Dont underestimate the importance of a stable table

Posted by thetazzbot

|

Dont underestimate the importance of a stable table June 30, 2015 02:09PM |

Registered: 9 years ago Posts: 396 |

This might sound crazy but...

My wife is out of town so I decided to set up temporary shop in the guest room. So i Moved my printer down stairs onto one of those folding tables.

I could not get a single decent print. I was so frustrated. But then i moved it back to my evil genius workshop that is a smaller room but i have a massive heavy table. I parked the printer there and it went back to printing beautifully again....

The only logical reason i could imagine is the shaking of the table causing crazy issues and skipping.

Yeah it sounds crazy even to me.

My wife is out of town so I decided to set up temporary shop in the guest room. So i Moved my printer down stairs onto one of those folding tables.

I could not get a single decent print. I was so frustrated. But then i moved it back to my evil genius workshop that is a smaller room but i have a massive heavy table. I parked the printer there and it went back to printing beautifully again....

The only logical reason i could imagine is the shaking of the table causing crazy issues and skipping.

Yeah it sounds crazy even to me.

|

Re: Dont underestimate the importance of a stable table June 30, 2015 03:33PM |

Registered: 10 years ago Posts: 770 |

|

Re: Dont underestimate the importance of a stable table June 30, 2015 05:23PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Dont underestimate the importance of a stable table June 30, 2015 06:54PM |

Registered: 9 years ago Posts: 396 |

Quote

the_digital_dentist

You're experiencing a symptom of a non-rigid printer frame. The same thing probably happens to a lesser degree even when the machine sits on a solid surface.

I shall address that

Yes, I am sure thats what it is...because it is a suck [expletive deleted] acrylic frame that I suckered myself into because I fell into the "I want to build a 3d printer, oh, here's one that looks cool" trap.

Yeah.... Wish I had known then what I know now.

I feel sorry for anyone building a Prusa i3 [acrylic frame variant] [edited].

Edited 1 time(s). Last edit at 06/30/2015 11:25PM by thetazzbot.

|

Re: Dont underestimate the importance of a stable table June 30, 2015 10:12PM |

Registered: 9 years ago Posts: 977 |

Quote

thetazzbot

...

I feel sorry for anyone building a Prusa i3.

Hmmm... that requires some clarifying, because there are so many variants of the Prusa i3 built with different materials and with vastly different component quality and engineering, and you probably built a low-quality one which was not correctly engineered for rigidity. Historically, I don't think Josef Prusa designed the Prusa i3 with "$uck a$$" acrylic (as you put it so eloquently) in mind.

The original Prusa i3 "boxframe" (see the wiki) which has the frame built from inexpensive rectangular pieces of MDF, provides a rather rigid frame that is good enough for excellent quality prints. If you want a slightly more engineered frame, you can use the Prusa i3 Twelvepro frame, which must be lasercut from 6mm plywood. And if you want a perfectly rigid, very well engineered frame, you can use a P3Steel frame, which again must be lasercut, but this time from 3mm structural steel.

As for a recommended table for a Prusa i3 or a linear delta, I am using a €7 (that's about $8.50) IKEA small table, it provides a very good base for the printer and I have designed a system where I have the ATX power supply suspended underneath the printer, and out of the way.

|

Re: Dont underestimate the importance of a stable table June 30, 2015 11:16PM |

Registered: 9 years ago Posts: 396 |

Like I said, I suckered myself. Didn't mean any disrespect to the RepRap godfather.

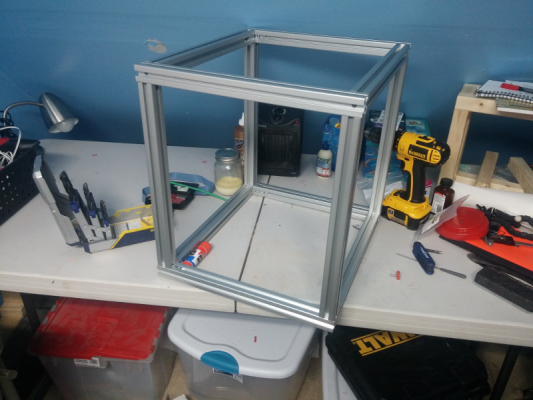

I like the "exo-skeletal" look of the printer, and it does in fact give me pretty darn good results just wish I hadn't gone the acrylic frame route (it is what I had accessible at the time). I have since then purchased rigid aluminum extrusion for a cube.

Besides, if it were easy, I wouldn't have learned anything...

Edited 2 time(s). Last edit at 06/30/2015 11:18PM by thetazzbot.

I like the "exo-skeletal" look of the printer, and it does in fact give me pretty darn good results just wish I hadn't gone the acrylic frame route (it is what I had accessible at the time). I have since then purchased rigid aluminum extrusion for a cube.

Besides, if it were easy, I wouldn't have learned anything...

Edited 2 time(s). Last edit at 06/30/2015 11:18PM by thetazzbot.

|

Re: Dont underestimate the importance of a stable table June 30, 2015 11:51PM |

Registered: 9 years ago Posts: 396 |

|

Re: Dont underestimate the importance of a stable table June 30, 2015 11:53PM |

Registered: 9 years ago Posts: 977 |

Well, I also mean no disrespect and I don't want to discourage you in your search for the ideal perfectly rigid frame, but the "aluminum profile cube frame" design has already been tried a number of times and the usual conclusion is that it is not in any way superior to the original Prusa i3 frame design, but it results in a more expensive RepRap printer to build, with many custom printed parts required. To me, it seems a little bit like reinventing the wheel, and I would be sad to see your creative energy and enthusiasm being wasted.

Why not just rebuild your acrylic Prusa i3 with good components and a properly designed and engineered rigid frame? You'll be up and running in no time at all with a good Prusa i3 ready to print the parts for your next RepRap design.

Why not just rebuild your acrylic Prusa i3 with good components and a properly designed and engineered rigid frame? You'll be up and running in no time at all with a good Prusa i3 ready to print the parts for your next RepRap design.

|

Re: Dont underestimate the importance of a stable table July 01, 2015 12:52AM |

Registered: 9 years ago Posts: 396 |

|

Re: Dont underestimate the importance of a stable table July 01, 2015 04:13AM |

Registered: 9 years ago Posts: 977 |

Well, take a look at this RepRap printer, I really like the clean design, and I believe the quality of the prints is very good too: [forums.reprap.org]

On the other hand, it is clearly a more complex design than your basic run-of-the-mill Prusa i3, more expensive to build, and I am quite confident that a properly built Prusa i3 could get you the same print quality.

On the other hand, it is clearly a more complex design than your basic run-of-the-mill Prusa i3, more expensive to build, and I am quite confident that a properly built Prusa i3 could get you the same print quality.

|

Re: Dont underestimate the importance of a stable table July 01, 2015 08:00AM |

Registered: 11 years ago Posts: 5,780 |

Maybe the people who tried cubic frames used extrusions with too small a cross section for the job, just as most (all?) the kits use too thin acrylic, mdf, aluminum sheet, plywood, etc. For some reason everyone buys 20mm square extrusions. If they build something with it and it doesn't work they conclude that aluminum extrusions suck, when it is just the 20mm cross section is too small for the job. You wouldn't use 1x2s in the walls of your house, you'd pay a little more and get 2x4s or 2x6s. The same principle applies.

My printer, with a cubic (well, actually rectangular) frame that is considerably larger and heavier than any of the i3s I've ever seen, uses 1.5" square extrusions and is rock solid. It produces very high quality prints and does it consistently, without frequent adjustment. The cross sectional area and the methods of joining pieces that determines the rigidity. A cubic frame, made with sufficiently large cross section extrusions (or other material), offers very high rigidity, easy verification of its squareness, and easy enclosure for ABS printing, and is well worth pursuing.

My printer, with a cubic (well, actually rectangular) frame that is considerably larger and heavier than any of the i3s I've ever seen, uses 1.5" square extrusions and is rock solid. It produces very high quality prints and does it consistently, without frequent adjustment. The cross sectional area and the methods of joining pieces that determines the rigidity. A cubic frame, made with sufficiently large cross section extrusions (or other material), offers very high rigidity, easy verification of its squareness, and easy enclosure for ABS printing, and is well worth pursuing.

|

Re: Dont underestimate the importance of a stable table July 01, 2015 11:28AM |

Registered: 9 years ago Posts: 396 |

|

Re: Dont underestimate the importance of a stable table July 01, 2015 01:43PM |

Registered: 9 years ago Posts: 977 |

@ the_digital_dentist

I agree entirely with you when you say that "the cross sectional area and the methods of joining the pieces" determine the rigidity of the frame for aluminum profile cube frames, that much is obvious.

However, what I am arguing here is that thetazzbot had a bad experience with an "underengineered" - actually just bad and low quality - copy of the Prusa i3, and is now risking "overengineering" his next RepRap.

If you really examine closely and reflect on the original design of some (imo brilliant) RepRap designs such as the Prusa i3, the Kossel mini, the Morgan, you'll notice that they are very much cost-optimized, they are "minimalist" in the sense that they have been designed to achieve a certain purpose (that is printing good quality parts) within severe constraints of cost, availability of basic materials/components, ease of assembly and maintenance, desktop space, noise, etc.

In my opinion it takes a lot more engineering talent to design a RepRap with good printing quality under these constraints, rather than going all out and adding industrial linear rails, industrial ball screws, kilograms upon kilograms of large section aluminum profile assembled into a cube shape, etc... to finally end up with something that costs as much as a (good) used car, requires two persons to move around the house, takes over an entire desktop, and yet prints the very same quality parts.

I agree entirely with you when you say that "the cross sectional area and the methods of joining the pieces" determine the rigidity of the frame for aluminum profile cube frames, that much is obvious.

However, what I am arguing here is that thetazzbot had a bad experience with an "underengineered" - actually just bad and low quality - copy of the Prusa i3, and is now risking "overengineering" his next RepRap.

If you really examine closely and reflect on the original design of some (imo brilliant) RepRap designs such as the Prusa i3, the Kossel mini, the Morgan, you'll notice that they are very much cost-optimized, they are "minimalist" in the sense that they have been designed to achieve a certain purpose (that is printing good quality parts) within severe constraints of cost, availability of basic materials/components, ease of assembly and maintenance, desktop space, noise, etc.

In my opinion it takes a lot more engineering talent to design a RepRap with good printing quality under these constraints, rather than going all out and adding industrial linear rails, industrial ball screws, kilograms upon kilograms of large section aluminum profile assembled into a cube shape, etc... to finally end up with something that costs as much as a (good) used car, requires two persons to move around the house, takes over an entire desktop, and yet prints the very same quality parts.

|

Re: Dont underestimate the importance of a stable table July 01, 2015 01:53PM |

Registered: 9 years ago Posts: 977 |

@ thetazzbot

If you decide to rebuild your Prusa i3 with an MDF box frame, check the wiki here: [reprap.org] There isn't much in the way of CNC woodworking required actually, at least for the original box frame: all it requires are 8 small rectangular pieces of 12mm MDF cut to precise dimensions.

There isn't much in the way of CNC woodworking required actually, at least for the original box frame: all it requires are 8 small rectangular pieces of 12mm MDF cut to precise dimensions.

And for discussing it, you can use the Prusa i3 specific forum below.

Edited 1 time(s). Last edit at 07/01/2015 01:55PM by AndrewBCN.

If you decide to rebuild your Prusa i3 with an MDF box frame, check the wiki here: [reprap.org]

There isn't much in the way of CNC woodworking required actually, at least for the original box frame: all it requires are 8 small rectangular pieces of 12mm MDF cut to precise dimensions.

There isn't much in the way of CNC woodworking required actually, at least for the original box frame: all it requires are 8 small rectangular pieces of 12mm MDF cut to precise dimensions.And for discussing it, you can use the Prusa i3 specific forum below.

Edited 1 time(s). Last edit at 07/01/2015 01:55PM by AndrewBCN.

|

Re: Dont underestimate the importance of a stable table July 01, 2015 02:53PM |

Registered: 9 years ago Posts: 396 |

Quote

AndrewBCN

@ the_digital_dentist

In my opinion it takes a lot more engineering talent to design a RepRap with good printing quality under these constraints, rather than going all out and adding industrial linear rails, industrial ball screws, kilograms upon kilograms of large section aluminum profile assembled into a cube shape, etc... to finally end up with something that costs as much as a (good) used car, requires two persons to move around the house, takes over an entire desktop, and yet prints the very same quality parts.

LOL, love that.

Anyway, my current on-going projects are based on the following motives:

1. Build a cartesian printer - Done, Prusa i3

2. Build a Delta - 80% done, Mini Kossel

3. Build a CoreXY or HBot - Just started (cube)

The goal for me is not to print plastic. The goal is to examine in detail all the individual components of each design and how they work to produce the desired results. Then improve where possible. Then print plastic.

For example, from my study of the Prusa i3 (I mistakenly purchased a set of "rework" plastic parts), I have determined that the "Rework" parts leave a lot to be desired. There are so many loose ends that it's a miracle it prints at all. But I've made adjustments, added rigidity, and replaced the parts that cause me the most headache with better ones. I could go into specifics but that can wait.

So anyway, this thread has sufficiently gone off the rails. I think I'll post in the Prusa i3 forum some observations and get some feedback there.

thanks

|

Re: Dont underestimate the importance of a stable table July 01, 2015 09:24PM |

Registered: 11 years ago Posts: 5,780 |

Optimization implies a trade between cost and performance/quality. The i3 isn't cost optimized, it is cost minimized without regard to performance or reliability. Using threaded rods and dual motor drive in the Z axis isn't an optimization, it's just a poor way to lower cost. Likewise using 4 screws to level the bed indicates a minimum of thought/understanding went into the "design".

Maybe I'm strange, but I've always expected machines to work reliably, A flimsy machine requires constant tweaking to get it to perform. My so-called "over-engineered" machine requires almost no tweaking. If your hobby is playing with your printer, by all means, get a poorly designed/built toy and tweak it until you can't tweak it any more. If you want a printer to enable other activities and prefer not to spend all your time tweaking the machine, "over-engineer" it.

Maybe I'm strange, but I've always expected machines to work reliably, A flimsy machine requires constant tweaking to get it to perform. My so-called "over-engineered" machine requires almost no tweaking. If your hobby is playing with your printer, by all means, get a poorly designed/built toy and tweak it until you can't tweak it any more. If you want a printer to enable other activities and prefer not to spend all your time tweaking the machine, "over-engineer" it.

|

Re: Dont underestimate the importance of a stable table July 01, 2015 10:57PM |

Registered: 9 years ago Posts: 977 |

@ the_digital_dentist

I guess you have your opinion on these matters and it is consistent with the machines you have built. However, as they say around here in Spain, "the proof is in the paella", and the Prusa i3 stands as a major success story among RepRap builders and also, for better or worse, made in China copycats.

I guess you have your opinion on these matters and it is consistent with the machines you have built. However, as they say around here in Spain, "the proof is in the paella", and the Prusa i3 stands as a major success story among RepRap builders and also, for better or worse, made in China copycats.

Sorry, only registered users may post in this forum.