a host computer and the printer- let's say it works right 95% of the time. Now let's add in the reliability of the filament supply and call it 95%. Now let's include the reliability of the extruder- call it 95% (it jams once in a while). All these seem like great numbers. The machine is going to deliver a good print 95% of the time, right? Wrong. You have to multiply the reliability of each factor to get to the overall reliability (probability of success). 0.95 x 0.95 x 0.95 x 0.95 x 0.95 x 0.95 = 0.735 Now start factoring in all the other compromises and you see why cheap printers require so much attention. The extra attention is required to try to eliminate the uncertainties and push the probability of a successful print up. You weigh the filament spool before you start a print- that will push probability of the filament supply up from 95% to maybe 99.9% (the filament can still tangle on the spool), you carefully clean, level, and zero the bed before each print, etc.

Of course these numbers are not entirely realistic. I use them merely as examples to demonstrate how even apparently high reliability of individual components can quickly turn into low overall reliability in a complex system/process like 3D printing. That is why attention to detail matters. If you can raise the probability of success in a few factors, you can dramatically increase the overall probability of printing success. You may do that each time you run a print, or you can try to increase the probability of success at the hardware level so that you don't have to do so much tweaking at the start of each print. Print from SD cards instead of host software and reliability goes up. Use rigid construction and lead screws driven by a single motor in the Z axis and reliability goes up. Use a quality extruder/hot end and reliability goes up.

A print that runs to completion but looks bad isn't really a successful print. If you include print quality in your definition of success, there are a lot of additional factors to include in the calculation of overall reliability. I can't think of anything you could do to improve reliability that would have a negative impact on print quality, but many of the things that improve reliability also improve print quality. Rigid frame construction, fully supported rails, quality bearings, all contribute to the probability of completion and quality of prints.

Edited 1 time(s). Last edit at 07/03/2015 09:59AM by the_digital_dentist.

|

Re: Hotbed flatness, voodoo or scientific method? July 03, 2015 04:05PM |

Registered: 9 years ago Posts: 396 |

All great points. Last night i had the bed disassembled to see if i could get a hole in the left side but no go. Not enough room.

I still have the one corner static and set z there yes then adjust diagonals. I checked with a straight edge and its flat.

sample print

Have a wierd banding issue... But anyway lots of good info in this thread. Im not expecting perfection from this printer. Need to finish my kossel amd get started on the overkill project

I still have the one corner static and set z there yes then adjust diagonals. I checked with a straight edge and its flat.

sample print

Have a wierd banding issue... But anyway lots of good info in this thread. Im not expecting perfection from this printer. Need to finish my kossel amd get started on the overkill project

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 01:01PM |

Registered: 11 years ago Posts: 1,277 |

Alright my new Y frame arrived and I was able to do a lot of measuring that I could not before and I am stumped and I need some help here or suggestions.

3/4 inch plywood base top to the stationary screw spot on the bottom of the new Y frame (btw, I love the pillow blocks) is the same distance as is the droopy side with no screw. From the top of the new Y frame to the bottom of the HPB+heatspreader is the same distance as the droopy side. So, nozzle gap at the screw that never gets adjusted is 0.Xmm slide the Y toward me so the nozzle is now in the home position and the gap is now 0.Xmm-2.7mm HOW?!? I don't get how when the measurements of the distances are all the same how is it that side droops by 2.7mm at the nozzle and the oposite side is the same as well BUT the gap is 0.Xmm+0.4mm so it is up.

I am at a complete loss.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

3/4 inch plywood base top to the stationary screw spot on the bottom of the new Y frame (btw, I love the pillow blocks) is the same distance as is the droopy side with no screw. From the top of the new Y frame to the bottom of the HPB+heatspreader is the same distance as the droopy side. So, nozzle gap at the screw that never gets adjusted is 0.Xmm slide the Y toward me so the nozzle is now in the home position and the gap is now 0.Xmm-2.7mm HOW?!? I don't get how when the measurements of the distances are all the same how is it that side droops by 2.7mm at the nozzle and the oposite side is the same as well BUT the gap is 0.Xmm+0.4mm so it is up.

I am at a complete loss.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 02:06PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 02:24PM |

Registered: 11 years ago Posts: 1,277 |

Yeah, I hate these two motor setups as it makes it a PITA, at least for me, to get everything right. What I did was measure from the plywood bed to the bottom 8mm smooth rod on X on each side with my digital calipers. A (upper left corner),B (home/upper right corner), C (lower left corner) and D (lower right corner) if D is 13mm distance and B is 13mm distance shouldn't the top of the bed be level and not drooping? I just now got so mad that I put a screw, and a spring, on the droopy side to ever so slightly raise it and on a cold bed everything seems to be in tight tolerance but on a hot bed I have no idea and it is so hot in there (86-90f) I am not going to heat it up right now. So hot my brand new LED 117vac Bulb went POP and was too hot to touch (LED bulbs are still not read for primetime imo but that is a completely different topic).

Wouldn't it seem that B shouldn't be drooping as far as the nozzle is concerned?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Wouldn't it seem that B shouldn't be drooping as far as the nozzle is concerned?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:06PM |

Registered: 9 years ago Posts: 396 |

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:09PM |

Registered: 9 years ago Posts: 396 |

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:14PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:17PM |

Registered: 9 years ago Posts: 396 |

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:27PM |

Registered: 11 years ago Posts: 1,277 |

If I could plus one you I would.Quote

thetazzbot

But i have to tell ya im so fed up with this i3 im about to dismantle it coompletely. Start over with something that delivers more prints than headaches.

I wanted to do the p3 steel since I don't need anything but a true frame but it really is a Spain only. Had this since Feb 2014 and very little time actually printing as most of my time has been spent fixing issues. This one has me completely stumped though. If I build one it will be a Cartesian and done with V-Slot and V-Wheels but I sure would like this one up and running before I run off to have a whole new set of issues. Time and money involved but I want to understand now.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:29PM |

Registered: 11 years ago Posts: 1,277 |

I am not understanding what you mean.Quote

JamesK

From what you describe it sounds like your smooth rods are not parallel. If you measure directly over one of the rods do you find a much smaller difference?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:38PM |

Registered: 9 years ago Posts: 1,873 |

Try doing the same test of setting Z0 at the front of the bed and then comparing with the back, but position the print head directly above one of the two smooth rods instead of out at the corner. If there is minimal difference between front/back when over the rod, and a greater difference when measuring away from the rod it will confirm that the problem is with the geometry of the rods, with the bed rotating and twisting as it moves front to back. I'm guessing you went for three bearings instead of four? A four bearing arrangement would be more likely to bind in this scenario, but a three bearing setup could have enough play to twist. Of course I may have just misunderstood what you are measuring, in which case some annotated photos might help clarify things.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:43PM |

Registered: 11 years ago Posts: 1,277 |

How do I position the print head/nozzle above one of the two smooth rods? in case you do not know this is an I3 Rework that I have so a variant of the I3.Quote

JamesK

Try doing the same test of setting Z0 at the front of the bed and then comparing with the back, but position the print head directly above one of the two smooth rods instead of out at the corner. If there is minimal difference between front/back when over the rod, and a greater difference when measuring away from the rod it will confirm that the problem is with the geometry of the rods, with the bed rotating and twisting as it moves front to back. I'm guessing you went for three bearings instead of four? A four bearing arrangement would be more likely to bind in this scenario, but a three bearing setup could have enough play to twist. Of course I may have just misunderstood what you are measuring, in which case some annotated photos might help clarify things.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:47PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 03:58PM |

Registered: 11 years ago Posts: 1,277 |

Oh, so it is directly over the Y smooth rod?

See it is the two back corners that are wonky but not really. left side is slightly up and right side is 3 times more down than the left corner is up. I have always seen this but not until I went to a 3 point leveling system did I see it wasn't my turning the leveling screws wrong since there are no leveling screws back there just the third one in the middle of the two wonky back corners.

btw, I could have sworn I posted a picture to help but I do not see it now. Let me get something up to clarify.

Let me get something up to clarify.

Edited 2 time(s). Last edit at 07/14/2015 04:04PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

See it is the two back corners that are wonky but not really. left side is slightly up and right side is 3 times more down than the left corner is up. I have always seen this but not until I went to a 3 point leveling system did I see it wasn't my turning the leveling screws wrong since there are no leveling screws back there just the third one in the middle of the two wonky back corners.

btw, I could have sworn I posted a picture to help but I do not see it now.

Let me get something up to clarify.

Let me get something up to clarify.Edited 2 time(s). Last edit at 07/14/2015 04:04PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 04:06PM |

Registered: 9 years ago Posts: 1,873 |

Right. The only way I can think of that that can happen is if one of the rods is slanted front to back more than the other, so that as the bed comes forward one corner is forced up and the other down. With the I3 having the rods quite close together it only takes a small error to create a fairly big difference when magnified out to the corners of the bed. I put my rods further apart to try and avoid that class of problems. One day I might find out if it worked or not...

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 04:09PM |

Registered: 11 years ago Posts: 1,277 |

This is how my bed is set up in that orientation. S1 is at the back of the bed and S2/S3 are at the front towards me. Home is P3 and as far as the nozzle is concerned it is drooping. P4 is slightly up but when actually measured they are all 0.03-0.04mm differences between the spacing so isn't really drooping. Now when I measured all of the gaps I measured them with the bed pulled all the way forward hitting the endstop so the nozzle was at home. So, the nozzle says drooping away from me and the caliper says no way.

edit: Yes, 3 bearings.

Edited 2 time(s). Last edit at 07/14/2015 04:11PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

edit: Yes, 3 bearings.

Edited 2 time(s). Last edit at 07/14/2015 04:11PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 09:20PM |

Registered: 9 years ago Posts: 1,873 |

OK, so I'm a bit confused now. If you're down to .03 to .04 mm differences then that sounds pretty close and you should be able to adjust it out with the screws. In the above you said all the measurements were with the bed moved forward. Before I thought we were talking about differences when you moved the bed from one extreme to the other, and of about 2.7mm?

Perhaps you could take us through the steps one by one of what you are doing, with a photo of each step showing what's happening?

Perhaps you could take us through the steps one by one of what you are doing, with a photo of each step showing what's happening?

|

Re: Hotbed flatness, voodoo or scientific method? July 14, 2015 10:06PM |

Registered: 11 years ago Posts: 1,277 |

Nope no photos but, as I have said, I move the bed away from me and the nozzle is over the area marked S3. Lower the nozzle and use a feeler gauge. Now do the same on S4 now move to S1 and when all of those are within a decent range of each other slide the bed towards me (if it isn't already) and move the head/nozzle over to P3 and that corner is now +2.7mm from the nozzle then move the nozzle to P4 and it is about 0.03-0.04mm closer to the nozzle (might as well say it is touching). The thing is the bed is flat and while the nozzle and the bed, at those points, does change the gap from the base to the bottom of the bed doesn't and all of the gaps from the base to the bottom 4 corners are within a very acceptable range of each other.

So, with all of the gaps being, all things considering, of equal distance from the base (say the floor) how in the hell is the distance from the nozzle to P3 growing as it gets close to P3? It shrinks as it gets closer to P4 until it is so close it is pretty much touching the glass.

edit: Another thing is today I did the testing with the gt2 belt off so the pull of a motor had no effect AND I don't think it is gripping because I can push it and it just glides back and forth the easiest I have ever felt. It was already easy now with the pillow blocks it just makes it so much nicer. I did have to move the rods/legs because where they were (for the frog plate) was too tight for the new plate. I think I moved it out about .5mm each side front and back and boy does it glide now. Anyway I am just bring all of this up because I don't think there is any binding happening.

Edited 4 time(s). Last edit at 07/15/2015 01:04AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

So, with all of the gaps being, all things considering, of equal distance from the base (say the floor) how in the hell is the distance from the nozzle to P3 growing as it gets close to P3? It shrinks as it gets closer to P4 until it is so close it is pretty much touching the glass.

edit: Another thing is today I did the testing with the gt2 belt off so the pull of a motor had no effect AND I don't think it is gripping because I can push it and it just glides back and forth the easiest I have ever felt. It was already easy now with the pillow blocks it just makes it so much nicer. I did have to move the rods/legs because where they were (for the frog plate) was too tight for the new plate. I think I moved it out about .5mm each side front and back and boy does it glide now. Anyway I am just bring all of this up because I don't think there is any binding happening.

Edited 4 time(s). Last edit at 07/15/2015 01:04AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 15, 2015 03:33PM |

Registered: 11 years ago Posts: 1,277 |

I have now took the bed off and went back to 3 point leveling and with my digital calipers all 4 corners are about 21.6mm from the bottom of the Y plate to the top of the bed. This means all 4 corners are level to within .02mm-.03mm of each other. What should I do next as the bed is still off (I have elimated the possibility of the bed and Y plate being the culprit at least as far as the corners go the rest I have no idea)?

A sidenote about the SC8UU that I didn't know but inside a SC8UU is a plain LM8UU and it even says LM8UU on the bearing only it is held in place by a pinch ring. I love the holder and I wonder if I can just pop a new LM8UU in it if I remove that ring or better yet use a LM8UU bushing?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

A sidenote about the SC8UU that I didn't know but inside a SC8UU is a plain LM8UU and it even says LM8UU on the bearing only it is held in place by a pinch ring. I love the holder and I wonder if I can just pop a new LM8UU in it if I remove that ring or better yet use a LM8UU bushing?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 15, 2015 09:03PM |

Registered: 11 years ago Posts: 335 |

Sorry, only registered users may post in this forum.